Академический Документы

Профессиональный Документы

Культура Документы

1CS134694 A

Загружено:

Dwi Mulyanti DwimulyantishopОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

1CS134694 A

Загружено:

Dwi Mulyanti DwimulyantishopАвторское право:

Доступные форматы

Sheet

1 (7)

Respons. dept Date Reg.

SYSTEM DESCRIPTION

MBX OET 2013-06-04 Tanjung Uncang

Prepared

Pulsation Monitoring System

B. Svensson BD000146U01-U02

This document is issued in Pulse.

PULSATION MONITORING SYSTEM _________________________________________________ 2

Purpose of the system _____________________________________________________________________________ 2

General description of the system, mechanical parts ____________________________________________________ 2

Major components ________________________________________________________________________________ 3

SIGNAL PROCESSING SYSTEM ____________________________________________________ 4

Purpose of the system _____________________________________________________________________________ 4

General Description _______________________________________________________________________________ 4

Main components _________________________________________________________________________________ 5

We reserve all rights in this document and in the information

FUNCTION ______________________________________________________________________ 6

contained therein. Reproduction, use or disclosure to third

© Siemens Industrial Turbomachinery AB

Parties without express authority is strictly forbidden.

Disturbances _____________________________________________________________________________________ 6

Testing and service ________________________________________________________________________________ 6

A 087 0474-B 00-03 MS Word 97

Approved Latest revision Archive HG

2013-06-17 A) First edition

Anna Grenestam 73 2124

Checked No.

2013-06-17

Fredrik Grönvall 1CS134694

Sheet

2 (7)

Respons. dept Date Reg.

SYSTEM DESCRIPTION

MBX OET 2013-06-04 Tanjung Uncang

Prepared

Pulsation Monitoring System

B. Svensson BD000146U01-U02

This document is issued in Pulse.

Pulsation monitoring system

Purpose of the system

The purpose of the system is to measure the dynamic pressure in the combustion chamber and

deliver analogue outputs to the control and protection system.

General description of the system, mechanical parts

We reserve all rights in this document and in the information

contained therein. Reproduction, use or disclosure to third

© Siemens Industrial Turbomachinery AB

Parties without express authority is strictly forbidden.

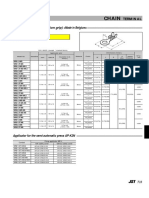

Figure 1: Schematic system drawing, mechanical parts

The system consists of three parts: measuring part, damping part and air supply.

Pressure waves in the combustion chamber are led to the sensors, which are located outside the

central casing, via narrow tubes (measurement part). Additional tubing is used beyond the sensor to

absorb pressure waves travelling through the pipe (acoustic resonance damping part). The air supply

feeds the measurement device with air from the compressor in order to avoid condensation in the

pipe system and to achieve a smoother temperature gradient in the pipe from the transducer to the

outer liner of the combustion chamber.

A 087 0474-B 00-03 MS Word 97

Approved Latest revision Archive HG

2013-06-17 A) First edition

Anna Grenestam 73 2124

Checked No.

2013-06-17

Fredrik Grönvall 1CS134694

Sheet

3 (7)

Respons. dept Date Reg.

SYSTEM DESCRIPTION

MBX OET 2013-06-04 Tanjung Uncang

Prepared

Pulsation Monitoring System

B. Svensson BD000146U01-U02

This document is issued in Pulse.

Air Supply system

Air is taken from the compressor in the location MBA10 BR001 (7), 'Pressure purge air from

compressor'.

Long line probe system

Damping device

Where the air supply pipe enters the damping box (4) it is split up in three identical systems, one for

each measuring point. Therefore the damping box includes three damping drums (5). The damping

box is insulated (3).

The damping box is located in the physically highest point in the system, i.e. on the combustion

chamber, located right behind the fuel manifolders.

Measurement device

We reserve all rights in this document and in the information

contained therein. Reproduction, use or disclosure to third

Measurement device consists of narrow tubes (8) between damping device and combustion chamber

© Siemens Industrial Turbomachinery AB

Parties without express authority is strictly forbidden.

outer liner, sensors (1), sensor holders (1) and insulation. Sensor holders are mounted directly in the

central casing and via wave guides are connected to the combustion chamber.

Major components

• Position 6,

The pipe feeds measuring device with purge air.

