Академический Документы

Профессиональный Документы

Культура Документы

1 Hareesha N G, Dept of Aero Engg, DSCE

Загружено:

Rajesh Shah0 оценок0% нашли этот документ полезным (0 голосов)

12 просмотров51 страницаThe document discusses liquid penetrant inspection, which is a nondestructive testing method used to reveal surface-breaking flaws. It works by applying a penetrant that is drawn into flaws by capillary action, then removing excess and applying a developer which draws the penetrant back out of the flaws to the surface where they are visible. The document outlines the basic processing steps which are surface preparation, penetrant application, penetrant dwell time, excess penetrant removal, and visual inspection. It also discusses common materials inspected using this method and advantages and disadvantages.

Исходное описание:

Liquid penetrant test of NDE

Оригинальное название

liquidpanetranttesting-140603033859-phpapp02

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThe document discusses liquid penetrant inspection, which is a nondestructive testing method used to reveal surface-breaking flaws. It works by applying a penetrant that is drawn into flaws by capillary action, then removing excess and applying a developer which draws the penetrant back out of the flaws to the surface where they are visible. The document outlines the basic processing steps which are surface preparation, penetrant application, penetrant dwell time, excess penetrant removal, and visual inspection. It also discusses common materials inspected using this method and advantages and disadvantages.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

12 просмотров51 страница1 Hareesha N G, Dept of Aero Engg, DSCE

Загружено:

Rajesh ShahThe document discusses liquid penetrant inspection, which is a nondestructive testing method used to reveal surface-breaking flaws. It works by applying a penetrant that is drawn into flaws by capillary action, then removing excess and applying a developer which draws the penetrant back out of the flaws to the surface where they are visible. The document outlines the basic processing steps which are surface preparation, penetrant application, penetrant dwell time, excess penetrant removal, and visual inspection. It also discusses common materials inspected using this method and advantages and disadvantages.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 51

Hareesha N G, Dept of Aero Engg, DSCE 1

LIQUID PENETRANT INSPECTION

Liquid penetrant inspection is a method that is used to

reveal surface breaking flaws by bleed out of a colored

or fluorescent dye from the flaw.

The technique is based on the ability of a liquid to be

drawn into a "clean" surface breaking flaw by capillary

action.

After a period of time called the "dwell," excess

surface penetrant is removed and a developer applied.It

draws the penetrant from the flaw to reveal its presence.

Colored (contrast) penetrants require good white light

while fluorescent penetrants need to be used in darkened

conditions with an ultraviolet "black light".

Hareesha N G, Dept of Aero Engg, DSCE 2

BASIC PROCESSING STEPS OF A LIQUID

PENETRANT INSPECTION

1. Surface Preparation

One of the most critical steps of a liquid penetrant

inspection is the surface preparation.

The surface must be free of oil, grease, water, or

other contaminants that may prevent penetrant

from entering flaws.

The sample may also require etching if mechanical

operations such as machining, sanding, or grit

blasting have been performed.

These and other mechanical operations can smear

metal over the flaw opening and prevent the

penetrant from entering.

Hareesha N G, Dept of Aero Engg, DSCE 3

2. Penetrant Application:

Once the surface has been thoroughly cleaned and

dried, the penetrant material is applied by

spraying, brushing, or immersing the part in a

penetrant bath.

Hareesha N G, Dept of Aero Engg, DSCE 4

3.Penetrant Dwell:

1. The penetrant is left on the surface for a

sufficient time to allow as much penetrant as

possible to be drawn from or to seep into a

defect.

2. Penetrant dwell time is the total time that the

penetrant is in contact with the part surface.

3. Dwell times are usually recommended by the

penetrant producers or required by the

specification being followed.

Hareesha N G, Dept of Aero Engg, DSCE 5

3.Penetrant Dwell:

4) The times vary depending on the application,

penetrant materials used, the material, the

form of the material being inspected, and the

type of defect being inspected for.

5. Minimum dwell times typically range from

five to 60 minutes. Generally, there is no

harm in using a longer penetrant dwell time

as long as the penetrant is not allowed to dry.

6. The ideal dwell time is often determined by

experimentation and may be very specific to

a particular application.

Hareesha N G, Dept of Aero Engg, DSCE 6

4.Excess Penetrant Removal:

This is the most delicate part

of the inspection procedure

because the excess penetrant

must be removed from the

surface of the sample while

removing as little penetrant as

possible from defects.

Depending on the penetrant system used,

this step may involve cleaning with a

solvent, direct rinsing with water, or first

treating the part with an emulsifier and

then rinsing with water.

Hareesha N G, Dept of Aero Engg, DSCE 7

Common Uses of Liquid Penetrant Inspection

1. Liquid penetrant inspection (LPI) is one of the most widely

used nondestructive evaluation (NDE) methods.

2. Its popularity can be attributed to two main factors: its

relative ease of use and its flexibility.

