Академический Документы

Профессиональный Документы

Культура Документы

Specs 1270-33 18 X 18

Загружено:

Hery Mardiono HeryОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Specs 1270-33 18 X 18

Загружено:

Hery Mardiono HeryАвторское право:

Доступные форматы

0127D1818033H

4 April 2016

Page 1 of 22

SPECIFICATIONS

FOR

ELLICOTT

STANDARD SERIES 1270 CUTTERHEAD DREDGE

18” x 18”

33 FOOT (10 M) DIGGING DEPTH

© ELLICOTT DREDGES, LLC - 2016

Ellicott is a registered trademark of Ellicott Dredges, LLC

0127D1818033H

4 April 2016

Page 2 of 22

TABLE OF CONTENTS

SECTION DESCRIPTION PAGE

1 GENERAL DESCRIPTION ................................................. 3

2 STRUCTURAL COMPONENTS

A. Hull ............................................................................... 5

B. Deckhouse and Control Center .................................... 5

3 DREDGING COMPONENTS

A. Cutter-Excavating Unit ................................................. 6

B. Pipe and Accessories ................................................... 6

C. Ladder and Supports .................................................... 7

D. Dredge Pump and Accessories .................................... 8

E. Spuds ........................................................................... 8

F. Swing Winches ............................................................. 9

G. Spud Winches .............................................................. 9

4 PRIME MOVERS ................................................................ 10

5 HYDRAULIC POWER SYSTEM ......................................... 11

6 ELECTRICAL SYSTEM ...................................................... 12

7 CONTROL CENTER AND OPERATING CONTROLS ....... 13

8 MISCELLANEOUS EQUIPMENT ...................................... 14

9 INSTRUCTION MANUALS ................................................. 15

10 PAINTING ........................................................................... 16

11 SHOP ASSEMBLY AND TESTING .................................... 17

12 FIELD ASSEMBLY AND FIELD TESTING ......................... 18

13 SUMMARY ........................................................................ 19

14 PRINCIPAL DIMENSIONS AND PARTICULARS............... 20-21

Ellicott is a registered trademark of Ellicott Dredges, LLC

0127D1818033H

4 April 2016

Page 3 of 22

1. GENERAL DESCRIPTION:

This Series, non-self-propelled transportable hydraulic pipeline cutterhead

dredge has been designed in accordance with Ellicott Dredges, LLC’s standard

practices for dredging service.

The dredge has been designed so that the operating cycle is controlled by one

man from the control center in the control room.

Wearing parts which require accessibility for replacement or repair are

designed and built for ease of assembly and economic replacement cost. Wearing

parts are independent of the structural components of the dredge in order to maintain

correct alignment of the machinery after installation and replacement.

The sectional pontoon type rectangular hull has been sized to meet the

requirements for strength and flotation and also provides the versatility that is

inherent in transportable equipment. The dredge is designed to be partially field

assembled on land and launched with final assembly afloat. Disassembly is

accomplished partially afloat and partially on land.

The main dredging plant is installed in the center hull pontoon and has been

designed for rugged use and durability.

The tubular steel dredging ladder mounted on the forward end of the center

hull pontoon carries the revolving cutter for excavating the materials to be dredged.

The variable speed, constant torque cutter is hydraulically driven and the

cutter drive assembly is mounted on the forward section of the ladder. The suction

pipe is mounted underneath and secured to the tubular ladder. A flexible connection

is provided between the ladder suction pipe and the hull.

A diesel driven, centrifugal dredging pump discharges materials to a floating

pipeline connected at the stern of the dredge.

When operating, the dredge swings across the cut, pivoting on the large cross

section working spud. The swing operation is accomplished with individual Ellicott

direct line winches. An A-frame and winch system does the ladder hoisting

operation. The spuds are single-part wire rope bottom-lift type actuated by individual

winches with provision for freefall.

Ellicott is a registered trademark of Ellicott Dredges, LLC

0127D1818033H

4 April 2016

Page 4 of 22

1. GENERAL DESCRIPTION: (Continued)

Ample diesel power drives hydraulic pumps which supply hydraulic fluid

through separate circuits to the respective hydraulic motors driving the cutter, the

swing and spud winches and the ladder hoist winch.

An electric generator, integrally mounted on the auxiliary engine, is included to

provide D.C. power for lighting for around-the-clock operation.

A fully enclosed control center with windows on all sides and operator's

console for fingertip control, is included.

Ellicott is a registered trademark of Ellicott Dredges, LLC

0127D1818033H

4 April 2016

Page 5 of 22

2. STRUCTURAL COMPONENTS:

A. HULL:

The hull is made up of rectangular welded steel pontoons, which are rigidly

connected to provide stability and ample freeboard. The hull components are

generally transversely framed but also have longitudinal stiffeners. Foundations are

provided under all machinery and the hull structure is reinforced in the way of these

foundations.

The removable, watertight side pontoons are compartmented and attached to

the center section by special watertight connections that are accessible from the

exterior of the hull.

The assembled hull provides for a ladder-well at the forward end to

accommodate the assembled ladder.

Each of the side pontoons has built-in fuel oil storage and water ballast tanks

provided with limbers and vents to prevent formation of air pockets.

Manholes are provided in the side pontoon, water or oil tight as required.

