Академический Документы

Профессиональный Документы

Культура Документы

Dynabolt Zinc Coated Steel Design Guide PDF

Загружено:

Shadin Asari ArabaniОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Dynabolt Zinc Coated Steel Design Guide PDF

Загружено:

Shadin Asari ArabaniАвторское право:

Доступные форматы

Dynabolt®

Zinc Coated Steel 1/4

¬ Sleeve type expansion anchor

Technical data

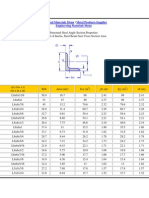

DYNABOLT Max. Max. thick Min thick Ø thread Drilling Ø drill Total Max. Eurocode

HEX NUT anchor of part to of base depth bit rod tighten

depth be fixed material length torque

(mm) (mm) (mm) (mm) (mm) (mm) (mm) (Nm)

hef tfix hmin d hO dO L Tinst

HN M6X40/8 26 8 55 M6 45 8 40 9 050234

Applications HN M6X66/30 30 30 55 M6 45 8 65 9 050235

HN M6X92/56 30 56 55 M6 45 8 90 9 050236

¬ Wall plates HN M8X49/10 34 8 65 M8 50 10 50 20 050238

¬ Porches HN M8X76/35 34 35 65 M8 50 10 75 20 050239

¬ Signs HN M8X103/62 34 62 65 M8 50 10 100 20 050240

HN M8X124/84 34 83 65 M8 50 10 125 20 050241

¬ Angle iron, hand rails HN M10X55/12 35 12 80 M10 65 12 60 40 050242

HN M10X70/18 44 18 80 M10 65 12 70 40 050243

HN M10X98/46 44 46 80 M10 65 12 100 40 050244

Material HN M10X126/74 44 74 80 M10 65 12 125 40 050245

¬ Bolt class 6.8 HN M12X62/12 39 12 95 M12 65 16 65 70 050246

HN M12X106/49 46 49 95 M12 65 16 110 70 050247

HN M12X140/83 46 83 95 M12 65 16 140 70 050248

HN M16X81/20 50 20 100 M16 70 20 80 150 050249

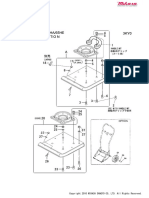

Installation

HN M16X113/52 50 52 100 M16 70 20 115 150 050250

HN M16X157/96 50 96 100 M16 70 20 160 150 050251

DYNABOLT

HEX BOLT

HB M6X45/8 26 8 55 M6 45 8 45 9 050252

HB M6X70/30 30 30 55 M6 45 8 70 9 050253

HB M6X95/56 30 56 55 M6 45 8 95 9 050254

HB M8X55/10 28 8 65 M8 50 10 55 20 050255

HB M8X80/35 34 35 65 M8 50 10 80 20 050256

HB M8X105/62 34 62 65 M8 50 10 105 20 050257

1 Drill a hole corresponding to HB M10X75/18 44 18 80 M10 65 12 75 40 050259

the external diameter of the HB M10X105/45 44 46 80 M10 65 12 105 40 050260

anchor with a depth equal to the HB M12X110/49 44 49 95 M12 65 16 110 70 050262

minimum anchor depth plus the

diameter of the anchor.

2 Position the anchor into the hole

until it just touches the part to be

fixed. Anchor mechanical properties

3 Tighten the anchor until the

recommended torque is achieved. Threaded part M4,5 M6 M8 M10 M12 M16

fuk (N/mm2) Min. tensile strength 600 600 600 600 600 600

fyk (N/mm2) Yield strength 480 480 480 480 480 480

Wel (mm3) Elastic section modulus 5,4 12,7 31,2 62,3 109,2 277,5

M0 Rk,s (Nm) Characteristic bending moment 3,8 9,15 22,5 44,8 72 166

M (Nm) Recommended bending moment 1,9 4,5 11,2 22,4 36,0 83,0

Technical Helpline UK: 0800 731 4924 Tsupport@itwcp.co.uk

Technical Helpline ROI: 1 800 882 388 www.itwcp.co.uk

Dynabolt®

Zinc Coated Steel 2/4

The loads specified on this page are derived from internal test results. For results derived from CC Methodology, please see overleaf.

