Академический Документы

Профессиональный Документы

Культура Документы

22 Meter MSE Wall

Загружено:

ANKESH SHRIVASTAVAОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

22 Meter MSE Wall

Загружено:

ANKESH SHRIVASTAVAАвторское право:

Доступные форматы

RESEARCH PAPERS

BEHAVIOR OF 22M TWO TIERED GEOGRID

REINFORCED SOIL WALL

By

ANKESH SHRIVASTAVA * D. KISHAN **

* Assistant Professor, Civil Engineering Department, Sati Vidisha.

** Associate Professor, Civil Engineering Department, Manit Bhopal.

ABSTRACT

Two types of 22m Two Tiered and 44m Four Tiered high geogrid reinforced soil walls with same kinds of concrete block

wall facing were constructed in Vijayawada Andhra Pradesh in which 22m high vertical reinforced soil wall with concrete

block wall facing has been started and using for the transportation purpose. From the beginning of the 22m reinforced

wall construction stage, wall displacement or strain of the geogrid, earth pressure, settlement of the foundation ground,

etc. were measured for a long period of time. The long term behavior of the geogrid reinforced soil walls was evaluated

based on these measurements and observations. This paper present a case history illustrate the use of finite-element

procedure as a design aid for the design and analysis of 22m two tiered soil wall by software PLAXIS 8.2. The finite-element

analysis provides relevant information on the mechanical behavior that was otherwise difficult to obtain from the limit-

equilibrium based current design approaches.

Keywords: 22m Geogrid, Reinforced Soil Wall, PLAXIS 8.2

INTRODUCTION of 22m two tiered geogrid reinforced soil walls based on

A 22m high reinforced two tiered soil walls with hollow these measurements and observations.

concrete block wall has constructed using geogrids and 1. Outline of the Reinforced Soil Walls and Survey

analysis is done by a finite element programmed PLAXIS The requirement of the road for the transportation purpose

8.2. From the construction stage, the wall displacement or continuously increases, and it is necessary invent new

strain of the geogrid, the earth pressure at the bottom of technique to minimize the use of cement concrete in

the reinforced soil walls, etc. were measured by PLAXIS 8.2 structures and generate a new environment friendly

revealing that no substantial change of the environments techniques for the construction of road. Ghat roads are

around any of these soil walls has occurred, and by using major issue for how to make roads in hilly areas. Therefore,

BS 8006-2000, and M. Koerner (1980). A text book for use in the present study, designing and analysis of two tiered

of geosyntheticsin soil wall initial designing of the wall has 22m soil reinforced wall has been carried out with the help

been carried out. of using finite element program PLAXIS.

The use of geogrids to build reinforced soil walls has been Finally, a model is proposed to evaluate the performance

increasing year by year since the geogrid rein- forced soil of a reinforced soil wall reinforced by SR-2/UX-1700

method was first introduced to Japan in 1983. Because geogrid with backfill soil, with respect to evaluate

the method was at the research and development stage settlement, stress-strain relations, axial forces, shear

when it was introduced, many of the reinforced soil walls forces, incremental deflection, and displacement.

were applied as temporary or trial construction, with the

1.1 Reinforced soil walls

result that there were few full-scale reinforced soil wall built

Reinforced soil wall of 22m high with slope gradients of

using geotextiles that have been measured continually

1:0.1. The wall facing used to build by hollow concrete

for more than 10 years.

blocks was constructed with wall facing by wrapping the soil

This report describes the results of a study of the behavior

26 i-manager’s Journal on Structural Engineering, Vol. 1 l

No. 1 l

March - May 2012

RESEARCH PAPERS

Min. Max. reinforced soil wall, drainage sand layer were taken by

X 0.000 15.4 placing horizontally and vertically behind the wall facing as

Y 0.000 22

shown in Figure 1. The banking material was compacted to

Table 1a. Model Dimensions

be 85% or more of maximum dry density. The out line of

Model Plane strain

Element 15-Noded geogrid reinforced soil wall is shown in Table 1.