Deck cleats are suitably located on the hull.

The hull shell plating thickness and stiffener sizes meet the requirements of

the American Bureau of Shipping Rules for Building and Classing Steel Vessels for

Service on Rivers and Intracoastal Waterways.

B. DECKHOUSE AND CONTROL CENTER:

The deckhouse side panels are fabricated from 3/16 inch thick steel and the

overhead panels and control center are fabricated from 12 gauge steel. Steel

hatches in the overhead panels are provided for equipment access. Full head room

and adequate, safe and weatherproof working space around all machinery is

provided to facilitate maintenance. The deckhouse has sliding windows for light and

ventilation and a side entrance doorway for access. Forced ventilation of the

deckhouse is accomplished by the fan cooled auxiliary engine.

A control center is mounted forward of the deckhouse. The low profile design

includes windows on all four sides for full view of the dredging operation. The front

window is sloped to minimize reflections and all windows are tinted to minimize

daytime glare. The control room is fabricated in one piece with disconnect fittings on

all piping and controls and can be removed intact for shipping. A door on each side

is provided for outside access from the main deck. A door is also provided for access

from the control room to the machinery space.

Functional design and construction provides comfort and conditions favorable

to increased operator efficiency.

Ellicott is a registered trademark of Ellicott Dredges, LLC

0127D1818033H

4 April 2016

Page 6 of 22

3. DREDGING COMPONENTS:

A. CUTTER-EXCAVATOR UNIT:

The compact cutter-excavating unit, with direct hydraulic power drive, is an

exclusive design and is complete with cutter. The construction facilitates adjusting

the angle of the cutter unit for shallow digging by means of rotating the wedge-

shaped structural tubular insert. The cutter is suitable for general dredging.

The cutter is driven by a radial piston type, watertight hydraulic motor through

a planetary speed reducer. This assembly is an integral part of the forward ladder

section with the motor, gears and bearings protected by a positive oil pressure

maintained inside the oiltight and watertight assembly. Constant torque available at

each digging speed is a design feature. Speed and reversing are controlled at the

operator's console in the control center. The entire system is protected from

overloads by relief valves.

The short main cutter shaft is of high tensile steel, machined all over,

operating on tapered roller bearings in an oiltight housing. The shaft is driven by the

hydraulic motor through the gear reducer. All connections to the gear reducer are

splined.

B. PIPE AND ACCESSORIES:

The cast steel suction hood is connected to the ladder under the cutter shaft

hub to reduce water dilution from above the suction hood and thereby obtain a

greater concentration of slurry feeding into the suction pipe. The hood is jointed to

the suction piping and the suction pipe is attached to the underside of the ladder.

The suction pipe is equipped with a cast steel cleanout just ahead of the

dredge pump to allow for removal of oversized material obstructing the pump.

An enclosed cast steel flap valve is installed in the discharge pipeline

immediately aft of the discharge elbow. When the pump is stopped, the flap valve

acts as a check valve and obstructs the slurry in the discharge pipe from returning to

the pump. Additionally, the flap valve assists in the pump priming operation by

effectively obstructing the discharge line.

A rubber sleeve or flanged flexible hose is available as an extra cost option to

connect the hull mounted discharge piping to the floating discharge pipeline. The

flanged flexible hose includes a jib crane for support.

Ellicott is a registered trademark of Ellicott Dredges, LLC

0127D1818033H

4 April 2016

Page 7 of 22

An optional swivel elbow, available at extra cost, can be located at the stern of

the dredge and serves as a flexible connection between the hull mounted discharge

pipe and the floating discharge pipeline. This unit consists of two (2) cast steel 90

degree elbows fixed together with a watertight connection so as to allow

approximately 60 degrees horizontal angular movement to the port and starboard of

the centerline of the hull mounted discharge pipe.

C. LADDER AND SUPPORTS:

The ladder has been designed to meet the strength requirements of dredging

service and to provide reliability and durability under rugged and severe conditions.

The aft section of the ladder is fabricated from structural steel plates for bending and

torsional strength. The forward section of the ladder is constructed from large

diameter structural steel pipe. Together they insure the necessary rigidity for

stabilizing the cutting action so as to be able to exert full cutter force on the material

being dredged.

The ladder hoist consists of an A-frame mounted at front end of the hull and

hydraulic winch mounted on the platform at the end of the ladder. The winch is

actuated by means of a fingertip lever control on the control console.

Steel safety straps for fixing the ladder in a raised position for towing and

maintenance are included.

Fabricated steel trunnions with replaceable bushings are fitted to the aft end of

the ladder. A connection for the ladder is provided by pins through the steel

trunnions and trunnion bearing brackets on the main hull.

The ladder suction pipe is connected to the suction pipe in the center hull

pontoon by means of a flexible reinforced rubber hose, permitting ladder inclination to

designed digging depth.

Swing sheaves with anti-friction bearings are provided. These swing sheaves

are mounted on the ladder just aft of the cutter module and are so designed as to

reduce wear and jamming of the swing wires and provide a direct fairlead to the

swing drums. Bronze bushed cast steel fleeting sheaves mounted just forward of the

swing drums provide a fairlead for the swing ropes onto the drums.

