Академический Документы

Профессиональный Документы

Культура Документы

Investigation of Kinetics of Hydroisomerization of C /C and C /C Alkanes and Their Binary Mixtures

Загружено:

Omar SaeedИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Investigation of Kinetics of Hydroisomerization of C /C and C /C Alkanes and Their Binary Mixtures

Загружено:

Omar SaeedАвторское право:

Доступные форматы

HUNGARIAN JOURNAL

OF INDUSTRIAL CHEMISTRY

VESZPRÉM

Vol. 39(1) pp. 117-120 (2011)

INVESTIGATION OF KINETICS OF HYDROISOMERIZATION OF

C5/C6 AND C6/C7 ALKANES AND THEIR BINARY MIXTURES

ZS. SZOBOSZLAI , J. HANCSÓK

University of Pannonia, Department of MOL Hydrocarbon and Coal Processing

8200, Veszprém Egyetem u. 10, HUNGARY

E-mail: szzsolt@almos.uni-pannon.hu

Modern gasoline quality requirements globally became stricter. These specifications parallel with the applied developments

of vehicle technologies contributing to the cleaner environment. Nowadays only the concentration of cyclo- and isoparaffins

are not limited in gasoline, because they burn cleaner, have high octane number, lower sensibility and better combustion

properties than aromatic or olefinic hydrocarbons. In the last decade because of the applied refinery investments both sulfur

and aromatic content of gasolines decreased, but the octane mass of the gasoline pool significantly decreased against the

increment of octane number requirement of spark ignition engines. Importance of isomerization of light paraffins has

been publicized in many papers. However few of them investigated, studied and explained the individual hydrocarbons

(C5/C6/C7) interaction with each other in multicomponent mixtures practically in similar to industrial hydrocarbon

feedstocks. Binary and multicomponent hydrocarbon mixture investigations can contribute to the understanding the results of

isomerization of real, feedstocks from multiple sources; which contain higher boiling point hydrocarbons (cycloparaffins,

benzene, and heptanes). Further these results can help to operate with higher flexibility, safety and economically a light

naphtha isomerization units. The hydroisomerization of n-pentane (n-C5), n-hexane (n-C6), cyclohexane (c-C6) and n-heptane

(n-C7) and their binary mixture were studied on Pt/sulfated zirconia catalyst at temperature 150–170 °C, total pressure

20 bar, 1:1 H2-hydrocarbon molar ratio. The apparent activation energies of all individual components, further the reaction

rates individually and in different composition binary mixtures were specified. Results of our experiments concluded that

the rate of reaction of the higher carbon number hydrocarbon or in case of the same carbon number the cycloparaffins (lower

volatility component) increased with increasing the concentration in the binary mixtures, while the rate of reaction of higher

volatility component decreasing.

Keywords: Isomerization, light naphtha

Introduction

Nowadays the fractions rich in isoparaffin are the most

important blending components of the gasolines because

they have high octane number, low sensibility, they are

practically free from sulphur, olefin, and aromatics, they

have low toxicity, and undesired molecules are not

generated under controlled combustion [1-4]. The

continuous demands for the application of isoparaffin

rich hydrocarbon fractions are the followings:

From 2000

– Low benzene and decreased aromatic concentration

(research octane number and octane number distribution) Figure 1: Constructed refinery investments in the EU

– Reducing the research octane number give away for high quality gasoline production until 2005

– Supplementation of the octane number decrease of the to fulfill the 2005 gasoline regulations

deep desulphurization of cracked naphthas

– Regulation of the application of MTBE The simultaneous reduction of the sulphur and

– Balancing the boiling range shifting in case of heavier aromatic content significantly decreased the octane number

ether (ETBE, TAME) application in high concentration of the gasoline pool against the increasing octane number

From 2005 requirements of the Otto engines (higher compression

– Further deep desulphurization ratio → higher octane number → higher volumetric

– Further reduced aromatic and benzene content efficiency and specific power with lower emission).

118

The importance of isoparaffin rich fractions is Experimental eqipment

presented in Fig. 1 which shows what the most important

investments are in the refineries to satisfy the demands

The applied catalytic system contains a 100 cm3 vertical

and meet the new specifications [1-4]. It can be clearly

reactor and every instrument which can be found in a

seen that the highest investments in the refinery were

commercial scale light naphtha isomerization unit.

the light paraffin isomerization processes (though the

The catalytic system contains a gas regulator/control

application of light paraffins was slightly reduced by the

and pretreatment system and an on-line gas chromatograph.

bioethanol blending, in spite of the significant effect of

the ethanol on the gasoline physical-chemical application

properties the etherification and alkylation capacity can

Materials

be significantly increased by taking advance of the

isomerization capacity), but the alkylation unit installation

and revamping was also important. The possible ways We applied 60cm3 of in situ dried and activated

to produce industrial economically isoparaffin rich Pt/sulphated-zirconia (extrudated, D: 1.5mm) catalyst and

fractions are the following: the empty space was filled with Raschig rings.