• Position 8,

The pipe transmits pressure waves to the damping device and transport air to the combustion

chamber.

• Position 4, Box MBX10BS005

This box enclose all dampers and heating device.

• Position 5, Damper MBX10BS005-MR01, MR02, MR03

• Position 1, Sensor holder

The sensor holder is mounted in the central casing and is a connection between the central casing,

the wave guide and the dynamic pressure transducer.

• Position 1, Dynamic pressure transducer MBA10CP085, MBA10CP090, MBA10CP095

The dynamic pressure transducer measures the dynamic pressure in the wave guide.

• Position 3, Insulation

This insulation insulates the air supply pipe and the damping box (30mm respectively 50mm).

A 087 0474-B 00-03 MS Word 97

Approved Latest revision Archive HG

2013-06-17 A) First edition

Anna Grenestam 73 2124

Checked No.

2013-06-17

Fredrik Grönvall 1CS134694

Sheet

4 (7)

Respons. dept Date Reg.

SYSTEM DESCRIPTION

MBX OET 2013-06-04 Tanjung Uncang

Prepared

Pulsation Monitoring System

B. Svensson BD000146U01-U02

This document is issued in Pulse.

Signal processing system

Purpose of the system

The signal processing system uses input signals from dynamic pressure sensors for processing and

delivers output signals to the control and protection system (CPS), via analogue signals or a relay

circuit.

General Description

We reserve all rights in this document and in the information

contained therein. Reproduction, use or disclosure to third

© Siemens Industrial Turbomachinery AB

Parties without express authority is strictly forbidden.

Input signals

The input signal to the signal-processing monitor comes from the pulsation monitoring measurement

chain, which includes a dynamic pressure sensor and a charge amplifier (A). The input signal is a mV

signal proportional to the dynamic pressure in the combustion chamber. The signal is connected to an

I/O module and can be externally strapped or internally cascade coupled.

Signal processing monitor

The signal-processing monitor is placed in a monitor rack with opportunity to handle up to fifteen

monitors. The signal-processing monitor filters and converts the input mV signal from the charge

amplifier. For each frequency band a RMS value is calculated. The buffered output (C) is used for

analysis and the signal from this output is not processed.

A 087 0474-B 00-03 MS Word 97

Approved Latest revision Archive HG

2013-06-17 A) First edition

Anna Grenestam 73 2124

Checked No.

2013-06-17

Fredrik Grönvall 1CS134694

Sheet

5 (7)

Respons. dept Date Reg.

SYSTEM DESCRIPTION

MBX OET 2013-06-04 Tanjung Uncang

Prepared

Pulsation Monitoring System

B. Svensson BD000146U01-U02

This document is issued in Pulse.

We reserve all rights in this document and in the information

contained therein. Reproduction, use or disclosure to third

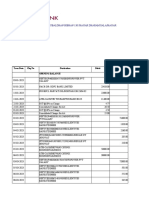

Figure 1: Bently Nevada rack and two views of Dynamic Pressure monitor.

© Siemens Industrial Turbomachinery AB

Parties without express authority is strictly forbidden.

Main components

• Position B: Bently Nevada Dynamic Pressure monitor 3500/64M-01-00

Signal processing monitor placed in a Bently Nevada 3500 rack

• Position A: Charge amplifier

The charge amplifier amplifies and transforms the charge signal into a mV-signal

A Brüel & Kjaer 2661 is used

• Position C: Buffered output

BNC connector used for signal analysis. The output is not processed.

• Position E: Isolation amplifier

The isolation amplifier creates a galvanic isolation between the DCS and Bently Nevada. A

Phoenix Contact MCR-CP is used

• Position D: Connection point to the CPS

A 087 0474-B 00-03 MS Word 97

Approved Latest revision Archive HG

2013-06-17 A) First edition

Anna Grenestam 73 2124

Checked No.

2013-06-17

Fredrik Grönvall 1CS134694

Sheet

6 (7)

Respons. dept Date Reg.

SYSTEM DESCRIPTION

MBX OET 2013-06-04 Tanjung Uncang

Prepared

Pulsation Monitoring System

B. Svensson BD000146U01-U02

This document is issued in Pulse.

Function

Start up

System active.

Continuous operation

System active.

Turbine stop

System active.

Stand still

System active.

We reserve all rights in this document and in the information

contained therein. Reproduction, use or disclosure to third

Disturbances

© Siemens Industrial Turbomachinery AB

Parties without express authority is strictly forbidden.