3. LPI can be used to inspect almost any material provided that

its surface is not extremely rough or porous.

4. Materials that are commonly inspected using LPI include the

following:

Metals (aluminum, copper, steel, titanium, etc.)

Glass

Many ceramic materials

Rubber

Plastics

Hareesha N G, Dept of Aero Engg, DSCE 8

Primary Advantages

1) The method has high sensitivity to small surface

discontinuities.

2) The method has few material limitations, i.e. metallic and

nonmetallic, magnetic and nonmagnetic, and conductive

and nonconductive materials may be inspected.

3) Large areas and large volumes of parts/materials can be

inspected rapidly and at low cost.

4) Parts with complex geometric shapes are routinely

inspected.

5) Indications are produced directly on the surface of the

part and constitute a visual representation of the flaw.

6) Aerosol spray cans make penetrant materials very

portable.

7) Penetrant materials and

Hareesha N G, Dept of Aeroassociated

Engg, DSCE equipment 9are

Primary Disadvantages

1) Only surface breaking defects can be detected.

2) Only materials with a relatively nonporous surface can

be inspected.

3) Precleaning is critical since contaminants can mask

defects.

4) Metal smearing from machining, grinding, and grit or

vapor blasting must be removed prior to LPI.

5) The inspector must have direct access to the surface

being inspected.

6) Surface finish and roughness can affect inspection

sensitivity.

7) Multiple process operations must be performed and

controlled.

8) Post cleaning of acceptable

Hareesha N G, Dept ofparts or materials is required.

Aero Engg, DSCE 10

Introduction

• This module is intended to provide an introduction to

the NDT method of penetrant testing.

• Penetrant Testing, or PT, is a nondestructive

testing method that builds on the principle

of Visual Inspection.

• PT increases the

“seeability” of small

discontinuities that

the human eye might

not be able to detect

alone.

Hareesha N G, Dept of Aero Engg, DSCE 11

How Does PT Work?

•In penetrant testing, a liquid with high surface wetting

characteristics is applied to the surface of a component

under test.

•The penetrant “penetrates” into surface breaking

discontinuities via capillary action and other mechanisms.

•Excess penetrant is removed from the surface and a

developer is applied to

pull trapped penetrant back

the surface.

•With good inspection

technique, visual

indications of any

discontinuities present

become apparent.

Hareesha N G, Dept of Aero Engg, DSCE 12

What Makes PT Work?

•Every step of the penetrant process

is done to promote capillary action.

•This is the phenomenon of a liquid

rising or climbing when confined to

small openings due to surface

wetting properties of the liquid.

•Some examples:

– Plants and trees draw water up from the

ground to their branches and leaves to

supply their nourishment.

– The human body has miles of capillaries

that carry life sustaining blood to our

entire body.

Hareesha N G, Dept of Aero Engg, DSCE 13

Basic Process of PT

1) Clean & Dry Component 4) Apply Developer

2) Apply Penetrant

5) Visual Inspection

3) Remove Excess

6) Post Clean Component

Hareesha N G, Dept of Aero Engg, DSCE 14

What Can Be Inspected Via PT?

Almost any

material that has

a relatively

smooth, non-

porous surface

on which

discontinuities or

defects are

suspected.

Hareesha N G, Dept of Aero Engg, DSCE 15

What Can NOT be Inspected Via PT?

•Components with rough

surfaces, such as sand castings,

that trap and hold penetrant.

•Porous ceramics

•Wood and other fibrous

materials.

•Plastic parts that absorb or

react with the penetrant Defect indications

materials. become less

•Components with coatings that distinguishable as

the background

prevent penetrants from

entering defects. “noise” level

increases.

Hareesha N G, Dept of Aero Engg, DSCE 16

What Types of Discontinuities Can

Be Detected Via PT?

All defects that are open to

the surface.

– Rolled products-- cracks,

seams, laminations.

– Castings--cold shuts, hot tears,

porosity, blow holes,

shrinkage.

– Forgings– cracks, laps, external

bursts.

– Welds– cracks, porosity,

undercut, overlap, lack of

fusion, lack of penetration.

Hareesha N G, Dept of Aero Engg, DSCE 17

Choices of Penetrant Materials

Penetrant Type

I Fluorescent

II Visible

Method

A Water Washable

B Postemulsifiable - Lipophilic

C Solvent Removable

D Postemulsifiable - Hydrophilic

Developer Form

Dry Powder

Wet, Water Soluble

Wet, Water Suspendable

Wet, Non-Aqueous

Hareesha N G, Dept of Aero Engg, DSCE 18

Penetrant Materials

Penetrants are formulated to possess a number of

important characteristics. To perform well, a

penetrant must:

– Spread easily over the surface being inspected.

– Be drawn into surface breaking defects by capillary action

or other mechanisms.

– Remain in the defect but remove easily from the surface of

the part.