● The proper naphtha fraction separation to iso- and The feedstocks were analytical grade, sulphur free n-

normal paraffin fractions pentane, n-hexane, cyclohexane and n-heptane. The

● Alkylation of isobutane with C3-C5 olefins (direct concentration of components was varied between 0–100%

alkylation) (0, 25, 50, 75 and 100% theoretically) in binary mixtures.

● Dimerization of C3-C5 fractions rich in olefins The practically sulfur free hydrocarbons continuous

(indirect alkylation) after hydrogenation demoisturising was done with Linde 4A molecule sieve.

● Isomerization of C5-C7 fractions rich in n-paraffins

o Isomerization of benzene containing fractions

Two-steps → two reactors and different Catalyst and test methods

catalysts

One step The applied catalyst was Pt/sulfated-zirconia. Main

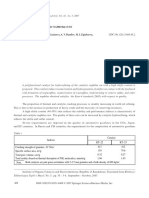

• isomerization of benzene containing properties of the catalyst were shown by Table 1.

fractions (the saturation of benzene and

isomerization of the n-paraffins is done in Table 1: The main characteristics of applied catalysts

the same reactor and on the catalyst) [5-6]

• in the same reactor with segmented beds Properties Values

with different catalysts [4] Pt-content, % 0.415

Pt-dispersion, % 69

The specifications of the benzene concentration of Acidity, mmolNH3/g 0.56

the naphtha fraction can be ensured by adequate pre- and Sametalic (metal (Pt) surface on the catalyst),

25.91

post-treating so the feed of reformation does not contain m2/g metal

2

benzene precursor or after the reformation they have to Smetal (specific metal surface), m metal/g cat. 0.108

be fractionated (if the reformation is gasoline purpose) APS (average particle size of the metal), nm 2.0

from the product and saturated in the isomerization plant. Specific acidity, mmolNH3/m2 cat. 0.0043

The feedstock of both of the etherification and BET surface, m2/g 130

alkylation technologies are the C4-C5 isoparaffins Microporous surface, m2/g 12.2

consequently the light paraffin isomerization will be Microporous volume, cm3/g 0.0045

one of the key processes just partly producing internal Mezoporous volume, cm3/g 0.2874

components/feeds for other technologies. Mezo-/microporous volume ratio 63.9

Average pore size, nm(Å) 8.5(85)

Experimental

Standard measurements methods were used. Pt content

of the catalyst was measured by UOP-274 standard.

Aim of our experimental work was the investigation of BET surface area and total acidity of the catalyst was

isomerization of hydrocarbons with different volatility measured by NH3 sorption according to ASTM D3663 and

and their binary mixtures. We investigated that the D4824 standards, while pore size distribution and pore

isomerization effects/rate on each other further how volume was measured by mercury intrusion porosimetry

influenced the individual hydrocarbon the other in method according to ASTM D4284 and D6761 standards

laboratory scale reactor on steady state activity catalyst. respectively. The feeds and products composition was

The inspiration of this research work was the absent of measured with gas chromatograph according to ASTM-

large scale, long term catalytic studies with near D5134 standard.

industrially parameters [7-14]. The sulphur content of all feeds and products

(GREENLAB Ltd./Analytik-Jena - Multi EA 3100-type

device) with EN ISO 20846 (2003), water content

(GREENLAB Ltd./KEM - MKA-610-type device) with

ISO 12937:2001 standard was determined.

119

Process parameters becomes higher and near the equilibrium concentration

(cyclohexane↔methylcyclopentane) the cracking reaction

come to front that ascribe to methylcyclopentane. In the

Experiments were measured on steady state activity

examination of the gas phase composition it was

catalyst. Based on preliminary results the experiments

observed that the C2/C4 molar ratio was very low so the

was taken on 20 bar total pressure, 1.0–4.0 LHSVs,

isomerization and cracking reaction probably to take

H2/HC molar ratio was 1.0:1.0. Fine changes of the

place through C12-C8 intermediate products.

parameter combination kept measuring where the low

conversion rates (5–15%) of the individual hydrocarbon

were not inhibited by the products. 20

Reaction rate, 10-8 mol/s.gcat.

reaction rate of n-hexane

Results and discussion 15 reaction rate of n-pentane

Near low conversion rates the individual hydrocarbons 10

initial reaction rates were measured then the logarithmized

values were presented versus the inverse of temperature. 5

These methods were applied to determine the apparent

activation energies of hydrocarbons. Based on the given

data they had relatively high deviation, and these values 0

can be given with relatively high inaccuracy. Our values 0 20 40 60 80 100

and the publicized values are relevated well (Table 2) but n-pentane concentration in binary mixture, %

the most of them were determined in different catalytic

Figure 2: Changes in reaction rate of individual

system and with different parameter combinations [11-15].

components in the binary mixture

For example in case of the cyclohexane the measured

(T: 150 °C, LHSV: 1.5 h-1, P: 20 bar)

values are well correlated with publicized data

(100–150 kJ/mol).