The data given in the pages “CC - Method” have to be applied.

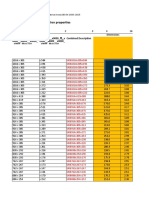

Ultimate (NRu,m, VRu,m) / characteristic loads (NRk, VRk) in kN

Mean Ultimate loads are derived from test results in admissible service conditions, and characteristic loads are statistically determined.

TENSILE SHEAR

Anchor size M4,5 M6 M8 M10 M12 M16 Anchor size M4,5 M6 M8 M10 M12 M16

Minimum anchorage depth VRu,m 3,2 7,3 13,2 20,9 30,4 56,4

hef 25 26 28 35 39 50 VRk 2,6 6,1 11,0 17,4 25,3 47,0

NRu,m 4,3 6,1 8,1 12,2 14,2 20,6

NRk 3,2 4,6 6,1 9,2 10,7 15,5

Maximum anchorage depth

hef - 30 34 44 46 -

NRu,m - 7,6 10,8 17,2 18,2 -

NRk - 5,7 8,1 12,9 13,7 -

Design Loads (NRd, VRd) for one anchor without edge or spacing influence in kN

N Rk * VRk *

N Rd = VRd =

γ Mc γ Ms

*Derived from test results

TENSILE SHEAR

Anchor size M4,5 M6 M8 M10 M12 M16 Anchor size M4,5 M6 M8 M10 M12 M16

Minimum anchorage depth VRd 1,6 3,8 6,9 10,9 15,8 29,4

hef 25 26 28 35 39 50 γMs = 1,6

NRd 1,5 2,2 2,9 4,4 5,1 7,4

Maximum anchorage depth

hef - 30 34 44 46 -

NRd - 2,7 3,9 6,1 6,5 -

γMc = 2,1

Recommended loads (Nrec, Vrec) for one anchor without edge or spacing influence in kN

N Rk * VRk *

N Rec = VRec =

γ Mγ F γ M .γ F

*Derived from test results

TENSILE SHEAR

Anchor size M4,5 M6 M8 M10 M12 M16 Anchor size M4,5 M6 M8 M10 M12 M16

Minimum anchorage depth VRec 1,2 2,7 4,9 7,8 11,3 21,0

hef 25 26 28 35 39 50 γMs = 1,6

NRec 1,1 1,6 2,1 3,1 3,6 5,3

Maximum anchorage depth

hef - 30 34 44 46 -

NRec - 1,9 2,8 4,4 4,7 -

γMc = 2,1

Recommended loads (Nrec, Vrec) in engineering clay bricks BP 400 (fc > 40 N/mm2) in kN

TENSILE SHEAR

Anchor size M6 M8 M10 M12 Anchor size M6 M8 M10 M12

hef 30 34 44 46 VRec 2,0 3,65 5,8 8,45

NRec 1,6 2,1 3,8 4,2

Technical Helpline UK: 0800 731 4924 Tsupport@itwcp.co.uk

Technical Helpline ROI: 1 800 882 388 www.itwcp.co.uk

Dynabolt®

Zinc Coated Steel 3/4

SPIT CC - Method

TENSILE in kN SHEAR in kN

¬ Pull-out resistance ¬ Concrete edge resistance

VRd,c = VRd

O

,c .fb .fβ ,V .ΨS − C ,V

N Rd,p = N O

Rd , p .fb

V0Rd,c Design concrete edge resistance

at minimum edge distance (Cmin)

