Академический Документы

Профессиональный Документы

Культура Документы

Jan Prusinski, P.E. Executive Director Cement Council of Texas

Загружено:

eros0 оценок0% нашли этот документ полезным (0 голосов)

23 просмотров21 страница2016 ACI RCC in Texas - Prusinski - 4-18-16

Оригинальное название

2016 ACI RCC in Texas - Prusinski - 4-18-16

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документ2016 ACI RCC in Texas - Prusinski - 4-18-16

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

23 просмотров21 страницаJan Prusinski, P.E. Executive Director Cement Council of Texas

Загружено:

eros2016 ACI RCC in Texas - Prusinski - 4-18-16

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 21

ACI – Milwukee

April 18, 2016a

Jan Prusinski, P.E.

Executive Director

Cement Council of Texas

OR

Jointed-Reinforced

Jointed-Plain (unreinforced)

Continuously Reinforced Roller Compacted Concrete

Concrete pavement placed a

different way

No-slump concrete (very stiff)

No forms

No reinforcing steel

Placed with asphalt-style

pavers

Consolidated with Vibratory

Rollers

No finishing

Low water-cement ration (i.e.

less shrinkage)

RCC vs. Asphalt

◦ Less expensive

◦ Rigid-less subgrade stress

◦ Less maintenance

◦ Placement time same or less

◦ Asphalt smoother

RCC vs. Conventional

Concrete

◦ Less expensive (no

reinforcing/dowels)

◦ Faster, high production

◦ Carries light traffic in hours

◦ Higher speed - grinding

Project size/complexity can

dictate economic benefits

1980’s – 2000: Lack of experienced

contractors

“One bad project” can hamper market or

owner in a region

Project size: small vs. large projects

Equipment requirements

◦ Pug mill & high density asphalt paver

◦ Ready mixed plant and conventional asphalt paver

Types of projects

Over and under specifying

Managing expectations

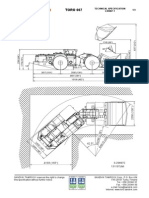

First large RCC job – Fort Hood

◦ Attribute COE acceptance to Dr.

David Pittman

1984 - 18,000 sy, 10” thick,

$58/sy at time

300 lb cement, 160 lb FA

1 ½” aggregate had some

segregation

¾” agg test area better

Placed in very hot, windy weather RCC Sawed Beam Test

Natural cracks

Flex strength of 800-900 psi

1987 – Second RCC project at Fort

Hood

Truck terminal

◦ 7” & 8” pavements

◦ 90,000 sy

◦ RCC bid 25% less than asphalt

Natural cracks 1987

◦ 23-50’ spacing

◦ Routed/sealed @ 5 yr

Continuous use, little

maintenace @ 26 yrs:

◦ Still performing – now used for

post office and UPS

◦ ~5,500 sy repairs performed

in 2014

Present-Day

Peltz

90,000 sq yd, Five

basins - “Dillo Dirt”

◦ 12 in thick, 2 lifts

◦ Haul roads, 9 in RCC

◦ 3:1, 5:1 and 10:1 slopes

Mix Design

◦ 12% cement, no fly ash

◦ ¾ in max aggregate

◦ 3300 psi @ 38 D

$43.47/cu yd or

~$31/sq yd

Still functions daily

Peltz

1999, 15 Acres

10 in, 2 lifts

5000 psi, 520 lbs

cement

Pavement

underdesigned,

replaced w/

conventional

pavement ~2011

Peltz

Spurred RCC Renaissance in TX

Largest RCC site in U.S.

◦ 45, 48, 35, 30 acres – 2007, 09,

12 and 15

14 and 18” RCC

◦ 2-lift construction

◦ 30 yr design

◦ 8” CTB, 4” perv, 12” lime/cem

Production:

◦ 8-11 acres/month RCC

◦ 2 acres/month PCC (2004 60

acre project)

Costs:

◦ RCC $45-$72/sy (18”)

◦ PCC $65-$100/sy (15”)

◦ 2009 alt: $32.2 Conv. vs.

