Академический Документы

Профессиональный Документы

Культура Документы

Deepwater Horizon: What Went Wrong

Загружено:

SimonRogersGuardianОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Deepwater Horizon: What Went Wrong

Загружено:

SimonRogersGuardianАвторское право:

Доступные форматы

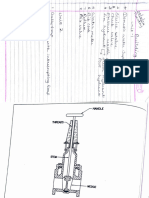

What went wrong?

The BP report identifies eight key elements The key times

in the Deepwater Horizon drilling operation -

20 April 9.40pm 20 April 9.49pm

each of which could have prevented the disaster Report: ‘The fire and

Report: ‘This

overwhelmed gas system did not

the … system’ prevent … ignition’

1 The cement that was supposed to 6 7 2 The cement and valve at the bottom

stop oil and gas reaching the well pipe of the drill pipe failed to stop oil and gas

casing did not work. The report blames bursting into the well pipe

the type of cement used

5

Well pipe metal Float collar Well

casing (one-way valve) pipe

Cement fills and shoe track

Deepwater Horizon Report: ‘If fluids cement

‘annulus’ gap had been diverted

rig

overboard … Shoe

d track

ile

consequences

i led may have been

Fa

Fa reduced’

Oil and gas Oil and gas

Riser

3 Staff misread a key pressure test 4 Oil and gas were now pouring up the

thinking high readings were an error well, but it took 40 minutes for this to be

noticed

20 April 8.50pm 4 Riser carries oil to rig

Report: ‘Rig crew

d

ile did not recognise

Fa the influx’

Oil and gas flowing

Key test involved filling the unnoticed

kill line to check pressure

on the drill. Because the Blowout

line was blocked, no fluids preventer il ed

escaped - leading staff to

assume everything

Fa

was working correctly

8 20 April 9.56pm

Report:

20 April 7.55pm 3 ‘Weaknesses

Report: ‘Site in the testing

leaders reached regime and

the incorrect view’ Blowout

maintenance preventer

management’

Sea floor at 5,000 feet

5 Once oil and gas started flooding to 6 The oil and gas ‘vented directly on to

the surface, they were not diverted the rig’. This made an explosion was

overboard but swept on to the rig inevitable

Drill pipe

ed il ed

il Fa

Fa

Cloud of gas spreads

around the rig and under

Oil and gas the deck

should have

been directed

overboard

7 The fire prevention system on the rig 8 The ‘failsafe’ blowout preventer

failed. The report says the ‘heating, (BOP) failed. Fire on the rig stopped it

ventilation and air conditioning system being remotely shut down, while an

… transferred a gas-rich mixture into the automated system also failed. The BOP

engine rooms’. Two huge explosions had flat batteries in one control pod and

followed, killing 11 crew members a faulty solenoid valve in another

il ed

Fa

Gas ignites,

destroying the rig

il ed

Fa

Oil-bearing rock at 18,000 feet

19 April 7.30pm–12.36am 1 Multiple cutoff

Report: ‘There were devices should

weaknesses in cement 2 have shut off the

design’ 20 April 4.50pm flow of oil and gas

Report: ‘The investigation automatically

team identified … failure’

SOURCE: BP DRAWINGS NOT TO SCALE

Вам также может понравиться

- Deepwater Horizon TragedyДокумент21 страницаDeepwater Horizon Tragedypeach5Оценок пока нет

- Deepwater Horizon Oil SpillДокумент24 страницыDeepwater Horizon Oil SpillRaymundo AlarconОценок пока нет

- Project Failure - Deepwater Horizon and The BP Oil SpillДокумент10 страницProject Failure - Deepwater Horizon and The BP Oil SpillDawn Mixon-Holding100% (6)

- Deepwater Horizon Oil SpillДокумент26 страницDeepwater Horizon Oil Spilleddy9881100% (2)

- Deepwater Horizon (TermPaper)Документ7 страницDeepwater Horizon (TermPaper)Marion AlyssaОценок пока нет

- Full ReportДокумент398 страницFull ReportHouston Chronicle100% (1)

- Behaviouralstudybpdeepwaterhorizon 140108130100 Phpapp02Документ14 страницBehaviouralstudybpdeepwaterhorizon 140108130100 Phpapp02frisbeeeОценок пока нет

- Macondo Report 20042011Документ33 страницыMacondo Report 20042011Dr K GallowglaichОценок пока нет

- Cement Lining of PipesДокумент28 страницCement Lining of PipesvenkyОценок пока нет

- Risk Assessment (BP Deepwater Horizon Disaster)Документ25 страницRisk Assessment (BP Deepwater Horizon Disaster)Muhammad Sajid Saeed100% (12)

