Академический Документы

Профессиональный Документы

Культура Документы

1021 AirCooledChillerTest

Загружено:

Abdul Mohid SheikhОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

1021 AirCooledChillerTest

Загружено:

Abdul Mohid SheikhАвторское право:

Доступные форматы

--SAMPLE-- Air-Cooled Chiller System Functional Test FT___

Functional Test

Project: ____________________________

FT- ____ CHILLER __________

Air Cooled Chiller

And Chiller System Including:

CHW Pumps _____________

Related Tests: _____________________________________________

1. Participants

Party Participation

Party filling out this form and witnessing testing ______________________________

Dates of tests ______________________

Dates of tests ______________________

2. Test Prerequisites

a. __ The following have been started up and startup reports* and prefunctional checklists submitted and

approved ready for functional testing:

Chiller: __Prefuctionals, __Startup report

Chilled water pumps: __Prefuctionals, __Startup report

Chilled water piping and valves: __Prefuctionals

Air handler units: __Prefuctionals, __Startup report

*The written chiller startup report must contain a full listing of all adjustable internal program settings.

b. __ All control system functions for this and all interlocking systems are programmed and operable per contract

documents, including final setpoints and schedules and with debugging, loop tuning and sensor and device

calibrations completed. _________________________________ _________________________

Controls Contractor Signature or Verbal Date

c. __ Piping system flushing complete and required report approved.

d. __ Water treatment system complete and operational.

e. __ Vibration control report approved (if required).

Notes:

File: 378003023.doc, 2/1/2018 --PECI Page 1 of 8

--SAMPLE-- Air-Cooled Chiller System Functional Test FT___

f. __ Test and balance (TAB) complete and approved for the hydronic system.

g. __ All A/E punchlist items to date for this equipment corrected.

h. __ These functional test procedures reviewed and approved by installing contractor.

i. __ Safeties and operating ranges reviewed.

j. __ Test requirements and sequences of operation attached.

k. __ Schedules and setpoints attached.

l. __ False loading equipment, system and procedures ready (cross-over piping, preheat or reheat coils, control

loops, over-ride on OSA dampers, etc.)

m. __ Sufficient clearance around equipment for servicing.

n. __ Sump or crankcase heaters have been on long enough to allow immediate starting of chillers.

o. __ Have all energy savings control strategies, setpoints and schedules been incorporated that this chiller and

control system are capable of? If not, list recommendations below.

p. __Misc. tools needed: __two-way radios (general c.), __original calibration temperature probe

(controls c.), pressure gages for evaporator dP (mechanical c.), temperature probe with 6 ft wire or data logger

(commissioner), amp meter for pump amps (commissioner).

q. __ Control Program Review. Review the software control program(s) for this equipment. Parameters,

setpoints and logic sequences appear to follow the specified written sequences.

r. __ Record made of All Values for Current Setpoints (SPt), Control Parameters, Limits, Delays, Lockouts,

Schedules, Etc. Changed to Accommodate Testing:

Returned Returned

Parameter Pre-Test to Pre-Test Parameter Pre-Test to Pre-Test

Values Values Values Values

Chiller OSAT lockout 55F CWRT Setpoint

Lead CHW pump ID: Safety Overrides or

Lag 1 ID: Jumpers

Delays/Timers

3. Sensor Calibration Checks. The sensors listed below checked for calibration and adequate location. This

is a spot check on a sample of the calibrations done during prefunctional checklisting.*

“In calibration” means making a reading with a calibrated test instrument within 6 inches of the site sensor.

Verify that the sensor reading (via the permanent thermostat, gage or building automation system (BAS))

compared to the test instrument-measured value is within the tolerances specified in the prefunctional checklist

requirements. If not, install offset in BAS, calibrate or replace sensor. Use the same test instruments as used

for the original calibration, if possible.

Notes:

File: 378003023.doc, 2/1/2018 --PECI Page 2 of 8

--SAMPLE-- Air-Cooled Chiller System Functional Test FT___

1st Final 1st Final

Gage Gage Chiller Gage Gage Chiller

Loc- or Instr. or Panel Loc- or Instr. or Panel

Sensor & ation BAS Meas’d BAS Pass Value Sensor & ation BAS Meas’d BAS Pass Value

Location OK1 Value Value Value Y/N? Location OK1 Value Value Value Y/N?

CHWST OSAT

CHWRT

Pump current

(CWP1-CUR)

1

Sensor location is appropriate and away from causes of erratic operation.