Gas turbine trip

Gas turbine trip does not affect the pulsation monitoring system.

Loss of power supply

Loss of power supply will shut down the signal-processing monitor and combustion chamber

monitoring will therefore not work.

Incorrect configuration of signal-processing monitor

Incorrect configuration of signal-processing monitor may affect output values to the CPS.

System fault

Fault in the signal-processing monitor may affect output signals to the CPS or completely stop

working.

Testing and service

Testing during operation

N/A

Replacement of faulty monitor

Not possible during operation. Replacement should be done during stand still. Rack has to be

switched of before removing faulty monitor.

A 087 0474-B 00-03 MS Word 97

Approved Latest revision Archive HG

2013-06-17 A) First edition

Anna Grenestam 73 2124

Checked No.

2013-06-17

Fredrik Grönvall 1CS134694

Sheet

7 (7)

Respons. dept Date Reg.

SYSTEM DESCRIPTION

MBX OET 2013-06-04 Tanjung Uncang

Prepared

Pulsation Monitoring System

B. Svensson BD000146U01-U02

This document is issued in Pulse.

Replacement of sensor and sensor cable

Not possible and not allowed to change sensor during operation. Cable should be changed during

stand-still

We reserve all rights in this document and in the information

contained therein. Reproduction, use or disclosure to third

© Siemens Industrial Turbomachinery AB

Parties without express authority is strictly forbidden.

A 087 0474-B 00-03 MS Word 97

Approved Latest revision Archive HG

2013-06-17 A) First edition

Anna Grenestam 73 2124

Checked No.

2013-06-17

Fredrik Grönvall 1CS134694

Вам также может понравиться

- Dragons ScaleДокумент13 страницDragons ScaleGuilherme De FariasОценок пока нет

- BopДокумент26 страницBopcrni roko100% (1)

- 1.3 Sustructure Assembly DrawingsДокумент31 страница1.3 Sustructure Assembly Drawingsdanielra85Оценок пока нет

- Zee DiagramДокумент58 страницZee DiagramHari Karki100% (1)

- The Other Twelve Part 1Документ5 страницThe Other Twelve Part 1vv380100% (2)

- Free ConvectionДокумент4 страницыFree ConvectionLuthfy AditiarОценок пока нет

- 1en 02 PDFДокумент96 страниц1en 02 PDFAndrey100% (2)

- 14S Operator ManualДокумент106 страниц14S Operator ManualUkht Al-Islam100% (1)

- A11 Rig MoveДокумент57 страницA11 Rig MoveJ.JohansenОценок пока нет

- 2 - Focus II C-307 DC Motor Sigma - IngДокумент127 страниц2 - Focus II C-307 DC Motor Sigma - IngMatias BruschiniОценок пока нет

- Sa 7627Документ2 страницыSa 7627Lv WanyОценок пока нет

- MoogДокумент34 страницыMoogSissaoui OmarОценок пока нет

- GenAdvisor ManualДокумент66 страницGenAdvisor ManualCristian VillalbaОценок пока нет

- ST 183 612-620-624 Descriere Senzori PDFДокумент38 страницST 183 612-620-624 Descriere Senzori PDFPopa MihaiОценок пока нет

- Man PDFДокумент37 страницMan PDFvamsiarangi100% (1)

- SOX0051136 - A - 0MS5002C Conversion To MS5002D Power CrystalДокумент77 страницSOX0051136 - A - 0MS5002C Conversion To MS5002D Power CrystalbaliОценок пока нет

- Otis Test Tool GAA21750AK3Документ86 страницOtis Test Tool GAA21750AK3Habibulla Bavaji75% (4)

- Operator's ManualДокумент110 страницOperator's ManualAdam0% (1)

- 1st Stage Lifting & Transportation AX 010915Документ95 страниц1st Stage Lifting & Transportation AX 010915Fauzan Rusmayadi ReharderОценок пока нет

- BD Service Tool Manual GAA30082DAC 2009-11-30Документ65 страницBD Service Tool Manual GAA30082DAC 2009-11-30naranbaatar_b100% (3)

- Training Design SprintДокумент11 страницTraining Design Sprintardi wiantoОценок пока нет

- Preventive Maintenance ScheduleДокумент1 страницаPreventive Maintenance Schedulenil006Оценок пока нет

