Академический Документы

Профессиональный Документы

Культура Документы

Pem PDF

Загружено:

kishanОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Pem PDF

Загружено:

kishanАвторское право:

Доступные форматы

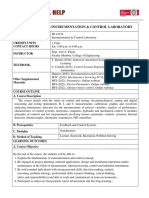

GUJARAT TECHNOLOGICAL UNIVERSITY

INSTRUMENTATION & CONTROL ENGINEERING (17)

PROJECT ENGINEERING & MANAGEMENT

SUBJECT CODE: 2181704

B.E. 8th SEMESTER

Type of course: Core Engineering

Prerequisite: Sensor/ transducer, field transmitters, converters, final control element, basic

instrumentation symbols, process control modes and techniques, Computer based control system

architecture

Rationale: For Instrumentation and Control engineer it is very important to know the kind of

standard documents available in manufacturing processes along with necessary design, test and

calibration procedure. This subject will help student to understand the project procedures and

various stages of project like planning, estimation, designing, installation, testing, calibration and

commissioning of instruments and systems. Last topic of the syllabus will introduce student with

quality manufacturing process.

Teaching and Examination Scheme:

Teaching Scheme Credits Examination Marks Total

L T P C TheoryMarks PracticalMarks Marks

ESE PA(M) ESE (V) PA

(E) PA ALA ESE OEP (I)

4 0 2 6 70 20 10 20 10 20 150

Content:

S. N. Content Total %

Hrs Weigh

tage

1 Introduction to project management 04 08

Definition of project purpose - Scope, time, quality and organization structure. Basic

and detailed engineering: Degree of automation, Project S curves, manpower

considerations, inter-department and inter-organization interactions, Multi agency

interaction. Types of projects and types of contracts e.g. EPC, BOOT etc.

2 Project management functions 04 08

Controlling, directing, project authority, responsibility, accountability, interpersonal

influences and standard communication formats, project reviews. project planning and

scheduling, life project engineering and management cycle phases, the statement of

work (SOW), projects specifications, bar charts, milestones, schedules, work

breakdown structures, cost breakdown structures and planning cycle.

3 Project cost and estimation 04 08

Types and estimates, pricing process, salary and other overheads, man-hours,

materials and support costs. program evaluation and review techniques (PERT) and

critical path method (CPM), estimating activity time and total program time, total

PERT/CPM planning crash times, software‘s used in project management.

4 Instrument Project Control 08 15

Project engineering documents and drawing: Process flow sheets, Mechanical flow

sheets, Instrument index sheets, loop wiring diagram, panel drawings and

specifications, plot plans, installation details, special drawings, purchase requisition,

other documents.

Information required: Process information, Instrument specifications and standards,

piping specifications, Electrical specifications, bid documents, Project procedure,

project schedule, Equipment Information, Vendor drawing

Work coordination: Project manager, process engineer, equipment engineer, Piping

design supervisor, Structural, architectural and civil, Electrical, purchasing and

expediting and others

Planning hints and Project check list

5 Engineering Design criteria 08 15

Pneumatic versus electronics system, Control centers, Future and spare capacity

Specifications for various measurement and control groups: Flow, Pressure,

Level, Temperature, Control valves, Control panels, Analytical instruments

Transmission systems: Pneumatic & Electronic – Materials, Distribution,

Terminations and Identification

Process connections – Take-offs and Piping, Location of taps, Sealing instruments

from process, Manifolds and gage valves

Miscellaneous Design Criteria: Mounting instruments, Selections of units, charts,

ranges; Instrument identification, Winterizing, Material of construction, Package

equipment systems

Electrical safety: NEC code, Purging and pressurization, Enclosures, Intrinsic safety

6 Selecting Measurement Methods and Control valves 15 29

Flow Instruments: Differentials meters, Rotameters, Magnetic meters, Turbine

meters, Target meters, Vortex meters, Positive displacement meters, Primary elements

for Differential meters

Level Instruments: Displacement type, Differential pressure type, Capacitance type,

ultrasonic types, Radiation types, and Miscellaneous type

Pressure Instruments: Manometers, Bourdon elements, Bellows, Diaphragm, Strain

gauges, Chemical seals

Temperature Instruments: Filled systems, thermocouples, RTDs, Thermister,

Bimetallic thermometers, Optical and Radiation pyrometers,

Miscellaneous types: Pyrometric cones, Temperature sensitive materials, Quartz

crystal thermometers, Temperature switch selection

Control valve Selection: Pressure drop requirement, capacity requirement, Valve

rangeability, Choosing the flow characteristic, Choosing body design, Single seat

versus Double seat construction, Selection of actuators, Use of valve positioner,

