Академический Документы

Профессиональный Документы

Культура Документы

STD WPS

Загружено:

Waqas WaqasОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

STD WPS

Загружено:

Waqas WaqasАвторское право:

Доступные форматы

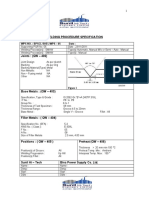

WELDING PROCEDURE SPECIFICATION (WPS)

Company Name:

WPS Number: Standard WPS No. Supporting PQRs:

Revision Number: Revision Date:

Welding Process: Shielded Metal Arc Welding (SWAW) Type: Manual

Joints (QW-402)

Joint Design: Single-V Details:

Backing: Required Backing Material Type: Weld Metal/Base Metal

Base Metals (QW-403) Filler Metals (QW-404) Root Balance

P-Number: 8 Group Number: 1 Specification Number (SFA): 5.9 5.4

to P-Number: 8 Group Number: 1 Classification: ERXXX (See below) EXXX-16 (See Below)

Thickness Range F-number: 6 5

Groove Welds: 1/16” to 8” A-Number: 8 8

Fillet Welds: All Maximum Deposited Weld

Pipe Diameter Range Metal Thickness - Groove: 8” 8”

Groove Welds: >1” O.D. - Fillet: All All

Fillet Welds: All Maximum Bead Thickness: 1/8” 3/8”

Flux Trade Name: N/A N/A

Consumable Insert: None N/A

Positions (QW-405) Postweld Heat Treatment Technique (QW-410)

(QW-407)

Welding Positions: All Temp. Range: None String or Weave Bead: Either

Welding Progression: Uphill Time Range: N/A Method of Backgouging: None

Preheat and Interpass Electrical Initial and Interpass Cleaning: Grind to re-

Temperature (QW-406) Characteristics move cutting oxide, solvent clean to remove

(QW-409) cutting oil. Grind or wire brush to remove

Minimum Preheat: 50˚F Current Type: DC slag or silica deposits.

Maximum Interpass: 350˚F* Polarity: See Table Orifice or Gas Cup Size: #4 to #12

Preheat Maintenance: Not Required Amperage: See Table Oscillation: N/A

Gas (QW-408) Electrode Feed Speed: N/A Contact Tube to Work Distance: N/A

Shielding Gas: 100% Argon Voltage: N/A Multiple or Single Pass: Either

Composition: Welding Gr. Travel Speed: See Table Multiple or Single Electrode: N/A

Flow Rate: 8-20 CFH Tungsten Type: 2% Thoria Peening: Not Permitted

Gas Backing: Ar or N at Tungsten Size: 3/32, 1/8” Other:

5-15 CFH Pulsed Current: None When welding different types of 300 series

Trailing Shield: None stainless to each other, select a filler metal

designated for both types.

Filler Metal Current Travel Other

Welding

Weld Layer Volts Speed * Base

Process Class Dia. (in) Type/Polarity Amps Filler Metal

(ipm) Metal

1 GTAW As Above 3/32 or 1/8 DCSP 60-100 2-4 304 308, 308L, 316, 316L

2 GTAW As Above 3/32 or 1/8 DCSP 70-100 2-4 304L 308L, 316, 316L

Balance SMAW As Above 3/32 DCRP 40-80 2-4 316 316, 316L

Balance SMAW As Above 1/8 DCRP 65-110 316L 316L

2-6

Balance SMAW As Above 5/32 DCRP 100-150 321,347 308L, 321

Balance SMAW As Above 3/16 DCRP 120-190 4-8 *These values are recommended

only, not mandatory

The undersigned contractor, a member of the Nation al Certified Pipe Welding Bureau, hereby adopts this

jointly developed procedure as its company Welding Procedure Specification and certifies that this

procedure has been qualified as shown on the attached Procedure Qualification Record.