*For every sensor originally found out of calibration, check one additional sensor not listed.

4. Device Calibration Checks. The actuators or devices listed below checked for calibration. This is a spot

check on a sample of the calibrations done during prefunctional checklisting and startup.**

“In calibration” means observing a readout in the BAS and going to the actuator or controlled device and verifying that the BAS

reading is correct. For items out of calibration or adjustment, fix now if easy, via an offset in the BAS, or a mechanical fix.

Device or 1st Site Final Device or 1st Site Final

Actuator & BAS Observ- BAS Pass Actuator & BAS Observ- BAS Pass

Location Readin ation Reading Y/N Location Reading ation Reading Y/N

g

**For every actuator or device originally found out of calibration, check one additional one not listed.

5. Verification of Misc. Prefunctional Checks.

Misc. site checks of the prefunctional checklist and startup reports completed successfully. Pass? Y / N _______

1. Verify that in the chiller control panel, Menu 3, that input 30 is enabling a remote chilled water setpoint.

Y/N _________

2. ___All hydronic isolation valves fully open.

3. ___Hydronic balancing valves adjusted per the balance report and permanently marked.

4. ___Pull 3 strainers in strategic locations where debri collection is likely, to verify flush (list):

___All OK?

6. Notes on Methods Used to False Load Chiller (for reference, see Note 6 at end of test)

___________________________________________________________________________________________

___________________________________________________________________________________________

___________________________________________________________________________________________

___________________________________________________________________________________________

7. General Conditions of Test

The chiller will be tested with the building in as normal mode as possible. Temperatures are expected to be in the

70’s creating sufficient load for most of the tests. False loading, lowering space setpoints and/or turning on the

preheat will be employed if necessary.

Notes:

File: 378003023.doc, 2/1/2018 --PECI Page 3 of 8

--SAMPLE-- Air-Cooled Chiller System Functional Test FT___

8. Testing Procedures and Record

Proced. Sequ Test Procedure3 Expected and Actual Response4 Pass

No. ence. (including special conditions) [Write ACTUAL response in brackets or circle] Note

ID Y/N #

No.1

1. 2; 3 Startup Sequence

(This is not the initial startup by

factory reps).

a. With chiller system off, with a. Observe that the CHW pump does not

schedule allowing chillers ON and come ON.

OSAT >56F, overwrite the OSAT to be

50F.

b. Return the OSAT to normal b. Observe the lead CHW pump coming ON

(assuming > 56F), turn chillers and after ____ min. [_______]. Observe in the

pumps to auto. Turn ON only one AHU BAS that the proof of flow has been made (or

and command the cooling coil valve see it at the chiller panel). Once there is proof

(CCV) to 18% open. A call for the of flow, observe that the chiller starts.

chillers will be made when any AHU Observe that the initial CHWST StPt is 49F

fan is ON and its CCV is => 15% open [_________] in chiller panel.

for ____minutes and OSAT is > 55F.

2. Min. Chiller Flow. Record pump amps [_____] and dP across

While only 1 CCV is < 20% open and pump [_____________] and dP across CHW

the other CCV is closed: evaporator [___________]. Make sure amps

aren’t over the RLA (________) of the pump.

Plot the operating point of the pump on the

pump curve and chiller O&M evap. Dp/gpm

chart to estimate gpm: [curve___________

gpm, chart_____________gpm]. Make sure

the gpm is greater than the minimum req’d

chiller flow of 408 gpm.

3. 2 Minimum On-Time Observe that the chiller and pump does NOT

With chiller on and running for less stop until the 10 min. min ON-time is expired.

than 10 minutes [_________],

command all cooling coil valves

closed.

Return CCVs to normal after

procedure.

4. 1; 6 Lead Pump Start Failure. Observe that after a call for the chiller is made

Turn chiller OFF. Turn lead pump to the lead pump for 45

(CWP ___) to OFF; turn lag pump seconds[ __________] an alarm is generated

[CWP ____) and chiller to auto. in the BAS [________]; and that the lag pump

Initiate a call for cooling per procedure starts and chiller starts.

1.

5. 3, 6, Lead-1 Pump Failure. Observe that the chiller stops [____________]

++ With chiller having been running in and 2 BAS alarms are generated (one for

auto for less than 10 minutes, and all pump failure and one for chiller low flow), that

pumps in auto, turn the operating the lag pump (CWP_____) starts

pump (CWP_____) to OFF. [____________] and the chiller restarts after a

timeout period of ________ minutes, having

been manually reset.