35

Table 2: The apparent activation energies of individual

Reaction rate, 10-8 mol/s.gcat.

30

hydrocarbons reaction rate of n‐heptane

25

reaction rate of n‐hexane

Hydrocarbon n-pentane n-hexane n-heptane cyclo- 20

hexane

15

Eapparent, 10

measured 130–170 99–107 149–163 113–146

5

values, kJ/mol

0

Eapparent,

0 20 40 60 80 100

publicized 145–153 120 109–135 100–150

n-heptane concentration in binary mixture, %

values, kJ/mol

Figure 3: Changes in reaction rate of individual

The targeted quantity was added to n-hexane and components in the binary mixture

above 20% concentration it caused significantly lower (T: 150 °C, LHSV: 1.5 h-1, P: 20 bar)

reaction rate. So the reaction rate of the main

component decreased causing lower effectiveness under

80

isomerization consequently the adequate composition of

Reaction rate, 10-8mol/s.gcat.

the feed(s) has to be kept assured! 70

reaction rate of cyclohexane

Based on our measurement the reactivity of 60

reaction rate of n‐hexane

the individual hydrocarbons were the following: 50

c-C6>n-C7>n-C6>n-C5, the main cause was that the 40

adsorption energies of cycloparaffins is higher than the 30

same carbon number linear paraffins on strongly acidic 20

catalysts so in their mixtures increasing the individual 10

component reaction rate change with different degree 0

with the concentration interdependently (Fig. 2-4). In the 0 20 40 60 80 100

hexane the other component concentration more than cyclohexane concentration in binary mixture, %

20–30% the n-hexane reaction rate was approximately

halved and its component reaction rate was Figure 4.: Changes in reaction rate of individual

comparable/similar to the other individual component components in the binary mixture

reaction rate. In case of cycloparaffin isomerization the (T: 150 °C, LHSV: 1.5 h-1, P: 20bar)

lower H2 pressure was beneficial though it increased the

selectivity of ring opening reaction. On stricter parameter

combinations the ring isomerization selectivity

120

Conclusions 6. ZS. SZOBOSZLAI, J. HANCSÓK, SZ. MAGYAR:

Upgrading of Benzene Containing Hexane Feeds by

Simultaneous Isomerization at Low Temperature and

The individual component reaction rates were lower in

Saturation of Benzene, 6th International Colloquium,

every case than in their binary mixtures. The reaction

Fuels 2007, Germany, Esslingen, 2007, In Proceedings

rates were significantly decreased in the mixtures with

(ISBN 3-924813-67-1), 293–302

increasing the concentration of individual paraffin

hydrocarbons. 7. G. D. YADAV, J. J. NAIR: Sulfated zirconia and its

Based on the measured and calculated values it was modified versions as promising catalysts for industrial

concluded that in case of the non-adequate feed or in processes, Microporous and Mesoporous Materials

case of non-adapted isomerization catalyst – where 33, (1999), 1–48

accordingly to the demands the changes of process 8. J. M. SERRA, A. CHICA, A. CORMA: Development of a

parameters have not indicated any opportunity – influence low temperature light paraffin isomerization catalysts

of some component on the isomerization efficiency with improved resistance to water and sulphur by

become significant degree hereby the main linear chain combinatorial methods, Applied Catalysis A: General,

components with low octane number reactions rate of 239(1-2), (2003), 35–42

isomerization was interfered. 9. W. TAKEMI, M. HIROMI: Reaction of linear,

branched, and cyclic alkanes catalyzed by Brönsted

ACKNOWLEDGMENT and Lewis acids on H-mordenite, H-beta, and

sulfated zirconia. Journal of Molecular Catalysis A.

We acknowledge the financial support of this work by 239, (2005), 32–40

the Hungarian State and the European Union under the

10. J. C. DUCHET, D. GUILLAUME, A. MONNIER, C.

TAMOP-4.2.1/B-09/1/KONV-2010-0003 project.

