Академический Документы

Профессиональный Документы

Культура Документы

49 Mag Fichetech GRATES XCC V6

Загружено:

mohammedАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

49 Mag Fichetech GRATES XCC V6

Загружено:

mohammedАвторское право:

Доступные форматы

cooler grates

«THE» solution to keep it cool!

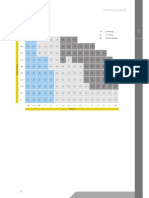

SOME RESULTS If we consider the average wear of the MAGOTTEAUX has developed Our solution:

complete grate, the net wear rates are new alloys and designs that offer great the patented Bar Grate Design for

respectively 2.59 and 0.67. benefits to conventional coolers, by optimal cooling through:

Comparison between standard alloy

and Xcc® in a 3,100mtpd cooler. enhancing both product performance

Xcc® grates are thus 3.85 times and lifetime. • Special air distribution system.

better in average than the ones in • Cooling of grates AND clinker.

standard alloys. Wear and thus performance of the • Strong resistance against

cooler grate plates depend to a large deformation.

extent on their location in the cooler.

Magotteaux therefore addresses each

g/

T zone in a different way in order to

develop and optimize solutions for

each one.

1. The hot zone (or drop zone).

2. The intermediate zone.

top: competition grate 3. The cold zone.

bottom: Xcc® grate. air channels in Magotteaux

both after 26 months patented Bar Grate

1. The hot zone.

Our «extra»:

1 2 Particular constraints: cast FMR61 alloy to resist:

For all questions, queries or tests, • High temperatures of clinker. • Oxidation.

do not hesitate to phone • Mechanical stresses (due to the • Corrosion at high temperature

+ 32 4 361 77 44 impact of the clinker falling from (sulfur).

the kiln). • Mechanical and thermal stresses.

or mail • Thermal stresses (due to uneven

exposure of the plates to the hot

perforated clinker vs cold air).

xcccoolergrates@magotteaux.com

left: Xcc® grate.

right: competition grate Visit our website:

both after 26 months www.magotteaux.com

cooler grates

Keep cool? Yes, we can!

2. The intermediate zone. 3. The cold zone. Our «extras»:

cast FMX250 alloy + Xcc® to resist:

Particular constraints: Particular constraints: • Abrasion and hence wear caused

by moving layers of clinker.

• Lower temperature but still an • Temperature is no longer a threat. • Superiority coefficient: from

issue. • Abrasion from clinker grains. 2 times better.

• Hardness of a quenched clinker

-> tends to wear the plates. Our solution:

• Preferential wear at rear portion of

the plates. The Pocket Grate Design to avoid

direct contact between moving layers

of clinker and surface of the cooler

Our solution:

the patented Bar Grate Design for: plates.

• Strong resistance to abrasion. standard + calorized

• «Self-protecting» design of grate.

cross section of the Pocket Grate

Our «extras»:

cast FMR56 alloy + Xcc® to resist: Its working principle is to always keep

a dead layer of cold clinker grains

• Wear. trapped inside the pocket. This layer

• Temperature. remaining still, the blowing holes

• Cracks. located at the bottom of the pockets

• Superiority coefficient: from

2 times better. will keep a constant opening during Pocket grated installed in a

the whole life of the cooler plates. 4,600 tpd cooler in Belgium

The information and data in this data sheet are accurate to the best

of our knowledge. They are intended for general information only.

Applications as suggested are described only to help readers make their

own assessment. They are neither guarantees nor to be construed as

express or implied warranties of suitability for these or other applications.

Вам также может понравиться

- Refractory: Zoning of Kilns and Brick SelectionДокумент26 страницRefractory: Zoning of Kilns and Brick Selectionrupesh soni100% (1)

- Arlon 38NДокумент4 страницыArlon 38NRavindrakumar ParvathiniОценок пока нет

- Belzona 1121: Product Specification SheetДокумент2 страницыBelzona 1121: Product Specification SheetQuy RomОценок пока нет

- T. Training Condition & Life Assessment Technique MPT Solution PDFДокумент22 страницыT. Training Condition & Life Assessment Technique MPT Solution PDFHarianto ArieОценок пока нет