Selection of other mechanical features, Manifolds, Split ranging control valve, Valve

noise problem, Special purpose valves

7 Construction and Start up 06 12

Organizing: Documents, schedule, cost control

Ordering and Receiving equipment and Material: Purchase orders, Material status,

storage

Installing instrument systems: Procedures, Coordination, Good installation practices

Calibration

Testing: Process connections, Pneumatic lines, Electrical

Loop checking: Flow transmitter , Temperature transmitter, Control valve,

Miscellaneous checks

Startup: Placing instruments in service, Tuning loop controls, evaluating process

upsets and disturbances, Repairing or replacing defective equipment, special

equipment, Additional control

8 Introduction to International quality systems - ISO 9000 03 05

Quality management practices worldwide, certifying agencies.

Quality, customers and ISO 9000

ISO 9000- A management overview

ISO 9000- Quality system

Inspection, Test standards and Calibration

Suggested Specification table with Marks (Theory):

Distribution of Theory Marks

R Level U Level A Level N Level E Level C Level

14 14 14 14 14 0

Legends: R: Remembrance; U: Understanding; A: Application, N: Analyze and E: Evaluate C: Create and

above Levels (Revised Bloom’s Taxonomy)

Note: This specification table shall be treated as a general guideline for students and teachers. The actual

distribution of marks in the question paper may vary slightly from above table.

Text Books

1. Applied Instrumentation in Process Industries by W.G. Andrew and H.B. Williams, Gulf Professional

Publishing, 3rd ed. 2008, ISBN-13: 978-0872010475.

2. Project management: A systems approach to planning scheduling and controlling by Harlod Kerzner and

Van Nostrand, John Wiley & Sons, 11th ed., 2013, ISBN: 978-1-118-02227-6.

3. Successful Instrumentation & Control Systems Design, by Michael D. Whitt, 2nd Edition, 2012, ISA,

ISBN: 978-1-93600-745-5.

4. ISO- 9000 Concepts, Methods & Implementation by Tapan B. Bagchi, Wheeler pub., 1995.

ISBN-81-85814-24-4

5. ISO- 9000 Guidelines for the chemical & process industries : By ASQC ( American Society of

Quality Control ) , ISBN-13: 978-0873893527, www.asq.org

Reference Books:

Instrument Engineers Handbook: Process Control by Bela G Liptak, CRC Press, 3rd ed., 1995, ISBN-

13: 978-0801982422.

Course Outcome:

After learning the course the students should be able to:

CO1 estimate different types of projects and its management.

CO2 design different documents and evaluate tools to be used.

CO3 prepare different instrumentation documents.

List of Experiments:

1) Study of standards and symbols (ANSI / ISA Std.)

2) Study of specification sheets.

3) Development of Process & Instrument diagram of typical process.

4) Development of Loop Wiring diagram.

5) Cable scheduling.

6) GA and mimic diagram of a control panel.

7) Development of Bar charts for certain project.

8) Prepare the cost estimation sheet for the project under consideration

9) Hands on experience for engineering management software such as MS Project, Primavera, etc.

10) Designing of control valve for liquid/gas/vapor applications as per standard

11) Design of orifice plates for liquid/gas/vapor as per ISO 5167

12) Operating range calculation for transmitters considering different applications.

Design based Problems (DP)/Open Ended Problem:

Consider a typical manufacturing process. For that start from estimation to commissioning stage of

instrumentation system, prepare detail report comprising of sample design calculations, justification for

selection of instruments and systems, work flow diagram and manpower estimation, necessary engineering

diagrams, test and operating procedure, etc.

Major Equipment:

Field instruments (includes sensor/ transducers, transmitters, single loop controllers, Converters, control

valve, etc.) for flow, level, pressure, temperature parameters.

Test and calibration instruments at least for temperature and pressure parameters.

List of Open Source Software/learning website:

http://vlab.co.in/

www.isa.org

http://nptel.ac.in/video.php

http://www.idc-online.com/

ACTIVE LEARNING ASSIGNMENTS: Preparation of power-point slides, which include videos,

animations, pictures, graphics for better understanding theory and practical work – The faculty will allocate

chapters/ parts of chapters to groups of students so that the entire syllabus to be covered. The power-point

slides should be put up on the web-site of the College/ Institute, along with the names of the students of the

group, the name of the faculty, Department and College on the first slide. The best three works should

submit to GTU.