Ellicott is a registered trademark of Ellicott Dredges, LLC

0127D1818033H

4 April 2016

Page 8 of 22

D. DREDGE PUMP AND ACCESSORIES:

The dredge pump has been designed and built by Ellicott Dredges, LLC, for

high hydraulic efficiency for the desired range of dredging conditions. The pump is

so placed in the dredge hull as to insure minimum friction in the suction and

discharge piping by avoiding all unnecessary bends, elbows, fittings and other

restrictions to flow.

The pump is of the centrifugal, single suction, volute type, directly driven by

diesel power through an Ellicott close-coupled totally enclosed, oil lubricated, speed

reduction gear. The direct mechanical connection, from crankshaft to impeller,

features high torsional strength through all pump operating speeds. A hydraulically

actuated clutch is provided between the engine and reduction gear.

The pump case and impeller are made of Ni-Hard IV or high chrome-carbide

alloy cast iron with a minimum Brinell of 500, but normally in excess of 600. The side

heads have renewable abrasion-resisting cast liners of chrome-carbide with the same

Brinell. The impeller is of the latest Ellicott design with three (3) blades and an 8.4

inch (213mm) theoretical particle clearance. Patented* recessed expeller vanes are

an Ellicott feature on the impeller shrouds for low wear and high efficiency. The

suction side head and the entrance to the impeller are protected from wear by means

of a renewable throat piece of chrome-carbide or Ni-Hard IV.

The impeller shaft is of high tensile steel. A stainless steel sleeve is provided

on the shaft where it passes through the pump stuffing box. The impeller shaft is an

integral part of the totally enclosed reduction gear.

A flexible coupling connects the diesel engine to the input shaft of the speed

reduction gear. The radial and thrust loads on the pump shaft are carried by anti-

friction bearings completely enclosed in the reduction gear assembly.

A pump priming system with required piping is provided.

E. SPUDS:

Two (2) tubular spuds with steel points are furnished for dredging to designed

depth. The spuds are designed for single-part wire rope bottom-lift and are raised by

individual single-drum winches with freefall provision for good spud penetration.

Fingertip lever controls are provided on the control console for raising and lowering

the spuds. The entire system is protected from overload by relief valves.

* U.S. Patent No. 3,535,051

Four (4) spud keepers, two (2) for each spud, are attached at the stern to the

top and bottom of the center hull. Gates are provided in each keeper with pin

connections to facilitate insertion and removal of spuds.

Ellicott is a registered trademark of Ellicott Dredges, LLC

0127D1818033H

4 April 2016

Page 9 of 22

F. SWING WINCHES:

The Ellicott Series 1270 direct line winches for swinging of the dredge are

arranged for efficient power transmission. The winch units are mounted on the

ladder to eliminate unnecessary sheaves and blocks, thus increasing efficiency while

reducing cable wear and are in view of the operator and readily accessible for

maintenance.

The winches are directly driven by radial piston hydraulic motors through a

splined shaft connection. Motor speed control and reversing are by means of

fingertip controls at the operator's control console. The motors are protected from

overload by relief valves. The winches are designed to provide safe, smooth

operation under all conditions of speed and power from the driving hydraulic motors.

The two (2) winch drums are of cast steel and are supported by anti-friction

bearings. Provision is made for hydraulic braking during operation and a pawl

locking device is provided for mooring.

G. SPUD WINCHES:

The spud winches are individual units each driven by a hydraulic motor

through a totally enclosed planetary reduction gearing. Each winch has an

automatic, hydraulically operated, totally enclosed, oil immersed, disc type brake for

holding the load and in addition, the winches incorporate totally enclosed, oil

immersed, disc type, freefall clutches for good spud penetration.

Each winch is arranged for control by fingertip levers at the operator's console.

Ellicott is a registered trademark of Ellicott Dredges, LLC

0127D1818033H

4 April 2016

Page 10 of 22

4. PRIME MOVERS:

The Series 1270 "DRAGON" is equipped with two (2) diesel engines as

follows:

TYPE RATING SERVICE STARTING COOLING

CAT C32 1000HP Continuous Dredge Electric Heat

Marine EPA Marine Tier 2 Pump Exchanger

& IMO Tier 1

CAT C9 350HP Intermittent Hydraulic Electric Radiator

EPA/CARB Tier 3 &

EU Stage IIIA

All engines are equipped with instrument panels with essential instruments.

Automatic shutdown for high water temperature, low oil pressure and low hydraulic oil

level is provided for the hydraulic pump engine while additional remote reading

gauges for water temperature and oil pressure are provided at the control center for

the dredge pump engine. Engines are warranted at the horsepower rating shown in

accordance with the manufacturer's recommendation for the service application.

Ellicott is a registered trademark of Ellicott Dredges, LLC

0127D1818033H

4 April 2016

Page 11 of 22

5. HYDRAULIC POWER SYSTEM:

The hydraulic system is made up of four (4) independent open loop circuits:

one circuit each for the cutter, the ladder hoist and swing winches, spud winches and

control pressure.

Two (2) single and one (1) multiple section gear pumps provide oil pressure

for:

a) The piston type hydraulic motor in the cutter circuit. Speed

control of approximately 60% of the speed range of the cutter is

attainable with maximum torque available at all speeds.

b) The piston type hydraulic motors in the swing winch circuit.