- Lessons Learned (Overfilling Vessels)Документ5 страницLessons Learned (Overfilling Vessels)kanakarao1Оценок пока нет

- BP Oil Spill Research PaperДокумент22 страницыBP Oil Spill Research PaperJeanОценок пока нет

- Exxon Valdez Oil SpillДокумент75 страницExxon Valdez Oil SpillProtect Florida's BeachesОценок пока нет

- 2 TB Davies Toolbox Talk Working at HeightДокумент30 страниц2 TB Davies Toolbox Talk Working at HeightMelv CookОценок пока нет

- 01 3 Introduction To Surface ProductionДокумент14 страниц01 3 Introduction To Surface ProductionFrancis RayeОценок пока нет

- Single-Trip Tubing-Conveyed Perforating, Production Testing, and Pressure-Buildup Testing in Nonflowing WellsДокумент5 страницSingle-Trip Tubing-Conveyed Perforating, Production Testing, and Pressure-Buildup Testing in Nonflowing Wellsabbas1368Оценок пока нет

- NSFMW 2001, Jade Paper1D, KZanker, US Letter SizeДокумент14 страницNSFMW 2001, Jade Paper1D, KZanker, US Letter Sizejose luisОценок пока нет

- COD100 Non Power Auto Drain-MANUAL BOOKДокумент26 страницCOD100 Non Power Auto Drain-MANUAL BOOKRizkyОценок пока нет

- Bs Sheet 1Документ10 страницBs Sheet 1Aarushi ParateОценок пока нет

- Horizontal Wells Production Logging: Monitoring of Multi-Phase Flow in Horizontal WellsДокумент12 страницHorizontal Wells Production Logging: Monitoring of Multi-Phase Flow in Horizontal WellsNoureddine AbidОценок пока нет

- Column Internals ImagesДокумент10 страницColumn Internals ImagespandianvijaybharathiОценок пока нет

- SPE Reelwell Drilling MethodДокумент9 страницSPE Reelwell Drilling Methodraj kumarОценок пока нет

- Surface Equipment - What To InspectДокумент42 страницыSurface Equipment - What To InspectAllen CheahОценок пока нет

- Basic Drilling Fluids and Casing Running Process Course 1664680810Документ60 страницBasic Drilling Fluids and Casing Running Process Course 1664680810Clau BustamanteОценок пока нет

- SPIJ - Flow 04 ProductionДокумент20 страницSPIJ - Flow 04 ProductionPandu Priyo Pambudi MbeОценок пока нет

- Oil and Gas ProductionДокумент38 страницOil and Gas ProductionArun Kumar PОценок пока нет

- 4.1.1 HAZOP Worksheet-Ammonia Unit-Raw - India ProjectДокумент116 страниц4.1.1 HAZOP Worksheet-Ammonia Unit-Raw - India Projectsafety pt pcsОценок пока нет

- PWOG-HZL-6033-PR-RE-004 - Draft - Pressure Loss CalculationДокумент2 страницыPWOG-HZL-6033-PR-RE-004 - Draft - Pressure Loss CalculationpavanОценок пока нет

- Mar FlexДокумент33 страницыMar FlexAshutosh MaiidОценок пока нет

- Pd-Va.4 (1996)Документ15 страницPd-Va.4 (1996)Santiago GarciaОценок пока нет

- Shell & Tube Heat Exchanger (STHE) Overpressure Protection From Tube RuptureДокумент33 страницыShell & Tube Heat Exchanger (STHE) Overpressure Protection From Tube RuptureMohamed Sayed AbdoОценок пока нет

- ABC Guide To Temporary PipeworkДокумент84 страницыABC Guide To Temporary PipeworkDamian RampersadОценок пока нет

- Sps and Wetwell NTL 3Документ1 страницаSps and Wetwell NTL 3Project ManagerStructuresОценок пока нет

- L1 - FPSO IntroductionДокумент32 страницыL1 - FPSO IntroductionZulkamal RoseleyОценок пока нет

- PCR 2022 PIPESIM COURSE Fundamentals Final PDFДокумент96 страницPCR 2022 PIPESIM COURSE Fundamentals Final PDFAndres MerloОценок пока нет

- Well Control Incident Report - Corralillos 112Документ5 страницWell Control Incident Report - Corralillos 112ANTONIO GARCIA HUERTAОценок пока нет

- Flare SystemsДокумент93 страницыFlare Systemssada sivaОценок пока нет

- Petroleum System Definition: Elements ProcessesДокумент29 страницPetroleum System Definition: Elements ProcessesAlameen GandelaОценок пока нет

- CI Spare ListДокумент1 страницаCI Spare ListআতীকОценок пока нет

- Cert of Leak Test - Comment ADNДокумент3 страницыCert of Leak Test - Comment ADNsrpri55Оценок пока нет