Contractor:

By: Date:

Title:

Вам также может понравиться

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Документ6 страницMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)attaullaОценок пока нет

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Документ1 страницаQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345Оценок пока нет

- Welding Procedure Specification (WPS) : in The Outer TubeДокумент1 страницаWelding Procedure Specification (WPS) : in The Outer TubeMohamed AlkhawagaОценок пока нет

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateДокумент2 страницыWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad PathanОценок пока нет

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Документ1 страницаWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaОценок пока нет

- 1662 15Документ117 страниц1662 15RajamanikkamОценок пока нет

- Oil Gas Construction Factory L.L.CДокумент2 страницыOil Gas Construction Factory L.L.CRenny DevassyОценок пока нет

- SA 387 Grade 91 Class 2Документ4 страницыSA 387 Grade 91 Class 2briang-2Оценок пока нет

- GMAWДокумент12 страницGMAWsushant47Оценок пока нет

- Lithika - 001Документ1 страницаLithika - 001Harkesh RajputОценок пока нет

- Ferrite Content ReportДокумент2 страницыFerrite Content ReportJawad MunirОценок пока нет

- Pressure Vessel Material Selection GuidelinesДокумент3 страницыPressure Vessel Material Selection Guidelinesarjun SinghОценок пока нет

- Sandvik 25.22.2.Lmn: (Welding Wire)Документ3 страницыSandvik 25.22.2.Lmn: (Welding Wire)Anonymous w6TIxI0G8lОценок пока нет

- WPS for FCAW Welding of SteelДокумент2 страницыWPS for FCAW Welding of SteelHamid MansouriОценок пока нет

- Welding Procedure Specification For GTAW & GMAWДокумент4 страницыWelding Procedure Specification For GTAW & GMAWanh thoОценок пока нет

- 1035 03Документ2 страницы1035 03Anuj ShahiОценок пока нет

- NPCIL Tube Fitting SpecificationsДокумент22 страницыNPCIL Tube Fitting Specificationssumant.c.singh1694100% (1)

- ASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationДокумент2 страницыASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationAmit SharmaОценок пока нет

- WPQДокумент10 страницWPQayoki100% (3)

- Wps GT 9b Cvn90 Rev 1 PDFДокумент6 страницWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniОценок пока нет

- WPS PQR-05Документ10 страницWPS PQR-05Ranjan KumarОценок пока нет

- Form UT, MT, PT, RTДокумент5 страницForm UT, MT, PT, RTLuong Ho Vu100% (1)

- Madina Trading WPS No. 017Документ12 страницMadina Trading WPS No. 017MAT-LIONОценок пока нет

- Reliance Industries Limited Line History Sheet For CS Piping Without PWHTДокумент1 страницаReliance Industries Limited Line History Sheet For CS Piping Without PWHTRavi ShankarОценок пока нет

- Helium leak test procedureДокумент7 страницHelium leak test procedureChandrasekhar mishraОценок пока нет

- PQR DT Macro 60mm Smaw Astm A 516 Gr60Документ4 страницыPQR DT Macro 60mm Smaw Astm A 516 Gr60Boran YelkenciogluОценок пока нет

- APV STD Insp & Test Plan API6D ValvesДокумент4 страницыAPV STD Insp & Test Plan API6D ValvesdbmingoОценок пока нет

- Epoxy Coating Batch Test CertificateДокумент1 страницаEpoxy Coating Batch Test CertificateTarun KaushalОценок пока нет

- Gtaw Smaw 6 Inch 6G CSДокумент1 страницаGtaw Smaw 6 Inch 6G CSKentDemeterio100% (1)

- Heat TreatmentДокумент5 страницHeat TreatmentsheikmoinОценок пока нет

- The NEW Company ProfileДокумент26 страницThe NEW Company ProfilewisandhaОценок пока нет

- Wip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreДокумент3 страницыWip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreVijayabaraniОценок пока нет

- Bharat Petroleum Corporation Limited M/S Durgapur EquipmentsДокумент3 страницыBharat Petroleum Corporation Limited M/S Durgapur EquipmentsSatyaprakash RayОценок пока нет