$27.5M RCC (15% savings)

Project Area Year

Ph. 6, S. 22 ac/18” Let 3/30/16

Container

“West Yard” 25 ac/18” 2016 Private lease

Container

Barbours Cut ~15 ac/14-18” 2016

Container

Phase 2 30 ac/18” 2017

Container

Phase 1 60 ac/18” 2017 Possibly 2

Container contracts

Phase 7 70 ac/18” 2019 Possibly 2

Container contracts

By 2020, POH will have 380 acres of mostly 18” RCC,

Nearly 1,000,000 cubic yards of RCC.

Grape Creek Road:

15,000 sy

50th Street: 30,000 sy

50-year design life

Years of deferred

maintenance on

asphalt roads

75 yr maintenance:

◦ Asphalt (8 yr sealcoat +

24-year mill/o’lay) =

$7.5M

◦ RCC (overlay @ 50-60 yrs

= 1.4 M)

Reece Albert

Rollcon, LLC Contractor

Pipe fabrication for Eagle

Ford oil/gas

60 acres

Originally 15” unsurfaced

aggregate

Replaced with 7” RCC on

stabilized base

20% cost savings

Significant maintenance

savings

Owner cited less risk/clean-

up in fuel/oil spills

60 acres placed in less than

two months

1 ¼ mile, 4-lane principal

arterial, 36,000 sy

Justified on life cycle cost:

◦ 3.5” Asphalt/12” base - $2.3M

◦ 7” RCC – $2.7M

◦ Reece Albert – Low bid on both

asphalt and concrete

First concrete pavement in

Midland in 40+ years

◦ 2 days of open house

True inlay

◦ 4 days – Southbound

◦ 3 days – Northbound

County standards added

for RCC

Developer wanted added

value and eliminate repairs

5” on CMS same cost as 2”

asphalt + 6” flex base

Largest RCC residential

developments in US

Bella Vista – + more

> 60 miles of streets,

nearly 1,000,000 sy

Rollcon

3 Trucks per day, sandy subgrade, 20-year life, 1 mile x 24 ft (126,000 sf)

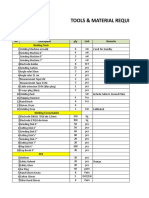

Traditional Asphalt + Aggregate RCC Pavement

$ 17,741 Curing

$155,145 $ 18,132 Saw Cutting

2” Asphalt $194,702 5” RCC

$88,282 6” Graded Agg.

$172,902 6” Cement Stab. Soil

$172,902 6” Cement Stab. Soil Compacted Subg.

Compacted Subg. $403,177 Total Cost

$416,329 Total Cost

$13,152 Cost Differential

Kendleton, TX (SW of

Houston)

◦ Started as opportunity

during 1st Port of Houston

◦ Several KCS yards in US

and Mexico

◦ Most recent, 57 ac, Wylie

(DFW-area), 10” and 7”

◦ AG Peltz and Rollcon

TxDOT beginning to use

RCC

◦ Special spec approved

◦ First project let: 16 lane-

miles frontage I-20 Abilene

(alt bid w/ asphalt – placed

as asphalt)

◦ Several safety rest areas (in

construction or bid)

◦ First State Highway – San

Angelo District, 2016

RCC can fill “gap” between asphalt and

conventional concrete

Non-concrete users may consider RCC after

dismissing conventional concrete

Asphalt contractors can transition to RCC

RCC can allow designers to “think outside the

box” with design

Continued use in industrial pavements

◦ Houston ship channel/intermodal, industrial

◦ Dallas intermodal

◦ South Texas trucking and industrial

TxDOT use should expand gradually

◦ Safety rest areas

◦ Rural frontage roads

◦ Lower volume FMs and oil/gas/wind farms with overweight

vehicles

Local public roads

◦ Arterials

◦ Residential

Smaller projects, RM production

Jan R. Prusinski, P.E.

