Академический Документы

Профессиональный Документы

Культура Документы

ISOASTM51205

Загружено:

Partth VachhaniАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

ISOASTM51205

Загружено:

Partth VachhaniАвторское право:

Доступные форматы

ISO/ASTM 51205:2002(E)

Standard Practice for

Use of a Ceric-Cerous Sulfate Dosimetry System1

This standard is issued under the fixed designation ISO/ASTM 51205; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision.

1. Scope safety concerns, if any, associated with its use. It is the

1.1 This practice covers the preparation, testing, and proce- responsibility of the user of this standard to establish appro-

dure for using the ceric-cerous sulfate dosimetry system to priate safety and health practices and determine the applica-

measure absorbed dose in water when exposed to ionizing bility of regulatory limitations prior to use.

radiation. The system consists of a dosimeter and appropriate 2. Referenced Documents

analytical instrumentation. For simplicity, the system will be

referred to as the ceric-cerous system. It is classified as a 2.1 ASTM Standards:

reference standard dosimetry system (see ISO/ASTM Guide C 912 Practice for Designing a Process for Cleaning Tech-

51261). Ceric-cerous dosimeters are also used as transfer–stan- nical Glasses3

dard dosimeters or routine dosimeters. D 941 Test Method for Density and Relative Density (Spe-

1.2 This practice describes both the spectrophotometric and cific Gravity) of Liquids by Lipkin Bicapillary Pycnom-

the potentiometric readout procedures for the ceric-cerous eter4

systems. D 1193 Specification for Reagent Water5

1.3 This practice applies only to g rays, X rays, and high E 170 Terminology Relating to Radiation Measurements

energy electrons. and Dosimetry6

1.4 This practice applies provided the following are satis- E 177 Practice for Use of the Terms Precision and Bias in

fied: ASTM Test Methods7

1.4.1 The absorbed-dose range shall be between 5 3 102 E 178 Practice for Dealing with Outlying Observations7

and 5 3 104 Gy (1).2 E 275 Practice for Describing and Measuring Performance

1.4.2 The absorbed-dose rate shall be less than 106 Gy/s (1). of Ultraviolet, Visible, and Near Infrared Spectrophotom-

1.4.3 For radionuclide gamma-ray sources, the initial pho- eters8

ton energy shall be greater than 0.6 MeV. For bremsstrahlung E 456 Terminology Relating to Quality and Statistics7

photons, the initial energy of the electrons used to produce the E 666 Practice for Calculating Absorbed Dose from Gamma

bremsstrahlung photons shall be equal to or greater than 2 or X Radiation6

MeV. For electron beams, the initial electron energy shall be E 668 Practice for Application of Thermoluminescence-

greater than 8 MeV. Dosimetry (TLD) Systems for Determining Absorbed Dose

in Radiation-Hardness Testing of Electronic Devices6

NOTE 1—The lower energy limits are appropriate for a cylindrical E 925 Practice for the Periodic Calibration of Narrow Band-

dosimeter ampoule of 12-mm diameter. Corrections for dose gradients

Pass Spectrophotometers8

across an ampoule of that diameter or less are not required for photons, but

may be required for electron beams (2). The ceric-cerous system may be E 958 Practice for Measuring Practical Spectral Bandwidth

used at lower energies by employing thinner (in the beam direction) of Ultraviolet-Visible Spectrophotometers8

dosimeter containers (see ICRU Report 35). E 1026 Practice for Using the Fricke Reference Standard

1.4.4 The irradiation temperature of the dosimeter shall be Dosimetry System6

between 0 and 62°C (3). 2.2 ISO/ASTM Standards:

51261 Guide for Selection and Calibration of Dosimetry

NOTE 2—The temperature coefficient of dosimeter response is known Systems for Radiation Processing6

only in this range. For use outside this range, the dosimetry system should 51400 Practice for Characterization and Performance of a

be calibrated for the required range of irradiation temperatures.

High-Dose Gamma Radiation Dosimetry Calibration

1.5 This standard does not purport to address all of the Laboratory6

51401 Practice for Use of a Dichromate Dosimetry System6

1

51607 Practice for Use of the Alanine-EPR Dosimetry

This guide is under the jurisdiction of ASTM Committee E10 on Nuclear

Technology and Applications and is the direct responsibility of Subcommittee System6

E10.01 on Dosimetry for Radiation Processing, and is also under the jurisdiction of 51707 Guide for Estimating Uncertainties in Dosimetry for

ISO/TC 85/WG 3.

Current edition approved Jan. 22, 2002. Published March 15, 2002. Originally

3

published as ASTM E 1205–88. Last previous ASTM edition E 1205–99. ASTM E Annual Book of ASTM Standards, Vol 15.02.

4

1205–93 was adopted by ISO in 1998 with the intermediate designation ISO Discontinued; see 1993 Annual Book of ASTM Standards, Vol 05.01.

5

15555:1998(E). The present International Standard ISO/ASTM 51205:2002(E) is a Annual Book of ASTM Standards, Vol 11.01.

6

revision of ISO 15555. Annual Book of ASTM Standards, Vol 12.02.

2 7

The boldface numbers in parentheses refer to the bibliography at the end of this Annual Book of ASTM Standards, Vol 14.02.

8

standard. Annual Book of ASTM Standards, Vol 03.06.

© ISO/ASTM International 2002 – All rights reserved 1

ISO/ASTM 51205:2002(E)

Radiation Processing6 continuing basis that the overall uncertainty meets the require-

2.3 International Commission on Radiation Units and ments of the specific application. This plan requires traceability

Measurements (ICRU) Reports:9 to, and consistency with, nationally or internationally recog-

ICRU Report 14 Radiation Dosimetry: X-Rays and Gamma nized standards.

Rays with Maximum Photon Energies Between 0.6 and 60 3.1.5 measurement traceability—the ability to demonstrate

MeV by means of an unbroken chain of comparisons that a mea-

ICRU Report 34 The Dosimetry of Pulsed Radiation surement is in agreement within acceptable limits of uncer-

ICRU Report 35 Radiation Dosimetry: Electrons with tainty with comparable nationally or internationally recognized

Initial Energies Between 1 and 50 MeV standards.

ICRU Report 37 Stopping Powers for Electrons and 3.1.6 molar linear absorption coeffıcient, em—a constant

Positrons relating the spectrophotometric absorbance, Al, of an optically

ICRU Report 60 Radiation Quantities and Units absorbing molecular species at a given wavelength, l, per unit

3. Terminology pathlength, d, to the molar concentration, c, of that species in

solution:

3.1 Definitions:

Al

3.1.1 absorbed dose, D—quantity of ionizing radiation em 5 d · c (3)

energy imparted per unit mass of a specified material. The SI

2 −1

unit of absorbed dose is the gray (Gy), where 1 Gy is SI unit: m mol

equivalent to the absorption of 1 J/kg of the specified material 3.1.6.1 Discussion—The measurement is sometimes ex-

(1 Gy = 1 J/kg). The mathematical relationship is the quotient pressed in units of L mol−1 cm−1.

of de by dm, where de is the mean incremental energy imparted 3.1.7 net absorbance, DA—change in measured optical

by ionizing radiation to matter of incremental mass dm (see absorbance at a selected wavelength determined as the absolute

ICRU 60). difference between the pre-irradiation absorbance, Ao, and the

post-irradiation absorbance, A, as follows:

dē

D 5 dm (1) DA 5 |A2Ao| (4)

3.1.1.1 Discussion—The discontinued unit for absorbed 3.1.8 radiation chemical yield, G(x)—the quotient of n(x)

dose is the rad (1 rad = 100 erg/g = 0.01 Gy). Absorbed dose by ē, where n(x) is the mean amount of a specified entity, x,

is sometimes referred to simply as dose. For a photon source produced, or changed by the mean energy, ē, imparted to the

under conditions of charged particle equilibrium, the absorbed matter.

dose, D, may be expressed as: n~x!