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Документ2 страницыWelding Procedure Specification (WPS) : (Asme Sec. Ix)Emmanuel Loayza100% (1)

- Astm A179 PDFДокумент1 страницаAstm A179 PDFgaminОценок пока нет

- WPS 03 GtawДокумент3 страницыWPS 03 GtawBiswajit DeyОценок пока нет

- B H e L Limited RTДокумент13 страницB H e L Limited RTbhavin17850% (2)

- Made in Italy - EuropeДокумент8 страницMade in Italy - EuropeenenickОценок пока нет

- Welding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelДокумент3 страницыWelding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelBudi Setia RahmanОценок пока нет

- JIMT Visual Inspection ReportДокумент1 913 страницJIMT Visual Inspection Reportgomathyselvi100% (1)

- WPS for Welding SA-335 P11 to SA-234 WP11Документ3 страницыWPS for Welding SA-335 P11 to SA-234 WP11Ganesh rohitОценок пока нет

- 03 WPS CS 1Документ3 страницы03 WPS CS 1mohammadОценок пока нет

- Sample quality assurance plan for shell and tube heat exchangersДокумент8 страницSample quality assurance plan for shell and tube heat exchangersAjit Patil100% (1)

- JHF 610-Xgat-Mm (2006 Ac)Документ1 страницаJHF 610-Xgat-Mm (2006 Ac)Arya Bayu WibisonoОценок пока нет

- WPS PQR For S 1 S Piping 02Документ5 страницWPS PQR For S 1 S Piping 02ravi00098Оценок пока нет

- GTL WPSДокумент6 страницGTL WPSYoucef ChorfaОценок пока нет

- Summary Report Plumbness - TK - 012Документ2 страницыSummary Report Plumbness - TK - 012yuwantoniОценок пока нет

- WPS-PQR ListДокумент1 страницаWPS-PQR ListSandra SandersОценок пока нет

- Weld MapДокумент1 страницаWeld MapFerdie OSОценок пока нет

- Rapid p0030 CPP U0030 Qac Mom 0024 Quality MeetingДокумент13 страницRapid p0030 CPP U0030 Qac Mom 0024 Quality MeetingAtuk Safiz100% (1)

- Material SpecДокумент1 страницаMaterial SpecDesignОценок пока нет

- Welder Wise Repair PercentageДокумент135 страницWelder Wise Repair PercentageaakashОценок пока нет

- OCS Prel WPS 007Документ2 страницыOCS Prel WPS 007vinothОценок пока нет

- FDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Документ15 страницFDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Gisela ViskaОценок пока нет

- Technics Offshore Engineering Pte LTD: Material & Weld Traceability RecordДокумент17 страницTechnics Offshore Engineering Pte LTD: Material & Weld Traceability RecordHanuman RaoОценок пока нет

- Asme PQR DemoДокумент3 страницыAsme PQR DemoMuthusamy AyyanapillaiОценок пока нет

- Rationalise List Welding ConsumablesДокумент19 страницRationalise List Welding ConsumablesMayank SadaniОценок пока нет

- WPS 11-23-1Документ3 страницыWPS 11-23-1Anoop Raj RaoОценок пока нет

- WPS 8 To 1-3-1 Rev2 (10-1-13)Документ5 страницWPS 8 To 1-3-1 Rev2 (10-1-13)ERA SSОценок пока нет

- Balajee Tanks & Vessels: QW 482 Welding Procedure Specifications (WPS)Документ2 страницыBalajee Tanks & Vessels: QW 482 Welding Procedure Specifications (WPS)Eswara Rao BodduОценок пока нет

- Auditing Welds Under ASME IX PDFДокумент21 страницаAuditing Welds Under ASME IX PDFkbldamОценок пока нет

- W1 Material and Welding For Gas Tankers W1Документ13 страницW1 Material and Welding For Gas Tankers W1AlbertОценок пока нет

- Technical Specification for Purchase Requisition TubesДокумент1 страницаTechnical Specification for Purchase Requisition TubesWaqas WaqasОценок пока нет