◦ Cement Council of Texas (Texas PCA affiliate)

◦ jprusinski@cementx.org

◦ 832-265-7130

Вам также может понравиться

- Paving With Roller Compacted Concrete - tcm45-341209Документ5 страницPaving With Roller Compacted Concrete - tcm45-341209spc268Оценок пока нет

- RCCP Provides Economical Concrete Pavement in 2 HoursДокумент15 страницRCCP Provides Economical Concrete Pavement in 2 HoursCES fourtwotwoОценок пока нет

- Roller Campacted Concrete Pavements by Robert R.Thompson, Columbus, OhioДокумент133 страницыRoller Campacted Concrete Pavements by Robert R.Thompson, Columbus, Ohiooscargon19100% (1)

- RCC Case Study Details Conversion of Auto Ramp to Intermodal FacilityДокумент9 страницRCC Case Study Details Conversion of Auto Ramp to Intermodal Facilitystructure123Оценок пока нет

- Roller Compacted ConcreteДокумент28 страницRoller Compacted ConcreteAyad SlabyОценок пока нет

- Concrete0709 PDFДокумент144 страницыConcrete0709 PDFlu190765Оценок пока нет

- SBland - Carolinas RCCДокумент91 страницаSBland - Carolinas RCCBartoFreitasОценок пока нет

- Dock C Project 11-5-13 Final Final v2Документ24 страницыDock C Project 11-5-13 Final Final v2api-214709308Оценок пока нет

- Lake Windcrest-3a 2021 Updated 5 26 21Документ5 страницLake Windcrest-3a 2021 Updated 5 26 21frank SchulerОценок пока нет

- ACI 325.10R-95: Reported by ACI Committee 325Документ32 страницыACI 325.10R-95: Reported by ACI Committee 325edgomurОценок пока нет

- Cement Stabilization Overview - PCAДокумент48 страницCement Stabilization Overview - PCAAlcides Rubén MerilesОценок пока нет

- Conc Pavt Thick Design 1Документ41 страницаConc Pavt Thick Design 1Bernd CastellarОценок пока нет

- 2016 APWA Conference - Roller Compacted Concrete - Pavement Placed Like AsphaltДокумент43 страницы2016 APWA Conference - Roller Compacted Concrete - Pavement Placed Like Asphaltgonzalez_m_aОценок пока нет

- Roller Compacted Concrete PDFДокумент34 страницыRoller Compacted Concrete PDFAdrian Luis Hernandez Garcia67% (3)

- Tayabji - Okamoto - Engineering Properties1136-004 PDFДокумент13 страницTayabji - Okamoto - Engineering Properties1136-004 PDFHenry Carrión VivarОценок пока нет

- ACI 32510r - 95 PDFДокумент32 страницыACI 32510r - 95 PDFFerdinand Yesaya NapitupuluОценок пока нет

- Construction Procedure of Transmission LinesДокумент21 страницаConstruction Procedure of Transmission LinesVikas SinghОценок пока нет

- Civil Engineering Basic Questions & Answers: A Facebook Group By-Md. Ahsan Habib RUET 090063Документ59 страницCivil Engineering Basic Questions & Answers: A Facebook Group By-Md. Ahsan Habib RUET 090063EngrDebashisMallickОценок пока нет

- HT Khanh RCC DamsДокумент70 страницHT Khanh RCC DamsManzar Mumtaz100% (1)

- Boring Hard RockДокумент5 страницBoring Hard Rockfajar agung setiawanОценок пока нет

- Pontoon ConstructionДокумент97 страницPontoon ConstructionasbanjohnpiousОценок пока нет

- Technical Paper (FINAL)Документ10 страницTechnical Paper (FINAL)jarabos8609Оценок пока нет