These motors are in series with the ladder hoist cylinders.

Speed control of one hundred percent (100%) of the speed

range of the winches is attainable with maximum torque

available at all speeds.

c) The hydraulic motor in each spud winch.

d) The freefall brake release circuit for each spud winch.

The pumps draw oil directly from the oil reservoir through a magnetic strainer.

Oil is returned to the reservoir through a heat exchanger and filter.

Features of the system include: wide range of speeds by means of flow

control; full torque or line pull available at all speeds; reversing control; demand

regulated pressure; and heat dissipation by means of an efficient oil cooling system.

Ellicott is a registered trademark of Ellicott Dredges, LLC

0127D1818033H

4 April 2016

Page 12 of 22

6. ELECTRICAL SYSTEM:

The electrical system is designed to provide for the following circuits:

a) 24 volt starting system on the engines.

b) Battery recharging system.

c) Dredge pump and auxiliary engine gauges and shutdown.

d) Non-glare, variable intensity, indirect dial illumination on the control

console.

e) Solenoid operated hydraulic control valves.

f) 24 volt internal and external lighting system with watertight fixtures

consisting of incandescent lighting in machinery and control spaces;

floodlights for illumination of the forward dredging and spud areas;

service outlets.

Ellicott is a registered trademark of Ellicott Dredges, LLC

0127D1818033H

4 April 2016

Page 13 of 22

7. CONTROL CENTER AND OPERATING CONTROLS:

The controls have been designed and mounted on the console in the control

center to provide for one-man operation of the dredging sequence.

The planned built-in comfort features of the control center combat operator

fatigue and prolong working efficiency.

The following specific controls and indicating instruments are provided:

Forward - off - reverse controls for cutter.

Speed control for cutter.

Forward - off - reverse controls for each swing winch.

Speed control for the swing winch/ladder hoist circuit.

Hydraulic braking control for each swing winch.

Raise - lower control for ladder.

Raise - lower and freefall control for each spud winch.

Cutter hydraulic circuit pressure gauge.

Swing winch hydraulic circuit pressure gauge.

Pump engine throttle.

Pump engine display.

Service water pressure gauge.

A dredging depth indicator visible from the control center is mounted at the

dredging ladder.

Starting, shutdown and clutch controls are adjacent to or on all engines, in

accordance with standard safety practices.

Ellicott is a registered trademark of Ellicott Dredges, LLC

0127D1818033H

4 April 2016

Page 14 of 22

8. MISCELLANEOUS EQUIPMENT

The dredge shall have auxiliary support equipment on board as follows:

a. Sea chest and strainers.

b. One service water pump, belt driven from the dredge pump engine to

provide water pressure for:

1. Dredge pump gland seal

2. Dredge pump priming

3. Cooling of lubrication and hydraulic oil

4. Dredge pump engine cooling

c. Main deck hand rail

d. Starting batteries and cables

e. Safety equipment (ABC fire extinguishers, life vests, life rings).

The following miscellaneous equipment is available at extra cost:

a. Portable fire and bilge pump

b. Wire rope

c. Swing anchors

d. Impeller lifting hook

e. Jib crane over pump

f. Stern jib crane

g. Rubber sleeve, flanged flexible hose, or discharge swivel elbow

h. Tool kit

i. Production Metering System

Ellicott is a registered trademark of Ellicott Dredges, LLC

0127D1818033H

4 April 2016

Page 15 of 22

9. INSTRUCTION MANUALS:

Two (2) sets of manuals shall be provided in the English language, each

including the following:

• Instructions giving the frequency and specifications for lubrication of the

equipment.

• Illustrated assembly drawings with part numbers for Ellicott Dredges, LLC

manufactured equipment.

• Parts list and available literature for principal equipment purchased by

Ellicott Dredges, LLC.

Ellicott is a registered trademark of Ellicott Dredges, LLC

0127D1818033H

4 April 2016

Page 16 of 22

10. PAINTING:

The dredge shall be painted according to Ellicott Dredges, LLC’s standard

schedule. The hull (consisting of the center tank and all side tanks) shall be

sandblasted before painting. The hull shall be blasted internally and externally to a

commercial grade (SSPC-SP-6). All other steel work will be wire brushed and

thoroughly cleaned of loose mill scale, rust, oil or other foreign matter before painting.

The hull shall be given one (1) coat of Carbomastic 15 or equal on the interior

and exterior of 5 mils thickness and an additional coat of Carboline D890 or equal on

the exterior of 5 mils thickness.

All fuel compartments shall receive one (1) coat of a fuel oil resistant

elastomer coating (minimum thickness 1.0 mils).

All other surfaces shall receive a primer coat of five (5) mils thickness of

Carbomastic 15 or equal and a finish coat of five (5) mils thickness of Carboline D890

or equal.

The primer coat will be allowed to dry thoroughly and harden before

application of the finish coat. Carbomastic 15 is a high solids aluminum epoxy

mastic. Carboline D890 is a high solids epoxy polyamide.

Ellicott is a registered trademark of Ellicott Dredges, LLC

0127D1818033H

4 April 2016

Page 17 of 22

11. SHOP ASSEMBLY AND TESTING:

The shop assembly and testing is necessarily limited to the machinery

modules which are assembled in the shop and which shall be tested as far as

practical under no-load or simulated load conditions.