G~x! 5 ē (5)

µen

D 5 f·E· r (2)

SI unit: mol J−1

3.1.9 reference–standard dosimeter—a dosimeter of high-

where:

f = particle fluence (particles/m2), metrological quality, used as a standard to provide measure-

E = energy of the ionizing radiation (J), and ments traceable to, and consistent with, measurements made

µen/r = mass energy absorption coefficient (m2/kg). If using primary–standard dosimeters.

bremsstrahlung production within the specified 3.1.10 transfer–standard dosimeter—a dosimeter, often a

material is negligible, the mass energy absorption reference–standard dosimeter suitable for transport between

coefficient (µen/r) is equal to the mass energy different locations, used to compare absorbed-dose measure-

transfer coefficient (µtr/r), and absorbed dose is ments.

equal to kerma if, in addition, charged particle 3.2 For definitions of other terms used in this practice that

equilibrium exists. pertain to radiation measurement and dosimetry, refer to

3.1.2 calibration facility—combination of an ionizing radia- ASTM Terminology E 170. Definitions in ASTM Terminology

tion source and its associated instrumentation that provides a E 170 are compatible with ICRU 60; that document, therefore,

uniform and reproducible absorbed dose, or absorbed-dose rate may be used as an alternative reference.

traceable to national or international standards at a specified

location and within a specific material, and that may be used to 4. Significance and Use

derive the dosimetry system’s response function or calibration 4.1 The ceric-cerous system provides a reliable means for

curve. measuring absorbed dose in water. It is based on a process of

3.1.3 electropotential—difference in potential, E, between reduction of ceric ions to cerous ions in acidic aqueous solution

irradiated and unirradiated solutions in an electrochemical cell, by ionizing radiation (1, 4).

measured in millivolts. 4.2 The dosimeter is a solution of ceric sulfate and cerous

3.1.4 measurement quality assurance plan—a documented sulfate in sulfuric acid in an appropriate container such as a

program for the measurement process that ensures on a flame-sealed glass ampoule. The solution indicates a level of

absorbed dose by a change (decrease) in optical absorbance at

9

Available from International Commission on Radiation Units and Measure- a specified wavelength in the ultraviolet region, or a change

ments, 7910 Woodmont Ave., Suite 800, Bethesda, MD 20814, USA. (increase) in electropotential. A calibrated spectrophotometer is

2 © ISO/ASTM International 2002 – All rights reserved

ISO/ASTM 51205:2002(E)

used to determine the change in absorbance and a potentiom- using chromic acid solution or an equivalent cleaning agent

eter, with a specially designed cell, is used to determine the (see ASTM Practice C 912). Rinse at least three times with

change in potential in millivolts. double-distilled water. Dry thoroughly and store under condi-

4.3 The dosimeter response has a temperature dependence tions that will minimize exposure to dust.

during irradiation that is approximately equal to −0.2 % per 6.4 Glass Ampoules—If required, clean glass ampoules in

degree Celsius between 0 and 62°C (3, 5, 6). boiling double-distilled water. Rinse twice with double-

4.4 For calibration with photons, the ceric-cerous dosimeter distilled water and oven dry.

shall be irradiated under conditions that approximate electron NOTE 5—The dosimetric ampoule normally used has a capacity of

equilibrium. approximately 2 mL. Quick-break glass ampoules, or Type 1 glass

4.5 The absorbed dose in other materials irradiated under colorbreak ampoules or equivalent containers, are commonly used.

equivalent conditions may be calculated. Procedures for mak- Commercially available ampoules have been found to give reproducible

ing such calculations are given in ASTM Practices E 666 and results without requiring additional cleaning.

E 668 and ISO/ASTM Guide 51261.

7. Reagents

NOTE 3—For a comprehensive discussion of various dosimetry meth-

7.1 Analytical reagent grade (or better) chemicals shall be

ods applicable to the radiation types and energies discussed in this

practice, see ICRU Reports 14, 34, 35, and 37. used for preparing all solutions.10

7.2 Use of double-distilled water from coupled all-glass and

5. Interferences silica stills is recommended for high-range dosimeters. For

5.1 The ceric-cerous dosimetric solution response is sensi- low-range stock solutions, use triply-distilled water. Water

tive to impurities, particularly organic impurities. Even in trace purity is very important since it is the major component of the

quantities, impurities can cause a detectable change in the dosimetric solutions, and therefore may be the prime source of

observed response (7). For high-accuracy results, organic contamination. Use of deionized water is not recommended.

materials shall not be used for any component in contact with Type III reagent water as specified in ASTM Specification

the solution. The effect of trace impurities is minimized by the D 1193 is considered to be of sufficient quality for use in

addition of cerous ions to the solution (8, 9) preparing all solutions.

5.2 Undesirable chemical changes in the dosimetric solution NOTE 6—Double-distilled water distilled from an alkaline potassium

can occur if care is not taken during flame-sealing of the permanganate (KMnO4) solution (2 g KMnO4 plus 5 g sodium hydroxide

ampoules (see 8.7). (NaOH) pellets in 2 L of distilled water) has been found to be adequate for

routine preparation of the dosimetric solution. High-purity water is

6. Apparatus commercially available from some suppliers. Such water labeled HPLC

(high-pressure liquid chromatographic) grade is usually sufficiently free

6.1 Spectrophotometric Method—For the analysis of the from organics to be used in this practice.

dosimetric solution, use a high-precision spectrophotometer

capable of measuring absorbance values up to two with an 7.3 Do not store purified water used in this practice in

uncertainty of no more than 61 % in the region from 254 to plastic containers or in containers with plastic caps or plastic

320 nm. Use quartz cuvettes with 10-mm path length for cap liners.

spectrophotometric measurements of absorbance of the solu- 8. Preparation of the Dosimetric Solution

tion.

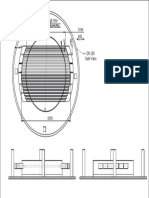

6.2 Potentiometric Method—Use an electrochemical cell, 8.1 The recommended concentrations for the ceric-cerous

similar to that in Annex A1 (see Fig. A1.1). Measure the dosimeter to measure absorbed doses from about 5 to 50 kGy

electropotential across the cell with a high-precision digital (high-range dosimeter) are 0.015-M ceric sulfate [Ce(SO4)2·

potentiometer that is capable of measuring d-c potentials in the 4H2O] and 0.015-M cerous sulfate [Ce2(SO4)3· 8H2O]. For

range from 1 to 100 mV within an uncertainty of 61 %. measurement of absorbed doses from about 0.5 to 10 kGy

(low-range dosimeter), the recommended concentrations are

NOTE 4—As shown in Fig. A1.1, the electrochemical cell has two 0.003-M [Ce(SO4)2· 4H2O] and 0.003-M [Ce2(SO4)3· 8H2O].

compartments separated by a porous junction, such as a glass frit, a 8.2 The dosimeters specified in 8.1 may be formulated from

ceramic or kaolin junction, or a fibreglass wick. The inner compartment is

filled with unirradiated solution. The lower compartment is filled with

the following nominal stock solutions: (a) 0.4-M and 4-M

solution transferred from an irradiated or unirradiated ampoule. The sulfuric acid (H2SO4), (b) 0.1-M Ce(SO4)2· 4H2O, and (c)

potential difference, E, generated between the platinum electrodes in the 0.1-M Ce2(SO4)3· 8H2O. Procedures for preparing these solu-

two compartments is measured by a digital potentiometer. tions are given in Annex A2.

6.3 Glassware—Use borosilicate glass or equivalent chemi-

cally resistant glass to store the reagents and the prepared 10

Reagent specifications are available from American Chemical Society, 1115

dosimetric solution. Clean all glassware, except ampoules, 16th St., Northwest, Washington, DC 20036, USA.