Notes:

File: 378003023.doc, 2/1/2018 --PECI Page 4 of 8

--SAMPLE-- Air-Cooled Chiller System Functional Test FT___

Proced. Sequ Test Procedure3 Expected and Actual Response4 Pass

No. ence. (including special conditions) [Write ACTUAL response in brackets or circle] Note

ID Y/N #

No.1

6. 1; 6 Lag Pump Start Failure. Observe that after a call for the chiller is made

Turn chiller OFF. Assign other pump to to the lead pump for 45

be lead. Turn lead pump (CWP ___) to seconds[ __________] an alarm is generated

OFF; turn lag pump [CWP ____) and in the BAS [________]; and that the lag pump

chiller to auto. Initiate a call for cooling starts and chiller starts.

per procedure 1.

7. ++ OSAT Lockout. Observe the chiller and pumps shut down.

With chiller and pumps in auto and

running, overwrite the OSAT to be 50F

or change the lockout to be 2F above

current OSAT.

8. ++, 6 Lead-2 Pump Failure. Observe that the chiller stops [____________]

Change other pump to be the lead and 2 BAS alarms are generated (one for

pump. With chiller running in auto and pump failure and one for chiller low flow), that

all pumps in auto, turn the operating the lag pump (CWP_____) starts

(lead) pump (CWP_____) to OFF. [____________] and the chiller restarts after a

timeout period of ________ minutes, having

been manually reset.

9. 3 General Chilled Water Temperature Record the CHWRT [_________] and CHWRT

Control. setpoint [________].

Have the chiller and pumps in auto for Observe that the 49F [_________] CHWST

less than 10 minutes. Wait for the 10 setpoint in the chiller is released and a new

min. timer to expire. setpoint [________] is sent to the chiller from

the BAS that will result in bringing the CHWRT

closer to setpoint. (If initial CHWRT is <

setpoint (supposed to be 52F), then the new

CHWST setpoint sent to the chiller should be

> 49 or increasing.

10. 3 TREND LOG 1. General Chilled Water Graph and observe that the chiller maintains

Temperature Control the CHWST setpoint being sent to it XX

Trend the OSAT, CHWST, CHWRT, and that the CHWRT is maintained at

;CHWST setpoint being sent to the setpoint. XX

chiller, CHWRT setpoint and both

ASU’s cooling coil valve positions at 2 Observe the CHWST setpoint and make sure

minute intervals for a 3 day period. that it is not lower than 45F until both CCVs

During the trended period, globally are > 75% open, otherwise the CHWRT

lower the space temperature setpoints setpoint may need to be raised from 52F,

10F for 3 hours to see the chiller go to

full load. XX

Within +/- 1F during stable periods without

hunting or overshoot (less than +/-3F during

staging, etc.).

11. 3 CHWST Hi/Low Alarm

With the chiller and pumps in auto,

overwrite the CHWST to be 39F. Observe a BAS alarm [_________].

Overwrite the CHWST to be 56F. Observe a BAS alarm [_________].

Return to normal.

Notes:

File: 378003023.doc, 2/1/2018 --PECI Page 5 of 8

--SAMPLE-- Air-Cooled Chiller System Functional Test FT___

Proced. Sequ Test Procedure3 Expected and Actual Response4 Pass

No. ence. (including special conditions) [Write ACTUAL response in brackets or circle] Note

ID Y/N #

No.1

12. 4 Chilled Water Pump Staging. a. Record pump amps [_____] and dP across

a. With the chillers and pumps in auto, pump [_____________]. Make sure amps

command the CCV on both ASUs to aren’t over the RLA (________) of the pump.

be _______% open, just under where Plot the operating point of the pump on the

lag pump will stage ON (orig. seq. pump curve to estimate gpm: [___________

was sum > 100%, but recommend gpm].

180%). b. Observe that the lag CWP does not start

b. Command CCVs sum to be just until a 5 min. timer expires.

over pump staging up point. Record both pump amps [CWP-1_____],

[CWP-2_____] and dP across pumps [CWP-1

_____________, CWP-2 __________] and dP

across evap [_____________]. Make sure

amps aren’t over the RLA (________) of the

pumps. Plot the operating points of the pumps

on the pump curve and evap dp vs gpm chart

to estimate gpm: [curve___________ gpm,

chart ______________gpm].

c. Within 5 minutes, command both

CCVs to be less than ½ of the above c. Observe that the lag pump remains ON

setting % [_________]. until the 10 min. pump ON timer expires

plus the 5 min. condition timer expires.