Вам также может понравиться

- Gujarat Technological University: Page 1 of 4Документ4 страницыGujarat Technological University: Page 1 of 4Aniket SafariОценок пока нет

- Pi 1Документ4 страницыPi 1Rutu ThakkarОценок пока нет

- SyllabusДокумент10 страницSyllabusroy rockОценок пока нет

- EE606-N Industrial InstrumentationДокумент4 страницыEE606-N Industrial InstrumentationJohn sonОценок пока нет

- NewSyllabus 954201771301586Документ3 страницыNewSyllabus 954201771301586Htat Myat AungОценок пока нет

- Instrument & Control EngineerДокумент7 страницInstrument & Control EngineerRidwan Dwi SОценок пока нет

- 2160503Документ3 страницы2160503Yash MadlaniОценок пока нет

- CEM Syllabus (GTURanker - Com)Документ4 страницыCEM Syllabus (GTURanker - Com)VARSHAОценок пока нет

- Course Syllabus Instrumentation Control Lab.Документ3 страницыCourse Syllabus Instrumentation Control Lab.Monique OrugaОценок пока нет

- SQAT Theory CHOДокумент9 страницSQAT Theory CHOUjjwal PraveenОценок пока нет

- Gujarat Technological University: Page 1 of 3Документ3 страницыGujarat Technological University: Page 1 of 3jpbhimaniОценок пока нет

- PMP SummaryДокумент7 страницPMP SummaryHuzaifa AliОценок пока нет

- Gujarat Technological UniversityДокумент3 страницыGujarat Technological UniversityPreeti VarmaОценок пока нет

- Software Testing Life CycleДокумент127 страницSoftware Testing Life CycleKunal AhireОценок пока нет

- Applied Mathematics, Applied Physics, Engineering Graphics, Manufacturing Technology-IIДокумент5 страницApplied Mathematics, Applied Physics, Engineering Graphics, Manufacturing Technology-IIPRASENJIT MUKHERJEEОценок пока нет

- CSE320 Lecture0Документ34 страницыCSE320 Lecture0naman vermaОценок пока нет

- Basic DesignДокумент18 страницBasic DesignM AhmadОценок пока нет

- CEB ResearchДокумент2 страницыCEB ResearchSaira Arish BukhariОценок пока нет

- Project Engineering in Oil & Gas Industry SharedДокумент24 страницыProject Engineering in Oil & Gas Industry SharedKojiro Hadate100% (3)

- Gujarat Technological University: W.E.F. AY 2018-19Документ3 страницыGujarat Technological University: W.E.F. AY 2018-19Hardik SonvaneОценок пока нет

- Deploying Defect AnalysisДокумент41 страницаDeploying Defect AnalysispriyaspvОценок пока нет

- CLD 20202 Process Instrumentation: Miss Nur Shahirah Mohd Aripen Ext: 2152Документ16 страницCLD 20202 Process Instrumentation: Miss Nur Shahirah Mohd Aripen Ext: 2152Faiz HassanОценок пока нет

- Course Curriculum: Uttar PradeshДокумент3 страницыCourse Curriculum: Uttar PradeshHtat Myat AungОценок пока нет

- Gujarat Technological University: Page 1 of 4Документ4 страницыGujarat Technological University: Page 1 of 4KSghОценок пока нет

- Gujarat Technological University - MeasurementДокумент4 страницыGujarat Technological University - MeasurementA SОценок пока нет

- Basic & Detail Engineering ServicesДокумент9 страницBasic & Detail Engineering ServicesbondreОценок пока нет

- ANDT - Student PanelДокумент7 страницANDT - Student Panelma.8840936885Оценок пока нет

- Project Standards and Specifications Process Control Package Rev01Документ10 страницProject Standards and Specifications Process Control Package Rev01Ahmad EmamОценок пока нет

- Metrology-and-Measurement-Laboratory-Manual ReferenceДокумент32 страницыMetrology-and-Measurement-Laboratory-Manual Referencechandrarao chОценок пока нет

- Introduction To MetrologyДокумент26 страницIntroduction To MetrologyDimon HeОценок пока нет

- BEng ME Module SynopsisДокумент4 страницыBEng ME Module SynopsisjeffreymacaseroОценок пока нет

- Chapter 1Документ40 страницChapter 1Hadeer AlbalushiОценок пока нет

- Mechanical Measurement and MetrologyДокумент2 страницыMechanical Measurement and MetrologyNarayanarao PalagaraОценок пока нет