Table 1b. Models The arrangement of geogrids was designed in order to

Identification EA [kN/m] ν satisfy the design safety factor (Fs=1.2) through stability

SR-2/UX-1700 64.10 0.00 calculations. It is reported that, reinforced earth retaining

Table 1c. Geotextile Data Sets Parameters

structures, beside its outstanding performance, a cost

Table 1. Outline of Geogrid Reinforced Soil Walls

saving of up to 30% to 50% below alternate solutions have

bags using a geogrid. The concrete blocks and the

been achieved. Seismic loading, differential heave and

geogrids were connected by attaching steel bars linked to

settlement requirements make rigid masonry and concrete

the geogrids to hooks installed in the concrete blocks. The

cantilever walls very difficult to achieve the desired safety

banking material was sandy soil, and because it contained

factor. Whereas, reinforced earth system when subjected to

fine-grain as reinforced soil as banking material of

seismic loads and differential earth movement has shown

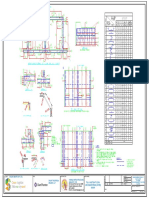

Figure 1. Reinforced Soil Wall

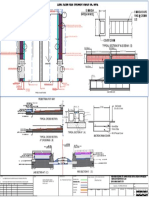

Figure 2. Cross Section of 22m MSE Wall

i-manager’s Journal on Structural Engineering, Vol. 1 l

No. 1 l

March - May 2012 27

RESEARCH PAPERS

exceptional performance due to its flexibility and displacement tends to advance through- out the entire

inherent energy absorption capacity. wall height. Although these displacement distributions

1.2 Outline of the survey seem to vary slightly according to the gradient of the wall,

these results are the typical displacement characteristics

Wall consisting of height of 22 meter with 2 tiered each of

corresponding to the structures of the wall facing.

11m consisting14 layer of SR2/UX-1700 geogrid

reinforcement of ultimate design strength of 175 kN/m2, Figure-3 (b) & (c) shows change over time of the horizontal

the length of reinforcing layer in first tiered wall is of 20m displacement of the 1st & 2nd tiered wall from the

and second tiered heaving 15m reinforcing layer, the size beginning of banking work. The longitudinal axis

of reinforcing layer depends up on the angle (tan30) of represents the horizontal displacement value which is the

failure envelope. With minimum spacing of 0.5m and value obtained by dividing the average horizontal

maximum spacing of 2.65m. Carry a surcharge loading displacement of the wall by the wall height.

of IRC class 'A' loading. For the facing work modular block

of M-30 grade of size 300X300mm in plan and 200mm in

height were to be used. A 1m with height of 200mm P.C.C

(Plan Cement Concrete) work is done for providing proper

plane surface. In the original design construction

specification required that the backfill material be

compacted to a minimum of 95% of standard proctor. A

chimney with the height of 22 meter is also design to drain

of the runoff water. The wall shows the total displacement (a)

is about .048mm.

Measurements were conducted from the beginning of

the construction stage, continuing after its completion

and analysis is done by using PLAXIS 8.2. As shown in Figure

2, the vertical and horizontal displacement of the wall, the

strain of the geogrid, the vertical earth pressure at the

bottom of the reinforced soil wall and the vertical earth

pressure at the bottom of the reinforced soil wall has been

analyzed.

2. Measurement Results

2.1 Deformation of the wall (b)

Figure-3 (a) shows the distribution of the horizontal

displacement of the wall after the completion of wall. To

exclude the effect of displacement of the foundation

ground, the reference point was set at the bottom of the

wall facing to represent the displacement as the relative

displacement. If relatively flexible wall facing material is

used the displacement of top layer of wall tends to lean

forward. If, however, relatively stiff wall facing material is

used, an arc-shaped distribution with the maximum point

near the middle of the wall height is formed and the ( c)

Figure 3. lateral displacement of wall

28 i-manager’s Journal on Structural Engineering, Vol. 1 l

No. 1 l

March - May 2012

RESEARCH PAPERS

The speed of displacement tended to decrease, as the overall smaller than that with relatively soft wall facing, and

deformation of the body of the reinforced soil wall settled. it is assumed that the confining effects for the

Differences based on the stiffness of the wall facing embankment due to the longitudinal stiffness of the wall

appeared conspicuously in displacement during banking facing is high.

work. The stiffness of the wall facing is extremely effective It shows that in Figure-5 the rate of increase of the strain is

in restraining the deformation. high near the wall surface in all geogrids, and that

The maximum horizontal displacement of the wall is 0.30 localized increase in tension occurs through the entire

mm. These are values that fall below the control reference height of the soil wall. In particular, the largest strain

value (allowable maximum value of 3.0% (0.03H)) of wall increase rate was found in geogrids installed near the

horizontal displacement for the vertical reinforced wall middle of the wall height 5m from the top in 1st tier, and

with concrete panel wall facing. 11m from the top i.e. in 2nd tier.