© ISO/ASTM International 2002 – All rights reserved 3

ISO/ASTM 51205:2002(E)

8.3 Use the following equations to determine the volume in neck. Flame seal the ampoules, exercising care to avoid heating

millilitres of each stock solution necessary to prepare 1 L of the body of the ampoule during sealing.

dosimetric solution: 8.8 Store dosimeters in a dark place at room temperature (23

High Range Low Range 6 5°C).

V1 0.015 V1 0.003 9. Analytical Instrument Performance

5 5 (6)

1000 M1 1000 M1 9.1 Spectrophotometer Performance:

V2 0.015 V2 0.003 9.1.1 Check the wavelength scale of the spectrophotometer

5 5 (7)

1000 M2 1000 M2 and establish its accuracy. The emission spectrum from a

low-pressure mercury arc lamp can be used for this purpose.

V3 0.4 V3 0.4

5 5 (8) Such lamps may be obtained from the spectrophotometer

1000 2 V1 M3 1000 2 V1 M3

manufacturer or other scientific laboratory instrument suppli-

V4 5 1000 2 V1 2 V2 2 V3 V4 5 1000 2 V1 2 V2 2 V3 (9) ers. Other appropriate wavelength standards are holmium-

oxide filters and solutions. For more details see ASTM Prac-

where: tices E 275, E 925, and E 958.

V1 = volume of nominal 0.1-M ceric-sulfate stock solu-

NOTE 8—For example, holmium-oxide solutions in sealed cuvettes are

tion, available as certified wavelength standards (SRM 2034) for use in the

V2 = volume of nominal 0.1-M cerous-sulfate stock solu- wavelength region from 240 to 650 nm (10).

tion,

9.1.2 Check the accuracy of the photometric (absorbance)

V3 = volume of nominal 4-M sulfuric-acid stock solution,

V4 = volume of distilled water, scale of the spectrophotometer. Certified absorbance standard

M1 = actual molarity of the ceric-sulfate stock solution, filters or solutions are available for this purpose.

M2 = actual molarity of the cerous-sulfate stock solution, NOTE 9—Examples of absorbance standards are solutions of various

and concentrations, such as SRM 931d (11) and SRM 935 (12), and metal-

M3 = actual molarity of the nominal 4-M sulfuric-acid on-quartz filters, such as SRM 2031 (13, 14).

stock solution. 9.1.3 Check the linearity of the absorbance scale of the

NOTE 7—If the nominal molarities of M1 = M2= 0.1, and M3= 4 are

spectrophotometer as a function of the ceric-ion concentration.

assumed, then V1= V2= 150 mL for the high range and V1= V2= 30 mL for This should be done at the peak of the absorbance spectrum for

the low range; V3= 85 mL for the high range and V3= 97 mL for the low the ceric ion at 320 nm at a constant temperature, preferably

range. If the molarities of the various stock solutions are significantly 25°C. The standardized ceric-sulfate stock solution (0.1-M

different from the nominal values, then use Eq 6-8 to determine the exact nominal in 0.4-M H2SO4), as described in A2.3, may be used

volumes. To prepare a volume of the dosimetric solution other than 1000 for this measurement. The plot of measured absorbance, A, per

mL, the result of these equations should be multiplied by the ratio of the

unit path length versus molar concentration shall be linear. The

desired volume in millilitres to 1000 mL.

slope of the line gives, em, the molar linear absorption

8.4 Determine all of the volumes given in 8.3 using a coefficient.

calibrated graduated cylinder that can be read to within 60.5

NOTE 10—A reference value for em is 561 m2·mol−16 0.4 % at 320 nm

mL. (3).

8.5 Transfer the volume of each component of the dosim- 9.2 Potentiometer and Electrochemical Cell Performance:

etric solution into a 1-L or larger glass storage container. Rinse 9.2.1 For the potentiometer method, correct performance

the graduated cylinder used for measuring V1, V2, and V3 by can be demonstrated by showing that the readings of dosim-

using some portion of the distilled water of V4. Stopper the eters given known absorbed doses are in agreement with the

container and shake well. Before use, allow the dosimetric expected readings within the limits of the dosimetry system

solution to stand for at least five days in the dark. uncertainty (see Section 13).

8.6 Quality control testing of the dosimetric solution prior to

ampouling can be performed by quantifying some of the NOTE 11—This method is only applicable for reference standard

dosimetry systems where the long term stability of the response has been

dosimetric solution parameters, such as ceric-ion concentra- demonstrated and documented.

tion, cerous-ion concentration, ceric-ion molar linear absorp-

tion coefficient, radiation chemical yield for the cerous ion, and 10. Calibration of the Dosimetry System

density. Procedures for performing these measurements are 10.1 Prior to use, the dosimetry system shall be calibrated in

given in Annex A3. Alternatively, quality control testing can be accordance with the user’s documented procedure that speci-

performed following ampouling by comparing calibration data fies details of the calibration process and quality assurance

with data obtained from previous batches (see 10.4.2). requirements. This calibration procedure shall be repeated at

8.7 Prepare dosimeters by filling ampoules with ;2mL of regular intervals to ensure that the accuracy of the absorbed

dosimetric solution. Take care not to contaminate the dosim- dose measurement is maintained within required limits. De-

etric solution with impurities. Exercise care in filling ampoules tailed calibration procedures are provided in ISO/ASTM Guide

to avoid depositing solution in the ampoule neck. Subsequent 51261.

heating during sealing may cause an undesirable chemical 10.2 Calibration Irradiation of Dosimeters—Irradiation is a

change in the dosimetric solution remaining inside the ampoule critical component of the calibration of the dosimetry system.

4 © ISO/ASTM International 2002 – All rights reserved

ISO/ASTM 51205:2002(E)

Calibration irradiations shall be performed by irradiating the trophotometric cuvette (sample cell) from the 25-mL volumet-

dosimeters using a calibration facility that provides an ab- ric flask.

sorbed dose or an absorbed-dose rate having measurement 10.3.6 Read the absorbance, A, in the spectrophotometer at

traceability to nationally or internationally recognized stan- 320 nm.

dards. 10.3.7 Calculate the mean absorbance of the unirradiated

10.2.1 For the spectrophotometric measurement, separate dosimeters, Āo (see 10.2.1). Calculate the net absorbance, DA,

five dosimeters from the remainder of the batch and do not for each irradiated dosimeter by subtracting its absorbance, A,

irradiate them. Use them in determining Āo(see 10.2.7). from Āo as follows:

10.2.2 Calibrate the dosimeters, using an irradiation facility

DA 5 Āo 2 A (10)

that has a dose rate traceable to national standards and that

meets the requirements specified in ISO/ASTM Practice 10.4 Potentiometric Measurement:

51400. Use a reference or transfer dosimetry system to 10.4.1 Place contents of an unirradiated dosimeter (am-

establish this traceability (see ISO/ASTM Guide 51261 and poule) into both compartments of the electrochemical cell. See

ASTM Practice E 1026). Annex A1 for a description of the electrochemical cell.

10.2.3 Specify the calibration dose in terms of absorbed 10.4.2 Allow the unirradiated dosimetric solution to remain

dose in water (for example, see ASTM Practice E 1026). in the electrochemical cell for about 30 min in order to

10.2.4 Position the dosimeters in the calibration radiation establish equilibrium across the porous junction. For a new

field in a defined, reproducible location. batch of dosimeters, or if a cell has not been used for one or

10.2.5 When using a gamma-ray source for calibration, two days, unirradiated solution should be left in both compart-

surround the dosimeters with a sufficient amount of material to ments for at least 16 h to ensure equilibrium across the porous

achieve approximate electron equilibrium conditions. junction.