- Tap & DrillДокумент1 страницаTap & DrillWaqas WaqasОценок пока нет

- Tensile TestДокумент1 страницаTensile TestWaqas WaqasОценок пока нет

- Bolt TighteningДокумент1 страницаBolt TighteningWaqas WaqasОценок пока нет

- Astm A350 LF2 PDFДокумент1 страницаAstm A350 LF2 PDFTanah Tak BertuanОценок пока нет

- ASTM E6-09b Standard Terminology Relating To Methods of Mechanical TestingДокумент27 страницASTM E6-09b Standard Terminology Relating To Methods of Mechanical TestingPacifier Nothingface0% (1)

- RFI Inspection Request for ProjectДокумент1 страницаRFI Inspection Request for ProjectWaqas WaqasОценок пока нет

- Face & Root BendДокумент1 страницаFace & Root BendWaqas WaqasОценок пока нет

- QW 381Документ1 страницаQW 381Waqas WaqasОценок пока нет

- ASME BPVC.IX-2017 welding standardsДокумент1 страницаASME BPVC.IX-2017 welding standardsWaqas WaqasОценок пока нет

- Weld Overlay Obtained by FCAW ProcessДокумент2 страницыWeld Overlay Obtained by FCAW ProcessWaqas WaqasОценок пока нет

- Procedure For Tank Shell To AnnularДокумент1 страницаProcedure For Tank Shell To AnnularWaqas WaqasОценок пока нет

- ISO IQA For DDFC by AJMAL29-04-14Документ52 страницыISO IQA For DDFC by AJMAL29-04-14Waqas WaqasОценок пока нет

- Procedure For Tank Shell To AnnularДокумент1 страницаProcedure For Tank Shell To AnnularWaqas WaqasОценок пока нет

- Welding API TankДокумент1 страницаWelding API TankWaqas WaqasОценок пока нет

- ISO IQA For DDFC by AJMAL29-04-14Документ52 страницыISO IQA For DDFC by AJMAL29-04-14Waqas WaqasОценок пока нет

- Auditing Welds Under ASME IX PDFДокумент21 страницаAuditing Welds Under ASME IX PDFkbldamОценок пока нет

- Welding Procedure SummaryДокумент1 страницаWelding Procedure SummaryWaqas WaqasОценок пока нет

- Reduced Sec. Tensile TestДокумент1 страницаReduced Sec. Tensile TestWaqas WaqasОценок пока нет

- 2010 Edition of The ASME Boiler and Pressure Vessel Code (BPVC)Документ6 страниц2010 Edition of The ASME Boiler and Pressure Vessel Code (BPVC)kangsungjinОценок пока нет

- 9.3 Qualification of WeldersДокумент1 страница9.3 Qualification of WeldersWaqas WaqasОценок пока нет

- ISO 14001 Environmental Management Systems: Training, Audit & Certification ServicesДокумент2 страницыISO 14001 Environmental Management Systems: Training, Audit & Certification ServicesWaqas WaqasОценок пока нет

- Changing AIAДокумент1 страницаChanging AIAWaqas WaqasОценок пока нет

- Dimensional Inspection Report: 175mm 150mm 55 29Документ3 страницыDimensional Inspection Report: 175mm 150mm 55 29Waqas WaqasОценок пока нет

- WPSДокумент25 страницWPSWaqas WaqasОценок пока нет

- Codes & Standards For Natural GasДокумент13 страницCodes & Standards For Natural Gasharikrishnanpd3327Оценок пока нет

- ASME MTC Types & Verification GuideДокумент47 страницASME MTC Types & Verification GuideSULTAN100% (1)

- M/S Hitesh Steel Duplex Steel Division Maharashtra IndiaДокумент10 страницM/S Hitesh Steel Duplex Steel Division Maharashtra IndiaM/S Hitesh SteelОценок пока нет

- 3Документ8 страниц3Muhammad HannanОценок пока нет

- Soldering TutorialДокумент29 страницSoldering TutorialFernando BalseiroОценок пока нет