2.2 Strain of the geogrids In Figure-5, the settlement by settlement plates (No. 1 to

No. 5) installed inside and at the top of the wall are

Figure-4 shows the typical distributions of strain of the

substituted for the relative settlement to the settlement of

geogrids classified according to wall facing. If relatively

the bottom of the wall facing to plot change over time

flexible wall facing is used, the strain of the geogrid at

from the beginning of the banking work. Here upon, the

each layer has a distribution shape resembling a

settlement of the bottom of the wall facing is assumed as

parabola with its peak near the active failure line. If stiff wall

the settlement at each point of the wall facing

surface material is used, the strain of each geogrid at

considering the stiffness of the wall facing material.

each level has a distribution shape that is uniform or

Therefore, a characteristic of the settlement of the

triangular with its peak near the wall facing, revealing the

reinforced soil body is that at the foundation ground level

effects of differences in the form of the wall facing. In this

(No. 1), the settlement of the wall facing is dominant to the

way, the strain distributions in Figure-5 can be assumed as

embankment side, but inside the embankment (No. 2 to

characteristic distribution shapes according on

No. 5), the embankment side tends to settle down larger

differences in the form of wall facing. The quantity of strain

than the wall facing, and in particular, the largest relative

of geogrid in the reinforced soil with stiff wall facing is

Curve 1 (blue) at top displacement of wall (2nd tier)

Curve 2 (red) at below foundation of wall (2nd tier)

Curve 3 (yellow) at top of wall (1st tier)

Curve 4 (pink) at below foundation (1st tier)

Figure 4. Lateral displacement of both walls with respect to time

i-manager’s Journal on Structural Engineering, Vol. 1 l

No. 1 l

March - May 2012 29

RESEARCH PAPERS

settlement occurs at the middle of the embankment the surcharge banking. The design values of vertical earth

height (settlement plate No. 2). This conforms to the pressure do not represent the actual distribution, and the

location of the geogrid where the rate of increase of the present design model that presumes.

strain near the wall facing shown in Figure-5 is highest. And The reinforced soil area to be a gravity retaining wall

the relative settlement of the embankment fluctuates until cannot be used to appropriately evaluate the behavior of

about 400 days and it is linked to the tendency of the a reinforced soil wall. The vertical earth pressure of a

increase of the strain of the geogrid. Consequently,

differences in the settlement of the banking material and

of the wall facing can be inferred as the principal cause of

the localized rise of strain of the geogrid near the wall

facing.

2.3 Vertical earth pressure at the bottom of reinforced

soil wall

Figure 6 shows the distribution of the vertical earth pressure

at the bottom of the MSE wall from the beginning of

banking work. In the case of relatively flexible wall facing,

the banking process caused vertical earth pressure

equivalent to the overburden pressure to act on the entire

bottom of the reinforced soil area. With stiff wall facing,

high earth pressure that exceeds the overburden pressure

is produced at the bottom of the wall facing from the initial

stage of the banking, and behind the wall facing, a

unique distribution that is far lower than the overburden

pressure is applied in a range that extends almost to the

active failure zone. These distributions are characteristics

dependent on the structure of the wall facing, and little

Figure 6. Vertical earth pressure at the bottom of reinforced soil wall

change can be seen, even approximately one year after

Curve 1(blue) strain curve for top of 2 tier wall

Curve 2 (red) strain curves below the foundation of 1 tier wall

Curve 3 (yellow) strain curve top of 1 tier wall

Curve 4 (pink) strain curves below the foundation of 2 tier wall

Figure 5. Strain vs. Depth

30 i-manager’s Journal on Structural Engineering, Vol. 1 l

No. 1 l

March - May 2012

RESEARCH PAPERS

reinforced soil wall could be considered to be equivalent to Within the observation of the excavation portions, no

the overburden pressure. Hence, it will be important to study defects such as breakage or other damage could be

a design model that can be used to appropriately express seen on the connections between the geogrid and the

the earth pressure at the bottom of reinforced soil wall. concrete blocks used as wall facing on the MSE walls. And