Then the lag pump shuts OFF.

13. 4 TREND LOG 2. Chilled Water Pump

Staging Observe that the staging of the pumps is

Trend each CWP status, each CWP reasonable and evaluate whether the pumps

current, chiller status, both ASU’s CCV stage ON too soon or too late relative to

position, OSAT, CHWST, CHWRT at 2 needs in the building, as shown by the CCV

minute intervals for 3 days. Also positions. Note that the chiller or pump are not

datalog or trend an indicator or chiller ON when OSAT is less than 55F.

load (current, kW, etc.).

During the trended period, globally

lower the space temperature setpoints

10F for 3 hours to see the chiller go to

full load.

14. 5 Chiller Staging OFF. Observe that the chiller remains ON until a 5

With the chiller and pumps in auto, minute timer expires and the chiller shuts OFF

command the CCVs on both ASUs to [_______]. The pump remains ON for another

less than 5% open. 2 minutes; then it shuts OFF [_________].

15. 7 Low ASU Coil Temp. Alarm.

a. Overwrite the OSAT to be 50F. With a. Observe the lead CWP start, but not the

the chiller in auto, overwrite ASU-1 chiller.

discharge temperature to be 34F.

b. Repeat with ASU-2. b. Observe the lead CWP start, but not the

chiller.

Notes:

File: 378003023.doc, 2/1/2018 --PECI Page 6 of 8

--SAMPLE-- Air-Cooled Chiller System Functional Test FT___

Proced. Sequ Test Procedure3 Expected and Actual Response4 Pass

No. ence. (including special conditions) [Write ACTUAL response in brackets or circle] Note

ID Y/N #

No.1

16. -- Return all changed control Check off in table of Section 2 above when

parameters and conditions to their completed

pre-test values5

17.

MONITORING AND TREND LOGGING.

Monitoring via BAS trend logs are required per test Procedures 10, 13. Trend logs all shall be provided in

electronic continuous columnar spreadsheet compatible format. Trends all shall be provided in hard tabular format

(continuous columnar with time in left column and at least four columns of point values in adjacent columns). All points

for a given trend will begin at exactly the same time. Provide a key to all abbreviations. Attach representative graphs

or columnar data and explanatory analysis to this test report.

SEQUENCES AND COMPONENTS NOT TESTED

Efficiency rating. Not tested.

Capacity Testing. Not tested.

Misc. Chiller Safeties (part of Trane

startup). Not tested.

NOTES

**Abbreviations: CWP = chilled water pump, Pt = setpoint, CHWS = chilled water supply, BAS = building automation

system, ++ refers to tests being conducted on issues not specifically listed in the sequences of operations provided to

date.

1

Sequences of operation attached to this test.

3

Step-by-step procedures for manual testing, trend logging or data-logger monitoring.

4

Include tolerances for a passing condition. Fill-in spaces or lines not in brackets denote sequence parameters still to

be specified by the A/E, controls contractor or vendor. Write “Via BAS” for verifications of device position from BAS

readout or “Via obs” for actual observation or from test instrument reading.

5

Record any permanently changed parameter values and submit changes to Owner.

6

Methods to False Load Chillers

1) If OSAT is less than 75F, prevent economizer cool OSA from entering the building.

a) Manually close the economizer OSA dampers, OR

b) Lower the changeover economizer setpoint below the OSAT (if DB type), OR lastly

c) Overwrite the OSAT value to be 80F or more so dampers won’t open.

2) Use OSA preheat coils to heat incoming OSA.

Enable the boiler by removing any lockouts, etc. Manually open the min. OSA preheat coil valve to preheat the

OSA. Increase the min. OSA discharge temperature setpoint and the heating water supply temperature, as

necessary.

3) Lower the space temperature setpoint.

4) Prior to the chiller test, manually preheat the building space temperature to 78F - 80F.

5) Lower the chilled water supply temperature setpoint.