- Focus On Caustic Stress Corrosion CrackingДокумент2 страницыFocus On Caustic Stress Corrosion Crackingcoolguy12345Оценок пока нет

- Utp Handbook InglesДокумент478 страницUtp Handbook InglesCURRITOJIMENEZ100% (1)

- Mid-Term Test: Material and Metal ProcessingДокумент8 страницMid-Term Test: Material and Metal ProcessingekanandaardiansyahОценок пока нет

- 4140 PDFДокумент28 страниц4140 PDFShariq KhanОценок пока нет

- Complete cleaning with Scale Sniper's new non-corrosive methodДокумент10 страницComplete cleaning with Scale Sniper's new non-corrosive methodGary M TrajanoОценок пока нет

- Fundamentals of Metal CastingДокумент18 страницFundamentals of Metal CastingtmcoachingcentreОценок пока нет

- Válvula Con Poste IndicadorДокумент20 страницVálvula Con Poste IndicadorAbel Enríquez RomeroОценок пока нет

- Nippon Steal Guidelines G2593R8Документ20 страницNippon Steal Guidelines G2593R8Grady HopkinsОценок пока нет

- BPVC Code Cases 5 PDFДокумент54 страницыBPVC Code Cases 5 PDFEymenОценок пока нет

- Lully's Alchemical ExperimentsДокумент8 страницLully's Alchemical ExperimentstravellerfellowОценок пока нет

- 226Документ16 страниц226Abhijeet Vardhe100% (5)

- Material Inconel 600Документ16 страницMaterial Inconel 600arvindgupta_2005100% (1)

- Mse2104 Lab06Документ6 страницMse2104 Lab06মোহাম্মদ ইসমাইল হোসেনОценок пока нет

- CTP Pistons & Kits for Diesel EnginesДокумент3 страницыCTP Pistons & Kits for Diesel EnginesMarlon Geronimo100% (1)

- TCN 02 - B1486 Painting SCH RanipetДокумент5 страницTCN 02 - B1486 Painting SCH RanipetSHIVAJI CHOUDHURYОценок пока нет

- DS BA Double Flanged Butterfly ValveДокумент5 страницDS BA Double Flanged Butterfly ValveraulОценок пока нет

- Application of Phase DiagramДокумент66 страницApplication of Phase Diagrammm11_nedОценок пока нет

- ISCAR Industries BrochureДокумент92 страницыISCAR Industries BrochureAnonymous CYdagIОценок пока нет

- A 220 - A 220M - 99 (2014) PDFДокумент5 страницA 220 - A 220M - 99 (2014) PDFأسامة وحيد الدين رمضانОценок пока нет

- Wps For Smaw06-001 (Pipe 6g CS)Документ10 страницWps For Smaw06-001 (Pipe 6g CS)walitedisonОценок пока нет

- Euro Chlor 8th Edition 2004Документ17 страницEuro Chlor 8th Edition 2004loercher01Оценок пока нет

- Dycal Tuigmrh en 1402 PDFДокумент2 страницыDycal Tuigmrh en 1402 PDFgisanuОценок пока нет

- Reaffirmed 1997Документ10 страницReaffirmed 1997Uppala Krishna ChaitanyaОценок пока нет

- EN24 and EN24T Steel: BS970: 1955 EN24, BS970/PD970: 1970 OnwardsДокумент2 страницыEN24 and EN24T Steel: BS970: 1955 EN24, BS970/PD970: 1970 OnwardsParesh Patel100% (1)

- How Are Electrons Arranged in The Atom?Документ24 страницыHow Are Electrons Arranged in The Atom?Ks WangОценок пока нет

- Steel Bars, Selection Guide, Composition, and Mechanical PropertiesДокумент9 страницSteel Bars, Selection Guide, Composition, and Mechanical Propertiesvinicius_bacellarОценок пока нет

- Iron PhosphateДокумент19 страницIron PhosphateGemaelFalestine100% (1)