– Remain fluid through the drying and developing steps so it

can be drawn back to the surface.

– Be highly visible or fluoresce brightly to produce easy to see

indications.

– Not be harmful to the inspector or to the material being

tested.

Hareesha N G, Dept of Aero Engg, DSCE 19

Sensitivity Levels

• Penetrants are also formulated to produce a variety of

sensitivity levels. The higher the sensitivity level, the

smaller the defect that the penetrant system is capable of

detecting.

• The five sensitivity levels are:

– Level 4 - Ultra-High Sensitivity

– Level 3 - High Sensitivity

– Level 2 - Medium Sensitivity

– Level 1 - Low Sensitivity

• As the sensitivity level increases, so does the number of

non relevant indications. Therefore, a penetrant needs to

be selected that will find the defects of interest but not

produce too many non relevant indications.

Hareesha N G, Dept of Aero Engg, DSCE 20

Visible Vs Fluorescent PT

• Inspection can be performed

using visible (or red dye) or

fluorescent penetrant

materials.

• Visible Pt is performed under

white light while fluorescent

PT must be performed using

Photo Courtesy of Contesco

an ultraviolet light in a

darkened area. All are all in

the level 1 sensitivity range.

• Fluorescent PT is more

sensitive than visible PT

because the eye is more

sensitive to a bright

indication on a dark

background. Sensitivity

ranges from 1 toHareesha

4. N G, Dept of Aero Engg, DSCE 21

Penetrant Removal Method

Penetrants are also classified by the method of

removing the excess penetrant.

•Solvent Removable penetrants are removed by

wiping with a cloth dampened with solvent. They are

supplied in aerosol cans for portability and are primarily

used for spot checks.

•Water Washable penetrants are removed with a

course spray of water. They are the easiest to employ

and most cost effective when inspecting large areas.

•Post-Emulsifiable penetrants are water-washable

only after they have reacted with an emulsifier solution.

A post-emulsifiable system is used when washing the

penetrant out of the defect is a concern. The emulsifier

is given time to reacts with the penetrant on the surface

but not the penetrant trapped in the flaw.

Hareesha N G, Dept of Aero Engg, DSCE 23

Developers

• The role of the developer is to pull trapped

penetrant out of defects and to spread it

out on the surface so that it can be seen.

Also provides a light background to

increase contrast when visible penetrant is used.

• Developer materials are available in several different forms

– Dry Powder is a mix of light fluffy powder that clumps together where penetrant

bleeds back to the surface to produces very defined indications.

– Wet, Water Suspendable is a powder that is suspended in a water that covers the

surface with a relatively uniform layer of developer when the water is evaporated. The

solution is somewhat difficult to maintain as the powder settles out over time.

– Wet, Water Soluble is a crystalline powder that forms a clear solution when mixed

with water. The solution recrystallizes on the surface when the water is driven off.

Indications sometimes lack definition and look milky. Not recommended for use with

water-washable penetrants.

– Wet, Non-Aqueous - is supplied in a spray can and is the most sensitive developer

for inspecting small areas. It is too costly and difficult to apply to large areas.

Hareesha N G, Dept of Aero Engg, DSCE 24

6 Steps of Penetrant Testing

1. Pre-Clean

2. Penetrant Application

3. Excess Penetrant Removal

4. Developer Application

5. Inspect/Evaluate

6. Post-clean

Hareesha N G, Dept of Aero Engg, DSCE 25

Pre-cleaning – Step 1

• Parts must be free of dirt,

rust, scale, oil, grease, etc.

to perform a reliable

inspection.

• The cleaning process must

remove contaminants from

the surfaces of the part

and defects, and must not

plug any of the defects.

Pre-cleaning is the most

important step in the PT

process!!!

Hareesha N G, Dept of Aero Engg, DSCE 26

Caution About Metal Smearing

Some machining, surface finishing and cleaning Before Sanding

operations can cause a thin layer of metal to

smear on the surface and prevent penetrant from

entering any flaws that may be present.

Etching of the surface prior to inspection is

sometimes required. After Sanding

After Etching

Hareesha N G, Dept of Aero Engg, DSCE 27

Penetrant Application – Step 2

Many methods

of application

are possible

such as:

– Brushing

– Spraying

– Dipping/

Immersing

– Flow-on

– And more

Hareesha N G, Dept of Aero Engg, DSCE 28

Dwell Time

•The penetrant solution must

be allowed to “dwell” on the

surface of the part to allow

the penetrant time to fill any

defects present.

•The dwell time vary

according to penetrant type,

temperature, material type

and surface finish.

Hareesha N G, Dept of Aero Engg, DSCE 29

Excess Penetrant Removal – Step 3

The removal technique depends upon the

type of penetrant used, as stated earlier…

– Solvent Removable

– Water Washable

– Post Emulsifiable

Hareesha N G, Dept of Aero Engg, DSCE 30

Excess Penetrant Removal – Step 3 (cont.)