DUJARDIN, J. P. GILSON, J. VAN GESTEL, G. SZABO,

P. NASCIMENTO: Isomerization of n-Hexane over

REFERENCES Sulfated Zirconia:Influence of Hydrogen and

Platinum, Journal of Catalysis 198, (2001), 328–337

1. U. SZALKOWSKA: Fuel quality - global overview,

7th international colloquium on fuels 2009, TAE, 11. A. HOLLÓ, J. HANCSÓK, D. KALLÓ: Kinetics of

Stuttgart/Ostfildern (Germany) hydroisomerization of C5-C7 alkanes and their

mixtures over platinum containing mordenite, Applied

2. H. WEYDA, E. KÖHLER: Modern refining concepts - Catalysis A: General, 229(1-2), (2002), 93–102

an update on naphtha-isomerization to modern

gasoline manufacture, Catalysis Today, 81(1), 12. T. LØFTEN, E. A. BLEKKAN: Isomerisation of n-

(2003), 51–55 hexane over sulphated zirconia modified by noble

metals, Applied Catalysis A: General 299, (2006),

3. SZ. MAGYAR, J. HANCSÓK, A. HOLLÓ: Key Factors 250–257

in the Production Of Modern Engine Gasolines, 6th

International Colloquim, Fuels 2007, Germany, 13. M. GUISNET, V. FOUCHE: Isomerization of n-hexane

Esslingen, 2007, In Proceedings (ISBN 3-924813- on platinum dealuminated mordenite catalysts, II.

67-1), 273–284 Kinetic Study, Appl. Catal, 71, (1991), 295–306

4. J. HANCSÓK, SZ. MAGYAR, ZS. SZOBOSZLAI, D. 14. H. LIU, G.D. LEI, W. M. H. SACHTLER: Alkane

KALLÓ: Investigation of energy and feedstock saving isomerization over solid acid catalysts. Effects of

production of gasoline blending components free of one-dimensional micropores, Appl. Catal., 137(1),

benzene, Fuel Processing Technology, 88(4), (2008), (1996), 167–177

393–399 15. C.-L. LI, L. SHI, G-X. HUANG, R.-Y. WANG: Scale-

5. J. HANCSÓK, SZ. MAGYAR, K. V. S. NGUYEN, ZS. up for Alkane Isomerization, Chem. Eng. Comm.,

SZOBOSZLAI, D. KALLÓ, A. HOLLÓ, GY. SZAUER: 121, (1993), 1–8

Simultaneous desulphurization, isomerization and

benzene saturation of n-hexane fraction on Pt-

H/MOR, Studies in Surface Science and Catalysis

(ISBN 0 444 52083 X), - Porous Materials in

Environmentally Friendly Processes 158, (2005),

1717–1724

Вам также может понравиться

- 2013 - JIEC - Octane Number Enhancement Studies Over Noble Metal Loaded Zeolite CatalystДокумент6 страниц2013 - JIEC - Octane Number Enhancement Studies Over Noble Metal Loaded Zeolite CatalystSandeep Kumar SaxenaОценок пока нет

- Light Naphtha Isomerization Process ReviewДокумент17 страницLight Naphtha Isomerization Process Reviewagarwalashwin32100% (2)

- Uop Tip and Once-Through Zeolitic Isomerization Processes: Nelson A. CusherДокумент12 страницUop Tip and Once-Through Zeolitic Isomerization Processes: Nelson A. CusherBharavi K SОценок пока нет

- Isomerization Process, Reactions, Effects of Process Variables. IsomerizationДокумент6 страницIsomerization Process, Reactions, Effects of Process Variables. IsomerizationAlaa El-sherbinОценок пока нет

- Penex Process PDFДокумент49 страницPenex Process PDFAhmed Mohamed KhalilОценок пока нет

- 1 - Journal of Chemical Technology & Biotechnology Volume 65 Issue 2 1996 Gayubo, Ana G. Benito, Pedro L. AguaДокумент7 страниц1 - Journal of Chemical Technology & Biotechnology Volume 65 Issue 2 1996 Gayubo, Ana G. Benito, Pedro L. AguaBehnam HosseinzaeiОценок пока нет

- Enhanced Performance of Zn-Sn/HZSM-5 Catalyst For The Conversion of Methanol To AromaticsДокумент9 страницEnhanced Performance of Zn-Sn/HZSM-5 Catalyst For The Conversion of Methanol To AromaticsArash AbbasiОценок пока нет

- IsomerizationДокумент8 страницIsomerizationWaraey50% (2)

- Development of A Kinetic Model For Catalytic ReformingДокумент9 страницDevelopment of A Kinetic Model For Catalytic ReformingFernandpОценок пока нет

- Oliver Van Rheinberg, Klaus Lucka, Heinrich Köhne, Thomas Schade, Jan T. AnderssonДокумент9 страницOliver Van Rheinberg, Klaus Lucka, Heinrich Köhne, Thomas Schade, Jan T. AnderssonbassamjavedОценок пока нет