N0Rd,p Design pull-out resistance Anchor size M4,5 M6 M8 M10 M12 M16

Anchor size M4,5 M6 M8 M10 M12 M16 Minimum anchorage depth

Minimum anchorage depth hef 25 26 28 35 39 50

hef 25 26 28 35 39 50 Cmin 45 45 50 60 70 110

N0Rd,p (C20/25) 1,5 2,2 2,9 4,4 5,1 7,4 Smin 85 85 100 115 170 220

Maximum anchorage depth V0Rd,c (C20/25) 2,1 2,3 2,9 4,2 5,9 13,0

hef - 30 34 44 46 - Maximum anchorage depth

N0Rd,p (C20/25) - 2,7 3,9 6,1 6,5 - hef - 30 34 44 46 -

γMc = 2,1 Cmin - 50 60 75 100 -

Smin - 95 120 145 200 -

V0Rd,c (C20/25) - 2,7 3,9 6,1 10,4 -

¬ Concrete cone resistance γMc = 1,5

N Rd,c = N ORd ,c .fb .Ψs .Ψc, N

¬ Pryout failure

0

N0Rd,c Design cone resistance VRd,cp = VRd ,cp .fb .Ψs .Ψc, N

Anchor size M4,5 M6 M8 M10 M12 M16

Minimum anchorage depth V0Rd,cp Design pryout resistance

hef 25 26 28 35 39 50 Dimensions M4,5 M6 M8 M10 M12 M16

N0Rd,c (C20/25) 3,0 3,2 3,6 5,0 5,8 8,5 Minimum anchorage depth

Maximum anchorage depth hef 25 26 28 35 39 50

hef - 30 34 44 46 - V0Rd,cp (C20/25) 4,2 4,5 5,0 7,0 8,2 11,9

N0Rd,c (C20/25) - 3,9 4,8 7,0 7,5 - Maximum anchorage depth

γMc = 2,1 hef - 30 34 44 46 -

V0Rd,cp (C20/25) - 5,5 6,7 9,8 10,5 -

γMcp = 1,5

¬ Steel resistance

¬ Steel resistance

NRd,s Design steel tensile resistance VRd,s Design steel shear resistance

Anchor size M4,5 M6 M8 M10 M12 M16 Anchor size M4,5 M6 M8 M10 M12 M16

NRd,s 2,7 6,3 11,5 18,1 26,4 - VRd,s 1,6 3,8 6,9 10,9 15,8 -

γMs = 2 γMs = 1,6

NRd = min(NRd,p ; NRd,c ; NRd,s) VRd = min(VRd,c ; VRd,cp ; VRd,s)

βN = NSd / NRd ≤ 1 βV = VSd / VRd ≤ 1

βN + βV ≤ 1.2

fB Influence of Concrete fβ,V Influence of Shear Loading Direction

Concrete class fB Angle β [°] fβ,V

C20/25 1.00 0 to 55 1

C30/40 1.14 60 1.1

C40/60 1.26 70 1.2

C50/60 1.34 80 1.5

90 to 180 2

Technical Helpline UK: 0800 731 4924 Tsupport@itwcp.co.uk

Technical Helpline ROI: 1 800 882 388 www.itwcp.co.uk

Dynabolt®

Zinc Coated Steel 4/4

SPIT CC - Method

Ψs Influence of spacing for concrete cone resistance in tensile load

spacing S Reduction factor Ψs spacing S Reduction factor Ψs

Minimum anchorage depth Maximum anchorage depth

M4,5 M6 M8 M10 M12 M16 M6 M8 M10 M12

85 1,00 1,00 95 1,00

100 1,00 120 1,00

115 1,00 145 1,00

170 1,00 200 1,00

220 1,00

Smin < S < Scr,N

Scr,N = 3.hef

ΨS must be used for each spacing

influenced the anchors group.

Ψc,N Influence of edge for concrete cone resistance in tensile load

EDGE C Reduction factor Ψs EDGE C Reduction factor Ψs

Minimum anchorage depth Maximum anchorage depth

M4,5 M6 M8 M10 M12 M16 M6 M8 M10 M12

45 1,00 1,00 50 1,00

50 1,00 60 1,00

60 1,00 75 1,00

70 1,00 100 1,00

110 1,00

Cmin < C < Ccr,N

Ccr,N = 1,5.hef

Ψc,N must be used for each distance

influenced the anchors group.