10.4.3 When the cell is being used for the first time, the

NOTE 12—The appropriate thickness of such material depends on the filled cell should be left to stand for at least 24 h before making

energy of the radiation (see ASTM Practices E 666 and E 668). For

measurement of absorbed dose in water, use materials that have radiation

any measurements.

absorption properties essentially equivalent to water. For example, for a 10.4.4 If the cell is not going to be used for more than three

60Co source, 3 to 5 mm of polystyrene (or equivalent polymeric material) days, drain all solution from the cell. Rinse both the inner and

should surround the dosimeter in all directions. outer compartments three times with distilled water, and allow

10.2.6 When using an electron beam for calibration, locate the cell to air dry. Refer to 10.4.1 and 10.4.2 before reusing the

the dosimeters in a well characterized position within the cell.

radiation field. 10.4.5 Drain the inner compartment and refill it with the

10.2.7 Make the calibration field within the volume occu- contents of another unirradiated dosimeter.

pied by the dosimeter(s) as uniform as possible. The variation 10.4.6 Connect the digital potentiometer across the cell. If

in dose rate within this volume should be within 61 %. the electropotential, E, is equal to zero within 60.2 mV, the

10.2.8 Control or monitor the temperature of the dosimeters cell is ready for use. Read at least three unirradiated dosim-

during irradiation. Calculate or measure the mean irradiation eters, and determine average value Ēo.

temperature of each set of dosimeters to an accuracy of 62°C 10.4.7 Expel the unirradiated solution from the outer com-

or better. partment and draw in the solution from each irradiated dosim-

10.2.9 Calibrate each batch of dosimeters prior to routine eter (ampoule) in turn, starting with the lowest and proceeding

use. to the highest absorbed dose. In each case, before measuring

the potential difference for any particular dosimeter, rinse the

10.2.10 Use a set of at least five dosimeters for each

cell by drawing in a little less than half of that dosimeter’s

absorbed dose value.

solution in order to reduce the effects of the previous dosim-

10.2.11 Irradiate these sets of dosimeters to at least five

eter. Expel the rinse solution into a waste container, and then

known dose values, covering the dose range from 5 to 50 kGy

draw in sufficient solution from that remaining in the dosimeter

for the high-range dosimeter or seven known dose values

ampoule to fully cover the porous junction.

covering the dose range from 0.5 to 10 kGy for the low-range

10.4.8 Read the electropotential, E, in millivolts, across the

dosimeter.

cell for each dosimeter after temperature equilibrium is estab-

10.3 Spectrophotometric Measurement:

lished within the cell. Subtract the average electropotential, Ēo,

10.3.1 For spectrophotometric measurement, dilute high-

to determine DE, the net potential value. Measure the readout

range dosimeters by a factor of 100 and low-range dosimeters

temperature near the electrochemical cell, and apply correction

by a factor of 50.

for this temperature.

10.3.2 Pipette 0.25 mL of high-range dosimetric solution or

0.5 mL of low-range dosimetric solution into a clean, dry NOTE 13—The electropotential, E, within the electrochemical cell, has

25-mL volumetric flask. a positive temperature coefficient of 0.33 % per °C between 20 and 30°C

(4).

10.3.3 Rinse the pipette with 0.4-M H2SO4 into the flask and

make up to volume with 0.4-M H2SO4. 10.5 Analysis:

10.3.4 Stopper the 25-mL flask, and mix well. 10.5.1 Prepare a calibration curve by plotting DA or DE

10.3.5 Transfer an appropriate amount into a quartz spec- values versus the absorbed dose, D. Determine a response

© ISO/ASTM International 2002 – All rights reserved 5

ISO/ASTM 51205:2002(E)

function by fitting the data by means of a least-squares method tested using statistical procedures, such as those found in

with an appropriate analytical form that provides a best fit to ASTM Practice E 178.

the data. The data for these ceric-cerous dosimeters should fit 10.6 Alternative Method of Analysis—If the procedures for

a third or fourth order polynomial of the form: quantifying dosimetric solution parameters given in Annex A3

v 5 bo 1 b1 x 1 b2 x2 1 b3 x3 1 b4 x4 (11) are carried out, approximate values for the dose can be

obtained from analytical functions.

where: 10.6.1 For spectrophotometric readings, calculate the ab-

v = DA or DE, sorbed dose, Ds, in grays, using the following equation:

x = absorbed dose, D, and

b4 = 0 for third order polynomial, b4 fi 0 for fourth order f · DA

D5 (14)

polynomial. G~Ce31! · em · r · d

NOTE 14—Computer software is available commercially for perform- where:

ing least-squares fits of data with polynomials or other analytical forms. f = dilution factor for the irradiated dosimeters,

To be technically correct, the response function should be in the form DA = change in absorbance of irradiated dosimeter,

measured response as a function of absorbed dose. However, for functions G(Ce3+) = average value for G(Ce3+) determined from Eq

like polynomials, it had been difficult to solve for the inverse of the A3.8,

function for absorbed dose, the quantity required during the use of the em = molar-linear absorption ccoefficient (m2 mol−1),

dosimetry system, since no inverse function exists. Many spreadsheets

r = density of the dosimetric solution, kg m−3, and

now have functions that will solve for the inverse equation of the form

signal = f(dose) using numerical methods. In Microsoft Excel 97t11, the

d = path length of spectrophotometer cell, m.

solver function may be used. In practice, for radiation processing 10.6.2 For potentiometric readings, calculate the absorbed

dosimeters, functions of the form absorbed dose = f(signal) are often used dose, Dp, in grays using the following equation:

F S DG

as the response function as they will not usually result in appreciable error

provided that the absorbed-dose range is not greater than one decade. If a 103 M4 1 M 5

Dp 5 M4 2 M5 DE (15)

function of the form absorbed dose = f(signal) is to be used, the rG~Ce31!

1 1 M antilog 59.16

calibration curves derived from the response functions obtained from the 4

two methods should be compared to confirm that no appreciable error is

introduced. where:

r = density of the dosimetric solution, kg m−3,

10.5.2 The inverse of the response function determined in G(Ce3+) = average value for G(Ce3+) determined from

10.5.1 will provide the absorbed dose for irradiations per- Eq A3.10,

formed at the temperature, Tc, used for the calibration irradia- DE = electropotential minus average electropoten-

tions. The variation with irradiation temperature depends on tial for unirradiated dosimeters, and

the cerous ion concentration (3). For irradiations at an average M4 and M5 = molarities of the ceric and cerous ions in the

irradiation temperature, T̄, correct the absorbed dose by the unirradiated dosimetric solutions, respec-

ratio G~Ce31! Tc/G~Ce31!T¯ tively, mol·L−1.

where: 10.6.3 Determine a response function of calculated ab-

G~Ce31! T5 ~2.3354420.00523T!31.03631027 ~high range! sorbed doses as a function of absorbed dose values from

(12) calibration.

G~Ce31! T5 ~2.4245220.00523T!31.03631027 ~low range! NOTE 15—The calculated absorbed doses values should be close to the

(13) absorbed dose values obtained from the calibration facility. The response

10.5.3 Compare the net absorbances or net potentials deter- function should give a good fit to a low order (first to third order)

mined by a given calibration with the results obtained from polynomial.

previous batches. Agreement should be within 63 % if the

11. Application of Dosimetry System

dosimetric solutions were properly prepared and all associated

analysis equipment was properly calibrated. 11.1 For use as a transfer–standard dosimeter, use a mini-

10.5.4 Estimate the component of uncertainty that can be mum of two dosimeters for each absorbed-dose measurement.

evaluated by statistical methods (Type A) of the individual The number of dosimeters required for the measurement of

dosimeter results from the results of replicate measurements at absorbed dose on or within a material is determined by the

a given absorbed-dose level. Type A uncertainty provides a precision of the dosimetry system and the required precision

measure of acceptable performance of the dosimetry system. associated with the application. Appendix X3 of ASTM Prac-

For the high range dosimeter, the Type A uncertainty, expressed tice E 668 describes a statistical method for determining this

as one standard deviation, should not exceed 60.005 absor- number.

bance units for an optical pathlength of 10 mm or 62 % of the 11.2 Use the irradiation and measurement procedures in

potential value. For the low range dosimeter, the Type A accordance with Section 10.

uncertainty should not exceed6 0.010 absorbance units or 11.3 Determine the absorbed dose from the net absorbance

62 % of the potential value. Suspected data outliers should be values or net potential values and the calibration curve.