False Loading Cooling Towers

1) False load the chiller (see above)

Notes:

File: 378003023.doc, 2/1/2018 --PECI Page 7 of 8

--SAMPLE-- Air-Cooled Chiller System Functional Test FT___

A SUMMARY OF DEFICIENCIES IDENTIFIED DURING TESTING IS ATTACHED

-- END OF TEST --

Notes:

File: 378003023.doc, 2/1/2018 --PECI Page 8 of 8

Вам также может понравиться

- Purpose of Contact Resistance TestДокумент1 страницаPurpose of Contact Resistance TestAbdul Mohid SheikhОценок пока нет

- Data Centers Cooling SystemsДокумент3 страницыData Centers Cooling SystemsAbdul Mohid SheikhОценок пока нет

- Testing of Earth Leakage RelayДокумент1 страницаTesting of Earth Leakage RelayAbdul Mohid SheikhОценок пока нет

- Rundown Tank Purpose and Working - Chemical Engineering WorldДокумент2 страницыRundown Tank Purpose and Working - Chemical Engineering WorldAbdul Mohid SheikhОценок пока нет

- Air Change CFM CalculatorДокумент1 страницаAir Change CFM CalculatorAbdul Mohid SheikhОценок пока нет

- Ball Valve Types and PartsДокумент2 страницыBall Valve Types and PartsAbdul Mohid SheikhОценок пока нет

- Air Conditioner BTU CalculatorДокумент1 страницаAir Conditioner BTU CalculatorAbdul Mohid SheikhОценок пока нет

- The Most Common Methods of Measuring The Resistance of An Earth Electrode - EEP-001Документ7 страницThe Most Common Methods of Measuring The Resistance of An Earth Electrode - EEP-001Abdul Mohid SheikhОценок пока нет

- Ground Testing in Difficult InstallationsДокумент3 страницыGround Testing in Difficult InstallationsAbdul Mohid SheikhОценок пока нет

- Pre RemovalДокумент8 страницPre RemovalAbdul Mohid SheikhОценок пока нет

- 4 Important Methods of Ground Resistance TestingДокумент5 страниц4 Important Methods of Ground Resistance TestingAbdul Mohid SheikhОценок пока нет

- Soiling Rates of PV Modules vs. Thermopile PyranometersДокумент3 страницыSoiling Rates of PV Modules vs. Thermopile PyranometersAbdul Mohid SheikhОценок пока нет

- Measuring ImpactДокумент58 страницMeasuring ImpactAbdul Mohid SheikhОценок пока нет

- IEC 61439: The Mystery of The Temperature Rise Limits: An Alert To Low-Voltage Switchgear BuyersДокумент3 страницыIEC 61439: The Mystery of The Temperature Rise Limits: An Alert To Low-Voltage Switchgear BuyersAbdul Mohid SheikhОценок пока нет

- Four Very Important Precautions For The Installation of Cables and Busbar Trunking SystemsДокумент11 страницFour Very Important Precautions For The Installation of Cables and Busbar Trunking SystemsAbdul Mohid SheikhОценок пока нет

- Method of Statement For Fire Fighting Works (Part-1)Документ5 страницMethod of Statement For Fire Fighting Works (Part-1)Abdul Mohid Sheikh100% (1)

- Honeywell - APT4000 Series 4-Wire PH AnalyzersДокумент8 страницHoneywell - APT4000 Series 4-Wire PH AnalyzersAbdul Mohid SheikhОценок пока нет

- Ring Main Unit (RMU) As An Important Part of Secondary Distribution SubstationsДокумент4 страницыRing Main Unit (RMU) As An Important Part of Secondary Distribution SubstationsAbdul Mohid SheikhОценок пока нет

- Connections and Composition of LV, MV, HV Capacitor BanksДокумент7 страницConnections and Composition of LV, MV, HV Capacitor BanksAbdul Mohid SheikhОценок пока нет

- The Art of Transformer Maintenance, Inspection and Repair (Recommended Practices)Документ5 страницThe Art of Transformer Maintenance, Inspection and Repair (Recommended Practices)Abdul Mohid SheikhОценок пока нет

- Transformer Temperature, Oil Level and Pressure GaugesДокумент2 страницыTransformer Temperature, Oil Level and Pressure GaugesAbdul Mohid SheikhОценок пока нет

- Transactions No.1, January 1992Документ11 страницTransactions No.1, January 1992Abdul Mohid SheikhОценок пока нет

- Just Give Me The Damn ManualДокумент1 страницаJust Give Me The Damn ManualAbdul Mohid SheikhОценок пока нет

- The Ufer GroundДокумент4 страницыThe Ufer GroundAbdul Mohid SheikhОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Ssangyong - Compliance Statement-02022017Документ11 страницSsangyong - Compliance Statement-02022017rexОценок пока нет

- NSCS 65-200 - 300 - W25VCC4 Q 116,9 MCH H 62,1 M NPSH 3,07 MДокумент4 страницыNSCS 65-200 - 300 - W25VCC4 Q 116,9 MCH H 62,1 M NPSH 3,07 MWeird StrangerОценок пока нет