2.4 Deformation of the reinforced soil body the roots of shrubs growing naturally on the top and other

parts of the reinforced soil walls were still growing after

Figure 7 shows the change of the measured vertical earth

passing through the geogrids.

pressure at the bottom surface of the reinforced soil wall

from the beginning of banking work. As above stated, it The finite element analyses performed in this study have

has been shown that the banking process caused indicated that geotextile reinforcement may be an

localized high increase in the earth pressure at the bottom effective method of improving the performance of

of the wall facing. But the vertical earth pressure at all embankments constructed over ghat road. The stabilizing

measuring points including the bottom of the wall facing effect of the geotextile was seen to increase as the

changed to almost steady. Therefore, even as ground geotextile modulus increased. The effect was greatest for

settlement continued, the functions of the reinforced soil shallower deposits. The effect of geotextile reinforcement

wall were maintained. was compared with alternative Construction techniques

which involved the use of light weight fill or berms alone and

Figure 7 shows change over time of the inclination of the

in conjunction with geotextile reinforcement. In particular, it

foundation ground and of the wall facing under the

was found that the combined use of geotextile

effects of settlement after the completion of the

reinforcement and light weight fill may be a very effective

surcharge banking.

means of improving the performance of embankments

Reinforced soil walls with concrete blocks as their wall

over hilly terrains. Sandy soil with cohesion shows less wall

facing are used often in Europe and U.S. to take

movements than cohesionless soil. Hence it is

advantage of their ability to improve the scenery. But, as

recommended that some cohesion can be added in

seen in the results of the measurement, it is necessary to

backfill soil by some additives or by soil stabilization.

estimate an appropriate design value by preparing a

Increased value of grid strength will end up with smaller

model that can quantitatively evaluate various

displacement therefore geogrid with higher strength is

phenomena such as the localized increase of tensile strain

recommended to use.

of the geotextile near the wall facing or a discontinuous

Conclusion

vertical earth pressure distribution at the bottom.

Various measurements of reinforced soil walls such as

3. Results of Observations of the Reinforced Soil Walls

displacement of wall, strain of geogrid, vertical earth

The external appearance of wall was observed practically

pressure at the bottom of reinforced soil wall, settlement

and part of each reinforced soil wall was excavated to

of embankment and foundation ground, etc. were

observe its interior in order to examine the state of

analyzed by FEM Method (PLAXIS). And part of each

vegetation on their wall surfaces, the soundness of

reinforced soil wall has been observed and after complete

structure of the wall facing, etc.

analysis it has obtained the following knowledge

The visual observations of the laid geogrids as

concerning the behavior of geogrid reinforced soil walls

reinforcement at the excavated points found no

over a long period of time and actual condition of wall

evidence of any defects such as tears or other damage.

facing and geogrid laid inside the embankment.

·Concerning the deformation of the wall after

construction, in the case of relatively flexible wall facing

material, displacement advances in the top layer, but in

Figure 7. Deformation of the Reinforcement (geogrid) the case of relatively stiff wall facing material, arc- shaped

i-manager’s Journal on Structural Engineering, Vol. 1 l

No. 1 l

March - May 2012 31

RESEARCH PAPERS

deformation with its peak close to the middle of the wall [2]. Koerner, R.M. and Welsh, J.P., (1980b). Construction

height appears. and Geotechnical Engineering Using. synthetic Fabrics.

·Concerning the increase of horizontal displacement [3]. Mr. P.T. Raju, construction of tiered reinforced soil

of the wall, for all three types of reinforced wall, most of the retaining walls for widening of ghat road to sri durga

increase occurs during banking, and the increase of malleswara swami varla devastanam, Vijayawada.

displacement after the completion is gentle gradual [4]. Yoo c., design of a geosynthetic reinforced

increase and tends to settle the foundation. segmental retaining wall in a tiered arrangement-use of

·Strains of the geogrid are, in the case of flexible wall numerical modelling as a design aid.

facing, distributed in the shape of a parabola with its peak [5]. thurst, R. J., Karpurapu, R. G. & Jarrett, P. M. (1992).

close to the active failure line, and if relatively stiff wall Finite elementanalysis of a geogrid reinforced soil wall. In

facing is done, its distribution is shaped like a triangle with Grouting, Soil Improvement and Geosynthetics (eds

its peak close to the wall facing. Borden, R. H., Holtz, R. O.and Juran, I.), Vol. 2, pp. 1213–1224.