- Chemical and Process Plant Commissioning Handbook: A Practical Guide to Plant System and Equipment Installation and CommissioningОт EverandChemical and Process Plant Commissioning Handbook: A Practical Guide to Plant System and Equipment Installation and CommissioningОценок пока нет

- ASHRAE Standard 202 - Commissioning Buildings - Schneider ElectricДокумент6 страницASHRAE Standard 202 - Commissioning Buildings - Schneider Electricangel_rojas_38Оценок пока нет

- Auditando Un Sistema ValidacionДокумент8 страницAuditando Un Sistema ValidacionIglesias LauraОценок пока нет

- Process and Instrumentation Diagram DevelopmentДокумент14 страницProcess and Instrumentation Diagram DevelopmentATUL SONAWANEОценок пока нет

- CV - E I SupervisorДокумент3 страницыCV - E I Supervisorabdullah100% (1)

- Metrlogy CurriculumДокумент3 страницыMetrlogy CurriculumDj GAMINGОценок пока нет

- Procedure System and Software Assessment STQC May14Документ13 страницProcedure System and Software Assessment STQC May14xhacksnОценок пока нет

- Compiled Syllabus SEM VI IC MSE II 2017-1Документ7 страницCompiled Syllabus SEM VI IC MSE II 2017-1Shubham AgrawalОценок пока нет

- Unit 32 Building Services Control SystemsДокумент12 страницUnit 32 Building Services Control Systemsk c tomОценок пока нет

- PROJECT STANDARDS and SPECIFICATIONS Instrumentation Project Engineering Rev01Документ20 страницPROJECT STANDARDS and SPECIFICATIONS Instrumentation Project Engineering Rev01Laurence Malanum50% (2)

- Quality Control Quality Assurance SystemДокумент48 страницQuality Control Quality Assurance SystemOnujabe Abdulmajeed100% (1)

- 15ee553 Estimation and CostingДокумент153 страницы15ee553 Estimation and CostingMohammed Sabeel KinggОценок пока нет

- DataДокумент85 страницDatasaquib hasanОценок пока нет

- AU 6th SEM - AU 21-22071021124330Документ12 страницAU 6th SEM - AU 21-22071021124330Sumit VermaОценок пока нет

- Gujarat Technological University: Mechanical (Cad/Cam) (08) / Mechanical (Machine Design) (09) SUBJECT CODE: 2740804Документ3 страницыGujarat Technological University: Mechanical (Cad/Cam) (08) / Mechanical (Machine Design) (09) SUBJECT CODE: 2740804N NandiniОценок пока нет

- Modern Power Generation PlantДокумент3 страницыModern Power Generation PlantNirbhayОценок пока нет

- K101-QC-PL.001 - Quality Plan - Rev 0 PDFДокумент85 страницK101-QC-PL.001 - Quality Plan - Rev 0 PDFberthitasОценок пока нет

- Tool EvaluationiДокумент10 страницTool EvaluationiPreeti GuptaОценок пока нет

- BVM Engineering College (An Autonomous Institution)Документ3 страницыBVM Engineering College (An Autonomous Institution)Prabhat SinghОценок пока нет

- Chemical Engineering & Plant DesignДокумент7 страницChemical Engineering & Plant DesignnuncafalhaОценок пока нет

- Tender Bulletin 05 Attachment #1 Project Deliverables & Requirements...Документ26 страницTender Bulletin 05 Attachment #1 Project Deliverables & Requirements...Hamza ShujaОценок пока нет

- Guidelines For The Quality Assurance Plan ChecklistДокумент8 страницGuidelines For The Quality Assurance Plan ChecklistManish PatelОценок пока нет

- ABSA - Pressure Piping Fabrication Requirement & QC Seminar - Selected PagesДокумент69 страницABSA - Pressure Piping Fabrication Requirement & QC Seminar - Selected PagesBhaiJan59100% (4)

- SMM Course HandoutДокумент23 страницыSMM Course HandoutMohammed IsmailОценок пока нет

- Managing the Testing Process: Practical Tools and Techniques for Managing Hardware and Software TestingОт EverandManaging the Testing Process: Practical Tools and Techniques for Managing Hardware and Software TestingРейтинг: 4 из 5 звезд4/5 (8)

- Exam Cram Essentials Last-Minute Guide to Ace the PMP Exam: First EditionОт EverandExam Cram Essentials Last-Minute Guide to Ace the PMP Exam: First EditionОценок пока нет