Water Washable

• A coarse water spray is

used to remove the excess

penetrant.

• The procedure used as a

guideline for the

inspection will specify

water temperature

(typically 50-100°F) and

pressure (typically not

more than 40 psi), etc.

Hareesha N G, Dept of Aero Engg, DSCE 31

Excess Penetrant Removal – Step 3 (cont.)

Solvent Removable

•The part is wiped with a

clean dry cloth to remove

the bulk of the excess

penetrant.

•Then, a cloth lightly

dampened with solvent is

used to remove any

remaining penetrant on

the surface.

Hareesha N G, Dept of Aero Engg, DSCE 32

Excess Penetrant Removal – Step 3 (cont.)

Solvent Removable (cont.)

Any time a solvent is

used in the penetrant inspection

process, a

suitable flash time is

required to allow excess solvent to

evaporate.

Hareesha N G, Dept of Aero Engg, DSCE 33

Excess Penetrant Removal – Step 3 (cont.)

Post Emulsifiable

•When there is concern about removing much of the penetrant

from the defect, a post emulsifiable system is used.

•This involves an additional step

in which an emulsifier is applied

to the surface of the part after

the penetrant dwell time.

•The emulsifier is given just

enough time to react with

the penetrant on the surface

to render it water washable

but not enough time to diffuse

into the penetrant trapped in

the defects.

Hareesha N G, Dept of Aero Engg, DSCE 34

Developer Application – Step 4

The method of developer application is is

dependent on the type of developer used. The

primary methods for the following main developer

types will be covered in the following slides.

– Dry

– Wet

– Nonaqueous Wet

Hareesha N G, Dept of Aero Engg, DSCE 35

Developer Application – Step 4 (cont.)

Dry Powder Developer

•Prior to applying a dry

powder developer, the

component must be

thoroughly dried. Drying is

usually accomplished in a hot

air circulating oven.

•The developer is then applied

by immersing the part in the

powder or by dusting of the

part with the powder.

•The part can also be placed in

a developer dust cloud

chamber.

Hareesha N G, Dept of Aero Engg, DSCE 36

Developer Application – Step 4 (cont.)

Wet Developer (water- suspended

and water- soluble)

•Wet developers are applied by

immersing or spraying the part

while it is still wet from the

penetrant removal process.

•The part is completely coated and

the excess liquid allowed to drain

to prevent pooling

•The part is then dried in a hot air

circulating oven.

Hareesha N G, Dept of Aero Engg, DSCE 37

Developer Application – Step 4 (cont.)

Nonaqueous Developer (AKA

Solvent-Suspended)

• Nonaqueous developer is

applied by a aerosol spray to a

thoroughly dried and cooled

part.

• A thin even coating should be

applied. The coating should be

white but still slightly

transparent when performing a

visible dye penetrant

inspection, and even thinner

when performing a fluorescent

penetrant inspection.

Hareesha N G, Dept of Aero Engg, DSCE 38

Inspection/Evaluation – Step 5

In this step the inspector

evaluates the penetrant

indications against specified

accept/reject criteria and

attempts to determine the

origin of the indication.

Non-relevant weld geometry indications

The indications are judged

to be either relevant, non-

relevant or false.

Relevant crack indications from an

abusive drilling process

Hareesha N G, Dept of Aero Engg, DSCE 39

Inspection/Evaluation – Step 5

A very important step of

evaluation is to

document findings on

an inspection report

form or other record

keeping form.

This may be supported

with drawings or photos

of indications, etc.

Hareesha N G, Dept of Aero Engg, DSCE 40

Post Clean – Step 6

The final step in the penetrant

inspection process is to

thoroughly clean the part that

has been tested to remove all

penetrant processing

materials.

The residual materials could

possibly affect the

performance of the part or

affect its visual appeal.

Hareesha N G, Dept of Aero Engg, DSCE 41

Penetrant Inspection Systems

Penetrant systems can be highly portable or

stationary.

Image courtesy of Nebraska Army National Guard

Portable Penetrant System Stationary Penetrant System

Hareesha N G, Dept of Aero Engg, DSCE 42

Verification of Penetrant System

Performance

Since penetrant testing

involves multiple processing

steps, the performance of the

materials and the processes

should be routinely checked

using performance verification

tools, which include:

– TAM Panels

– Crack Sensitivity Panels

– Run Check Panels

Hareesha N G, Dept of Aero Engg, DSCE 43

Advantages of Penetrant Testing

• Relative ease of use.

• Can be used on a wide range of material types.

• Large areas or large volumes of parts/materials can be

inspected rapidly and at low cost.

• Parts with complex geometries are routinely

inspected.

• Indications are produced directly on surface of the

part providing a visual image of the discontinuity.

• Initial equipment investment is low.

• Aerosol spray cans can make equipment very

portable.