·In the case of relatively stiff wall facing, in all the laid ASCE Geotechnical Special publication No. 30.

geogrids, a localized high strain increase rate is observed [6]. Rowe, R. K., MacLean, M. D. and Soderman, K. L.,

near the wall facing, with the highest rate of strain increase Analysis of a geotextile reinforced embankment

confirmed in geogrid laid particularly close to the middle constructed on peat. Canadian Geotech.J. 21 (3) (1984)

of the wall height. 563-76

·Concerning the vertical earth pressure at the bottom [7]. Rowe, R. K., MacLean, M. D. and Barsvary, A. K., The

of reinforced soil walls, in the case of flexible wall facing, obser ved behavior of a geotextile reinforced

earth pressure equivalent to the overburden pressure is embankment constructed on peat. Canadian

produced across the entire bottom of the rein- forced soil Geotechnical J., 21 (2) (1984) 289-304.Rowe, R. K., The

area, while in the case of stiff wall facing work, the earth analysis of an embankment constructed on a

pressure has a unique distribution with high localized geotextile.Proc. Second Int. Conf. on Geotextiles, Las

pressure at the bottom of the wall facing. Vegas, 2 (1982) 677--82

·The study has also confirmed that the geogrid and [8]. Rmaine, J. T. & Ladd, C. C. (1988). Triaxial testing of

wall facing effectively provides a restraining effect saturated cohesive soils. In Advanced Triaxial Testing of

against deformation of the foundation ground that Soil and Rock, ASTM Special Technical Publication No.

continues after construction so that it follows this ground 977, pp. 421–459.Philadelphia, PA: ASTM.

deformation maintaining its functions as a sound soil

[9]. ALIBURTOTN., A. (1981). Use of engineering fabric in

structure.

roadand embankment construction. Seminar on the Use of

·The partial excavation and survey of the reinforced synthetic Fabrics in Civil Engineering, Toronto, pp. 66-94.

soil walls found no evidence of any damage to the

[10]. Public Works Research Institute, (1992). Design and

geogrids or the wall facings that were used, confirming

Construction Manual for Reinforced Earth with Geotextile

that they were in sound condition.

(in Japanese), 404p

References

[11]. Tsukada, Y., Ochiai, Y. Miyatake, H. and Tajiri, N.

[1]. Koerner, R.M., and Ko, F.K., (1982). Laboratory Studies

(1998). Field Performance Test of a Geosynthetic-

of Long Term Drainage Capability ofGeotextiles,

Reinforced Soil Wall with Rigid Facing, 6th International

Proceedings, Part I. Second International Congress on

Conference on Geosynthetics, pp.577-580

Geotextiles, LasVegas, August.

32 i-manager’s Journal on Structural Engineering, Vol. 1 l

No. 1 l

March - May 2012

RESEARCH PAPERS

ABOUT THE AUTHORS

* Assistant Professor, Civil Engineering Department, Sati Vidisha.

** Associate Professor, Civil Engineering Department, Manit Bhopal.

i-manager’s Journal on Structural Engineering, Vol. 1 l

No. 1 l

March - May 2012 33

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- 6th Central Pay Commission Salary CalculatorДокумент15 страниц6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Drain Design FinalДокумент4 страницыDrain Design FinalANKESH SHRIVASTAVA100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Table of Content: Construction Quality Management and Surveillance System Quality Assurance Quality Control ManualДокумент154 страницыTable of Content: Construction Quality Management and Surveillance System Quality Assurance Quality Control ManualUdomsin WutigulpakdeeОценок пока нет

- Wasteland Settlement Generator - Printer Friendly PDFДокумент11 страницWasteland Settlement Generator - Printer Friendly PDFJoan Fortuna100% (2)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Post Installation Evaluation and Repair of Installed Reinforced Concrete PipeДокумент37 страницPost Installation Evaluation and Repair of Installed Reinforced Concrete PipeMunarwand Ahmad100% (1)