11.4 Record the calculated absorbed dose values and all

11

Microsoft Excel 97 is a registered trademark of Microsoft Corporation. other relevant data as outlined in Section 12.

6 © ISO/ASTM International 2002 – All rights reserved

ISO/ASTM 51205:2002(E)

12. Minimum Documentation Requirements other classifications, such as precision and bias, may be useful.

12.1 Calibration: 13.2 If this practice is followed, the estimate of the com-

12.1.1 Record the dosimeter type and batch number (code). bined uncertainty of an absorbed dose determined by this

12.1.2 Record or reference the date, irradiation temperature, dosimetry system should be within about 64 % at a 95 %

temperature variation (if any), absorbed-dose range, radiation confidence level (a coverage factor k = 2).

source, and associated instrumentation used to calibrate and NOTE 16—The identification of Type A and Type B uncertainties is

analyze the dosimeters. based on the methodology adopted in 1993 by the International Organi-

12.2 Application: zation for Standardization (ISO) for estimating uncertainty. This is

12.2.1 Record the date and temperature of irradiation, tem- different from the way uncertainty has been traditionally expressed in

perature variation (if any), and the date and temperature of terms of precision and bias, where precision is a measure of the extent to

absorbance measurement for each dosimeter. which replicate measurements made under specified conditions are in

agreement, and bias is a systematic error (see ASTM Terminologies E 170

12.2.2 Record or reference the radiation source type and

and E 456, and ASTM Practice E 177). The purpose of using the method

characteristics. of expressing uncertainties as Type A and Type B recommended in the ISO

12.2.3 Record the absorbance or potential, net absorbance Guide to the Expression of Uncertainty in Measurement (16) is to promote

or net potential value, temperature correction (if applicable), an understanding of how uncertainty statements are arrived at and to

and resulting absorbed dose for each dosimeter. Reference the provide a basis for the international comparison of measurement results.

calibration curve used to obtain the absorbed dose values. NOTE 17—ISO/ASTM Guide 51707 defines possible sources of error in

12.2.4 Record or reference the uncertainty in the value of dosimetry performed in radiation processing facilities and offers proce-

the absorbed dose. dures for estimating the resulting magnitude of the uncertainties in the

measurement results. Basic concepts of measurement, estimate of the

12.2.5 Record or reference the measurement quality assur-

measured value of a quantity, true value, error, and uncertainty are defined

ance plan used for the dosimetry system application. and discussed. Components of uncertainty are discussed, and methods are

given for evaluating and estimating their values. Their contributions to the

13. Measurement Uncertainty standard uncertainty in the reported values of absorbed dose are consid-

13.1 To be meaningful, a measurement of absorbed dose ered, and methods are given for calculating the combined standard

shall be accompanied by an estimate of uncertainty. Compo- uncertainty and an estimate of overall (expanded) uncertainty.

nents of uncertainty shall be identified as belonging to one of

two groups: 14. Keywords

(A) those that are evaluated by statistical methods or 14.1 absorbed dose; ceric-cerous sulfate dosimeter; dose;

(B) those that are evaluated by other means. dose measurement; dosimeter; dosimetry system; electron

Additional information is given in ISO/ASTM Guide 51707 beam; gamma radiation; ionizing radiation; irradiation; pho-

and Refs (15) and (16), where these components are referred to tons; radiation; radiation processing; reference–standard do-

as Type A and Type B, respectively. In reporting uncertainty, simeter; X rays; ICS 17.240

ANNEXES

(informative)

A1. ELECTROCHEMICAL CELL

A1.1 The electrochemical cell shown in Fig. A1.1 has both two solutions and shall have a porosity of less than 2 µm.

an inner and outer compartment, A and B, respectively,

separated by a porous junction, C, such as a glass frit, a A1.5 The small open tip of compartment B is inserted into

ceramic or kaolin junction, or a fibreglass wick. the neck of a dosimeter ampoule, D. The glass syringe, E, is

used alternately to draw into compartment B the dosimetric

A1.2 Compartment A contains the unirradiated dosimetric

solution and then expel the solution after measurement.

solution.

A1.3 Compartment B contains either unirradiated or irra- A1.6 Leads F and G provide a means for measuring the

diated dosimetric solution. potential difference across the electrochemical cell when they

are connected to a potentiometer or multimeter.

A1.4 The porous junction, C, provides contact between the

© ISO/ASTM International 2002 – All rights reserved 7

ISO/ASTM 51205:2002(E)

FIG. A1.1 Electrochemical Cell

A2. PROCEDURE FOR PREPARING NOMINAL STOCK SOLUTIONS FOR THE DOSIMETER

A2.1 Nominal 0.4-M Sulfuric Acid (H2SO4): A2.2.3 Standardize resulting solution similarly as for 0.4-M

A2.1.1 Transfer 22.2 mL of 18-M H2SO4 into a clean, dry H2SO4.

1-L volumetric flask containing about 700 mL of double- A2.3 Nominal 0.1-M Ceric Sulfate:

distilled water. A2.3.1 In a 1-L volumetric flask, dissolve 58 g of ceric

A2.1.2 Carefully cool contents and make up to volume with sulfate, Ce(SO4)2·4H2O, in 600 mL of 0.4-M H2SO4.

double-distilled water, stopper, and mix well. A2.3.2 Shake contents until all Ce(SO4)2· 4H2O is dis-

A2.1.3 Standardize resulting solution using sodium carbon- solved. Allow solution to stand at least two weeks in the dark.

ate primary standard or equivalent. A2.3.3 Add enough 0.4-M H2SO4 solution to dilute to 1 L.

Filter if necessary through a clean sintered-glass filter (medium

NOTE A2.1—Add H2SO4 cautiously to the water as a considerable

amount of heat is released.

porosity).

A2.3.4 Transfer into a glass bottle provided with a ground

A2.2 Nominal 4-M Sulfuric Acid (H2SO4): glass stopper, and store in a dark place.

A2.3.5 Standardize 0.1-M Ce(SO4)2· 4H2O using arsenious

A2.2.1 Transfer 222 mL of 18-M H2SO4 into a clean, dry oxide, primary standard, osmium-tetroxide catalyst, and feroin-

1-L volumetric flask containing about 700 mL of double- indicator solution.

distilled water.

A2.2.2 Carefully cool contents and make up to volume with A2.4 Nominal 0.1-M Cerous Sulfate:

double-distilled water, stopper, and mix well. A2.4.1 In a 1-L volumetric flask, dissolve 36 g cerous

8 © ISO/ASTM International 2002 – All rights reserved

ISO/ASTM 51205:2002(E)

sulfate, Ce(SO4)3·8H2O in 600 mL of double-distilled water. A2.5.1 Pipette with a to contain pipette 1 mL of the

A2.4.2 Shake contents until all Ce2(SO4)3· 8H2O is dis- cerous-sulfate stock solution into a 100-mL volumetric flask,

solved. Allow solution to stand at least two weeks in the dark. followed with a rinse of the pipette with double-distilled water.

A2.4.3 Add enough double-distilled water to dilute to 1 L. Make up to volume with double-distilled water, stopper, and

Filter if necessary through a clean sintered-glass filter (medium mix well.

porosity). A2.5.2 Read the absorbance, A, at 254 nm in a spectropho-

A2.4.4 Transfer into a glass bottle provided with a ground tometer with double-distilled water in the reference cuvette.

glass stopper, mix well, and store in a dark place.