Ψs-c,V Influence of spacing and edge distance for concrete edge resistance in shear load

¬

For single anchor fastening Factor Ψs-c,V

Non-cracked concrete

C 1,0 1,2 1,4 1,6 1,8 2,0 2,2 2,4 2,6 2,8 3,0 3,2

Cmin

Ψs-c,V 1,00 1,31 1,66 2,02 2,41 2,83 3,26 3,72 4,19 4,69 5,20 5,72

Ψs − c,V c c

¬ For 2 anchors Factor Ψs-c,V

= . Non-cracked concrete

cmin cmin C

Cmin

S

1,0 1,2 1,4 1,6 1,8 2,0 2,2 2,4 2,6 2,8 3,0 3,2

Cmin

1,0 0,67 0,84 1,03 1,22 1,43 1,65 1,88 2,12 2,36 2,62 2,89 3,16

1,5 0,75 0,93 1,12 1,33 1,54 1,77 2,00 2,25 2,50 2,76 3,03 3,31

2,0 0,83 1,02 1,22 1,43 1,65 1,89 2,12 2,38 2,63 2,90 3,18 3,46

2,5 0,92 1,11 1,32 1,54 1,77 2,00 2,25 2,50 2,77 3,04 3,32 3,61

3,0 1,00 1,20 1,42 1,64 1,88 2,12 2,37 2,63 2,90 3,18 3,46 3,76

Ψs − c,V 3.c + s c 3,5 1,30 1,52 1,75 1,99 2,24 2,50 2,76 3,04 3,32 3,61 3,91

= .

6.cmin cmin

4,0

4,5

1,62 1,86 2,10

1,96 2,21

2,36

2,47

2,62

2,74

2,89

3,02

3,17

3,31

3,46

3,60

3,75

3,90

4,05

4,20

5,0 2,33 2,59 2,87 3,15 3,44 3,74 4,04 4,35

5,5 2,71 2,99 3,28 3,71 4,02 4,33 4,65

6,0 2,83 3,11 3,41 3,71 4,02 4,33 4,65

¬ For 3 anchors or more

3.c + s1 + s2 + s3 + ... + sn −1 c

Ψs − c,V = .

3nc c

Technical Helpline UK: 0800 731 4924 Tsupport@itwcp.co.uk

Technical Helpline ROI: 1 800 882 388 www.itwcp.co.uk

Вам также может понравиться

- Standard Hooks Card-ASTM PDFДокумент2 страницыStandard Hooks Card-ASTM PDFIsmael PerezОценок пока нет

- HILTI Anchor Selection GuideДокумент4 страницыHILTI Anchor Selection Guidesebastian9033Оценок пока нет

- Construction of Multi-Level ParkingДокумент13 страницConstruction of Multi-Level Parkingdunknown15Оценок пока нет

- C1155Документ8 страницC1155dinhtung2210Оценок пока нет

- 2-Way Spanning Insitu Concrete Slabs To Bs 81101997 (Table 3.14)Документ4 страницы2-Way Spanning Insitu Concrete Slabs To Bs 81101997 (Table 3.14)alialiОценок пока нет

- Pipe Bridge DesignДокумент2 страницыPipe Bridge DesignerickquintoОценок пока нет

- Aashto Rigid Pavement DesignДокумент5 страницAashto Rigid Pavement DesignJorge Luis MezaОценок пока нет

- Week 8 Lecture Material - WatermarkДокумент75 страницWeek 8 Lecture Material - WatermarkVaibhav Sharma100% (1)

- Design of Isolated Footing With Vertical Load Only - According To ACI 318M-99Документ1 страницаDesign of Isolated Footing With Vertical Load Only - According To ACI 318M-99mahmoud IbrahemОценок пока нет