- Box Culvert 1+825-3Документ1 страницаBox Culvert 1+825-3ANKESH SHRIVASTAVAОценок пока нет

- Box Culvert 1+825-1Документ1 страницаBox Culvert 1+825-1ANKESH SHRIVASTAVAОценок пока нет

- Low-Volume Roads EngineeringДокумент183 страницыLow-Volume Roads Engineeringeng_osman_mukhtar100% (1)

- Box Culvert 1+825-2Документ1 страницаBox Culvert 1+825-2ANKESH SHRIVASTAVAОценок пока нет

- Footpath Sections All PDFДокумент1 страницаFootpath Sections All PDFANKESH SHRIVASTAVAОценок пока нет

- Presentation FRPДокумент35 страницPresentation FRPANKESH SHRIVASTAVAОценок пока нет

- Grid FloorsДокумент52 страницыGrid FloorsNani Tirumalasetti100% (5)

- TP LOGS - MeterДокумент15 страницTP LOGS - MeterWaqas AhmedОценок пока нет

- BioGrace-I Excel Tool - Version 4d (N20 - Urea)Документ138 страницBioGrace-I Excel Tool - Version 4d (N20 - Urea)imran.teknikkimia100% (3)

- CBLM HorticultureДокумент67 страницCBLM HorticultureJason Dicon100% (2)

- All Angels' School Vidisha (M.P.) : Open Area For Proposed Building 391.67 SQ.MДокумент2 страницыAll Angels' School Vidisha (M.P.) : Open Area For Proposed Building 391.67 SQ.MANKESH SHRIVASTAVAОценок пока нет

- Job Information: Job No Sheet No RevДокумент95 страницJob Information: Job No Sheet No RevANKESH SHRIVASTAVAОценок пока нет

- Bus Stand Design EstimateДокумент109 страницBus Stand Design EstimateANKESH SHRIVASTAVAОценок пока нет

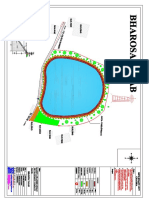

- 3.0 DRAWINGS - Bharosa PondДокумент1 страница3.0 DRAWINGS - Bharosa PondANKESH SHRIVASTAVAОценок пока нет

- Irc 73 Geometric Design PDFДокумент11 страницIrc 73 Geometric Design PDFANKESH SHRIVASTAVAОценок пока нет

- Volume 2 Building Works Ss R 2012Документ262 страницыVolume 2 Building Works Ss R 2012bbaplОценок пока нет

- Cover Latter For Customer SerivceДокумент1 страницаCover Latter For Customer SerivceANKESH SHRIVASTAVAОценок пока нет

- Comprative BW Deleted Vs PreposedДокумент1 страницаComprative BW Deleted Vs PreposedANKESH SHRIVASTAVAОценок пока нет

- Job Information: Job No Sheet No RevДокумент95 страницJob Information: Job No Sheet No RevANKESH SHRIVASTAVAОценок пока нет

- Estimate No. 2 - Internal Road - Fatte Singh MargДокумент7 страницEstimate No. 2 - Internal Road - Fatte Singh MargANKESH SHRIVASTAVAОценок пока нет

- 18 PDFДокумент6 страниц18 PDFANKESH SHRIVASTAVAОценок пока нет

- CFD Pump SumpДокумент9 страницCFD Pump SumpANKESH SHRIVASTAVAОценок пока нет

- Hoek-Brown Critera and GSIДокумент112 страницHoek-Brown Critera and GSIMohit VermaОценок пока нет

- Read MeДокумент1 страницаRead MeANKESH SHRIVASTAVAОценок пока нет

- Public ToiletДокумент1 страницаPublic ToiletANKESH SHRIVASTAVAОценок пока нет

- Im Paper 25 K KawakitaДокумент10 страницIm Paper 25 K KawakitaTAPAS SINGHОценок пока нет

- Vigyan & Prodyogiki (By-Rahul Sharma) - 1Документ168 страницVigyan & Prodyogiki (By-Rahul Sharma) - 1Sandeep yadavОценок пока нет

- Cover Latter For Customer SerivceДокумент1 страницаCover Latter For Customer SerivceANKESH SHRIVASTAVAОценок пока нет