- Performance Guide - SAP SEM BW BPSДокумент26 страницPerformance Guide - SAP SEM BW BPSmkmОценок пока нет

- bmmsys55-55X-55SR-550 01Документ78 страницbmmsys55-55X-55SR-550 01Biblioteca Brasil AviationОценок пока нет

- RS Moahmed Bakri OsmanДокумент27 страницRS Moahmed Bakri Osmanbakri OmanОценок пока нет

- CPA FormДокумент1 страницаCPA FormRafaqat AliОценок пока нет

- 1149826Документ7 страниц1149826Charbel TadrosОценок пока нет

- MRI-FM-26 NewДокумент1 страницаMRI-FM-26 NewAbrar ArainОценок пока нет

- User Manual: Safety Module Sm-EДокумент28 страницUser Manual: Safety Module Sm-Eait mimouneОценок пока нет

- Target Cleanliness WorksheetДокумент6 страницTarget Cleanliness WorksheetMauricio Marin PinedaОценок пока нет

- Ba Transmitterm 300cond2channele521213180507Документ64 страницыBa Transmitterm 300cond2channele521213180507Leo PastinОценок пока нет

- Plant Design RequirementsДокумент106 страницPlant Design RequirementsaprendizajeautonomoОценок пока нет

- Maintenance Report (Form) Rev.03 JOHANДокумент9 страницMaintenance Report (Form) Rev.03 JOHANjoh SaragihОценок пока нет

- Abis MappingДокумент25 страницAbis MappingVNDSОценок пока нет

- RoastingДокумент81 страницаRoastingAj JainОценок пока нет

- PREPAIDДокумент1 страницаPREPAIDzanmikenzieОценок пока нет

- Roland Sc540 Service ManualДокумент201 страницаRoland Sc540 Service ManualburnabysignaramaОценок пока нет

- RTD Te 103 AbДокумент5 страницRTD Te 103 Abriswan nugrahaОценок пока нет

- Speedometer Installation Manua Online Version 092507 PDFДокумент58 страницSpeedometer Installation Manua Online Version 092507 PDFAddyTossaОценок пока нет

- Roland SOLJET-Pro2 SC 540 CJ-540 Service Notes Manual (SM, PM, CD) 200606 14Документ199 страницRoland SOLJET-Pro2 SC 540 CJ-540 Service Notes Manual (SM, PM, CD) 200606 14guibsgv100% (1)

- PROM Eng 2.06.02Документ66 страницPROM Eng 2.06.02Jonald DagsaОценок пока нет

- Manual Transmitter M200 Easy e 52121501 Sept09Документ76 страницManual Transmitter M200 Easy e 52121501 Sept09prancesiОценок пока нет

- Starting & Charging System: SectionДокумент26 страницStarting & Charging System: SectionascguateОценок пока нет

- DJJ5123 Pneumatic & Hydraulics: Mechanical Engineering Department Politeknik Sultan Mizan Zainal AbidinДокумент8 страницDJJ5123 Pneumatic & Hydraulics: Mechanical Engineering Department Politeknik Sultan Mizan Zainal AbidinZul HaikalОценок пока нет

- Sensation: CT023/02/P Update Instructions CTДокумент12 страницSensation: CT023/02/P Update Instructions CTAmmar SaadОценок пока нет

- RAN and Transmission Huawei InspectionДокумент8 страницRAN and Transmission Huawei InspectionAnleyОценок пока нет

- GEN-FORM-083 - Fire Extinguisher ChecklistДокумент1 страницаGEN-FORM-083 - Fire Extinguisher ChecklistAbdeltawab YoussefОценок пока нет

- Lab Activity #7Документ2 страницыLab Activity #7JASPER PENALBAОценок пока нет

- Fj50 Service ManualДокумент110 страницFj50 Service ManualSOLUTIONS IGFОценок пока нет

- Catalogo Z 45-25jДокумент17 страницCatalogo Z 45-25jCristyan GabrielОценок пока нет

- Gammmsra 000006Документ23 страницыGammmsra 000006Flyer FlyerОценок пока нет

- AbbcdДокумент36 страницAbbcdArga SimanjuntakОценок пока нет

- F4-PFS205 DiagramДокумент21 страницаF4-PFS205 DiagramncirОценок пока нет

- Spe Paper InfoДокумент3 страницыSpe Paper InfosiriuslotОценок пока нет

- LogbooksДокумент9 страницLogbooksNassim AissatОценок пока нет

- Form Sa Ahass - PDF: DownloadДокумент3 страницыForm Sa Ahass - PDF: Downloadherman srОценок пока нет