- WorldPipelines August 2015Документ182 страницыWorldPipelines August 2015Integridad de Equipos y Gestión de Activos Nelcam100% (3)

- Report of Bekasi Homebase On Job Training Program: Dimas Helmy Engineer TraineeДокумент36 страницReport of Bekasi Homebase On Job Training Program: Dimas Helmy Engineer TraineeDimas HelmyОценок пока нет

- Effect of Flow Rate On Paraffin Accumulation in Plastic, Steel, and Coated PipeДокумент5 страницEffect of Flow Rate On Paraffin Accumulation in Plastic, Steel, and Coated PipeAYAUWU LOVEDAYОценок пока нет

- Deepwater Horizon Accident Investigation Static Presentation PDFДокумент39 страницDeepwater Horizon Accident Investigation Static Presentation PDFbaguvix borlaloyОценок пока нет

- Vessel Volume & Area CalcДокумент5 страницVessel Volume & Area CalcgagilamОценок пока нет

- 1 Driller Log, Mud Log, Cutting Log RevДокумент45 страниц1 Driller Log, Mud Log, Cutting Log RevAri Natama100% (1)

- Pressure Drop Calculation Equations For PIPING and PIPELINEДокумент6 страницPressure Drop Calculation Equations For PIPING and PIPELINEpavijayaОценок пока нет

- Mud Programs and Drilling Problems Pertaining To 4$? %'@Документ12 страницMud Programs and Drilling Problems Pertaining To 4$? %'@SyafiqОценок пока нет

- Well AssessmentДокумент1 страницаWell Assessmentcool cooperyОценок пока нет

- Pressure DropДокумент5 страницPressure Dropalexmuchmure2158Оценок пока нет

- Materi Uts EnminДокумент23 страницыMateri Uts EnminChristian Jhonson NapitupuluОценок пока нет

- Working Drawing V 04Документ1 страницаWorking Drawing V 04Jean-Pierre CarlierОценок пока нет

- Lifting Appliances Maintenance PlanДокумент32 страницыLifting Appliances Maintenance PlanAndrej KoОценок пока нет

- AAPG Exercise - Prospect Analysis and VolumetricsДокумент35 страницAAPG Exercise - Prospect Analysis and VolumetricsrkolarskyОценок пока нет

- PROPOSAL 20180 IrirДокумент70 страницPROPOSAL 20180 IrirSabariyantoОценок пока нет

- Process Flow Diagram Magod Fusion Technologies PVT LTDДокумент2 страницыProcess Flow Diagram Magod Fusion Technologies PVT LTDSamadhan MoreОценок пока нет

- Company Profile PT - PHE-WMOДокумент30 страницCompany Profile PT - PHE-WMOHendri Anur100% (2)

- 8138 Turbine Inspection Report 2Документ14 страниц8138 Turbine Inspection Report 2ArabyAbdel Hamed SadekОценок пока нет

- Borescope Sample Report PDFДокумент14 страницBorescope Sample Report PDFWalter TrajadaОценок пока нет

- 13 Trap PrimerДокумент6 страниц13 Trap PrimerJavier Enrique Diaz ChacinОценок пока нет

- San Serriffe, 1977Документ7 страницSan Serriffe, 1977SimonRogersGuardianОценок пока нет

- Carbon Emissions by Country, 2009Документ1 страницаCarbon Emissions by Country, 2009SimonRogersGuardianОценок пока нет

- US 2012 Elections GuideДокумент1 страницаUS 2012 Elections GuideSimonRogersGuardian100% (1)

- Public Spending 2009/10 by UK Government DepartmentДокумент1 страницаPublic Spending 2009/10 by UK Government DepartmentSimonRogersGuardianОценок пока нет

- Population Change Across The UK, 2009Документ1 страницаPopulation Change Across The UK, 2009SimonRogersGuardianОценок пока нет

- Mortality of The British Army, 1858Документ58 страницMortality of The British Army, 1858SimonRogersGuardian100% (2)

- September 7, 1940 - First Night of The London BlitzДокумент1 страницаSeptember 7, 1940 - First Night of The London BlitzSimonRogersGuardian50% (2)

- Public Spending by UK Government DepartmentДокумент1 страницаPublic Spending by UK Government DepartmentSimonRogersGuardianОценок пока нет

- Afghanistan IED Attacks - 2006 To 2009Документ1 страницаAfghanistan IED Attacks - 2006 To 2009SimonRogersGuardian100% (3)

- Afghan Fallen: The 300Документ1 страницаAfghan Fallen: The 300SimonRogersGuardianОценок пока нет

- UNHCR Refugee Statistics 2010Документ1 страницаUNHCR Refugee Statistics 2010SimonRogersGuardian100% (1)