The molarity, M2, of the stock cerous-sulfate solution is given,

NOTE A2.2—Cerous sulfate may require recrystallization before use in mol L−1, by the following equation:

(6).

M2 5 ~0.146!A (A2.1)

A2.5 Molarity of Stock Cerous-Sulfate Solutions:

A3. PROCEDURES FOR QUANTIFYING DOSIMETRIC SOLUTION PARAMETERS

A3.1 Ceric-Ion Concentration: where:

A3.1.1 Use a to contain pipette to deliver 0.25 mL of M5 = cerous-sulfate molarity of the dosimetric solution,

high-range dosimetric solution or 0.50 mL of low-range mol L−1.

dosimetric solution into a clean, dry 25-mL volumetric flask. NOTE A3.1—The total cerous-ion concentration determined for each

A3.1.2 Rinse the pipette with 0.4-M H2SO4. into the flask sample will be slightly greater than the sum of the ceric and cerous ions

and make up to volume with 0.4-M H2SO4. in the dosimetric solution. The difference is due to the presence of cerous

A3.1.3 Stopper the 25-mL flask, and mix well. ions in the ceric-sulfate reagents. The cerous-ion concentration is deter-

A3.1.4 Transfer an appropriate amount into a quartz spec- mined by subtracting the ceric-ion concentration from the total cerous-ion

trophotometric cuvette (sample cell) from the 25-mL volumet- concentration.

ric flask.

A3.3 Ceric-Ion Molar Linear Absorption Coeffıcient:

A3.1.5 Read the absorbance, A, in the spectrophotometer at

320 nm using 0.4-M H2SO4 in the reference cell. A3.3.1 Pipette 2 mL of the dosimetric solution into a 25-mL

A3.1.6 Determine the ceric concentration, M4, using the volumetric flask to which 0.4-M H2SO4 is added to make up to

following equation: the volume.

A3.3.2 Similarly, pipette 2, 3, 4, 5, and 6 mL of the resultant

M4 5 ~0.01782!A (A3.1)

solution of A3.3.1 respectively into separate 100-mL flasks to

where: which 0.4-M H2SO4 is added to make up to the volume.

M4 = ceric-sulfate molarity of the dosimetric solution, mol A3.3.3 Stopper each flask, and mix well.

L−1, and A3.3.4 Read the absorbance, A, of each sample at 320 nm in

A = absorbance the spectrophotometer with 0.4-M H2SO4 in the reference cell.

A3.3.5 Using the molarity obtained in A3.1.6, the dilution

A3.2 Cerous-Ion Concentration: factors associated with the samples prepared in A3.3.2, and the

A3.2.1 Irradiate at least three dosimeters to an absorbed absorbances determined in A3.3.3, determine the molar linear

dose sufficient to completely reduce all ceric ions to cerous absorbance coefficient, em, by the slope of the plot of absor-

ions (for example, 80 kGy for high-range dosimeter or 20 kGy bance versus molarity as expressed by the following equations:

for low-range dosimeter). Ai 5 103 em Mi d ~high range! (A3.3)

A3.2.2 Pipette 0.25 mL of the irradiated high-range dosim-

Ai 5 e m M i d ~low range! (A3.4)

etric solution or 0.50 mL of low-range dosimetric solution from

each ampoule into separate, clean, dry 25-mL volumetric where:

flasks. Ai = absorbance of sample i,

A3.2.3 Rinse the pipette with 0.4-M H2SO4 into the flask Mi = molarity of sample i, mol·L−1,

and make up to volume with 0.4-M H2SO4. Stopper flasks and d = path length of spectrophotometer sample cell, m, and

mix well. i = 1, 2,..., 5 (representing samples prepared in A3.3.2).

A3.2.4 Transfer an appropriate amount into a quartz spec-

NOTE A3.2—The value of em should be equal to 561 m2 mol−16 0.4 %

trophotometer cuvette. or 5610 L mol−1 cm−16 0.4 %, at 320 nm (3).

A3.2.5 Read the absorbance, A, in the spectrophotometer at

254 nm using 0.4-M H2SO4 in the reference cell. A3.4 Density of Dosimetric Solution—Determine the den-

A3.2.6 Determine the average absorbance, Ā. sity of the dosimetric solution at 25°C using the pycnometer

A3.2.7 The following equation gives the resultant total method (See ASTM Test Method D 941).

cerous-ion concentration:

NOTE A3.3—The density should be 1.032 (60.002) 3 103 kg m−3 at

M5 5 0.146Ā (A3.2) 25°C (8).

© ISO/ASTM International 2002 – All rights reserved 9

ISO/ASTM 51205:2002(E)

A3.5 Radiation Chemical Yield of Cerous Ion, G(Ce+3), by A3.5.9 Plot Dj versus G (Ce3+)j. The results should be linear

the Spectrophotometric Method: with a slope equal to zero. If a significant deviation from zero

A3.5.1 Prepare a sufficient number of dosimeters (at least slope is observed, that is, an apparent dependence of G(Ce3+)

18) by filling 2-mL ampoules with the dosimetric solution. on absorbed dose, the solution may be unacceptable, (for

After filling, flame seal the ampoules. example, contaminated by organic impurities).

A3.5.2 Irradiate dosimeters, three at a time, at a calibrated A3.6 Radiation Chemical Yield of Cerous Ion, G(Ce+3), by

position in a cobalt 60 facility to at least five dose levels, for the Potentiometric Method:

example, approximately 5, 15, 25, 35, and 50 kGy for

high-range solution and 0.5, 1, 4, 7, and 10 kGy for low-range A3.6.1 Prepare dosimeters and irradiate them in accordance

solution. Control or monitor the temperature of the dosimeter with A3.5.1 and A3.5.2.

during irradiation. A3.6.2 Place contents of an unirradiated dosimeter (am-

poule) into both compartments of the electrochemical cell. See

A3.5.3 Prepare diluted (by a factor of 100 or 50) samples of

Annex A1 for a description of the electrochemical cell.

dosimeters, including the three unirradiated ones. Pipette 0.25

A3.6.3 Allow the unirradiated dosimetric solution to remain

or 0.50 mL from each dosimeter into 25-mL volumetric flasks,

in the electrochemical cell for about 30 min in order to

and make up to volume with 0.4-M H2SO4.

establish equilibrium across the porous junction.

A3.5.4 Using 0.4-M H2SO4 in the reference cell, read the A3.6.4 Drain the cell and refill it with the contents of

absorbance, A, of the diluted samples prepared in accordance another unirradiated dosimeter.

with A3.5.3 at 320 nm in the spectrophotometer. A3.6.5 Connect the digital potentiometer across the cell. If

A3.5.5 Determine the change in absorbance, DA, of each the difference in potential is equal to zero within 60.2 mV, the

irradiated sample as follows: cell is ready for use.

DAij 5 Āo 2 Aij (A3.5) A3.6.6 Expel the unirradiated solution from the lower cell

compartment, and draw in the solution from each irradiated

where: dosimeter (ampoule) in turn, starting with the lowest and

Āo = average absorbance of the diluted samples of the proceeding to the highest absorbed dose. In each case, before

unirradiated dosimeters, measuring the potential difference for any particular dosimeter,

i = 1, 2, and 3 (number of identifying dosimeters at each rinse the cell with that dosimeter’s solution in order to reduce

absorbed dose level), and the effects of the previous dosimeter.

j = 1,2,..., n (number of identifying absorbed dose levels). A3.6.7 Read the potential, E, in millivolts, across the cell

A3.5.6 Plot DA versus D in accordance with the following for each dosimeter after temperature equilibrium is established

equation: within the cell.