The dredge pump, reduction gear and main engine cannot be tested until the

dredge hull is completely assembled and launched.

The hull tanks will be individually tested for watertightness.

The hydraulic system will be shop tested to insure proper installation and

control. Final testing of complete hydraulic power systems will be done after

launching.

Ellicott is a registered trademark of Ellicott Dredges, LLC

0127D1818033H

4 April 2016

Page 18 of 22

12. FIELD ASSEMBLY AND FIELD TESTING:

The field assembly of a transportable dredge requires proper preparation of

launching and assembly site in the field upon or before the arrival of the dredge

components at the site. Complete field assembly and launching instructions will be

provided.

A trained Field Engineer is available to assist the Purchaser's crew in the

supervision of the field assembly. He can also supervise the following operations:

a) The final check of the dredge pump, reduction gear and main

engine after the dredge has been launched and is afloat with all

major machinery installed.

b) The testing of the diesel engine driven hydraulic power drives

installed on the center hull tank, including inspection of the piping

connections to the cutter drive, the ladder hydraulic hoist

cylinders and operational test of the complete hydraulic system

to insure proper functioning and performance.

c) Test operation of dredge pump, cutter, winches and controls.

These operations can be completed quickly and at minimum cost provided the

Purchaser has adequate tools and a sufficient crew of the appropriate skills available.

The costs for the Field Engineer plus all other costs and charges in connection

with field assembly, alignment and testing in the field shall be at the expense of the

Purchaser and are not included in the contract price unless otherwise agreed.

Ellicott is a registered trademark of Ellicott Dredges, LLC

0127D1818033H

4 April 2016

Page 19 of 22

13. SUMMARY

All the machinery described in these specifications is coordinated to form a

balanced operating unit.

All materials and machinery components will be new and the workmanship

shall be of high order.

It is the policy of the manufacturer to make continual improvements in the

design and manufacture of our products; therefore, the right is reserved to modify

these specifications to provide for the use of any such improvements, which may

have been developed prior to the time of actual manufacture.

Ellicott is a registered trademark of Ellicott Dredges, LLC

0127D1818033H

4 April 2016

Page 20 of 22

ELLICOTT SERIES 1270 "DRAGON"

33 FT DIGGING DEPTH MODEL 0127D1818033H

14. PRINCIPAL DIMENSIONS AND PARTICULARS

HULL:

Length, Feet (m) 68 (20.73)

Width, Feet (m) 30 (9.14)

Depth, Feet (m) 4-1/2 (1.37)

Weight, Approximate Pounds (kg)

(Including Main Deckhouse) 90,000 (40,823)

Plate Thickness, Inches (mm)

Hull and Bulkheads Up to 3/8 (9.5)

Reinforcing Up to 3/4 (19)

Basic Frame Spacing, Feet (m) 4 (1.2)

PRIME MOVERS:

Dredge Pump Engine (CAT C32) HP (kW)

Continuous 1000 (746)

Auxiliary Engine (CAT C9) HP (kW)

Intermittent 350 (260)

CUTTER-BASKET TYPE:

Shaft Horsepower (kW) 155 (116)

Speed Range, RPM Approximate 29 - 42

Cutting Force, Approximate

Total Pounds (kg) 7,991 (3,625)

Pounds Per Linear Inch (kg/cm) 214 (97)

Head Mean Diameter, Inches (mm) 54 (1,372)

Number of Blades 6

Number of Motors 1

Head Weight, Pounds (kg) 2770 (1256)

SWING WINCH: (TWO)

Shaft Horsepower (kW) 49 (36.5)

Line Speed - ft/min (m/min) )first 0-103 (0-31.5)

Line Pull - Pounds (kg) )layer 15,000 (6,804)

Wire Size - Inches (mm) 5/8 (15.9)

Drum Capacity - Ft. of Wire (m) 400 (122)

Ellicott is a registered trademark of Ellicott Dredges, LLC

0127D1818033H

4 April 2016

Page 21 of 22

ELLICOTT SERIES 1270 "DRAGON"

33 FT DIGGING DEPTH MODEL 0127D1818050H

14. PRINCIPAL DIMENSIONS AND PARTICULARS (CONT.)

LADDER HOIST:

Shaft Horsepower (kW) 42 (31)

Line Speed - ft/min (m/min) )first 61.4 (18.7)

Line Pull - Pounds (kg) )layer 19,703 (8937)

Wire Size - Inches (mm) 3/4 (19)

SPUD WINCHES: (TWO)

Shaft Horsepower (kW) 46.6 (34.75)

Line Speed - ft/min (m/min) )first 50.2 (15.3)

Line Pull - Pounds (kg) )layer 26,738 (12,128)

Wire Size - Inches (mm) 7/8 (22)

GENERAL:

Mean Draft, Operating Condition -

Approximate Feet (m) 2.83 (0.86)

Digging Depth, Feet (m) Maximum 33 (10.0)

Fuel Oil Capacity -

Gallons (Liters) 10,600 (40,125)

Suction Pipe

Inches (mm) 18 (457)

Discharge Pipe

Inches (mm) 18 (457)

Ladder Length, Feet Approximate (m) 59.6 (18.2)

WEIGHTS - POUNDS (Kg): (Approximate)

Total Assembly Dry Weight 221,000 (100,244)

Center Hull Complete

(With Machinery) 90,000 (40,824)

Ladder 35,000 (15,875)

Spuds - Each 10,456 (4,742)

Control Room 2,500 (1,130)

Dredge Pump Casing 4,200 (1,190)

Dredge Pump Engine (Bare) 9,700 (4,400)

Dredge Pump Reduction Gear

(Including Clutch) 6,100 (2,767)

Ellicott is a registered trademark of Ellicott Dredges, LLC

0127D1818033H

4 April 2016

Page 22 of 22

The above specifications are approximate and subject to change because of

improvements in the design, modifications required during construction or addition of

equipment not described in these specifications.