- Roller-Compacted Concrete For Ports PDFДокумент2 страницыRoller-Compacted Concrete For Ports PDFHugo LeiteОценок пока нет

- AASHTO 1993 Concrete Pavement Design with WinPASДокумент9 страницAASHTO 1993 Concrete Pavement Design with WinPASFabricio OrtegaОценок пока нет

- 2011 ASCE Pavement DesignДокумент54 страницы2011 ASCE Pavement DesignJeffОценок пока нет

- 1 Singel - RCC IntroДокумент23 страницы1 Singel - RCC IntroTran TuyenОценок пока нет

- Sustainable Concrete Technology For The 21th CenturyДокумент50 страницSustainable Concrete Technology For The 21th CenturyFatiullah KhanОценок пока нет

- Design and Construction of Cement-Bound Macadam PavementsДокумент11 страницDesign and Construction of Cement-Bound Macadam PavementsviralisursОценок пока нет

- Design Fundamentals DPWHДокумент96 страницDesign Fundamentals DPWHJerome Angelo B. Baybay100% (1)

- SPE 133286 Remedial Cementing in Limestone Formation Using Bradenhead Squeeze: A Case History of KS-X22Документ10 страницSPE 133286 Remedial Cementing in Limestone Formation Using Bradenhead Squeeze: A Case History of KS-X22geryОценок пока нет

- AWMA CO2 SequestrationДокумент23 страницыAWMA CO2 SequestrationSabatini AntonyОценок пока нет

- Design of CRCP for Bus Terminal with Embedded Heating SystemДокумент13 страницDesign of CRCP for Bus Terminal with Embedded Heating Systemvish5610100% (1)

- Bayport Container Terminal To Date Design Criteria For PavementДокумент4 страницыBayport Container Terminal To Date Design Criteria For PavementmasteriragaОценок пока нет

- 5th Bill N7 To N6 NewДокумент15 страниц5th Bill N7 To N6 NewTanya HenryОценок пока нет

- RollerДокумент4 страницыRollerkapola100% (1)

- Solar Ready Trusses For Distribution RДокумент7 страницSolar Ready Trusses For Distribution REiz Zu Deen0% (1)

- Airport Pavement Rehabilitation: Rubblization of Deteriorated Concrete PavementДокумент74 страницыAirport Pavement Rehabilitation: Rubblization of Deteriorated Concrete PavementRubn GtОценок пока нет

- 461352ijsetr13810 395Документ8 страниц461352ijsetr13810 395Ameem Ahmed KhanОценок пока нет

- Concrete vs. Asphalt: Benefits of Concrete PavingДокумент2 страницыConcrete vs. Asphalt: Benefits of Concrete PavingGregor GrbecОценок пока нет

- Working Examples of Pavement DesignДокумент2 страницыWorking Examples of Pavement DesignSafdar Khan100% (2)

- Road Maintenance MethodsДокумент5 страницRoad Maintenance MethodsYibeltal ChaneОценок пока нет

- Otta Seal PDFДокумент2 страницыOtta Seal PDFLuis PilaresОценок пока нет

- Khulna Mongla Port Rail Line Project BangladeshДокумент25 страницKhulna Mongla Port Rail Line Project BangladeshCEG BangladeshОценок пока нет

- Fast Construction Precast Concrete BridgesДокумент27 страницFast Construction Precast Concrete Bridgesrizky100% (1)

- SMART TITLEДокумент47 страницSMART TITLErajibchattarajОценок пока нет

- Data Rates-CD Works Part 1Документ20 страницData Rates-CD Works Part 1vpmohammedОценок пока нет

- Laboratory Study On Mechanical Strength and Mix Proportions of RCC Pavements in Cold RegionsДокумент11 страницLaboratory Study On Mechanical Strength and Mix Proportions of RCC Pavements in Cold RegionsFoolad GharbОценок пока нет

- Recycled Aggregate: Construction and Demolition RecyclingДокумент4 страницыRecycled Aggregate: Construction and Demolition RecyclingSandeep Sagar ReddypoguОценок пока нет