- 476 ApicellaДокумент6 страниц476 ApicellaSudhir PatelОценок пока нет

- Anisole and Guaiacol Hydrodeoxygenation Over Monolithic PT SN CatalystsДокумент8 страницAnisole and Guaiacol Hydrodeoxygenation Over Monolithic PT SN CatalystsClaudia Elizabeth Ruiz DávilaОценок пока нет

- Catalytic ReformingДокумент18 страницCatalytic ReformingAleem AhmedОценок пока нет

- 5 - IsomДокумент72 страницы5 - IsomAn Lê TrườngОценок пока нет

- Fuel Processing Technology: Xianghai Meng, Zhixi Wang, Rui Zhang, Chunming Xu, Zhichang Liu, Yadong Wang, Qiang GuoДокумент5 страницFuel Processing Technology: Xianghai Meng, Zhixi Wang, Rui Zhang, Chunming Xu, Zhichang Liu, Yadong Wang, Qiang GuoRehim EhmedovОценок пока нет

- Chemcon 2013: Modeling, Simulation and Optimization of Naphtha Reforming Process On ASPEN Plus PlatformДокумент5 страницChemcon 2013: Modeling, Simulation and Optimization of Naphtha Reforming Process On ASPEN Plus PlatformArash AbbasiОценок пока нет

- Vernikovskaya2011 BanyakДокумент7 страницVernikovskaya2011 BanyakAisah Cory PrasonoОценок пока нет

- Enhanced Performance of Non-PGM Catalysts in Air Operated PEM-Fuel Cells 2016Документ7 страницEnhanced Performance of Non-PGM Catalysts in Air Operated PEM-Fuel Cells 2016Nikolay KorneevОценок пока нет

- Pujro 2014Документ32 страницыPujro 2014brianОценок пока нет

- Catalytic Conversion of C4 Fraction For The Production of Light OlefinsДокумент5 страницCatalytic Conversion of C4 Fraction For The Production of Light Olefinsaegosmith100% (1)

- IsomerizationДокумент10 страницIsomerizationRizwan Shehzad100% (2)

- Commercial Experience in The Operation of Ards Units in Kuwait National Petroleum Company at Mina Al-Ahmadi RefineryДокумент15 страницCommercial Experience in The Operation of Ards Units in Kuwait National Petroleum Company at Mina Al-Ahmadi RefineryOwais AhmedОценок пока нет

- Synthesis of Anisole by Vapor Phase Methylation of Phenol With Methanol Over Catalysts Supported On Activated AluminaДокумент3 страницыSynthesis of Anisole by Vapor Phase Methylation of Phenol With Methanol Over Catalysts Supported On Activated AluminaNitish Singh SengarОценок пока нет

- Hydrorefining of Catalytic Naphtha CutsДокумент3 страницыHydrorefining of Catalytic Naphtha CutsDavood IranshahiОценок пока нет

- Benzene XyleneChemicals 30052012Документ50 страницBenzene XyleneChemicals 30052012Chakravarthy Bharath100% (1)

- Bisphenol A Synthesis - Modeling of Industrial Reactorand Catalyst DeactivationДокумент7 страницBisphenol A Synthesis - Modeling of Industrial Reactorand Catalyst DeactivationDaniela JuradoОценок пока нет

- Hydrogen-Rich Gas Production With A Ni-Catalyst in A Dual Fluidized Bed Biomass GasifierДокумент15 страницHydrogen-Rich Gas Production With A Ni-Catalyst in A Dual Fluidized Bed Biomass GasifieraberahОценок пока нет

- Synthetic Jet Fuel Production by Combined Propene Oligomerization and Aromatic Alkylation Over Solid Phosphoric AcidДокумент7 страницSynthetic Jet Fuel Production by Combined Propene Oligomerization and Aromatic Alkylation Over Solid Phosphoric AcidMohammed GhanemОценок пока нет

- Ch4 Lect 1 - Catalytic Reforming & IsomerizationДокумент8 страницCh4 Lect 1 - Catalytic Reforming & IsomerizationTarlan AllahverdiyevОценок пока нет

- Improvement of Gasoline Octane Number by Using OrganicДокумент7 страницImprovement of Gasoline Octane Number by Using OrganicRawezh Muhtasim MustafaОценок пока нет

- Topsoe Prereforming CatalystДокумент13 страницTopsoe Prereforming CatalystReza RhiОценок пока нет

- GT2009 60333Документ16 страницGT2009 60333PaulОценок пока нет

- 3 - Project Structure PDFДокумент191 страница3 - Project Structure PDFAn Nguyen BinhОценок пока нет

- Planta PilarizacionДокумент5 страницPlanta PilarizacionarbeyvillalbaОценок пока нет