Ellicott is a registered trademark of Ellicott Dredges, LLC

Вам также может понравиться

- Dual Displacement Radial Piston Staffa Motors: Certified Company ISO 9001 - 14001Документ74 страницыDual Displacement Radial Piston Staffa Motors: Certified Company ISO 9001 - 14001Usama Popatia100% (1)

- HS - Marine KatalogДокумент20 страницHS - Marine KatalogGogyОценок пока нет

- Alatas S51394 (W) Inspection Report MV Sveti Vlaho Feb 08Документ15 страницAlatas S51394 (W) Inspection Report MV Sveti Vlaho Feb 08Faraz AhmedОценок пока нет

- Hyd Inc SwivelsДокумент140 страницHyd Inc SwivelsCentral HydraulicsОценок пока нет

- Masina de Carma - HydrosterДокумент10 страницMasina de Carma - HydrosterMaria100% (1)

- CH165A-AB: 13,700 LB First Layer Line PullДокумент2 страницыCH165A-AB: 13,700 LB First Layer Line Pulliyan supriadiОценок пока нет

- Spare Parts Manual: 6.2.2 Crane House AssemblyДокумент2 страницыSpare Parts Manual: 6.2.2 Crane House AssemblyZdravko LovićОценок пока нет

- GrabДокумент15 страницGrabvihaanОценок пока нет

- SAI - GM Tech CatalogДокумент54 страницыSAI - GM Tech CatalogBoban SimicОценок пока нет

- Protecciones EmdДокумент8 страницProtecciones EmdHANSELL MIRANDA ALVAОценок пока нет

- HRP Thruster Systems: Instruction Manual ForДокумент28 страницHRP Thruster Systems: Instruction Manual ForMustafa GözütokОценок пока нет

- Braden Winch CH 230-2Документ2 страницыBraden Winch CH 230-2wessamalexОценок пока нет

- Conmaco 385 Winch ManualДокумент44 страницыConmaco 385 Winch ManualdarioОценок пока нет

- Single Rope Timber Grab - OPERATION MANUALДокумент12 страницSingle Rope Timber Grab - OPERATION MANUALSlamet SusantoОценок пока нет

- SKF Hydraulic NutsДокумент220 страницSKF Hydraulic NutsPieter van der MeerОценок пока нет

- InstallationManual Azipull RRM000341953 54Документ3 страницыInstallationManual Azipull RRM000341953 54Maricel Hincu0% (1)

- DFM54 EngДокумент2 страницыDFM54 EngAnonymous KWO434Оценок пока нет

- Viking: Product ManualДокумент26 страницViking: Product ManualCristian RobiconОценок пока нет

- Beaver 45 - Especificaão TécnicaДокумент2 страницыBeaver 45 - Especificaão TécnicaLenin ValerioОценок пока нет

- HMC080 KawasakiДокумент12 страницHMC080 KawasakiEDB50% (2)

- 420 Mobile Piston Pump Design Code CДокумент41 страница420 Mobile Piston Pump Design Code CFernando Sabino100% (1)

- 007 Niigata Power SystemДокумент2 страницы007 Niigata Power SystemRamos KristinouvОценок пока нет

- FДокумент66 страницFpandunugraha04Оценок пока нет

- PZH (PZ-8) Pump Parts List AF 19002011Документ25 страницPZH (PZ-8) Pump Parts List AF 19002011mantilla7Оценок пока нет

- V222TI Operation & Maintenance ManualДокумент294 страницыV222TI Operation & Maintenance ManualLisandroОценок пока нет

- EVK Seal ManualДокумент18 страницEVK Seal Manualgelo_17100% (1)

- Yanmar 5 KDL Manual BookДокумент56 страницYanmar 5 KDL Manual Bookaleshas453Оценок пока нет

- M-38 Stern Tube SealsДокумент246 страницM-38 Stern Tube SealsMehmet AGAGÜNDÜZОценок пока нет

- TTS Hose Handling CranesДокумент4 страницыTTS Hose Handling CranesCaptIsqanОценок пока нет

- 02 - Operation Instructions - Stern RollerДокумент15 страниц02 - Operation Instructions - Stern Rollermiguel100% (1)

- Slipway Winch - Aimix Marine Slipway Winch For SaleДокумент13 страницSlipway Winch - Aimix Marine Slipway Winch For SaleJf LarongОценок пока нет