- Technical Keywords For RecruitersДокумент22 страницыTechnical Keywords For RecruitersDeepthiОценок пока нет

- Corner Cast in Place AnchorДокумент7 страницCorner Cast in Place Anchorwaweng22Оценок пока нет

- 2.0 Handrail Standard DetailsДокумент1 страница2.0 Handrail Standard DetailsRey GonzalesОценок пока нет

- Sample Grouted Riprap EstimateДокумент2 страницыSample Grouted Riprap EstimateShadin Asari ArabaniОценок пока нет

- Hilti Anchor BoltsДокумент1 страницаHilti Anchor Boltsmosros123Оценок пока нет

- Sand Heap AnalogyДокумент23 страницыSand Heap AnalogyTatyGendadeReynosoОценок пока нет

- Plain Concrete Footing Design Based On ACI 318-14: Input Data Design SummaryДокумент4 страницыPlain Concrete Footing Design Based On ACI 318-14: Input Data Design SummaryShadin Asari ArabaniОценок пока нет

- Wilo Pump DataДокумент58 страницWilo Pump Datapolaris100% (1)

- Steel Silo - AaaДокумент22 страницыSteel Silo - AaaABDUL AASHIKОценок пока нет

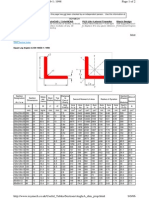

- ASTM Structural Steel Angle Section PropertiesДокумент3 страницыASTM Structural Steel Angle Section PropertiesMujjo Sahb100% (1)

- Moment of Inertia of Compound Section Lip ChannelДокумент7 страницMoment of Inertia of Compound Section Lip Channelabhi aroteОценок пока нет

- Star AngleДокумент1 страницаStar AngleDebasish MondalОценок пока нет

- SS400 Plate SpecificationДокумент1 страницаSS400 Plate Specificationthiruprema100% (2)

- AutoGrid5 User GuideДокумент621 страницаAutoGrid5 User GuideLC Sosa100% (3)

- Anchor BoltДокумент2 страницыAnchor BoltGinzeycha Gazheyvcha Oxyphenia100% (1)

- Castellated Beams STAAD-Pro2004Документ13 страницCastellated Beams STAAD-Pro2004Lukman Nul HakimОценок пока нет

- A325 and Class 8.8Документ3 страницыA325 and Class 8.8rajedmaglinte100% (1)

- Sedecal sm0510R4Документ90 страницSedecal sm0510R4PatriciaAraujo100% (3)

- Aisc LRFDДокумент30 страницAisc LRFDlapt75100% (1)

- Calculating Length of Reinforcing BarsДокумент3 страницыCalculating Length of Reinforcing BarsswarluОценок пока нет

- Fischer Anchor BoltДокумент10 страницFischer Anchor Bolticehorizon88Оценок пока нет

- Equal Angle Section TableДокумент2 страницыEqual Angle Section Tableezarul fitri100% (1)

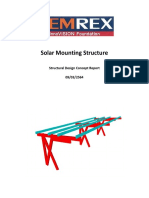

- Solar Mounting Structure: Structural Design Concept Report 09/03/2564Документ13 страницSolar Mounting Structure: Structural Design Concept Report 09/03/2564Surat Warit100% (1)

- Calculation Sheet For Strengthening Concrete Slab With Steel BeamДокумент26 страницCalculation Sheet For Strengthening Concrete Slab With Steel BeamMohamed Kadry100% (2)

- Web Application DevelopmentДокумент3 страницыWeb Application DevelopmentGhanshyam SharmaОценок пока нет

- Perhitungan Analysis Angkur Bolt-ExcelДокумент26 страницPerhitungan Analysis Angkur Bolt-ExcelbonnicoОценок пока нет

- Universal Beams To BS4 Part 1 - 1993Документ3 страницыUniversal Beams To BS4 Part 1 - 1993Aristotle MedinaОценок пока нет