Hareesha N G, Dept of Aero Engg, DSCE 44

Limitations of Penetrant Testing

• Only detects surface breaking defects.

• Requires relatively smooth nonporous material.

• Precleaning is critical. Contaminants can mask

defects.

• Requires multiple operations under controlled

conditions.

• Chemical handling precautions necessary (toxicity,

fire, waste).

• Metal smearing from machining, grinding and other

operations inhibits detection. Materials may need to

be etched prior to inspection.

• Post cleaning is necessary to remove chemicals.

Hareesha N G, Dept of Aero Engg, DSCE 45

Summary

• Penetrant testing (PT) is one of the most widely

used nondestructive testing methods.

• Its popularity can be attributed to two main factors,

which are its relative ease of use and its flexibility.

• However, PT involves a number of processing steps

that must be closely control to achieve optimal

sensitivity.

Hareesha N G, Dept of Aero Engg, DSCE 46

Glossary of Terms

• Capillary Action - the tendency of certain liquids

to travel or climb when exposed to small

openings.

• Contrast - the relative amount of light emitted or

reflected between and indication and its

background.

• Defect - a discontinuity that effects the usefulness

of a part or specimen.

• Developer - a finely divided material applied over

the surface of a part to help promote reverse

capillary action and thus bring out a penetrant

indication.

Hareesha N G, Dept of Aero Engg, DSCE 47

Glossary of Terms

• Discontinuity - any interruption in the normal

physical structure of a part or weld. It may or

may not affect the usefulness of a part.

• Dwell Time - the period of time that a penetrant

or developer must remain in contact with the

surface of a part under test.

• Emulsification Time - the time allowed for the

emulsifier to render the penetrant water

washable and thus allow the part to be washed.

• Emulsifier - a material applied over a film of

penetrant that renders it water washable.

Hareesha N G, Dept of Aero Engg, DSCE 48

Glossary of Terms

• Evaluation - the process of deciding as to the

severity of the condition after an indication has

been interpreted.

• False Indication - an indication caused by

improper processing; not caused by a relevant or

non-relevant condition.

• Flash Time - the time required for the solvent to

evaporate from the surface of a part when used

to preclean or remove excess penetrant.

• Fluorescent Dye - a dye which becomes

fluorescent (gives off light) when exposed to short

wave radiation such as ultraviolet light.

Hareesha N G, Dept of Aero Engg, DSCE 49

Glossary of Terms

• Indication - the visible evidence or penetrant

bleed-out on the surface of the specimen

• Interpretation - the process of evaluating an

indication in an attempt to determine the cause

and nature of the discontinuity.

• Non-Aqueous Developer - a developer in which

developing powder is applied as a suspension in a

quick drying solvent

• Penetrant - a liquid used in fluorescent or visible

dye penetrant inspection to penetrate into the

surface openings of parts inspected via these

methods

Hareesha N G, Dept of Aero Engg, DSCE 50

Glossary of Terms

• Relevant Indication - an indication that has been

determined not to be false or non-relevant - and

actual discontinuity

• Seeability - the characteristic of an indication that

enables it to be seen against the adverse conditions

of background, outside light, etc.

• Sensitivity - the ability of a penetrant to detect

surface openings. Higher sensitivity indicates

smaller discontinuities can be detected

• Ultraviolet Light (or Black Light) - light energy just

below the visible range of violet light (356

nanometers).

Hareesha N G, Dept of Aero Engg, DSCE 51

Glossary of Terms

• Viscosity - the resistance of a fluid to the motion

of its particles

• Washability - the property of a penetrant which

permits it to be cleaned from the surface of a part

by washing with water

Hareesha N G, Dept of Aero Engg, DSCE 52

Вам также может понравиться

- Liquid Penetrant Testing L.PДокумент51 страницаLiquid Penetrant Testing L.PPRABHU LОценок пока нет

- Government Polytechnic Junagadh: Liquid Penerant TestingtДокумент16 страницGovernment Polytechnic Junagadh: Liquid Penerant TestingtArvind DedunОценок пока нет

- Non - Destructive Testing: UNIT-5Документ26 страницNon - Destructive Testing: UNIT-5Jones Jones Jr.Оценок пока нет

- LPTДокумент22 страницыLPTPratik SalveОценок пока нет

- Penetrant Testing, or PT, Is A NondestructiveДокумент10 страницPenetrant Testing, or PT, Is A NondestructiveMastram HatheshОценок пока нет

- LPT Study Material LatestДокумент33 страницыLPT Study Material Latestbeltranrommel100% (2)

- Liquid Penetrant Testing PDFДокумент20 страницLiquid Penetrant Testing PDFgueridiОценок пока нет

- Dye Penetrant Inspection (DPI) - Liquid Penetrant Inspection (LPI) - Liquid Penetrant Testing (PT)Документ9 страницDye Penetrant Inspection (DPI) - Liquid Penetrant Inspection (LPI) - Liquid Penetrant Testing (PT)ISHITA ROY CHOUDHURYОценок пока нет