- Spare Parts 3.100 KCДокумент28 страницSpare Parts 3.100 KCGogaОценок пока нет

- T ISS PX01 Instruction Manual Rev.01Документ9 страницT ISS PX01 Instruction Manual Rev.01Louis Marino100% (1)

- Braden: 2Nd Generation "CH" Series Planetary HoistsДокумент44 страницыBraden: 2Nd Generation "CH" Series Planetary HoistsBook Valencia100% (1)

- Arneson Surface Drives CatalogueДокумент12 страницArneson Surface Drives CatalogueWoodsy12Оценок пока нет

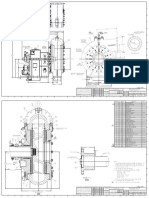

- 3.7 - 1270 Pump Assy - 15114504Документ2 страницы3.7 - 1270 Pump Assy - 15114504Hery Mardiono HeryОценок пока нет

- Technical Analysis of Kort Nozzle Application ForДокумент7 страницTechnical Analysis of Kort Nozzle Application ForMuhammad KamranОценок пока нет

- Marine Hydraulic Telescopic Crane YSQ 1250-3t/9mДокумент24 страницыMarine Hydraulic Telescopic Crane YSQ 1250-3t/9mAndriy Goloborodko0% (1)

- PUSNES Deck Machinery Installation ProcedureДокумент18 страницPUSNES Deck Machinery Installation ProcedurexatzaraОценок пока нет

- Cat 3408c Gen SetДокумент4 страницыCat 3408c Gen Setshinichie100% (1)

- 4 Marine Design Machining TENMATДокумент49 страниц4 Marine Design Machining TENMATWalter JosephОценок пока нет

- FUKUSHIMA Hydraulic Deck MachineryДокумент26 страницFUKUSHIMA Hydraulic Deck MachinerypcatruongОценок пока нет

- Instructions For JDN Bop Handling Systems T Y P E S B H 4 0 - B H 2 0 0Документ10 страницInstructions For JDN Bop Handling Systems T Y P E S B H 4 0 - B H 2 0 0Reda El-AwadyОценок пока нет

- Anchor-Capstan Winch Manual YN513301Документ62 страницыAnchor-Capstan Winch Manual YN513301phankhoa83-1100% (1)

- ML Couplings Instruction ManualДокумент4 страницыML Couplings Instruction ManualGer BosОценок пока нет

- SB LT32575Документ14 страницSB LT32575zzapiecheОценок пока нет

- Masterpact NT NW InglesДокумент204 страницыMasterpact NT NW InglesLuís LulaОценок пока нет

- Merchant - Condensing Unit For Ac PDFДокумент14 страницMerchant - Condensing Unit For Ac PDFAmmar RamanОценок пока нет

- ZOLLERN-Broschuere ZAT Drewerksgetriebe ENGДокумент20 страницZOLLERN-Broschuere ZAT Drewerksgetriebe ENGMomin G.S.100% (1)

- DM 625 Technical SpecДокумент4 страницыDM 625 Technical SpecPrashant PoudelОценок пока нет

- HLRM90 5SДокумент2 страницыHLRM90 5SAna HafidzОценок пока нет

- CRT 350 Interlock Panel User ManualДокумент74 страницыCRT 350 Interlock Panel User ManualAliHabesОценок пока нет

- Bombas AllweilerДокумент14 страницBombas AllweilerCARLOS ANDRES CARVAJAL SUAREZОценок пока нет

- IPU Spring Starter PDFДокумент6 страницIPU Spring Starter PDFHumberto Mateus Becerra100% (1)

- Owners Manual ENGДокумент86 страницOwners Manual ENGНиколайОценок пока нет

- UL - General Fact Sheet - November 2005Документ2 страницыUL - General Fact Sheet - November 2005RICROD71Оценок пока нет

- Boxcooler ManualДокумент18 страницBoxcooler Manualhpss77Оценок пока нет

- 01 - Main Engines 2003Документ328 страниц01 - Main Engines 2003Grid Lock100% (1)

- Conreting Record 15Документ2 страницыConreting Record 15Hery Mardiono HeryОценок пока нет

- B - 670 Pump PerformanceДокумент1 страницаB - 670 Pump PerformanceHery Mardiono HeryОценок пока нет

- Frame Section CДокумент1 страницаFrame Section CHery Mardiono HeryОценок пока нет

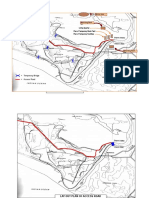

- Rangka Baja Peluncur Dredger-Layout3Документ1 страницаRangka Baja Peluncur Dredger-Layout3Hery Mardiono HeryОценок пока нет

- You Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterДокумент1 страницаYou Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterHery Mardiono HeryОценок пока нет

- Living Quarter Plan of Temporary Stock YardДокумент2 страницыLiving Quarter Plan of Temporary Stock YardHery Mardiono HeryОценок пока нет

- Recommended Stock Spare Parts For Dredge Series 370: Ellicott Dredges, LLCДокумент1 страницаRecommended Stock Spare Parts For Dredge Series 370: Ellicott Dredges, LLCHery Mardiono HeryОценок пока нет

- 450mm Booster Pump GA - 15394000Документ4 страницы450mm Booster Pump GA - 15394000Hery Mardiono HeryОценок пока нет