- Camino Rural SC y TSDДокумент2 страницыCamino Rural SC y TSDIngenieria JBOОценок пока нет

- 1bridge CriteriaДокумент14 страниц1bridge CriteriarowatersОценок пока нет

- 183 Status Report - 12-8-10Документ24 страницы183 Status Report - 12-8-10Irving BlogОценок пока нет

- Oakland-Macomb Interceptor Drain Project - Project Plan Overview - (June 10, 2009)Документ20 страницOakland-Macomb Interceptor Drain Project - Project Plan Overview - (June 10, 2009)Peter CavanaughОценок пока нет

- 4th March 2023 Full Day RPD Design RPДокумент184 страницы4th March 2023 Full Day RPD Design RPrajibchattarajОценок пока нет

- Polyaspartic Webinar Protective and MarineДокумент47 страницPolyaspartic Webinar Protective and MarinequimizaОценок пока нет

- Roller-Compacted Concrete Pavements For Highways and StreetsДокумент15 страницRoller-Compacted Concrete Pavements For Highways and StreetsJohnОценок пока нет

- Package 1c Tender Presentation 160407Документ49 страницPackage 1c Tender Presentation 160407PCcrazyОценок пока нет

- Transactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Reinforced Concrete Pier ConstructionОт EverandTransactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Reinforced Concrete Pier ConstructionОценок пока нет

- Concrete in Highway Engineering: International Series of Monographs in Civil EngineeringОт EverandConcrete in Highway Engineering: International Series of Monographs in Civil EngineeringРейтинг: 4 из 5 звезд4/5 (5)

- Sewage Disposal Works: Their Design and ConstructionОт EverandSewage Disposal Works: Their Design and ConstructionОценок пока нет

- Hover On Weather April 19, 2016-FNLДокумент106 страницHover On Weather April 19, 2016-FNLerosОценок пока нет

- Using technology to prevent rework at construction sitesДокумент17 страницUsing technology to prevent rework at construction siteserosОценок пока нет

- Thixotropy, Flocculation and Laser Spectroscopy: Experimental Study on Cement SuspensionДокумент16 страницThixotropy, Flocculation and Laser Spectroscopy: Experimental Study on Cement SuspensionerosОценок пока нет

- ACI Spring 2016 - Thixotropy - Kawashima - FinalДокумент17 страницACI Spring 2016 - Thixotropy - Kawashima - FinalerosОценок пока нет

- Study On Interaction Between Rocking Wall System and Surrounding Structure - ACI2016 - Spring - AndyLiuДокумент24 страницыStudy On Interaction Between Rocking Wall System and Surrounding Structure - ACI2016 - Spring - AndyLiuerosОценок пока нет

- Use of thixotropy model to capture competition between paste deflocculation and sand particle migration in fresh mortarsДокумент20 страницUse of thixotropy model to capture competition between paste deflocculation and sand particle migration in fresh mortarserosОценок пока нет

- ACI Presentation Mehdi FinalДокумент13 страницACI Presentation Mehdi FinalerosОценок пока нет

- Ramme - An Update On Combustion Products Utilization in Wisconsin 41916Документ68 страницRamme - An Update On Combustion Products Utilization in Wisconsin 41916erosОценок пока нет

- Khodaie Et Al-ACI Spring 2016Документ13 страницKhodaie Et Al-ACI Spring 2016erosОценок пока нет

- Khodaie Et Al-ACI Spring 2016Документ23 страницыKhodaie Et Al-ACI Spring 2016erosОценок пока нет

- Recent Developments in High-Strength Reinforcing BarsДокумент35 страницRecent Developments in High-Strength Reinforcing BarserosОценок пока нет

- Khodaie Et Al-ACI Spring 2016Документ23 страницыKhodaie Et Al-ACI Spring 2016erosОценок пока нет