DAij 5 b Dj (A3.6) NOTE A3.4—The potential difference, E, within the electrochemical

cell has a positive temperature coefficient of 0.33 % per °C between 25

where: and 30°C (8). For the best accuracy, normalize measurements to a constant

DA = change in absorbance of irradiated sample, temperature, thereby accounting for this effect.

i = 1,2, and 3 (number identifying dosimeters at each

absorbed dose level), and A3.6.8 Average the DE values for the three dosimeters

j = 1,2,..., n (number identifying absorbed dose levels), irradiated to the same absorbed dose level. Use the average

D = absorbed dose, Gy, and values, DE , to calculate G(Ce3+) in accordance with the

b = slope, kg·J−1, of the plot determined by a least- following equation:

F S DG

squares linear regression fit of the data. 103 M4 1 M 5

A3.5.7 Determine G(Ce3+), mol J−1, from the following G~Ce31!j 5 rD M4 2

j M5 DE

equation: 1 1 M antilog10 59.16

4

f·b (A3.9)

G~Ce31! 5 e rd (A3.7)

m

where:

where: M4 and M5 = molarities of ceric and cerous ions in the

em = molar-linear absorption coefficient (m2 mol−1), unirradiated dosimetric solution, respec-

b = slope, kg·J−1, of the plot determined by a least- tively, mol·L−1,

squares linear regression fit of the data, D = absorbed dose, Gy,

r = density, kg·m−3, r = density of the dosimetric solution, kg m−3,

d = path length of spectrophotometer cell, m, and and

f = dilution factor for the samples of irradiated dosim- j = 1,2,...n (number identifying absorbed dose

eters. levels).

A3.5.8 Calculate the average G(Ce3+) from the following A3.6.9 Calculate the average G~Ce31! from the following

equation: equation:

n n

1 1

G~Ce31! 5 n ( G~Ce31!j

j51

(A3.8) G~Ce31! 5 n ( G~Ce31!j

j51

(A3.10)

10 © ISO/ASTM International 2002 – All rights reserved

ISO/ASTM 51205:2002(E)

A3.6.10 Plot Dj versus G(Ce3+)j. The results should be NOTE A3.5—The values of G(Ce3+) determined in accordance with

linear with a slope equal to zero. If a significant deviation from A3.5.7 and A3.6.9 should be equal approximately to 2.3 3 10−7 to 2.5 3

zero slope is observed, that is, an apparent dependence of 10−7 mol·J−1 at 25°C for the molarities of ceric and cerous ions specified

G(Ce3+) on absorbed dose, the solution may be unacceptable, for the dosimetric solution in this test method.

(for example, contaminated by organic impurities).

BIBLIOGRAPHY

(1) Bjergbakke, E., “The Ceric Sulfate Dosimeter,” Manual on Radiation (10) Weidner, V. R., Mavrodineanu, R., Mielenz, K. D., Zelapoldi, R. A.,

Dosimetry, Marcel Dekker, New York, 1970, pp. 323-326. Eckerie, K. L. and Adams, B., “Standard Reference Materials:

(2) Sharpe, P. H. G., and Burns, D. T., “The Relative Response of Fricke, Holmium Oxide Solution Wavelength Standard from 240-650 nm-

Dichromate and Alanine Dosimeters to 60Co and High Energy Electron SRM 2034,” NBS Special Publication 260-102, 1986.

Beam Radiation,” Journal of Radiation Physics and Chemistry, Vol (11) Burke, R. W., Deardoff, E. R., and Menis, O., “Liquid Absorbance

46, 1995, pp. 1273-1277. Standards,” Journal of Research of the National Bureau of

(3) Matthews, R. W., “Effect of Solute Concentration and Temperature on

Standards—A, Physics and Chemistry, Vol 76A, 1972, pp. 51-64.

the Ceric-Cerous Dosimeter,” Radiation Research, Vol 55, 1973, pp.

242-255. (12) Burke, R. W., and Mavrodineanu, R., “Standard Reference Materials:

(4) Fricke, H., and Hart, E. J., “Chemical Dosimetry,” Radiation Dosim- Certification and Use of Acidic Potassium Dichromate Solutions as

etry, Vol II, Second Edition, Academic Press, New York, 1966, pp. an Ultraviolet Absorbance Standard—SRM 935,” NBS Special Pub-

167-239. lication 260-54, 1977.

(5) Matthews R. W., “Aqueous Chemical Dosimetry,” International Jour- (13) Mavrodineanu, R., and Bladwin, J. R., “Standard Reference Materi-

nal of Applied Radiation and Isotopes, Vol 33, 1982, pp. 1159-1170. als: Metal-on-Quartz Filters as a Standard Reference Material for

(6) Matthews, R. W., Mahlman, H. A., and Sworski, T. J., “Kinetics of the Spectrophotometry—SRM 2031,” NBS Special Publication 260-68,

Oxidation of Cerium (III) by Peroxysulfuric Acids Induced by 1980.

Cobalt-60 Radiation,” Journal of Physical Chemistry, Vol 74, 1970, (14) Burke, R. W., Smith M. V., Powell, L. J., and Mavrodineanu, R.,

pp. 2475-2479. “Performance Characteristics of NBS Glass and Metal-on-Quartz

(7) Taimuty, S. L., Towie, L. H., and Peterson, D. L., “Ceric Dosimetry: Transmittance Standards,” American Laboratory, July, 1986, pp.

Routine Use at 105-107 Rads,” Nucleuonics, Vol 17, No. 8, 1959, p. 67-76.

103.

(8) Matthews, R. W., “Potentiometric Estimation of Megarad Dose with (15) Taylor, B. N., and Kuyatt, C. E. “Guidelines for Evaluating and

Ceric-Cerous System,” International Journal of Applied Radiation and Expressing the Uncertainty of NIST Measurement Results,” NIST

Isotopes, Vol 23, 1972, pp. 179-185. Technical Note 1297, National Institute of Standards and Technology,

(9) Matthews, R. W., “An Evaluation of the Ceric-Cerous System As an Gaithersburg, MD, 1994.

Impurity-Insensitive Megarad Dosimeter,” International Journal of (16) “Guide to the Expression of Uncertainty in Measurement,” Interna-

Applied Radiation and Isotopes, Vol 22, 1971, pp. 199-207. tional Organization for Standardization, 1993, ISBN 92-67-10188-9.

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ISO, Case postale 56, CH-1211, Geneva 20, Switzerland, and ASTM International, 100 Barr Harbor

Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States. Individual reprints (single or multiple copies) of this

standard may be obtained by contacting ASTM at the above address or at 610-832-9585 (phone), 610-832-9555 (fax), or

service@astm.org (e-mail); or through the ASTM website (www.astm.org).