- Champ LMV HID LuminairesДокумент8 страницChamp LMV HID LuminairesFarekhОценок пока нет

- Carbide Roll MaterialДокумент10 страницCarbide Roll MaterialziadОценок пока нет

- Preventing Stress Corrosion Cracking in The Carbon Dioxide Absorber of Ammonia PlantsДокумент8 страницPreventing Stress Corrosion Cracking in The Carbon Dioxide Absorber of Ammonia PlantsSADIQ KHATTAKОценок пока нет

- Dow CorningДокумент2 страницыDow Corningwardoyoclp75Оценок пока нет

- Heat Pipe Vapor Chamber Heat Sink Design Guidelines Thermal Live 2016Документ29 страницHeat Pipe Vapor Chamber Heat Sink Design Guidelines Thermal Live 2016svishnuvОценок пока нет

- Champ VMV Hid LuminairesДокумент10 страницChamp VMV Hid LuminairesLekan AnthonyОценок пока нет

- Materials For Engineering 17 - Heat - Treatable Aluminum AlloysДокумент23 страницыMaterials For Engineering 17 - Heat - Treatable Aluminum AlloysKris WilochОценок пока нет

- Alloy-20 DS US ENДокумент2 страницыAlloy-20 DS US ENmimouniОценок пока нет

- MI Tube Skin Thermocouple AssembliesДокумент6 страницMI Tube Skin Thermocouple AssembliesAlonso MooriОценок пока нет

- TDS Loctite Nordbak Wearing - CompoundДокумент3 страницыTDS Loctite Nordbak Wearing - CompoundSadamОценок пока нет

- TecamidДокумент2 страницыTecamidTejas HuddarОценок пока нет

- DOWSIL+Q1-9226+Thermally+Conductive+Adhesive+TDS ENДокумент3 страницыDOWSIL+Q1-9226+Thermally+Conductive+Adhesive+TDS ENMisikEEОценок пока нет

- SGL Technical Competence Sheet DIABON BHX CK NCKДокумент2 страницыSGL Technical Competence Sheet DIABON BHX CK NCKNoo SokiОценок пока нет

- Crouse Hinds Champ VMV Hid Catalog PageДокумент8 страницCrouse Hinds Champ VMV Hid Catalog PageJuan Carlos Bacca RomeroОценок пока нет

- Features and Benefits: End of Life ProtectionДокумент2 страницыFeatures and Benefits: End of Life ProtectionjambomillerОценок пока нет

- SF-0015.1 IGT HPT Abradables ENДокумент8 страницSF-0015.1 IGT HPT Abradables ENThanaraj SanmughamОценок пока нет

- 3) Superpave Binder TestingДокумент69 страниц3) Superpave Binder TestingعزОценок пока нет

- Controlling Heat Treatment Distortion in Gear Rings - MachineMfgДокумент37 страницControlling Heat Treatment Distortion in Gear Rings - MachineMfgxiao mingОценок пока нет

- What Is Rogers CLTE PCBДокумент6 страницWhat Is Rogers CLTE PCBjackОценок пока нет

- PB Unimax English160604152107Документ12 страницPB Unimax English160604152107filipeОценок пока нет

- Evonik-Amicure PACMДокумент5 страницEvonik-Amicure PACMuzzy2Оценок пока нет

- Gas Turbine Hot Path MaterialsДокумент66 страницGas Turbine Hot Path Materialsronyjohnson100% (4)

- TDS For Rubber Lining 1056HTДокумент2 страницыTDS For Rubber Lining 1056HTYao WangОценок пока нет

- TS H5200G - Carburizing, Quenching and TemperingДокумент15 страницTS H5200G - Carburizing, Quenching and TemperinghkatzerОценок пока нет

- DuraplateДокумент4 страницыDuraplatelovaldes62Оценок пока нет

- Anti-Corrosion Coating: StandardsДокумент2 страницыAnti-Corrosion Coating: StandardsMuhamad Rizky KurniawanОценок пока нет

- Ramax Hh-Eng P 1604 E6Документ8 страницRamax Hh-Eng P 1604 E6venkithankamОценок пока нет

- Natural Convection Concentric CylindersДокумент17 страницNatural Convection Concentric Cylindersgac_12484412Оценок пока нет