- NDT Module 2Документ21 страницаNDT Module 2Sajeesh Saji100% (1)

- Material Science AlfathiДокумент5 страницMaterial Science AlfathiAnonymous UdOhqLMОценок пока нет

- Liquid Penetrant Inspection 3Документ24 страницыLiquid Penetrant Inspection 3Taha KhanОценок пока нет

- Unit - 3-Non-Destructive Testing Overview of Nondestructive TestingДокумент70 страницUnit - 3-Non-Destructive Testing Overview of Nondestructive TestingGopinathОценок пока нет

- EXPERIMENT No.: - Liquid Penetrant TestДокумент6 страницEXPERIMENT No.: - Liquid Penetrant TestVandan GundaleОценок пока нет

- Liquid Penetrant TestingДокумент20 страницLiquid Penetrant Testingajayghosh3140Оценок пока нет

- Liquid Penetrant TestingДокумент20 страницLiquid Penetrant TestingsanjibkrjanaОценок пока нет

- Non Destructive TestingДокумент30 страницNon Destructive TestingRahul GajjeОценок пока нет

- Dye Penetrant Inspection - Wikipedia, The Free EncyclopediaДокумент5 страницDye Penetrant Inspection - Wikipedia, The Free Encyclopediaviswamanoj100% (1)

- Dye Penetrant InspectionДокумент5 страницDye Penetrant Inspectionrashm006ranjanОценок пока нет

- Module1 Testing and Flaw Detection of Materials and ComponentsДокумент12 страницModule1 Testing and Flaw Detection of Materials and ComponentsHari GovindОценок пока нет

- PT Theory FromДокумент75 страницPT Theory FromYousef Adel HassanenОценок пока нет

- Fluorescent Dye Lab ReportДокумент10 страницFluorescent Dye Lab Reportkaushallyaa navindranОценок пока нет

- Dye Penetrant InspectionДокумент6 страницDye Penetrant InspectionHabib ur RehmanОценок пока нет

- DPTДокумент10 страницDPTShabbir HassanОценок пока нет

- Non Destructive TestingДокумент7 страницNon Destructive Testingk_mughalОценок пока нет

- Dye Penetrant InspectionДокумент5 страницDye Penetrant Inspectionrajasekar21Оценок пока нет

- Non Destructive Testing and Evaluation Course Module Topic - Dye Penetrant TestingДокумент118 страницNon Destructive Testing and Evaluation Course Module Topic - Dye Penetrant TestingV.Muthu KumarОценок пока нет

- 4 Intro To Penetrant 03092013 OKДокумент27 страниц4 Intro To Penetrant 03092013 OKnishant kumar singhОценок пока нет

- Dye Penetrant InspДокумент5 страницDye Penetrant InspVysakh VasudevanОценок пока нет

- Penetrant RaportДокумент6 страницPenetrant RaportMeritan BaballariОценок пока нет

- PT Level Ii FM1Документ41 страницаPT Level Ii FM1ucheОценок пока нет

- Liquid Penetrant Testing (ASME BPVC Section V - Article 6, ASTM E-165-02)Документ4 страницыLiquid Penetrant Testing (ASME BPVC Section V - Article 6, ASTM E-165-02)Lakshmi KruthigaОценок пока нет

- Introduction and History of - Docx PenetrantДокумент56 страницIntroduction and History of - Docx PenetrantHamydОценок пока нет

- Experiment No.3 Dye Penetration TestДокумент4 страницыExperiment No.3 Dye Penetration TestChristian D. AllanaОценок пока нет

- Liquid Penetrant Test Level-IiДокумент39 страницLiquid Penetrant Test Level-IiAabhas UpadhyayaОценок пока нет

- Non-Destructive Inspection Practical: NAME:-Amol Rajhans Talekar Roll No.: - Name of DepartmentДокумент40 страницNon-Destructive Inspection Practical: NAME:-Amol Rajhans Talekar Roll No.: - Name of DepartmentAniket DhoneОценок пока нет

- 2 2Документ11 страниц2 2RAJESH. RОценок пока нет

- Basic Processing Steps of A Liquid Penetrant InspectionДокумент16 страницBasic Processing Steps of A Liquid Penetrant Inspectionssrames7282Оценок пока нет

- Non-Destructive TestingДокумент61 страницаNon-Destructive TestingRehan SharmaОценок пока нет

- Nondestructive Testing (NDT)Документ14 страницNondestructive Testing (NDT)Javeed A. KhanОценок пока нет

- Dye Penetrant InspectionДокумент2 страницыDye Penetrant InspectionsuparnaОценок пока нет

- Module 2 Surface Gears MethodsДокумент12 страницModule 2 Surface Gears MethodsNAVEEN H V MEОценок пока нет