- Mechanical - Anchoring - DynaBolt Plus PDFДокумент6 страницMechanical - Anchoring - DynaBolt Plus PDFAnonymous dSFbLxc9Оценок пока нет

- Submittal Information: Dynabolt SleeveДокумент2 страницыSubmittal Information: Dynabolt Sleeveanto081287Оценок пока нет

- STR DWG ChecklistДокумент2 страницыSTR DWG Checklistomar42170Оценок пока нет

- Pile Cap DesignДокумент4 страницыPile Cap DesignMohamed RifdyОценок пока нет

- Steel Section PropertiesДокумент2 страницыSteel Section Propertiesman.drakeОценок пока нет

- Steel Section WeightДокумент25 страницSteel Section WeightRoshan de Silva100% (1)

- RAMP Staadpro Output FileДокумент192 страницыRAMP Staadpro Output Fileravi4paperОценок пока нет

- Pile Set Calculation Dated 07-May-2018Документ4 страницыPile Set Calculation Dated 07-May-2018hauzhiОценок пока нет

- Calculation Hook For Lifting PileДокумент2 страницыCalculation Hook For Lifting PileDica Rasyid MaulidhaniОценок пока нет

- Anchor BoltДокумент1 страницаAnchor BoltNugraha BintangОценок пока нет

- AISI 4140 Steel, Oil Quenched, 650°C (1200°F) Temper, 25 MM (1 in PDFДокумент2 страницыAISI 4140 Steel, Oil Quenched, 650°C (1200°F) Temper, 25 MM (1 in PDFDiegoAlvarezHuguezОценок пока нет

- SANS Section Properties Steel Profiles Rev2Документ10 страницSANS Section Properties Steel Profiles Rev2JakesОценок пока нет

- Alum A Beam Product SheetДокумент2 страницыAlum A Beam Product SheetatiОценок пока нет

- Aksesoris Tube ScaffoldingДокумент3 страницыAksesoris Tube ScaffoldingArief FirmansyahОценок пока нет

- Prayer Room & Guard Room Structure With CalculationДокумент42 страницыPrayer Room & Guard Room Structure With CalculationNazrinОценок пока нет

- Dynabolt Zinc Coated Steel Design GuideДокумент4 страницыDynabolt Zinc Coated Steel Design GuideMuhammad SarajevoОценок пока нет

- Bolt Torque TighteningДокумент2 страницыBolt Torque Tighteningqc_531040655Оценок пока нет

- Sample Spiral Stair Assembly Drawing PDFДокумент1 страницаSample Spiral Stair Assembly Drawing PDFvna29710% (1)

- Standard Profile Inertia CalculationДокумент17 страницStandard Profile Inertia CalculationFian ArdiyanaОценок пока нет

- Bar Bending Schedule OF Box CulvertДокумент1 страницаBar Bending Schedule OF Box CulvertvishalОценок пока нет

- Etag 001 Part 5 Bonded Anchors 2013 04 08 PDFДокумент33 страницыEtag 001 Part 5 Bonded Anchors 2013 04 08 PDFKhoonShihHsienОценок пока нет

- Comparison of OMF IMF and SMFДокумент2 страницыComparison of OMF IMF and SMFCarlo Dizon100% (1)

- Rectangular Hollow Section Cold Formed..BS en 102191997Документ4 страницыRectangular Hollow Section Cold Formed..BS en 102191997Jagdish ChhuganiОценок пока нет

- H Beams in Accordance With JISДокумент3 страницыH Beams in Accordance With JISaselabollegalaОценок пока нет

- BS 1881Документ8 страницBS 1881Nurul Izzati Raihan RamziОценок пока нет

- Spit Dynabolt PDFДокумент4 страницыSpit Dynabolt PDFAchmad Zaki ZulkarnainОценок пока нет