- Wip-S DrawingДокумент1 страницаWip-S DrawingbasvkaranОценок пока нет

- Tech Uddeholm Vanax en PDFДокумент8 страницTech Uddeholm Vanax en PDFRuang Sudut OfficialОценок пока нет

- Dow Corning TC-5022Документ38 страницDow Corning TC-5022pageuppagedownОценок пока нет

- DC 781 Acetoxy SealantДокумент3 страницыDC 781 Acetoxy SealantL.S.Оценок пока нет

- PSP 108 Alloy2507Документ2 страницыPSP 108 Alloy2507Nitin KurupОценок пока нет

- Lexan Thermoclear Technical ManualДокумент26 страницLexan Thermoclear Technical ManualPavo PerkovićОценок пока нет

- Adhesive Transfer Tapes With Adhesive 200: Technical Data September, 2002Документ4 страницыAdhesive Transfer Tapes With Adhesive 200: Technical Data September, 2002Reza AbdolahiОценок пока нет

- BELZONA 1111 Product Specification SheetДокумент2 страницыBELZONA 1111 Product Specification SheetMohamed NouzerОценок пока нет

- Manufacturing Process CheatSheet PDFДокумент2 страницыManufacturing Process CheatSheet PDFMy Inspiration100% (1)

- Datasheet Saphir Flex 2016 EN v1Документ2 страницыDatasheet Saphir Flex 2016 EN v1André CardosoОценок пока нет

- Loctite Nordbak Wear Resistant Putty: Product Description MixedДокумент3 страницыLoctite Nordbak Wear Resistant Putty: Product Description MixedFurqan ShabbirОценок пока нет

- Tigi A3 Brochure Hc1-A 2017Документ4 страницыTigi A3 Brochure Hc1-A 2017GonzaloDiazInostrozaОценок пока нет

- B-TVS-M: Metallized BOPP FilmДокумент2 страницыB-TVS-M: Metallized BOPP FilmSayed FathyОценок пока нет

- Leaking Heat Exchangers?: Is This How You Are Stopping YourДокумент2 страницыLeaking Heat Exchangers?: Is This How You Are Stopping YourDebelmeОценок пока нет

- Ex DB Iic, Ex Eb Iic, Ex TB Iiic, Ex NR Iic: Captive Component Gland WITH DELUGE SEAL For Multi Armoured CableДокумент2 страницыEx DB Iic, Ex Eb Iic, Ex TB Iiic, Ex NR Iic: Captive Component Gland WITH DELUGE SEAL For Multi Armoured CableMAZHAR IQBALОценок пока нет

- Ficha Tecnica - Empalmadora de Mano EX39 - KomshineДокумент7 страницFicha Tecnica - Empalmadora de Mano EX39 - KomshineluisfernandortОценок пока нет

- RT Duroid 5870 5880 Data Sheet PDFДокумент2 страницыRT Duroid 5870 5880 Data Sheet PDFNom MonОценок пока нет

- Gasket Design Fundamentals v1.2Документ9 страницGasket Design Fundamentals v1.2michaelОценок пока нет

- Datasheet Saphir HCE 2021 EN v1Документ2 страницыDatasheet Saphir HCE 2021 EN v1André CardosoОценок пока нет

- Datasheet SD Ferralium 255 SD50 BarДокумент4 страницыDatasheet SD Ferralium 255 SD50 Barpranav kariaОценок пока нет

- PP Compound - PP15T1020Документ2 страницыPP Compound - PP15T1020Chaimae HanynyОценок пока нет

- Arm Grout HF66 VДокумент3 страницыArm Grout HF66 VRajesh GiriОценок пока нет

- Belzona 1121 InstrustionsДокумент2 страницыBelzona 1121 Instrustionssh4kesОценок пока нет

- 14 TecnostopДокумент2 страницы14 Tecnostopumangg594Оценок пока нет

- Zirconia MaterialsДокумент2 страницыZirconia MaterialsFlexiblecsiОценок пока нет

- Thermal Power Dissipation SG - VishayДокумент8 страницThermal Power Dissipation SG - Vishaypietro zugnoniОценок пока нет