- Reuse of Spent FCC Catalyst For Removing Trace Olefins From AromaticsДокумент5 страницReuse of Spent FCC Catalyst For Removing Trace Olefins From AromaticsphantanthanhОценок пока нет

- Detailed Description of Kinetic and Reactor Modeling For Naphtha CA 2011 FueДокумент20 страницDetailed Description of Kinetic and Reactor Modeling For Naphtha CA 2011 FuedownloadОценок пока нет

- Fuel Processing Technology: Hao Ling, Qiang Wang, Ben-Xian ShenДокумент5 страницFuel Processing Technology: Hao Ling, Qiang Wang, Ben-Xian ShenpeymanОценок пока нет

- EOR With Penn State Surfactants: T.G. ArfДокумент11 страницEOR With Penn State Surfactants: T.G. ArfSajad FalahОценок пока нет

- Ahmad Hamidd IzomerizationДокумент6 страницAhmad Hamidd Izomerizationاحمد حمید کارسول عزیزОценок пока нет

- Metal Supported Zeolite For Heavy Aromatics Transalkylation ProcessДокумент10 страницMetal Supported Zeolite For Heavy Aromatics Transalkylation ProcessArash AbbasiОценок пока нет

- Advances in CatalystsДокумент104 страницыAdvances in CatalystsKrishnamoorthy VijayalakshmiОценок пока нет

- Optimization of The Reaction Parameters of Heavy Naphtha Reforming Process Using Pt-Re/Al2O3 Catalyst SystemДокумент9 страницOptimization of The Reaction Parameters of Heavy Naphtha Reforming Process Using Pt-Re/Al2O3 Catalyst SystemrujunliОценок пока нет

- Yoshimura 2001Документ11 страницYoshimura 2001Clive GriffithsОценок пока нет

- Light Alkane (Mixed Feed) Selective Dehydrogenation Using Bi-Metallic Zeolite Supported CatalystДокумент8 страницLight Alkane (Mixed Feed) Selective Dehydrogenation Using Bi-Metallic Zeolite Supported Catalystbinapaniki6520Оценок пока нет

- Snamprogetti New MTBE Production Design PDFДокумент13 страницSnamprogetti New MTBE Production Design PDFViệt HàОценок пока нет

- Coking Kinetics On The Catalyst During Alkylation of FCC Off-Gas With Benzene To EthylbenzeneДокумент7 страницCoking Kinetics On The Catalyst During Alkylation of FCC Off-Gas With Benzene To EthylbenzeneAndres PeñaОценок пока нет

- Determination of Metals in Lubricating Oil by ICP-OES: Application NoteДокумент6 страницDetermination of Metals in Lubricating Oil by ICP-OES: Application NoteIan RidzuanОценок пока нет

- 10 1016@j Ijhydene 2016 07 072Документ13 страниц10 1016@j Ijhydene 2016 07 072peymanОценок пока нет

- Cha Acterization Delayed Feedstocks and Products 1H and Uc NMRДокумент8 страницCha Acterization Delayed Feedstocks and Products 1H and Uc NMRrozecamОценок пока нет

- Towards A Zero Gasoline Refinery PTQ Parts 1 2Документ15 страницTowards A Zero Gasoline Refinery PTQ Parts 1 2Anil UpadhyaОценок пока нет

- Industrial Catalytic Processes Phenol PRДокумент15 страницIndustrial Catalytic Processes Phenol PRJesús MorenoОценок пока нет

- A Planning Model For The Optimal Production of A Real-World Ethylene PlantДокумент10 страницA Planning Model For The Optimal Production of A Real-World Ethylene PlantmarraezОценок пока нет

- Biopolymer Plugging Effect Laboratorypressurized Pumping 2004Документ1 страницаBiopolymer Plugging Effect Laboratorypressurized Pumping 2004Meghna SharmaОценок пока нет

- Transesterification Catalyzed by Industrial Waste Lime - 2014 - Energy ConversiДокумент8 страницTransesterification Catalyzed by Industrial Waste Lime - 2014 - Energy ConversiVincent PilienОценок пока нет

- Cul Faz 1984Документ10 страницCul Faz 1984ViolitaОценок пока нет

- Graphene-based Carbocatalysis: Synthesis, Properties and Applications: Volume 1От EverandGraphene-based Carbocatalysis: Synthesis, Properties and Applications: Volume 1Оценок пока нет

- Multiphase Reactor Engineering for Clean and Low-Carbon Energy ApplicationsОт EverandMultiphase Reactor Engineering for Clean and Low-Carbon Energy ApplicationsYi ChengОценок пока нет

- Hydrogen Production TechnologiesОт EverandHydrogen Production TechnologiesMehmet SankirОценок пока нет