- (Msia) Guide To Sewer Selection and Installation (Dec2006) - VC Pipe pg17Документ168 страниц(Msia) Guide To Sewer Selection and Installation (Dec2006) - VC Pipe pg17Rachael Hoo100% (7)

- V47 Components From Crank To Link Head (Conical) : Crank and Crank PlateДокумент4 страницыV47 Components From Crank To Link Head (Conical) : Crank and Crank PlatebalaОценок пока нет

- Chapter 6 - Beam-Columns PDFДокумент15 страницChapter 6 - Beam-Columns PDFNj Concepcion RobeniolОценок пока нет

- Standard Penetration TestДокумент59 страницStandard Penetration TestcuervohijoguachoОценок пока нет

- Structural Investigation of Historic Buildings - David C FischettiДокумент10 страницStructural Investigation of Historic Buildings - David C FischettiMohammad Javad AarabiОценок пока нет

- Simplified Concrete Modeling With Mat - Concrete - Damage - Rel3: Leonard E SchwerДокумент14 страницSimplified Concrete Modeling With Mat - Concrete - Damage - Rel3: Leonard E Schwersvk_ntОценок пока нет

- Peppers A2LCF GlandДокумент2 страницыPeppers A2LCF GlandBob JohnsonОценок пока нет

- QuakeBond 220UR PDS 0120Документ2 страницыQuakeBond 220UR PDS 0120awОценок пока нет

- Reinforcement Pad CalculationДокумент4 страницыReinforcement Pad CalculationMohammad AbdullahОценок пока нет

- 9 TH Plate (Sub)Документ12 страниц9 TH Plate (Sub)hemantОценок пока нет

- KuwaitДокумент16 страницKuwaitGualberto AlarconОценок пока нет

- BQ - Pedestrian BridgeДокумент25 страницBQ - Pedestrian Bridgemarzuki0202Оценок пока нет

- Guidelines For The Use of Steel Piling For Bridge FoundationsДокумент21 страницаGuidelines For The Use of Steel Piling For Bridge FoundationsHermann PankowОценок пока нет

- AHP Balubaid, Rami Alamoudi 2015Документ9 страницAHP Balubaid, Rami Alamoudi 2015ChristinaTriAstutiPauОценок пока нет

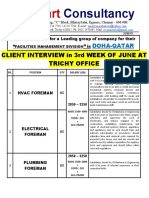

- MBA Qatar Company InterviewДокумент2 страницыMBA Qatar Company InterviewTradiyo ForexОценок пока нет

- METROДокумент12 страницMETRONIVYA PCОценок пока нет

- 04 - Tata Power Work at Height ProcedureДокумент21 страница04 - Tata Power Work at Height Procedurehse bsjОценок пока нет

- FloSet BrochureДокумент6 страницFloSet BrochureHector TosarОценок пока нет

- Pump System CurveДокумент6 страницPump System CurveMohan MalavОценок пока нет

- A786a786m PDFДокумент11 страницA786a786m PDFleroy2007Оценок пока нет

- Access Hardware Architectural CatalogueДокумент87 страницAccess Hardware Architectural CatalogueAccess HardwareОценок пока нет

- Issb - CollectedДокумент19 страницIssb - CollectedBrhane Gadiyon100% (1)

- HORMANN Industrial Sectional Doors Depth 42 MM enДокумент3 страницыHORMANN Industrial Sectional Doors Depth 42 MM enAndonie Alina CristinaОценок пока нет

- De710 Track NewДокумент172 страницыDe710 Track NewJALFARORO67% (3)

- 23Cr Infrastructure TNPAДокумент15 страниц23Cr Infrastructure TNPAHarul Ganesh S BОценок пока нет

- Medium-Hard-Drawn Copper Wire: Standard Specification ForДокумент4 страницыMedium-Hard-Drawn Copper Wire: Standard Specification ForRizwanОценок пока нет

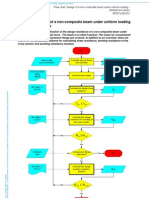

- EC3 Flow Chart Design of A Non-Composite Beam Under Uniform Loading - Detailed ProcedureДокумент5 страницEC3 Flow Chart Design of A Non-Composite Beam Under Uniform Loading - Detailed Procedurejskolmen100% (1)

- Ducted Concealed-Medium StaticДокумент25 страницDucted Concealed-Medium StaticHussain Al SanonaОценок пока нет