© ISO/ASTM International 2002 – All rights reserved 11

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- RT Level IIДокумент24 страницыRT Level IIEtnad Ortsac0% (1)

- 03 WirelineДокумент317 страниц03 WirelineYoo Man100% (1)

- The Unique Art of Gamma LogДокумент26 страницThe Unique Art of Gamma LogAbdur RahmanОценок пока нет

- GM16R - ManualДокумент80 страницGM16R - ManualCapacitacion TodocatОценок пока нет

- Asnt RT L1, 2 & 3Документ80 страницAsnt RT L1, 2 & 3jasminnee92% (12)

- Astm F 22-2002 (2007)Документ2 страницыAstm F 22-2002 (2007)Partth VachhaniОценок пока нет

- Aluminium Dross Waste - Topics by Science - GovДокумент198 страницAluminium Dross Waste - Topics by Science - GovPramod Reddy TilletiОценок пока нет

- Astm G15Документ5 страницAstm G15Partth VachhaniОценок пока нет

- Fixed Bolted JointДокумент16 страницFixed Bolted JointPartth VachhaniОценок пока нет

- Science: Quarter 2 - Module 2Документ22 страницыScience: Quarter 2 - Module 2Mercy Mangaoil92% (13)

- All in OneДокумент142 страницыAll in OneppglОценок пока нет

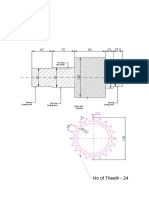

- 5358 5185 400 DN 200 Gate Valve: Furnace Shell Outer DiameterДокумент1 страница5358 5185 400 DN 200 Gate Valve: Furnace Shell Outer DiameterPartth VachhaniОценок пока нет

- Hearth Cooling PDFДокумент1 страницаHearth Cooling PDFPartth VachhaniОценок пока нет

- Gearbox Pinion PDFДокумент1 страницаGearbox Pinion PDFPartth VachhaniОценок пока нет

- Gearbox Pinion PDFДокумент1 страницаGearbox Pinion PDFPartth VachhaniОценок пока нет

- Adp5e High Performace FlowДокумент3 страницыAdp5e High Performace FlowPartth VachhaniОценок пока нет

- All in OneДокумент142 страницыAll in OneppglОценок пока нет

- 1.1 Background: Chapter 1 - IntroductionДокумент12 страниц1.1 Background: Chapter 1 - IntroductionPartth VachhaniОценок пока нет

- PM Material SelectionДокумент19 страницPM Material SelectionPartth VachhaniОценок пока нет

- Astm E2592-07Документ4 страницыAstm E2592-07Partth VachhaniОценок пока нет

- Design Validations of 450 T Eot Crane With Fea ApproachДокумент73 страницыDesign Validations of 450 T Eot Crane With Fea ApproachPartth VachhaniОценок пока нет

- Astm E1434Документ17 страницAstm E1434Partth VachhaniОценок пока нет

- Corrosion Testing of Products of Zirconium, Hafnium, and Their Alloys in Water at 680°F (360°C) or in Steam at 750°F (400°C)Документ8 страницCorrosion Testing of Products of Zirconium, Hafnium, and Their Alloys in Water at 680°F (360°C) or in Steam at 750°F (400°C)Partth VachhaniОценок пока нет

- ISOASTM51261Документ19 страницISOASTM51261Partth VachhaniОценок пока нет

- Dosimetry in An Electron Beam Facility For Radiation Processing at Energies Between 80 and 300 KevДокумент8 страницDosimetry in An Electron Beam Facility For Radiation Processing at Energies Between 80 and 300 KevPartth VachhaniОценок пока нет

- Characterization and Performance of A High-Dose Radiation Dosimetry Calibration LaboratoryДокумент5 страницCharacterization and Performance of A High-Dose Radiation Dosimetry Calibration LaboratoryPartth VachhaniОценок пока нет

- ISOASTM51204Документ10 страницISOASTM51204Partth VachhaniОценок пока нет

- Use of Radiation-Sensitive Indicators: Standard Guide ForДокумент3 страницыUse of Radiation-Sensitive Indicators: Standard Guide ForPartth VachhaniОценок пока нет

- R0001Документ3 страницыR0001Partth VachhaniОценок пока нет

- Use of A Radiochromic Film Dosimetry System: Standard Practice ForДокумент5 страницUse of A Radiochromic Film Dosimetry System: Standard Practice ForPartth VachhaniОценок пока нет

- Design and Fabrication of DIE For Comp Action of Metal Powder in Powder MetallurgyДокумент69 страницDesign and Fabrication of DIE For Comp Action of Metal Powder in Powder MetallurgyPartth VachhaniОценок пока нет

- ISOASTM51204Документ10 страницISOASTM51204Partth VachhaniОценок пока нет

- Vacancy For Mech and Civil - 11!10!2017Документ1 страницаVacancy For Mech and Civil - 11!10!2017Partth VachhaniОценок пока нет

- M.tech Seminar IARДокумент2 страницыM.tech Seminar IARPartth VachhaniОценок пока нет

- Assignment 1Документ3 страницыAssignment 1Partth VachhaniОценок пока нет

- Genetic Algorithm: Artificial Neural Networks (Anns)Документ10 страницGenetic Algorithm: Artificial Neural Networks (Anns)Partth VachhaniОценок пока нет

- CEIAPresentation GBДокумент48 страницCEIAPresentation GBFranck Yvan Lantohery RaveloarisonОценок пока нет

- Compton Scattering ExperimentДокумент3 страницыCompton Scattering ExperimentCollege of Computer Sciences BasirpurОценок пока нет

- IGCSE UNIT - 5 ATOMIC PHYSICS NotesДокумент12 страницIGCSE UNIT - 5 ATOMIC PHYSICS Notesvishrudh lakshminarasimhanОценок пока нет

- Iso Astm 51939-17Документ13 страницIso Astm 51939-17Oh No PotatoОценок пока нет

- Nuclear Power Engineering: Aiub Dr. M. Tanseer Ali NPWR Lec 04 /1Документ23 страницыNuclear Power Engineering: Aiub Dr. M. Tanseer Ali NPWR Lec 04 /1Naushed NihalОценок пока нет

- Nuclear Energy (Radioactivity, Nuclear Fission and Fusion)Документ14 страницNuclear Energy (Radioactivity, Nuclear Fission and Fusion)Mohammad Irfan YousufОценок пока нет

- EMP and The Radio AmateurДокумент21 страницаEMP and The Radio AmateursantosoОценок пока нет

- ICSE Class 10 Physics Question Paper Solution 2015Документ17 страницICSE Class 10 Physics Question Paper Solution 2015SANDEEP SINGHОценок пока нет

- BNDT Catalog 04162012 v13 WEBsecureДокумент31 страницаBNDT Catalog 04162012 v13 WEBsecureEsin DenizОценок пока нет

- Neutron Flux Measurement PDFДокумент30 страницNeutron Flux Measurement PDFCorina Matei100% (1)

- What Is The EM SpectrumДокумент13 страницWhat Is The EM SpectrumJones JonnyОценок пока нет

- Kolej Islam Sultan Alam Shah: Peperiksaan Percubaan Tahun 2010 ScienceДокумент21 страницаKolej Islam Sultan Alam Shah: Peperiksaan Percubaan Tahun 2010 ScienceFikri ArifОценок пока нет

- p31220 RadioactivityДокумент14 страницp31220 RadioactivityAHKEEL LESTER JONESОценок пока нет

- Digital Image Processing Notes VtuДокумент72 страницыDigital Image Processing Notes VtuNikhil KumarОценок пока нет

- Noor Azman 2014Документ174 страницыNoor Azman 2014هاجر رياض خالدОценок пока нет

- Positive Effects of The Electromagnetic RadiationДокумент8 страницPositive Effects of The Electromagnetic RadiationTyrone Stavros BarracaОценок пока нет

- Radioactive GHJNVN PDFДокумент37 страницRadioactive GHJNVN PDFReality of lifeОценок пока нет

- Cambridge IGCSE: Physics 0625/23Документ20 страницCambridge IGCSE: Physics 0625/23Vaibhav reddyОценок пока нет

- Density LogДокумент24 страницыDensity LogBarqun DzulqurnainОценок пока нет

- LaViolette - Earth - Under - Fire - Galactic - Superwaves - Aug - 2009 PDFДокумент18 страницLaViolette - Earth - Under - Fire - Galactic - Superwaves - Aug - 2009 PDFΧάρης Φραντζικινάκης100% (1)

- Radioactivity - Free Exam AcademyДокумент1 страницаRadioactivity - Free Exam AcademyMoaz ErakyОценок пока нет

- Shielding Design CalculationsДокумент88 страницShielding Design CalculationsKimal DjamОценок пока нет

- The Protocols of The Learned Elders of Islam Si'ra 10Документ95 страницThe Protocols of The Learned Elders of Islam Si'ra 10Ali Akbar KhanОценок пока нет