Академический Документы

Профессиональный Документы

Культура Документы

Welding Procedure

Загружено:

GobinderSinghSidhu0 оценок0% нашли этот документ полезным (0 голосов)

14 просмотров7 страницhaiiia

Оригинальное название

welding procedure

Авторское право

© © All Rights Reserved

Доступные форматы

PDF или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документhaiiia

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

14 просмотров7 страницWelding Procedure

Загружено:

GobinderSinghSidhuhaiiia

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

Вы находитесь на странице: 1из 7

Aq panoiddy Aq panouddy

Aq pameinayy Aq pamainey,

Aq paxoeyo. Qa w SAQ MPL] Aq paxoeya

‘aunjeuBiS SueN einjeubig | _ owen

TWOdN 404 PY 34d Sastidiaquy jespog 404

(vo)seuiny Touey—_[(vO) uBuis yeesdueyy|

AeeA9 Busey prey 9-93111095

Paod9y UolwoysEND einpedoig/uoNeoy!oads ainpaccig BUIp|OM : Uw93)

Aq panouddy Ag pamainey / pax2eUuD

Payuny7 SaajeA s0pesy ‘ VIN {SON SSA /188US BIg

VIN : OU-BLS9-S-Od-y8E-ddVy} —:- ON Dads YDeL TION]

xt99g SWS H IS@C]_€0-Hd-SN-8/59-3-Od-Y8E-ddVH-S/-ONZ-€0| | ON UNIRid / 9eds Arenbus|

£102'Z4'6b'LG €1/00-990/290/0d/SVAISLINAd/E0: ON Od

Woo'senjeAlepea|@ybulsewel Woo senjeniepes|Ooul __feUra| woo 'espop@ned Aefues / woo'jespop@yo'uespuauns :

¥680627-1810 ‘ON xe4 80S / LOS €6.00%-2Z0: ON xe4

99906>Z-1810 ON auoUd 00% $6 00%-220 :_ON eu0Ud|

‘y00rPL-delung “seupueler| 290 O0b - }equiny “uoeBaio5 ‘peo: yu]

‘eaay leWsnpul ‘ys ‘es} ‘eoeds PUI ‘BuIM - Vv ‘semo} WSL ‘Z0Z|

Pew] SeAleA 19pe07 'S/INI PI Wd sesudiequ3 lespog s/w

‘SS3UCQV GNV SINVN YOGNSA YOLOVLNOD 3OvHOVd

YB € dd 10 ebeyoed Pue|s| BUIGIN] Jo aouR|eg : Seed PRE ddW- SAN : eloJd|

SdM 40d sy] aed

£0 ASU SL/STMOaYO 31177:

ON ASH THI AWTY3AO ONIDVA GYVH 9-3LITSLS

vO'NeY ZE/STSAMVYO as

ee ee

VIN GTSM

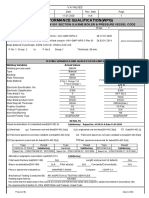

‘ ee WELDING PROCEDURE SPECIFICATION (WPS)

r (SECTION 1X 2010, Clause QW-482, ASME BOILER & PRESSURE VESSEL. CODE)

1 Company Name : M/S. LEADER VALVES LIMITED BY: JARNAILSINGH

Welding Procedure Specification No. QA/WPS/JS/32__Date’-07-08-2013, ‘Supporting POR Nos.: QA/POR/IS/75

Revision No. 4 Date: 14-03-2014

Welding Procedure (S}: GTAW Typels): MANUAL

GOIN (aw403) Detals

Hioints Design

[Backing (Ves): VES Wok

ease i Plate Spmeces Fok

(ie oben re) CHEmeAL COMosITION pREMeED|

[wetal Nonfusing Metal |sukewe |

nonmetal former e

sketches, Production Drawings, Weld symbols or Written

[Description should show the genoral arrangement of the parts to

lbe welded. Where applicable the root spacing & the details of

|Weld groove may be specified,

(At the option ofthe Mgr. Sketches may be attached to lustate — |334

joint design, weld layers & bead sequence.e.g.fornoteh toughness [6 ia

procedures for multiple joint procedures ete.