- Gage R&R Study: Data Collection Form Runorder Operators Parts Measurements 1 1 1 - 2 1 3 - 3 1 2Документ9 страницGage R&R Study: Data Collection Form Runorder Operators Parts Measurements 1 1 1 - 2 1 3 - 3 1 2Hemant SharmaОценок пока нет

- Meridium APM Asset Strategy Management V3.6.0.0.0Документ469 страницMeridium APM Asset Strategy Management V3.6.0.0.0RajeevОценок пока нет

- Electircal SLDДокумент25 страницElectircal SLDEzhu MalaiОценок пока нет

- Agileire 8872 ManualДокумент167 страницAgileire 8872 ManualEdgar I RamirezОценок пока нет

- Scales & Balances World Summary: Market Values & Financials by CountryОт EverandScales & Balances World Summary: Market Values & Financials by CountryОценок пока нет

- Fuel & Feedstock Gases World Summary: Market Values & Financials by CountryОт EverandFuel & Feedstock Gases World Summary: Market Values & Financials by CountryОценок пока нет

- Connectors World Summary: Market Values & Financials by CountryОт EverandConnectors World Summary: Market Values & Financials by CountryОценок пока нет

- Industrial Gases, Type World Summary: Market Values & Financials by CountryОт EverandIndustrial Gases, Type World Summary: Market Values & Financials by CountryОценок пока нет

- 576560Документ1 страница576560Dwi Mulyanti DwimulyantishopОценок пока нет

- 89239Документ1 страница89239Dwi Mulyanti DwimulyantishopОценок пока нет

- 572004Документ1 страница572004Dwi Mulyanti DwimulyantishopОценок пока нет

- 576040Документ1 страница576040Dwi Mulyanti DwimulyantishopОценок пока нет

- Arteor: Italian / US Standards 83.5 MM Fixing Centres - Flush Mounting Boxes, Support Frames and PlatesДокумент1 страницаArteor: Italian / US Standards 83.5 MM Fixing Centres - Flush Mounting Boxes, Support Frames and PlatesDwi Mulyanti DwimulyantishopОценок пока нет

- 576040Документ1 страница576040Dwi Mulyanti DwimulyantishopОценок пока нет

- Arteor: Italian / US Standards 83.5 MM Fixing Centres - Flush Mounting Boxes, Support Frames and PlatesДокумент1 страницаArteor: Italian / US Standards 83.5 MM Fixing Centres - Flush Mounting Boxes, Support Frames and PlatesDwi Mulyanti DwimulyantishopОценок пока нет

- SLS-75-ELE-DS-004 Data Sheet UPS System - Arun, Rev. 1 - AFC PDFДокумент5 страницSLS-75-ELE-DS-004 Data Sheet UPS System - Arun, Rev. 1 - AFC PDFDwi Mulyanti DwimulyantishopОценок пока нет

- XT SACE Tmax XTДокумент18 страницXT SACE Tmax XTDwi Mulyanti DwimulyantishopОценок пока нет

- TdsДокумент1 страницаTdsDwi Mulyanti DwimulyantishopОценок пока нет

- Wallis Complete Cat.Документ7 страницWallis Complete Cat.Dwi Mulyanti DwimulyantishopОценок пока нет

- CCTVДокумент16 страницCCTVDwi Mulyanti Dwimulyantishop100% (1)

- Technical OfferДокумент9 страницTechnical OfferDwi Mulyanti DwimulyantishopОценок пока нет

- SLS-75-ELE-DS-001 Data Sheet LV Switchgear and MCC - Arun, Rev. 0 - AFCДокумент7 страницSLS-75-ELE-DS-001 Data Sheet LV Switchgear and MCC - Arun, Rev. 0 - AFCDwi Mulyanti DwimulyantishopОценок пока нет

- SLS-75-ELE-DS-004 Data Sheet UPS System - Arun, Rev. 1 - AFC PDFДокумент5 страницSLS-75-ELE-DS-004 Data Sheet UPS System - Arun, Rev. 1 - AFC PDFDwi Mulyanti DwimulyantishopОценок пока нет