- David Cameron's CabinetДокумент1 страницаDavid Cameron's CabinetSimonRogersGuardianОценок пока нет

- The Deficit MountainДокумент1 страницаThe Deficit MountainSimonRogersGuardianОценок пока нет

- How Unequal Is Britain?Документ1 страницаHow Unequal Is Britain?SimonRogersGuardian100% (3)

- Carbon EmissionsДокумент1 страницаCarbon EmissionsSimonRogersGuardian67% (3)

- ADM-FR-003 Student Directory FormДокумент2 страницыADM-FR-003 Student Directory FormRahayuОценок пока нет

- 329 Cryogenic Valves September 2016Документ8 страниц329 Cryogenic Valves September 2016TututSlengeanTapiSopanОценок пока нет

- Site AnalysisДокумент4 страницыSite AnalysisS O NALОценок пока нет

- Shakespeare Ubd Unit PlanДокумент16 страницShakespeare Ubd Unit Planapi-239477809Оценок пока нет

- Harmonica IntroДокумент5 страницHarmonica Introapi-26593142100% (1)

- Balfour Castle EstateДокумент20 страницBalfour Castle EstatejahumphriesОценок пока нет

- VtmsДокумент2 страницыVtmsLorenz YatcoОценок пока нет

- Linberg V MakatiДокумент2 страницыLinberg V MakatiChimney sweepОценок пока нет

- Product Management Software Director in Austin TX Resume Chad ThreetДокумент2 страницыProduct Management Software Director in Austin TX Resume Chad ThreetChad ThreetОценок пока нет

- IRDM Assignment-I PDFДокумент4 страницыIRDM Assignment-I PDFPiyush AggarwalОценок пока нет

- The Little MermaidДокумент6 страницThe Little MermaidBobbie LittleОценок пока нет

- Lagundi/Dangla (Vitex Negundo)Документ2 страницыLagundi/Dangla (Vitex Negundo)Derrick Yson (Mangga Han)Оценок пока нет

- Chapter 3 Rotation and Revolution NotesДокумент12 страницChapter 3 Rotation and Revolution NotesMERLIN ANTHONYОценок пока нет

- Head and Neck Seminal Papers From Tata HospitalДокумент29 страницHead and Neck Seminal Papers From Tata HospitalSudhir NairОценок пока нет

- FeCl3 Msds - VISCOSITYДокумент9 страницFeCl3 Msds - VISCOSITYramkesh rathaurОценок пока нет

- (FORD) Manual de Propietario Ford Ranger 1998Документ160 страниц(FORD) Manual de Propietario Ford Ranger 1998Marly Salas GonzalezОценок пока нет

- G5 Series User ManualДокумент22 страницыG5 Series User ManualDaniel MekonnenОценок пока нет

- Waste SM4500-NH3Документ10 страницWaste SM4500-NH3Sara ÖZGENОценок пока нет

- 01 Childrenswear Safety Manual 2009 - ClothingДокумент57 страниц01 Childrenswear Safety Manual 2009 - Clothingmorshed_mahamud705538% (8)

- Lecture # 3 Introduction To JqueryДокумент88 страницLecture # 3 Introduction To JqueryDanial AhmadОценок пока нет

- OXE Training - Complete (2011)Документ94 страницыOXE Training - Complete (2011)Dhexter Villa75% (4)

- Differentialequations, Dynamicalsystemsandlinearalgebra Hirsch, Smale2Документ186 страницDifferentialequations, Dynamicalsystemsandlinearalgebra Hirsch, Smale2integrationbyparths671Оценок пока нет

- Basic Definition of Manufacturing SystemДокумент18 страницBasic Definition of Manufacturing SystemRavenjoy ArcegaОценок пока нет

- 3500 Ha027988 7Документ384 страницы3500 Ha027988 7Gigi ZitoОценок пока нет

- 17 Samss 518Документ20 страниц17 Samss 518Mohamed H. ShedidОценок пока нет

- Alma Matter SpeechДокумент1 страницаAlma Matter Speechlariza gallegoОценок пока нет

- Concept of InsuranceДокумент4 страницыConcept of InsuranceNazrul HoqueОценок пока нет

- Data Mining With Apriori AlgorithmДокумент12 страницData Mining With Apriori AlgorithmMAYANK JAINОценок пока нет

- Robotech Hannibal Digital 114dpi V1.0Документ119 страницRobotech Hannibal Digital 114dpi V1.0nonfarb14thОценок пока нет

- Macroeconomics Measurement: Part 2: Measurement of National IncomeДокумент13 страницMacroeconomics Measurement: Part 2: Measurement of National IncomeManish NepaliОценок пока нет