- Pie y OpcionesДокумент2 страницыPie y Opcionestalleres villaОценок пока нет

- SPIT Fix-II Zinc CoatedДокумент4 страницыSPIT Fix-II Zinc CoatedAhmed SakrОценок пока нет

- Fix-Z-A4 Stainless Steel Design GuideДокумент4 страницыFix-Z-A4 Stainless Steel Design GuidedineshОценок пока нет

- HILTI HST Catalogue PageДокумент2 страницыHILTI HST Catalogue PageGoutam HotaОценок пока нет

- Linde Service GuideДокумент3 страницыLinde Service GuideMário AndradeОценок пока нет

- Helisolid Key Locking InsertsДокумент6 страницHelisolid Key Locking InsertsVijet BhandiwadОценок пока нет

- Summary Sheet: Shieham Construction and EnterprisesДокумент13 страницSummary Sheet: Shieham Construction and EnterprisesShadin Asari ArabaniОценок пока нет

- Summary Sheet: Shieham Construction and EnterprisesДокумент26 страницSummary Sheet: Shieham Construction and EnterprisesShadin Asari ArabaniОценок пока нет

- Detailed Estimate: Project Title: Location: DurationДокумент46 страницDetailed Estimate: Project Title: Location: DurationShadin Asari ArabaniОценок пока нет

- C1 W12x65 Full CalculationДокумент5 страницC1 W12x65 Full CalculationShadin Asari ArabaniОценок пока нет

- C1 W12x65 Full CalculationДокумент5 страницC1 W12x65 Full CalculationShadin Asari ArabaniОценок пока нет

- Budget Allocation ControlДокумент11 страницBudget Allocation ControlShadin Asari ArabaniОценок пока нет

- Product Data Sheet: Sika® Anchorfix-3001Документ7 страницProduct Data Sheet: Sika® Anchorfix-3001Shadin Asari Arabani100% (1)

- 19 372 Degic TunnelДокумент4 страницы19 372 Degic TunnelShadin Asari ArabaniОценок пока нет

- C1 W12x65 Summary CalculationДокумент2 страницыC1 W12x65 Summary CalculationShadin Asari ArabaniОценок пока нет

- 1 Identification of The Substance/preparation and of The Company/undertakingДокумент7 страниц1 Identification of The Substance/preparation and of The Company/undertakingShadin Asari ArabaniОценок пока нет

- C1 W12x65 Summary CalculationДокумент2 страницыC1 W12x65 Summary CalculationShadin Asari ArabaniОценок пока нет

- Builderware Price List 5Документ38 страницBuilderware Price List 5Jongson Dantes RodriguezОценок пока нет

- Injection System PDFДокумент20 страницInjection System PDFb4rfОценок пока нет

- Baggage General Rules As of 04jul17 PDFДокумент32 страницыBaggage General Rules As of 04jul17 PDFjrОценок пока нет

- Practical PDFДокумент1 страницаPractical PDFArjay PlautaОценок пока нет

- 2D Frame Analysis: Analysis of A 2D Frame Subject To Distributed Loads, Point Loads and MomentsДокумент26 страниц2D Frame Analysis: Analysis of A 2D Frame Subject To Distributed Loads, Point Loads and MomentsShadin Asari ArabaniОценок пока нет

- Basic Soil and Rock CharacteristicsДокумент31 страницаBasic Soil and Rock CharacteristicsShadin Asari ArabaniОценок пока нет

- A 00Документ1 страницаA 00Shadin Asari ArabaniОценок пока нет

- Bid Form: Civil / Structural / Architectural WorksДокумент54 страницыBid Form: Civil / Structural / Architectural WorksShadin Asari ArabaniОценок пока нет

- Standards For 7-Day and 28-Day Strength Test Results PDFДокумент2 страницыStandards For 7-Day and 28-Day Strength Test Results PDFShadin Asari ArabaniОценок пока нет

- For Layout PDFДокумент1 страницаFor Layout PDFShadin Asari ArabaniОценок пока нет