- SLS-70-CIV-DW-002 Civil, Structure & Architecture General Notes, Rev-A, Rejected PDFДокумент1 страницаSLS-70-CIV-DW-002 Civil, Structure & Architecture General Notes, Rev-A, Rejected PDFDwi Mulyanti DwimulyantishopОценок пока нет

- SLS-75-ELE-CL-005 0.48 KV-0.4 KV Transformer Sizing - Arun, Rev. 0 - AFCДокумент6 страницSLS-75-ELE-CL-005 0.48 KV-0.4 KV Transformer Sizing - Arun, Rev. 0 - AFCDwi Mulyanti DwimulyantishopОценок пока нет

- SLS-95-ELE-DW-010 Panel Schedule - Belawan, Rev. 1 - AFC PDFДокумент1 страницаSLS-95-ELE-DW-010 Panel Schedule - Belawan, Rev. 1 - AFC PDFDwi Mulyanti DwimulyantishopОценок пока нет

- SLS-75-ELE-LI-002 Electrical Equipment List - Arun, Rev. 1 - AFCДокумент5 страницSLS-75-ELE-LI-002 Electrical Equipment List - Arun, Rev. 1 - AFCDwi Mulyanti DwimulyantishopОценок пока нет

- SLS-75-ELE-DW-015 Electrical Connection Diagram For MOV - Arun, Rev. 0 - AFC PDFДокумент1 страницаSLS-75-ELE-DW-015 Electrical Connection Diagram For MOV - Arun, Rev. 0 - AFC PDFDwi Mulyanti DwimulyantishopОценок пока нет

- SLS-75-ELE-DW-011 Grounding and Lightning Layout - Arun, Rev. 0 - AFCДокумент2 страницыSLS-75-ELE-DW-011 Grounding and Lightning Layout - Arun, Rev. 0 - AFCDwi Mulyanti DwimulyantishopОценок пока нет

- SLS-95-ELE-DW-001 Legend and Symbol - Belawan, Rev. 0 - AFCДокумент1 страницаSLS-95-ELE-DW-001 Legend and Symbol - Belawan, Rev. 0 - AFCDwi Mulyanti DwimulyantishopОценок пока нет

- SLS-75-ELE-DW-011 Grounding and Lightning Layout - Arun, Rev. 0 - AFCsДокумент1 страницаSLS-75-ELE-DW-011 Grounding and Lightning Layout - Arun, Rev. 0 - AFCsDwi Mulyanti DwimulyantishopОценок пока нет

- SLS-95-ELE-DW-005 Electrical Equipment Layout at Electrical Room - Belawan, Rev. 0 - AFCДокумент1 страницаSLS-95-ELE-DW-005 Electrical Equipment Layout at Electrical Room - Belawan, Rev. 0 - AFCDwi Mulyanti DwimulyantishopОценок пока нет

- SLS-95-ELE-DW-010 Panel Schedule - Belawan, Rev. 1 - AFCДокумент1 страницаSLS-95-ELE-DW-010 Panel Schedule - Belawan, Rev. 1 - AFCDwi Mulyanti DwimulyantishopОценок пока нет

- SLS-70-CIV-DW-002 Civil, Structure & Architecture General Notes, Rev-A, RejectedДокумент1 страницаSLS-70-CIV-DW-002 Civil, Structure & Architecture General Notes, Rev-A, RejectedDwi Mulyanti DwimulyantishopОценок пока нет

- SLS-70-CIV-DB-001 Civil Design Basis, Rev C - App W CommentДокумент36 страницSLS-70-CIV-DB-001 Civil Design Basis, Rev C - App W CommentDwi Mulyanti DwimulyantishopОценок пока нет

- Sls-70-Civ-db-001 Civil Design Basis, Rev. D - AfdДокумент36 страницSls-70-Civ-db-001 Civil Design Basis, Rev. D - AfdDwi Mulyanti DwimulyantishopОценок пока нет

- SLS-75-ELE-DW-015 Electrical Connection Diagram For MOV - Arun, Rev. 0 - AFCДокумент1 страницаSLS-75-ELE-DW-015 Electrical Connection Diagram For MOV - Arun, Rev. 0 - AFCDwi Mulyanti DwimulyantishopОценок пока нет