- Use of thixotropy model to capture competition between paste deflocculation and sand particle migration in fresh mortarsДокумент20 страницUse of thixotropy model to capture competition between paste deflocculation and sand particle migration in fresh mortarserosОценок пока нет

- Design Model For Bond-Loss Resistance of Pretensioned I-GirdersДокумент21 страницаDesign Model For Bond-Loss Resistance of Pretensioned I-GirderserosОценок пока нет

- ACI Spring 2016 - Nanofibers - Kawashima - FinalДокумент35 страницACI Spring 2016 - Nanofibers - Kawashima - FinalerosОценок пока нет

- Thai Dam ACI Milwaukee 2016Документ21 страницаThai Dam ACI Milwaukee 2016erosОценок пока нет

- Thixotropy, Flocculation and Laser Spectroscopy: Experimental Study on Cement SuspensionДокумент16 страницThixotropy, Flocculation and Laser Spectroscopy: Experimental Study on Cement SuspensionerosОценок пока нет

- ACI Specification Discussion WeissДокумент14 страницACI Specification Discussion Weisseros100% (1)

- ACI Presentation Mehdi FinalДокумент13 страницACI Presentation Mehdi FinalerosОценок пока нет

- Ramme - An Update On Combustion Products Utilization in Wisconsin 41916 PDFДокумент68 страницRamme - An Update On Combustion Products Utilization in Wisconsin 41916 PDFerosОценок пока нет

- Khodaie Et Al-ACI Spring 2016Документ13 страницKhodaie Et Al-ACI Spring 2016erosОценок пока нет

- Development of High-Performance Cement Using Cellulose NanocrystalsДокумент23 страницыDevelopment of High-Performance Cement Using Cellulose NanocrystalserosОценок пока нет

- ACI CONVENTION 2016: Imaging Ion Transport in Cement Using X-RaysДокумент55 страницACI CONVENTION 2016: Imaging Ion Transport in Cement Using X-RayserosОценок пока нет

- ACI - Presentation.settingbar BendingRequirementsForHigh StrengthSteelBarsДокумент19 страницACI - Presentation.settingbar BendingRequirementsForHigh StrengthSteelBarserosОценок пока нет

- 160418-ACI Specification Discussion-Weiss PDFДокумент27 страниц160418-ACI Specification Discussion-Weiss PDFerosОценок пока нет

- SlagOntario ACI Spring 2016v3Документ20 страницSlagOntario ACI Spring 2016v3erosОценок пока нет

- Research in Progress-J.canulДокумент17 страницResearch in Progress-J.canulerosОценок пока нет

- Alkhrdaji - ACI 562 - Design Strength LimintsДокумент18 страницAlkhrdaji - ACI 562 - Design Strength LimintserosОценок пока нет

- Material & Consumables RequirementsДокумент6 страницMaterial & Consumables RequirementsDoc TorОценок пока нет

- TORO 007 Technical SpecificationДокумент3 страницыTORO 007 Technical SpecificationArutnev EduardoОценок пока нет

- Separation of Rayon Thread Thread Using Filter PaperДокумент14 страницSeparation of Rayon Thread Thread Using Filter PaperPandi Selvi ASОценок пока нет

- GT2000 TurbineplansДокумент27 страницGT2000 TurbineplansSzabolcs Szalai100% (1)

- Chiller Plant Control - Io Summary: Chilled Water SystemДокумент2 страницыChiller Plant Control - Io Summary: Chilled Water SystemMohammed AminuddinОценок пока нет

- 813 02e Oil-GasДокумент20 страниц813 02e Oil-GasLuong AnhОценок пока нет

- Design of Composite ColumnsДокумент7 страницDesign of Composite Columnsabozaid19Оценок пока нет