- Synthetic Natural Gas: From Coal, Dry Biomass, and Power-to-Gas ApplicationsОт EverandSynthetic Natural Gas: From Coal, Dry Biomass, and Power-to-Gas ApplicationsTilman J. SchildhauerОценок пока нет

- Carbon Nanomaterials for Advanced Energy Systems: Advances in Materials Synthesis and Device ApplicationsОт EverandCarbon Nanomaterials for Advanced Energy Systems: Advances in Materials Synthesis and Device ApplicationsWen LuОценок пока нет

- General Catalogue 0819 Gb-3Документ186 страницGeneral Catalogue 0819 Gb-3Omar SaeedОценок пока нет

- iN7kgJ Temperature Controller Ai518518p Operation Manual PDFДокумент57 страницiN7kgJ Temperature Controller Ai518518p Operation Manual PDFOmar SaeedОценок пока нет

- Archive of SIDДокумент11 страницArchive of SIDOmar SaeedОценок пока нет

- AN-DOWINETANK-E RevB 0919 v1Документ5 страницAN-DOWINETANK-E RevB 0919 v1Omar SaeedОценок пока нет

- RON, MON, Aromatics, Benzene, and Olefins in GasolineДокумент4 страницыRON, MON, Aromatics, Benzene, and Olefins in GasolineOmar SaeedОценок пока нет

- Calculations of Stratified Wavy Two-Phase Ow in Pipes: Petter Andreas Berthelsen, Tor YtrehusДокумент22 страницыCalculations of Stratified Wavy Two-Phase Ow in Pipes: Petter Andreas Berthelsen, Tor YtrehusOmar SaeedОценок пока нет

- Quality Control of Gasoline: Rapid Determination of RON, MON, AKI, Aromatic Content, and DensityДокумент5 страницQuality Control of Gasoline: Rapid Determination of RON, MON, AKI, Aromatic Content, and DensityOmar SaeedОценок пока нет

- Applied Mathematical Modelling: David Winfield, Nick Croft, Mark Cross, David PaddisonДокумент14 страницApplied Mathematical Modelling: David Winfield, Nick Croft, Mark Cross, David PaddisonOmar SaeedОценок пока нет

- Catalytic Steam Gasification of Mengdong Coal in The Presence of Iron Ore For Hydrogen-Rich Gas ProductionДокумент13 страницCatalytic Steam Gasification of Mengdong Coal in The Presence of Iron Ore For Hydrogen-Rich Gas ProductionOmar SaeedОценок пока нет

- 1200C Hydrogen Atmosphere Furnace PDFДокумент10 страниц1200C Hydrogen Atmosphere Furnace PDFOmar SaeedОценок пока нет

- 3.1. Two Dimensional Fluid Bed, Two Fluid Model (TFM) - MFiX 18.1.0 Documentation 2Документ16 страниц3.1. Two Dimensional Fluid Bed, Two Fluid Model (TFM) - MFiX 18.1.0 Documentation 2Omar SaeedОценок пока нет

- Approved Service CentresДокумент4 страницыApproved Service CentresOmar SaeedОценок пока нет

- Unequally Numerical DifferentiationДокумент4 страницыUnequally Numerical DifferentiationOmar SaeedОценок пока нет

- FORZA Oxidation IHT Copy. - CompressedДокумент1 страницаFORZA Oxidation IHT Copy. - CompressedOmar SaeedОценок пока нет

- MODEL: 73VR21: Paperless Recording System Paperless Recorder (3) Power InputДокумент18 страницMODEL: 73VR21: Paperless Recording System Paperless Recorder (3) Power InputOmar SaeedОценок пока нет

- Low Profile Side Access Calibration TrailerДокумент2 страницыLow Profile Side Access Calibration TrailerOmar SaeedОценок пока нет

- DehydrogenationДокумент6 страницDehydrogenationOmar SaeedОценок пока нет

- Cx2000 Conductivity/ Resistivity Transmitter: Product Specification SheetДокумент1 страницаCx2000 Conductivity/ Resistivity Transmitter: Product Specification SheetOmar SaeedОценок пока нет

- Parafuel Crude Oil AnalyzerДокумент2 страницыParafuel Crude Oil AnalyzerOmar SaeedОценок пока нет

- 17CEO-1 - CEO Interview - Odin EnergyДокумент5 страниц17CEO-1 - CEO Interview - Odin EnergyOmar SaeedОценок пока нет

- Micromac Hardness On Line Analyzer For Hardness Monitoring in WaterДокумент2 страницыMicromac Hardness On Line Analyzer For Hardness Monitoring in WaterOmar SaeedОценок пока нет

- Please See The Selected Items With Orang Squares.Документ1 страницаPlease See The Selected Items With Orang Squares.Omar SaeedОценок пока нет