BASE METALS (QWa08)

P.Nos 8 Group No: 1 0 P.No. NA Group No, NA

oR

Specification Type & Grade A240 Grade304

|To Specification Type & Grade: STELUTE:6 HARD OVERLAY

oR

|Chemical Analysis & Mech, Properties Na

[To.chemical Analysis & mechanical Properties NA

hthickness Range:

base Metal 14.25mm___Groaver_NA. Filet:

Pipe dia Range NA (Groove: NA. File:

lother

|* FILLER METALS (@wva0a)

wmnoiSen 5.21 ERCOCrA Stelle 6)

JAWS No.(Class) 85.23 a

No. n

IANo.:

sizeof Filer Metals: 3.5mm & Amen

|weld metal

[Thinkness Range: 4.5mm to 9mm

Groove: _NA

Fillet: NA

Electrode Fux (Cass): NA

Flux Trade Name NA,

[Consumable Insert NA.

Filler metat product form:- solid wire

Other _Ezanenien "e

JB men KD Sm

WPS No. APs /i5/22 few 8

lroaons(aw-a05) JPost WetD HEAT TREATIOENT[aW-aD7)

resitons: nar sc) temperature Range NL

wetting Proresscn: Up NA Down —NA_lTime Range Soa) mi

Postion fur eaotne iw

mena caw-ace) [eas rawaosy

rohest Temperature Min ie Percent Composition

Inter Pos Tempeatre Mae: ware Gasies) Miure low Rates

Preneat Martenance u

cornu ope heating where notated beret) | sheng ARGON 99908 __szte

Hretng NANA. HA.

owing WANA NAL

JLEcTRICAL cHaRACTERSTICS(QW-409)

curent Acero: ve. Polarity smear

JAMPS Range} TADS1@T 160-100 vote (Range): -BOREVLRS27V

nesen electrode Si Type 20mm & nm G2 Trot)

Mode of Meta! Transfer for GMAW WA

eectrode Wire Food Speed Range WA

[recHmaUE (aw 410)

Surg or Weave Res: sTANG WeaWNG

orice Orcas Cup a.

nits 8 iteresseanng(orsting/Grndng; rushing

ethod ot ck Gouging NA

osctauen NA

contact Tube to Work Ostance : NA

Mall or Sl Pas (nde: Mulipace

Mulino singe coed Siege

rave Speed Range) 7580 maven

cone Ma

lower NA

FILERMETAT

Weld | Prous] Ges] oe Travel Speed Weatioaae

paen Range

i | Saw TST ERCOGE SS Wimm/mn GTN

Aste 6}

and | craw | az eRCOC mm wmv hsb

Astle 6)

‘AIRY KUMAR

‘OATEOF cenTexrms5SEP2018

PROCEDURE QUALIFICATION RECORDS (POR)

2 {GECTION IXCLAUSE QW-483, ASME Boller and Pressure Vessel Code)

- Record Actual Conditions Uted to Weld Test Coupon.

company Name; __M/S. Leader vanes United

Procedure Cuaiieation Resords No: ___CA/PORISPIS bate pnpeons

eins 3 fev, Date: 22-08-2014

lwrs no. eAMRSpS/sa_REVOR

Welding Presses) AW

lrineanua astra Seto) waanval

FIGs Fay

sew eng ‘cameigs. | Toe CHEMISTAY S HEOCLES,

ROTOAL

SERED BORER

:

2

Penn

Prewceness | AER ORNATE on AePReACHATE

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- OH&S Documents ChecklistДокумент6 страницOH&S Documents ChecklistGobinderSinghSidhuОценок пока нет

- Gas Cylinders DetailДокумент1 страницаGas Cylinders DetailGobinderSinghSidhuОценок пока нет

- "Master List of Documents": PlansДокумент7 страниц"Master List of Documents": PlansGobinderSinghSidhuОценок пока нет

- Qw-484 Welder Performance Qualification (WPQ) : SEE QW-301 Section Ix, Asme Boiler & Pressure Vessel CodeДокумент8 страницQw-484 Welder Performance Qualification (WPQ) : SEE QW-301 Section Ix, Asme Boiler & Pressure Vessel CodeGobinderSinghSidhuОценок пока нет

- Summary Sheet: AS ATTACHED OFFER LIST (QA/LVL/2300/01 & QA/LVL/2300/02)Документ1 страницаSummary Sheet: AS ATTACHED OFFER LIST (QA/LVL/2300/01 & QA/LVL/2300/02)GobinderSinghSidhuОценок пока нет

- Ioc ApiДокумент3 страницыIoc ApiGobinderSinghSidhuОценок пока нет

- Cswip Renewal FormДокумент4 страницыCswip Renewal FormGobinderSinghSidhu0% (1)