- Beam CheckingДокумент5 страницBeam CheckingShadin Asari ArabaniОценок пока нет

- Load TabulationДокумент4 страницыLoad TabulationShadin Asari ArabaniОценок пока нет

- ScaffoldДокумент2 страницыScaffoldShadin Asari ArabaniОценок пока нет

- Analysis of Mat Foundation Using FeaДокумент15 страницAnalysis of Mat Foundation Using FeaShadin Asari ArabaniОценок пока нет

- Analysis of Mat Foundation Using FeaДокумент15 страницAnalysis of Mat Foundation Using FeaShadin Asari ArabaniОценок пока нет

- ZFSДокумент24 страницыZFSAlphaQ by raks100% (1)

- Computer NotesДокумент5 страницComputer NotesMahrukh NasirОценок пока нет

- ComputerForensics GlossaryДокумент4 страницыComputerForensics GlossaryGDIAZОценок пока нет

- Microprocessor& Micro ControllerДокумент3 страницыMicroprocessor& Micro ControllersujithОценок пока нет

- KTM 450 EXC Electric ChecksДокумент3 страницыKTM 450 EXC Electric Checksburgerbiter100% (1)

- VOP Users GuideДокумент136 страницVOP Users GuidejkmosaicОценок пока нет

- Bit 101 Reviewer Group 1-5Документ10 страницBit 101 Reviewer Group 1-5Cleofe Jane PatnubayОценок пока нет

- LC195EM9BДокумент57 страницLC195EM9BJorge AlbertoОценок пока нет

- Spengler DLH 609Документ55 страницSpengler DLH 609Gal CristianОценок пока нет

- Rotex COMPLETE Limit Switch Catalog 2013Документ31 страницаRotex COMPLETE Limit Switch Catalog 2013Fikrinala MargaliuОценок пока нет

- c29 Je y (ST) y BDДокумент1 страницаc29 Je y (ST) y BDNarendra Reddy BhumaОценок пока нет

- Manual DVR BOLIDE MVR9008-3G UserДокумент43 страницыManual DVR BOLIDE MVR9008-3G UserJhonatan SepulvedaОценок пока нет

- CCNAS - Chp2 - PTActA - Syslog-SSH-NTP - InstructorДокумент5 страницCCNAS - Chp2 - PTActA - Syslog-SSH-NTP - InstructorAziz LondonОценок пока нет

- 8255Документ34 страницы8255Manjula Bn100% (1)

- GPU Gems - Chapter 7Документ13 страницGPU Gems - Chapter 7Sebastian SytaОценок пока нет

- Operators Question 1Документ21 страницаOperators Question 1rahul rastogiОценок пока нет

- Pcloadletter Co Uk 2012 07 06 Iemgd For Vaio PДокумент17 страницPcloadletter Co Uk 2012 07 06 Iemgd For Vaio PioОценок пока нет

- Pointers: Starting Out With C++, 3 EditionДокумент39 страницPointers: Starting Out With C++, 3 EditionswapnilОценок пока нет

- Toshiba Satellite M300 M305 Quanta TE1 Laptop SchematicsДокумент40 страницToshiba Satellite M300 M305 Quanta TE1 Laptop SchematicsErick RodriguezОценок пока нет

- Data Sheet: Modbus High Level Interface (Hli)Документ4 страницыData Sheet: Modbus High Level Interface (Hli)Alberth Rojas CastellanosОценок пока нет

- 901595Документ1 страница901595Fortem PuseОценок пока нет

- Biblioteca Solomonara - Studiorum (2015.07.09)Документ1 страницаBiblioteca Solomonara - Studiorum (2015.07.09)green_numbersОценок пока нет

- Rental RatesДокумент1 страницаRental RatesZigundОценок пока нет

- Catalyst 2960 24TC LДокумент39 страницCatalyst 2960 24TC Lblack_alynaОценок пока нет

- Androidx Class MappingДокумент52 страницыAndroidx Class MappingBrittany ZirkleОценок пока нет