- Aeon 9000spДокумент1 страницаAeon 9000spOmar Saeed100% (1)

- Dowex HCR SS LДокумент2 страницыDowex HCR SS LOmar SaeedОценок пока нет

- 478 1Документ90 страниц478 1Omar SaeedОценок пока нет

- Frants in A 2014Документ11 страницFrants in A 2014Omar SaeedОценок пока нет

- Alkene Preparation and ReactionsДокумент46 страницAlkene Preparation and Reactionsnlprofessional07Оценок пока нет

- 9.3 Alkenes and AlkynesДокумент10 страниц9.3 Alkenes and AlkynesMirjeta ZymeriОценок пока нет

- 2019 p2 Revision MaterialДокумент127 страниц2019 p2 Revision MaterialTafiОценок пока нет

- Readable!Документ342 страницыReadable!Mot EmbyОценок пока нет

- Naphtha HydrotreatingДокумент19 страницNaphtha HydrotreatingAnge JoОценок пока нет

- IUPAC Nomenclature of Organic Chemistry: Basic PrinciplesДокумент17 страницIUPAC Nomenclature of Organic Chemistry: Basic PrinciplesSUBHENDU5174124Оценок пока нет

- 0620 w16 QP 41Документ16 страниц0620 w16 QP 41SuryaОценок пока нет

- Q=Mxcxδt: Df1 - Getting Energy From FuelsДокумент6 страницQ=Mxcxδt: Df1 - Getting Energy From FuelskjОценок пока нет

- Execises - Organic Chemistry Chapter 2 Part 1Документ2 страницыExecises - Organic Chemistry Chapter 2 Part 1Michelle ChicaizaОценок пока нет

- Notes of CH 4 Carbon and Its Compounds - Class 10th Science Study RankersДокумент15 страницNotes of CH 4 Carbon and Its Compounds - Class 10th Science Study Rankersjaya kumariОценок пока нет

- Organic Chemistry: The Chemistry of Life and Living ThingsДокумент27 страницOrganic Chemistry: The Chemistry of Life and Living ThingsdsaОценок пока нет

- 1 6htyjkДокумент43 страницы1 6htyjkBukhara PS PILEDUОценок пока нет

- Kendall Hunt-Chemcom - Chemistry in The Community-Kendall Hunt Pub Co (1996) PDFДокумент662 страницыKendall Hunt-Chemcom - Chemistry in The Community-Kendall Hunt Pub Co (1996) PDFFranklin Manrique100% (1)

- Basoflux Paraffin Control For The Oil IndustryДокумент6 страницBasoflux Paraffin Control For The Oil Industryyugatha100% (1)

- Petro FullДокумент239 страницPetro FullOhol Rohan BhaskarОценок пока нет

- Activity On AlkanesДокумент3 страницыActivity On AlkanesKayobi BuenviajeОценок пока нет

- The Future of Metalworking Fluid Aditivies in IndiaДокумент9 страницThe Future of Metalworking Fluid Aditivies in IndiaGaurav ChauhanОценок пока нет

- Report For Apiay Blend OficialДокумент1 страницаReport For Apiay Blend OficialweinigunОценок пока нет

- HowStuffWorks - How Oil Refining WorksДокумент3 страницыHowStuffWorks - How Oil Refining Worksnishant361Оценок пока нет

- Organic ChemistryДокумент26 страницOrganic Chemistryapi-379837460% (5)

- Hydrocarbons Class 11 Notes Chemistry Chapter 13 - Learn CBSEДокумент1 страницаHydrocarbons Class 11 Notes Chemistry Chapter 13 - Learn CBSEjaindhruv850Оценок пока нет

- Class X Chemistry Asm Term IiДокумент10 страницClass X Chemistry Asm Term IiAarush GuptaОценок пока нет

- Selective Oxidation PDFДокумент16 страницSelective Oxidation PDFLam DesmondОценок пока нет

- Notes On AlcoholsДокумент3 страницыNotes On AlcoholsAnchal ChadhaОценок пока нет

- Test For UnsaturationДокумент3 страницыTest For UnsaturationJanaye IfillОценок пока нет

- Practice Final ExamДокумент18 страницPractice Final Examdeckbyte865Оценок пока нет

- Energy Chemistry NotesДокумент11 страницEnergy Chemistry NotesClayton Feng100% (1)

- JOTUN Tankguard Flexline Resistance List 19 Aug 21Документ57 страницJOTUN Tankguard Flexline Resistance List 19 Aug 21aleksandarshoylevОценок пока нет

- Summative Test - HydrocarbonsДокумент2 страницыSummative Test - HydrocarbonsJoselyn Villena MarquezОценок пока нет

- Spe 9235Документ10 страницSpe 9235Anonymous 2MI1EjFN3cОценок пока нет