- Typical Cross Section RoadДокумент1 страницаTypical Cross Section RoadANKESH SHRIVASTAVAОценок пока нет

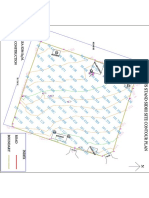

- Contour Plan Bus StandДокумент1 страницаContour Plan Bus StandANKESH SHRIVASTAVAОценок пока нет

- Fatteh Singh OGLДокумент10 страницFatteh Singh OGLANKESH SHRIVASTAVAОценок пока нет

- Penetration of Cover Crop Roots Through Compacted SoilsДокумент13 страницPenetration of Cover Crop Roots Through Compacted Soilscontadino_impazzitoОценок пока нет

- Guide To Rainforestation Timber Species PDFДокумент12 страницGuide To Rainforestation Timber Species PDFYor CabzОценок пока нет

- Ready Reckoner Test MaterialДокумент46 страницReady Reckoner Test MaterialBilal A BarbhuiyaОценок пока нет

- Book Review: Expansive Soils-Problems and Practice in Foundation and Pavement EngineeringДокумент2 страницыBook Review: Expansive Soils-Problems and Practice in Foundation and Pavement EngineeringABDIRAHMANОценок пока нет

- Cantilever Wall Analysis Input DataДокумент20 страницCantilever Wall Analysis Input DatabeadveeОценок пока нет

- Artificial Ground Water RechargeДокумент40 страницArtificial Ground Water RechargeOtoma OrkaidoОценок пока нет

- Slope Stability Analysis of Unsaturated Soil - IMPORTANTE PDFДокумент18 страницSlope Stability Analysis of Unsaturated Soil - IMPORTANTE PDFAngela GonzálezОценок пока нет

- NarcДокумент4 страницыNarcLybah RehmanОценок пока нет

- Geospatial Assessment of Climatic Variability and Aridity in Katsina State, NigeriaДокумент11 страницGeospatial Assessment of Climatic Variability and Aridity in Katsina State, NigeriaInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- FRQ Fa AnswerДокумент46 страницFRQ Fa AnswerAllan YUОценок пока нет

- View TendДокумент18 страницView TendUyavie ObonnaОценок пока нет

- Commoner's Law of EcologyДокумент8 страницCommoner's Law of EcologyPau Figuerres0% (1)

- Forage Morphology (Grass & Legumes)Документ99 страницForage Morphology (Grass & Legumes)Al Pavillon100% (1)

- Soil PH PDFДокумент4 страницыSoil PH PDFZairiffZainalОценок пока нет

- Chap 4 - Shallow Ult PDFДокумент58 страницChap 4 - Shallow Ult PDFChiến Lê100% (2)

- 07 - Chapter 1 PDFДокумент34 страницы07 - Chapter 1 PDFMohit JangidОценок пока нет

- Design and Construction of A Moisture Level Detector For Nigerian Soil ConditionsДокумент6 страницDesign and Construction of A Moisture Level Detector For Nigerian Soil Conditionsmaduakolam stanleyОценок пока нет

- Cde Floriculture 2012Документ41 страницаCde Floriculture 2012api-101186640Оценок пока нет

- The Australian GeoGuides For Slope Management and MaintenanceДокумент25 страницThe Australian GeoGuides For Slope Management and MaintenanceTony ChanОценок пока нет

- Risk Assessment Guide For PetroleumДокумент69 страницRisk Assessment Guide For PetroleumSri KanthОценок пока нет

- Types and Importance of Soil StructureДокумент12 страницTypes and Importance of Soil StructureLorelie SinongОценок пока нет

- Rabbit Manure As Potential Raw Material For Organic Ferlilizer)Документ7 страницRabbit Manure As Potential Raw Material For Organic Ferlilizer)Rizky Alfian PratamaОценок пока нет

- Simulation of Sediment and Streamflow in Dabus River Blue Nile BasinДокумент9 страницSimulation of Sediment and Streamflow in Dabus River Blue Nile BasinBilal KemalОценок пока нет

- Myth of Empires User Manual EN-1Документ120 страницMyth of Empires User Manual EN-1Fenix Jimenez HackОценок пока нет