- Boiler Performance & Technical Data JT-K13467-E01-0Документ15 страницBoiler Performance & Technical Data JT-K13467-E01-0Puntanata Siagian0% (1)

- Dose Response StudiesДокумент2 страницыDose Response StudiesSooraj Rajasekharan KarthaОценок пока нет

- PD Cen TR 15314 2006 (En)Документ16 страницPD Cen TR 15314 2006 (En)Ramzi BEN AHMEDОценок пока нет

- T040032 00Документ17 страницT040032 00Doanh HoangОценок пока нет

- ErДокумент27 страницErAsif UllahОценок пока нет

- Design of A Gauge MetrologyДокумент8 страницDesign of A Gauge MetrologyQuality HosurОценок пока нет

- Some Interesting Facts About: Mechanical EngineeringДокумент9 страницSome Interesting Facts About: Mechanical EngineeringHaraprasad SОценок пока нет

- Solutions To 7.012 Problem Set 1Документ4 страницыSolutions To 7.012 Problem Set 1attiqueОценок пока нет

- DocumentДокумент89 страницDocumentRajeev Sharma100% (1)

- Ethylene Ethanol DEE H2O: Senyawa Input Reaktor Output Reaktor KG/HR Kmol/hr KG/HRДокумент11 страницEthylene Ethanol DEE H2O: Senyawa Input Reaktor Output Reaktor KG/HR Kmol/hr KG/HRyohanamd14Оценок пока нет

- Rohs Material Confirmation CertificateДокумент2 страницыRohs Material Confirmation Certificateimtiyaz aliОценок пока нет

- 01-Experiment-The Effect of PH On Food PreservativeДокумент9 страниц01-Experiment-The Effect of PH On Food Preservativejul.cotrimОценок пока нет

- Polyester Process Brochure PDFДокумент16 страницPolyester Process Brochure PDFtexpartОценок пока нет

- Revision Notes On Heat TransferДокумент11 страницRevision Notes On Heat TransferAnonymous vRpzQ2BLОценок пока нет

- Poster NAM Reyna-2Документ1 страницаPoster NAM Reyna-2omarОценок пока нет

- De Thi Hoc Sinh Gioi Lop 9 Mon Tieng Anh Huyen Vinh Phuc Nam 2013 2014Документ5 страницDe Thi Hoc Sinh Gioi Lop 9 Mon Tieng Anh Huyen Vinh Phuc Nam 2013 2014Hồng NhungОценок пока нет

- S102.C.0814 - TestMaster Line Card - Rs PDFДокумент2 страницыS102.C.0814 - TestMaster Line Card - Rs PDFGeLoRa66Оценок пока нет

- Evolution of Oilfield BatteriesДокумент16 страницEvolution of Oilfield BatteriesPasquale CutriОценок пока нет

- What Is A BatteryДокумент2 страницыWhat Is A Batteryshahzad444Оценок пока нет

- Installation Manual - Brazed Heat Exchangers - UK PDFДокумент2 страницыInstallation Manual - Brazed Heat Exchangers - UK PDFesteban vasquezОценок пока нет

- 2010 enДокумент12 страниц2010 encristi_mt100% (1)

- Hensotherm 820ks PDFДокумент4 страницыHensotherm 820ks PDFglendatpОценок пока нет

- Sika PDS E Intraplast ZXДокумент2 страницыSika PDS E Intraplast ZXlwin_oo2435Оценок пока нет

- Dehydration ProcessesДокумент43 страницыDehydration ProcessesKatib Sultan100% (6)

- Sla PC Data SheetДокумент2 страницыSla PC Data Sheettejashraj93Оценок пока нет

- Volume 1Документ378 страницVolume 1Avinash RajuОценок пока нет

- MetallurgyДокумент2 страницыMetallurgygjabyОценок пока нет

- Isotropic Electrical Sheet Steel Under GOST 21427.2-83, ASTM A677A677M-89, EN 10106-96Документ2 страницыIsotropic Electrical Sheet Steel Under GOST 21427.2-83, ASTM A677A677M-89, EN 10106-96mindphaserОценок пока нет

- Illumionation ExamДокумент4 страницыIllumionation ExamRegie NojaldaОценок пока нет

- Experiment 3: Gravimetric Analysis of Chloride Salt: + (Aq) - (Aq) (S)Документ4 страницыExperiment 3: Gravimetric Analysis of Chloride Salt: + (Aq) - (Aq) (S)bianca uyОценок пока нет