- Osaka Jack Front PageДокумент1 страницаOsaka Jack Front PagemohammedОценок пока нет

- A2FM Bent Axis MotorsДокумент29 страницA2FM Bent Axis MotorsmohammedОценок пока нет

- 724 Eaton ValveДокумент2 страницы724 Eaton ValvemohammedОценок пока нет

- FlangesДокумент1 страницаFlangesmohammedОценок пока нет

- Level 1 Mechatronics Support Hydraulic SymbolДокумент1 страницаLevel 1 Mechatronics Support Hydraulic SymbolmohammedОценок пока нет

- Cylinder PDFДокумент1 страницаCylinder PDFmohammedОценок пока нет

- Daman Main Catalog 2013.1Документ214 страницDaman Main Catalog 2013.1mohammedОценок пока нет

- Connection Table PDFДокумент1 страницаConnection Table PDFmohammedОценок пока нет

- Timken 1Документ1 страницаTimken 1mohammedОценок пока нет

- GS Hydro PipingДокумент1 страницаGS Hydro PipingmohammedОценок пока нет

- Connection Table PDFДокумент1 страницаConnection Table PDFmohammedОценок пока нет

- Basic Connection TableДокумент1 страницаBasic Connection TablemohammedОценок пока нет

- Cavities RexrothДокумент1 страницаCavities RexrothmohammedОценок пока нет

- 2 Tax RatesДокумент12 страниц2 Tax RatesuvaarajОценок пока нет

- Hydraulic Planetary Gear WinchesДокумент2 страницыHydraulic Planetary Gear WinchesAndré HagenОценок пока нет

- 1 Latest EIC G 1001 0 (Logic Valves)Документ15 страниц1 Latest EIC G 1001 0 (Logic Valves)Sujeet KumarОценок пока нет

- Quick Reference Chart of Dash Size EquivalentsДокумент1 страницаQuick Reference Chart of Dash Size EquivalentsmohammedОценок пока нет

- Quick Reference Chart of Dash Size EquivalentsДокумент1 страницаQuick Reference Chart of Dash Size EquivalentsmohammedОценок пока нет

- cOMPACT Winches 08-2013Документ42 страницыcOMPACT Winches 08-2013cudalbgeoОценок пока нет

- Parker COMOSO 0600P E Complete 3-28-2013 Valvair II SeriesДокумент40 страницParker COMOSO 0600P E Complete 3-28-2013 Valvair II SeriesmohammedОценок пока нет

- Plastics WeldingДокумент4 страницыPlastics Weldingmehdi7891Оценок пока нет

- cOMPACT Winches 08-2013Документ42 страницыcOMPACT Winches 08-2013cudalbgeoОценок пока нет

- Hydraulic Planetary Gear WinchesДокумент2 страницыHydraulic Planetary Gear WinchesAndré HagenОценок пока нет

- cOMPACT Winches 08-2013Документ42 страницыcOMPACT Winches 08-2013cudalbgeoОценок пока нет

- 0403 BДокумент20 страниц0403 BmohammedОценок пока нет

- Smartvibro E 20180122095110.842 XДокумент2 страницыSmartvibro E 20180122095110.842 XmohammedОценок пока нет

- Manual VinciДокумент21 страницаManual VinciElena TurcuОценок пока нет

- cOMPACT Winches 08-2013Документ42 страницыcOMPACT Winches 08-2013cudalbgeoОценок пока нет

- Smart Vibro MeterДокумент7 страницSmart Vibro MetermohammedОценок пока нет

- Concentration of SolutionsДокумент32 страницыConcentration of SolutionsRaja Mohan Gopalakrishnan100% (2)

- GusekДокумент177 страницGusekAitorAlbertoBaezОценок пока нет

- Time ResponseДокумент105 страницTime ResponseFrogie HuniebieОценок пока нет

- Geo Technical Ii Quiz QuestionsДокумент11 страницGeo Technical Ii Quiz QuestionsSukritiDanОценок пока нет

- Chem 105 Lab Manual 08 EKIM 1Документ42 страницыChem 105 Lab Manual 08 EKIM 1hooraОценок пока нет