- Dye Penetrant TestДокумент4 страницыDye Penetrant TestRavi kumarОценок пока нет

- PT Test & SafetyДокумент42 страницыPT Test & SafetyRushabh KapadiaОценок пока нет

- Dye PenetrantДокумент17 страницDye Penetrantsen_subhasis_58Оценок пока нет

- Liquid Penetrant Testing ModuleДокумент59 страницLiquid Penetrant Testing ModuleDITAОценок пока нет

- NDT Basics PresentationsДокумент154 страницыNDT Basics Presentationskirans60100% (1)

- Dye Penetrant Lab ReportДокумент6 страницDye Penetrant Lab Reportking kong80% (5)

- Penetrant TestingДокумент22 страницыPenetrant Testingmanafl salhlОценок пока нет

- MSE Experiment No. 7 - Dye Penetration TestДокумент4 страницыMSE Experiment No. 7 - Dye Penetration TestRushikesh Kale100% (1)

- Penetrant PresentationДокумент20 страницPenetrant PresentationJayesh100% (3)

- Penetrant Testing: Principles, Techniques, Applications and Interview Q&AОт EverandPenetrant Testing: Principles, Techniques, Applications and Interview Q&AОценок пока нет

- Site Safety Handbook for the Petroleum IndustryОт EverandSite Safety Handbook for the Petroleum IndustryРейтинг: 5 из 5 звезд5/5 (1)

- NDE Handbook: Non-Destructive Examination Methods for Condition MonitoringОт EverandNDE Handbook: Non-Destructive Examination Methods for Condition MonitoringKnud G. BøvingРейтинг: 4.5 из 5 звезд4.5/5 (4)

- Technical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationОт EverandTechnical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationОценок пока нет

- Analisys and application of dry cleaning materials on unvarnished pain surfacesОт EverandAnalisys and application of dry cleaning materials on unvarnished pain surfacesОценок пока нет

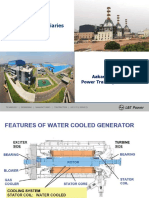

- Power Plant Engineering: Aditya Engineering College (A) Aditya Engineering College (A)Документ82 страницыPower Plant Engineering: Aditya Engineering College (A) Aditya Engineering College (A)Rajesh ShahОценок пока нет

- Design and FabricationДокумент31 страницаDesign and FabricationRajesh ShahОценок пока нет

- Energy-Efficient Systems and Benefits of Green ManufacturingДокумент97 страницEnergy-Efficient Systems and Benefits of Green ManufacturingRajesh ShahОценок пока нет

- Introduction To MCMT PPT (Autosaved)Документ16 страницIntroduction To MCMT PPT (Autosaved)Rajesh ShahОценок пока нет

- Application - FORM - PHD 2020 PDFДокумент5 страницApplication - FORM - PHD 2020 PDFRajesh ShahОценок пока нет

- METROLOGY JNTUK Mech III - IIДокумент103 страницыMETROLOGY JNTUK Mech III - IIRajesh Shah0% (3)

- Surface Engineering NotesДокумент17 страницSurface Engineering NotesRajesh Shah0% (1)

- Design and FabricationДокумент31 страницаDesign and FabricationRajesh ShahОценок пока нет

- Unit Ii Automated Flow LinesДокумент94 страницыUnit Ii Automated Flow LinesRajesh Shah100% (1)

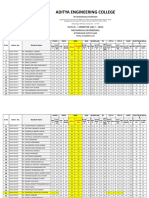

- Aditya Engineering College (A) : Lesson PlanДокумент5 страницAditya Engineering College (A) : Lesson PlanRajesh ShahОценок пока нет

- Objective QuestionsДокумент73 страницыObjective QuestionsRajesh ShahОценок пока нет

- Surname First Name Gender: Ms. FemaleДокумент24 страницыSurname First Name Gender: Ms. FemaleRajesh ShahОценок пока нет

- Aim NotesДокумент164 страницыAim NotesRajesh ShahОценок пока нет

- II To IV B.tech. II Semester Lesson Plan 2017-18Документ6 страницII To IV B.tech. II Semester Lesson Plan 2017-18Rajesh ShahОценок пока нет

- II B.tech I Sem JNTUK Final AttendanceДокумент31 страницаII B.tech I Sem JNTUK Final AttendanceRajesh ShahОценок пока нет

- Title Middle Name Mother's Name: Miss AAA AAA AAA Aaa1Документ9 страницTitle Middle Name Mother's Name: Miss AAA AAA AAA Aaa1Rajesh ShahОценок пока нет

- 6/3/2014 1 Hareesha N G, Dept of Aero Engg, DSCEДокумент41 страница6/3/2014 1 Hareesha N G, Dept of Aero Engg, DSCERajesh ShahОценок пока нет

- High Speed Stir ModelДокумент27 страницHigh Speed Stir ModelRajesh ShahОценок пока нет