- SLS-70-CIV-DB-001 Civil Design Basis, Rev B - App W CommentДокумент36 страницSLS-70-CIV-DB-001 Civil Design Basis, Rev B - App W CommentDwi Mulyanti DwimulyantishopОценок пока нет

- Ferrero A.M. Et Al. (2015) - Experimental Tests For The Application of An Analytical Model For Flexible Debris Flow Barrier Design PDFДокумент10 страницFerrero A.M. Et Al. (2015) - Experimental Tests For The Application of An Analytical Model For Flexible Debris Flow Barrier Design PDFEnrico MassaОценок пока нет

- LAB REPORT - MGCLДокумент5 страницLAB REPORT - MGCLKali stringsОценок пока нет

- 3-A Y 3-B Brenda Franco DíazДокумент4 страницы3-A Y 3-B Brenda Franco DíazBRENDA FRANCO DIAZОценок пока нет

- Embedded Software Development ProcessДокумент34 страницыEmbedded Software Development ProcessAmmar YounasОценок пока нет

- Chapter 4 Signal Flow GraphДокумент34 страницыChapter 4 Signal Flow GraphAbhishek PattanaikОценок пока нет

- DatuinMA (Activity #5 - NSTP 10)Документ2 страницыDatuinMA (Activity #5 - NSTP 10)Marc Alen Porlaje DatuinОценок пока нет

- Teamcenter 10.1: Publication Number PLM00015 JДокумент122 страницыTeamcenter 10.1: Publication Number PLM00015 JmohanОценок пока нет

- TCGRX BullsEye Tablet SplitterДокумент2 страницыTCGRX BullsEye Tablet SplittermalucОценок пока нет

- Chain: SRB Series (With Insulation Grip)Документ1 страницаChain: SRB Series (With Insulation Grip)shankarОценок пока нет

- Batron: 29 5 MM Character Height LCD Modules 29Документ1 страницаBatron: 29 5 MM Character Height LCD Modules 29Diego OliveiraОценок пока нет

- (Schottel) Aspects of The Design Procedure For Propellers Providing Max Bollard PullДокумент10 страниц(Schottel) Aspects of The Design Procedure For Propellers Providing Max Bollard Pulldevu2chodankarОценок пока нет

- Earth Science NAME - DATEДокумент3 страницыEarth Science NAME - DATEArlene CalataОценок пока нет

- Case Study McsДокумент4 страницыCase Study McsManjushree PatilОценок пока нет

- Performance Task 2Документ3 страницыPerformance Task 2Edrose WycocoОценок пока нет

- Ishrana Studenata I Nastavnika Visoke Škole U Subotici Tokom Pandemije COVID-19Документ4 страницыIshrana Studenata I Nastavnika Visoke Škole U Subotici Tokom Pandemije COVID-19DejanОценок пока нет

- XXXX96 01 01 2023to28 08 2023Документ18 страницXXXX96 01 01 2023to28 08 2023dabu choudharyОценок пока нет

- Handout Waste Catch BasinДокумент2 страницыHandout Waste Catch BasinJonniel De GuzmanОценок пока нет

- Kursus Jabatan Kejuruteraan Mekanikal Sesi Jun 2014Документ12 страницKursus Jabatan Kejuruteraan Mekanikal Sesi Jun 2014ihsanyusoffОценок пока нет

- An Introduction To Routine and Special StainingДокумент13 страницAn Introduction To Routine and Special StainingBadiu ElenaОценок пока нет

- Ferroelectric RamДокумент20 страницFerroelectric RamRijy LoranceОценок пока нет

- Volcanoes Sub-topic:Volcanic EruptionДокумент16 страницVolcanoes Sub-topic:Volcanic EruptionVhenz MapiliОценок пока нет

- Calendar of Activities A.Y. 2015-2016: 12 Independence Day (Regular Holiday)Документ3 страницыCalendar of Activities A.Y. 2015-2016: 12 Independence Day (Regular Holiday)Beny TawanОценок пока нет

- Elasticsearch, Logstash, and Kibana - CERTДокумент35 страницElasticsearch, Logstash, and Kibana - CERTManuel VegaОценок пока нет

- University of Ghana: This Paper Contains Two Parts (PART I and PART II) Answer All Questions From Both PARTSДокумент3 страницыUniversity of Ghana: This Paper Contains Two Parts (PART I and PART II) Answer All Questions From Both PARTSPhilip Pearce-PearsonОценок пока нет