- Question 197: (Forces Moments) : (At The 50cm Mark)Документ8 страницQuestion 197: (Forces Moments) : (At The 50cm Mark)ekjon1Оценок пока нет

- Iteration: Chapter GoalsДокумент46 страницIteration: Chapter GoalsAni AniОценок пока нет

- The Chemistry of Copper: Number 83 WWW - Curriculum-Press - Co.ukДокумент5 страницThe Chemistry of Copper: Number 83 WWW - Curriculum-Press - Co.uks7076728g100% (1)

- 1.1.1.A.VEX SimpleMachineInvestigationДокумент14 страниц1.1.1.A.VEX SimpleMachineInvestigationDivya Sureshkannan100% (2)

- Dynamics of Structures Apuntes PDFДокумент112 страницDynamics of Structures Apuntes PDFHero Djoni SОценок пока нет

- FOCSWATER.C Water Cooled Chiller - R134a - 2012!01!01Документ15 страницFOCSWATER.C Water Cooled Chiller - R134a - 2012!01!01ntt_121987Оценок пока нет

- Quantum Theory of The AtomДокумент18 страницQuantum Theory of The AtomSpace MonkeyОценок пока нет

- Kindergarten-DLL Week 1 (June 3-7, 2019)Документ7 страницKindergarten-DLL Week 1 (June 3-7, 2019)Ma. Cristina DumallagОценок пока нет

- Summative Test Gr7Документ1 страницаSummative Test Gr7Les Angelz100% (1)

- Properties of LiOH and LiNO3 Aqueous SolutionsДокумент13 страницProperties of LiOH and LiNO3 Aqueous Solutionstim tengОценок пока нет

- Lab Report Welding (SMAW) - FizaДокумент13 страницLab Report Welding (SMAW) - FizaCheng Yee71% (7)

- Fasteners For Use With PC BoardsДокумент25 страницFasteners For Use With PC BoardsJustin PhanОценок пока нет

- Powerflex 750-Series Ac Drives: Technical DataДокумент242 страницыPowerflex 750-Series Ac Drives: Technical DataJosé Santiago Miranda BernaolaОценок пока нет

- Detection of Mastitis and Lameness in Dairy Cows UsingДокумент10 страницDetection of Mastitis and Lameness in Dairy Cows UsingKalpak ShahaneОценок пока нет

- Fan Laws: Table 1 Fan Laws Parameters Variable ‘n' Speed Variable ‘ρ' Density Variable ‘d' Impeller Diameter p Q PpowДокумент3 страницыFan Laws: Table 1 Fan Laws Parameters Variable ‘n' Speed Variable ‘ρ' Density Variable ‘d' Impeller Diameter p Q Ppowgeetikag_23Оценок пока нет

- Principles of Communication Reviewer MidtermДокумент5 страницPrinciples of Communication Reviewer MidtermVon Ryan AlcazarОценок пока нет

- Venturi and OrificemeterДокумент10 страницVenturi and OrificemeterVikrant KumarОценок пока нет

- 01 - Enhancing Power Density in SMPS With MasterganДокумент44 страницы01 - Enhancing Power Density in SMPS With MasterganNWorKОценок пока нет

- Altivar Process Ride Through Time - IE04Документ3 страницыAltivar Process Ride Through Time - IE04Goran MladenovicОценок пока нет

- Hach 8021 Cloro Residual Ed 09Документ8 страницHach 8021 Cloro Residual Ed 09Beth AlvaradoОценок пока нет

- Oxygen Flak Combustion MethodДокумент2 страницыOxygen Flak Combustion MethodSandip Firke100% (2)

- 0w 30 Yağ ÖzellikleriДокумент2 страницы0w 30 Yağ ÖzellikleriahmetОценок пока нет

- Data Communication: By:Eng - Alaa I.HaniyДокумент8 страницData Communication: By:Eng - Alaa I.Haniypömo cОценок пока нет

- Microprocessors and Digital ICs For Control of Power Electronics and DrivesДокумент79 страницMicroprocessors and Digital ICs For Control of Power Electronics and DrivesTianmingyuОценок пока нет

- Lehmann Et Al 2013 PDFДокумент13 страницLehmann Et Al 2013 PDFJack HamiltonОценок пока нет