- Class 18Документ51 страницаClass 18Rajesh ShahОценок пока нет

- Lec 12 - 13 Shaping Planing and Slotting OperationsДокумент36 страницLec 12 - 13 Shaping Planing and Slotting OperationsAnonymous lTQDM21Оценок пока нет

- Parte 3.-Piping Design Carrier HandBookДокумент122 страницыParte 3.-Piping Design Carrier HandBookNestor Sanchez Villasmil100% (8)

- Design of Single Plate Shear ConnectionsДокумент12 страницDesign of Single Plate Shear Connectionssecanet10Оценок пока нет

- 2002 - Mohandy - Sustainable Bio-Composites From Renewable ResourcesДокумент8 страниц2002 - Mohandy - Sustainable Bio-Composites From Renewable ResourcesanfkОценок пока нет

- 77 - 170 PDFДокумент14 страниц77 - 170 PDFraja100% (1)

- ASTM Norm E 164 - 97 - RTE2NC05NWДокумент23 страницыASTM Norm E 164 - 97 - RTE2NC05NWAngelОценок пока нет

- List of Contents: Station: NTPC Simhadri BHEL REF NO: PS-DC-186-500-Ntpc Ref No: Sim/1/Ts/1Документ12 страницList of Contents: Station: NTPC Simhadri BHEL REF NO: PS-DC-186-500-Ntpc Ref No: Sim/1/Ts/1Premkumar VasudevanОценок пока нет

- Instrumentation Quick-Connect Stems, With Shutoff: SS-QC6-D-4PFДокумент2 страницыInstrumentation Quick-Connect Stems, With Shutoff: SS-QC6-D-4PFAdeilton CabocloОценок пока нет

- 03171344yzet PDFДокумент30 страниц03171344yzet PDFRobin LeeОценок пока нет

- Hvac Design Thumb Rules PDFДокумент52 страницыHvac Design Thumb Rules PDFmohd yusuf ansariОценок пока нет

- ASTM-D570-98 - Water Absorption of Plastics1Документ2 страницыASTM-D570-98 - Water Absorption of Plastics1Ruwan Sampath WickramathilakaОценок пока нет

- E DMT 041424Документ80 страницE DMT 041424Girlie YapОценок пока нет

- Purge With NitrogenДокумент5 страницPurge With NitrogenSurya Kiran KОценок пока нет

- Technical Data Sheet - (Linear Low-Density Polyethylene) : Product DescriptionДокумент2 страницыTechnical Data Sheet - (Linear Low-Density Polyethylene) : Product DescriptionchinchotarngОценок пока нет

- A Review On Binderless Tungsten Carbide DevelopmenДокумент37 страницA Review On Binderless Tungsten Carbide DevelopmenRubens RochaОценок пока нет

- Penthouse Summer 08Документ2 страницыPenthouse Summer 08John M. CavoteОценок пока нет

- 05 Hand ProtectionДокумент18 страниц05 Hand ProtectionmgphyopyaesoneaungОценок пока нет

- CMP ManualДокумент65 страницCMP Manualnarayanan.um2640100% (2)

- Company Profile - en - Mailversion KlumppДокумент2 страницыCompany Profile - en - Mailversion KlumppJulio NeumannОценок пока нет

- Fig. 7444 PDFДокумент2 страницыFig. 7444 PDFDanielОценок пока нет

- SKF Explorer ACBB 10572 en TCM 12-32273Документ8 страницSKF Explorer ACBB 10572 en TCM 12-32273ankitsarvaiyaОценок пока нет

- Pelton Crane OCM OCR Sterilizer Service ManualДокумент8 страницPelton Crane OCM OCR Sterilizer Service ManualWilliam Hernandez100% (1)

- Defogger: SectionДокумент72 страницыDefogger: SectionJavier SiñaniОценок пока нет

- Meurer Parts ListДокумент2 страницыMeurer Parts ListvinayОценок пока нет

- 05 SedimentationДокумент70 страниц05 SedimentationAnonymous Cpe6vcОценок пока нет

- Sikafloor 415 PDSДокумент6 страницSikafloor 415 PDSVi NeОценок пока нет

- White Topping: An Excellent Solution For Pavement RehabilitationДокумент23 страницыWhite Topping: An Excellent Solution For Pavement RehabilitationLohith Kumar HPОценок пока нет

- Generator AuxiliariesДокумент39 страницGenerator Auxiliariesharry2586Оценок пока нет

- Surface Prepairation STD For PC ASTM D6386Документ4 страницыSurface Prepairation STD For PC ASTM D6386Rohit SangwanОценок пока нет

- Phoenix Contact Datasheet 5378758Документ6 страницPhoenix Contact Datasheet 5378758Abraham RamirezОценок пока нет

- Denim Finishing: Weko Offers Solutions ..Документ8 страницDenim Finishing: Weko Offers Solutions ..孙兴峰Оценок пока нет