- XT702PДокумент3 страницыXT702PBDMОценок пока нет

- Lab Test: Fakulti Teknologi Kejuruteraan Mekanikal Dan Pembuatan Universiti Teknikal Malaysia MelakaДокумент6 страницLab Test: Fakulti Teknologi Kejuruteraan Mekanikal Dan Pembuatan Universiti Teknikal Malaysia MelakaHairul Effendy Ab MaulodОценок пока нет

- Experimental and Numerical Analysis of Aluminum Alloy Aw5005 Behavior Subjected To Tension and Perforation Under Dynamic LoadingДокумент15 страницExperimental and Numerical Analysis of Aluminum Alloy Aw5005 Behavior Subjected To Tension and Perforation Under Dynamic LoadingmuitefaОценок пока нет

- Pages From Asme Sec Ix 2017-4Документ1 страницаPages From Asme Sec Ix 2017-4Akhtar AnsariОценок пока нет

- Bissell Premier User Guide Owners Manual 47A2 80R4 17N4 36Z9 SeriesДокумент20 страницBissell Premier User Guide Owners Manual 47A2 80R4 17N4 36Z9 SeriesGreg Johnson50% (2)

- Fundamentals of EPDM Compounding for Cost and PerformanceДокумент14 страницFundamentals of EPDM Compounding for Cost and PerformanceJicheng PiaoОценок пока нет

- Norme FranciseДокумент2 страницыNorme FranciseCalin GiosanОценок пока нет

- Program of NEWCA Workshop (V27-04)Документ2 страницыProgram of NEWCA Workshop (V27-04)Queiroz PortorrealОценок пока нет

- Toyota 7FG 7FD 7FGK 7FDK Forklift Trucks Repair Manual PDFДокумент111 страницToyota 7FG 7FD 7FGK 7FDK Forklift Trucks Repair Manual PDFdolientes plazaamericas100% (2)

- Exercise 23 - Sulfur OintmentДокумент4 страницыExercise 23 - Sulfur OintmentmaimaiОценок пока нет

- Åîáñôþìáôá AccessoriesДокумент10 страницÅîáñôþìáôá Accessoriesbrane12Оценок пока нет

- VFPE Geomembrane Installation For Landfill Capping Applications EngineeringДокумент3 страницыVFPE Geomembrane Installation For Landfill Capping Applications EngineeringDAVE MARK EMBODOОценок пока нет

- Inside BopДокумент5 страницInside BopNigin Parambath100% (1)

- Technical Bulletin: Three Bond 2217HДокумент3 страницыTechnical Bulletin: Three Bond 2217HbehzadОценок пока нет

- DC Machine Dimensions and TypesДокумент13 страницDC Machine Dimensions and TypesShang Divina Ebrada100% (1)

- Ariston AVL84EU Service Manual RussianДокумент30 страницAriston AVL84EU Service Manual RussianHappyDancingManОценок пока нет

- Centralized Suply of Gas SystemДокумент43 страницыCentralized Suply of Gas SystemAmir ChakaОценок пока нет

- Performance of Concrete by Using Palm Oil Fuel Ash (POFA) As A Cement Replacement MaterialДокумент6 страницPerformance of Concrete by Using Palm Oil Fuel Ash (POFA) As A Cement Replacement MaterialShaik ChandiniiОценок пока нет

- Chapter 1 Oil Seal IntroductionДокумент6 страницChapter 1 Oil Seal IntroductionNCvetarskyОценок пока нет

- Uniclass2015 PR v1 18Документ229 страницUniclass2015 PR v1 18abdullah sahibОценок пока нет

- Maxlyzer Service Manual PDFДокумент37 страницMaxlyzer Service Manual PDFFidaa JaafrahОценок пока нет

- Calcium Silicate Bricks or Sand Lime BricksДокумент4 страницыCalcium Silicate Bricks or Sand Lime Bricksmanhal alnoaimyОценок пока нет

- Cold Soak Testing & Filter Blocking TendencyДокумент2 страницыCold Soak Testing & Filter Blocking TendencyGISELLEОценок пока нет