- Dsi-Usa Dywidag Tie Rods Us 02Документ12 страницDsi-Usa Dywidag Tie Rods Us 02Hery Mardiono HeryОценок пока нет

- B - 370 Pump PerformanceДокумент1 страницаB - 370 Pump PerformanceHery Mardiono HeryОценок пока нет

- Denah Kasir PDFДокумент1 страницаDenah Kasir PDFHery Mardiono HeryОценок пока нет

- A - 670 Theoretical Pump PerformanceДокумент1 страницаA - 670 Theoretical Pump PerformanceHery Mardiono HeryОценок пока нет

- 3.7 - 1270 Pump Assy - 15114504 - 1 PDFДокумент2 страницы3.7 - 1270 Pump Assy - 15114504 - 1 PDFHery Mardiono HeryОценок пока нет

- C - 1270 Pump AnalysisДокумент1 страницаC - 1270 Pump AnalysisHery Mardiono HeryОценок пока нет

- 3.7 - 1270 Pump Assy - 15114504Документ2 страницы3.7 - 1270 Pump Assy - 15114504Hery Mardiono HeryОценок пока нет

- CAIP Vol II PropellersДокумент32 страницыCAIP Vol II PropellersSHM 555Оценок пока нет

- Car Ent GB E05.01Документ34 страницыCar Ent GB E05.01slawny77Оценок пока нет

- Tutorial Spur GearДокумент2 страницыTutorial Spur GearMayankVijayОценок пока нет

- Cocoa Cutting and Splitting MachineДокумент22 страницыCocoa Cutting and Splitting MachineAnil KumarОценок пока нет

- Operation Manual 1-SamgongДокумент61 страницаOperation Manual 1-Samgongdamianro1993100% (1)

- DC Servo Systems Catalog 053106Документ64 страницыDC Servo Systems Catalog 053106miencattrang878Оценок пока нет

- Oml and Omm Orbital Motors Repair InstructionsДокумент16 страницOml and Omm Orbital Motors Repair Instructionsjose manuel barroso pantojaОценок пока нет

- 500 TransДокумент5 страниц500 TransRodney WellsОценок пока нет

- Acs Lab ManualДокумент59 страницAcs Lab ManualAanshu SinghОценок пока нет

- BPB Pumps Data SheetДокумент2 страницыBPB Pumps Data Sheetkosmc123Оценок пока нет

- Machine DesignДокумент6 страницMachine DesignRishi SinghОценок пока нет

- Automatic Vacuum Cleaner PDFДокумент29 страницAutomatic Vacuum Cleaner PDFproteuscarrillusОценок пока нет

- (1922) Automobile Trade TrainingДокумент636 страниц(1922) Automobile Trade TrainingHerbert Hillary Booker 2nd100% (2)

- SYNTEC CNC Application ManualV10.0Документ155 страницSYNTEC CNC Application ManualV10.0serege0% (1)

- UnimogДокумент19 страницUnimogMichael KalbfleischОценок пока нет

- Manuel D'utilisation REDUREX Gear Unit - FLENDERДокумент128 страницManuel D'utilisation REDUREX Gear Unit - FLENDERAhmedОценок пока нет

- 04 Fault Analysis 2006Документ57 страниц04 Fault Analysis 2006peach5Оценок пока нет

- Magazine Farmax enДокумент24 страницыMagazine Farmax enAbdi LadiantoОценок пока нет

- Design and Analysis of Twin Motor Planetary Gear Drive For Dual Speed and Safety Optimization in Hoist ApplicationДокумент5 страницDesign and Analysis of Twin Motor Planetary Gear Drive For Dual Speed and Safety Optimization in Hoist ApplicationIJIRSTОценок пока нет

- Kinematics of Machinary April 2021Документ2 страницыKinematics of Machinary April 2021mighty statusОценок пока нет

- Parts Catalogue: Voltas Diesel Forklift Truck Model: DVX 506 Max at HVM Bs IiiДокумент127 страницParts Catalogue: Voltas Diesel Forklift Truck Model: DVX 506 Max at HVM Bs IiiHARI SANKAR100% (1)

- Alignment of KilnДокумент27 страницAlignment of KilnMKPashaPasha100% (5)

- Technical Catalogue B Iec Atex en Rev2Документ183 страницыTechnical Catalogue B Iec Atex en Rev2rogerОценок пока нет

- Bhs PDF en RDVДокумент10 страницBhs PDF en RDVolgiertОценок пока нет

- MERITOR Platform G 9 - 10-SpeedДокумент37 страницMERITOR Platform G 9 - 10-SpeedEvgeniiMSОценок пока нет

- FlenderTechnicalHandbook PDFДокумент79 страницFlenderTechnicalHandbook PDFWagner OliveiraОценок пока нет

- Rolling GearДокумент14 страницRolling GearRamesh SalriaОценок пока нет

- Transmission Unit 3Документ103 страницыTransmission Unit 3Ram SaaceОценок пока нет

- Me 323 - Machine Elements (6-8) ModuleДокумент35 страницMe 323 - Machine Elements (6-8) ModulePetingco, Jemimah Grace, ME2BОценок пока нет

- Citycom.300: Service ManualДокумент271 страницаCitycom.300: Service ManualAlvaro Goncalves Albornoz0% (1)