Академический Документы

Профессиональный Документы

Культура Документы

Reiss 1967

Загружено:

Daniel Camilo Cano BlancoИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Reiss 1967

Загружено:

Daniel Camilo Cano BlancoАвторское право:

Доступные форматы

literature Cited Sege, G., LYoodfield, F. W., Chem. Eng. Progr. 50, No.

8, 396-402

(1954).

Gier, R. G., “Application of the Pulse Column to the Purex Weech, M. E., P’Pool, R. S., McQueen, D. K., “Interim Report

Process,” Symposium on the Reprocessing of Irradiated Fuels, on the Development of an Air Pulstr for Pulse Column Ap-

Brussels, Belgium, May 1957 (TID-7534, Book I). plication,” IDO-14559 (Sept. 22, 1961) ( U S . Dept. of Com-

Hamming, R. W.,“Numerical Methods for Scientists and Engi- merce, Office of Technical Services, Springfield, Va.).

neers,’’ McGraw-Hill, New York, 1962.

Perry, John H., “Chemical Engineer’s Handbook,” 3rd ed., p. 383, RECEIVED

for review October 31, 1966

McGraw-Hill, New York, 1950. ACCEPTED March 27, 1967

COCURRENT GAS-LIQUID CONTACTING

IN PACKED C O L U M N S

L. P H I L I P REISS1

Shell Development Go., Emeryville, Calif.

New experimental data obtained for a variety of packing materials in small-scale and semicommercial-

scale equipment for cocurrent gas-liquid contacting in packed columns are presented, including pressure

loss, liquid holdup, radial liquid distribution, ammonia absorption, and oxygen desorption mass-transfer

coefficients. Existing correlations for single-phase and two-phase pressure loss and liquid holdup ade-

quately describe the experimental data. New correlations for mass transfer capacity coefficient are

based on the concept of energy dissipation per unit volume. Cocurrent gas-liquid contacting is advan-

tageous over countercurrent contacting when only one equilibrium contacting stage is required: physical

absorption a t large liquid-to-gas ratios, physical desorption a t low liquid-to-gas ratios, and transfer with

a consuming chemical reaction in one phase.

HE vast majority of the commercial packed columns for operations where only one equilibrium stage is required.

Tgas-liquid contacting is operated countercurrently. The For example, as pointed out by Wen et al. (1963a), if the

liquid phase falls downward because of gravity, while the gas transferring component is transferred from one fluid phase and

phase moves upward through the column because of a n im- is consumed by chemical reaction in the other phase, only one

posed pressure gradient. The gas throughput in this type of equilibrium stag? is required. For a conventional absorption

operation is limited. Above a critical gas velocity the gravity a t large liquid-to-gas ratios, the concentration of the trans-

forces on the downfloiving liquid are exceeded by the drag ferring component in the liquid phase is low, because of the

forces imposed on the liquid by the upflowing gas. This excess of liquid. Because this shifts the equilibrium, only one

unstable condition is known as flooding and is the charac- equilibrium stage may be required to reduce the concentration

teristic of all countercurrent gas-liquid contacting operations. of the transferring component in the gas phase to the desired

One means of overcoming this throughput limitation of level. The same applies in reverse for stripping operations a t

countercurrent operation is to operate the packed column low liquid-to-gas ratios. With an excess of gas, the gas-phase

cocurrently. Both the gas and liquid are introduced a t the concentration of the transferring component may be so low

top of the column and flow cocurrently doivnward through the that the equilibrium is shifted. Hence, a stripping operation

column because of a combination of gravity and applied could conceivably also be carried out in one equilibrium stage.

pressure gradient. There is no flooding limit for this type of Operation a t high liquid-to-gas or low liquid-to-gas ratios in

operation and the throughput of gas and liquid, up to choked the cocurrent mode does not present the flooding problem that

flow, depends only on the available pressure to drive the fluids these extreme liquid-to-gas ratios might present in counter-

through the column. current operation.

Cocurrent operation appears advantageous from the fluid Therefore, cocurrent gas-liquid contacting is generally

mechanics standpoint, in that flooding can be eliminated. applicable for operations involving only one equilibrium

However, from a mass-transfer standpoint, cocurrent operation stage. These include absorption with chemical reaction in

has a definite limitation relative to countercurrent operation. one phase-Le., gas-liquid chemical reactors, absorption a t

The over-all concentration driving force and the number of high liquid-to-gas ratios, and desorption or stripping a t low

equilibrium stages in countercurrent operation are greater than liquid-to-gas ratios. Cocurrent operation is not limited by

in cocurrent operation. I n fact, cocurrent operation results flooding. Hence, greater throughputs of gas and liquid can

in only one equilibrium stage. be achieved than in conventional countercurrent packed

There are, however, a number of gas-liquid contacting columns of similar size, or smaller equipment may be able to

do the same job.

Present address, Research and Development Laboratory, There is a large body of literature devoted to the design and

Shell Pipe Line Corp., Houston, Tex. operation of countercurrent packed columns. By contrast,

486 l&EC PROCESS D E S I G N A N D DEVELOPMENT

only comparatively few references have appeared o n cocurrent and Myers, 1964), and i n only two cases (Hoftyzer, 1964;

contacting. Table I summarizes the experimental data avail- Weekman and Myers, 1964) the flow was actually cocurrent.

able i n the literature which are applicable to the design of Extensive pressure loss data are available for single-phase flow

cocurrent gas-liquid packed column contactors. T h e gas through random and stacked packing. A successful means of

and liquid rates range from those characteristic of “trickle correlating these data has been suggested by Ergun (1952).

phase” operation (V, x 0.5 foot per second, Vi x 0.01 foot There are many areas where design data are insufficient or

per second) to higher rates which are more representative of completely lacking (Table I), particularly i n cocurrent con-

absorption operation ( V g = 5 feet per second, V i= 0.1 foot per tacting mass transfer, and no consistent design procedure has

second). been established for cocurrent gas-liquid contacting in packed

T h e more significant papers o n cocurrent contacting are by columns. This is somewhat surprising i n view of the potential

Larkins (1959, 1961), McIlvroid (1956), and Wen (1963, a, b). attractiveness of this mode of packed column operation. This

Larkins measured pressure drop and liquid holdup for co- work presents new experimental data on single-phase and two-

current flow through beds of dumped packing and correlated phase pressure loss, liquid holdup, liquid radial distribution,

these data using a n approach similar to that of Lockhart and and gas-phase and liquid-phase resistance controlling mass

Martinelli (1 949). These represent the only design correla- transfer for cocurrent gas-liquid contacting i n packed columns

tions for two-phase pressure drop and holdup i n cocurrent flow and correlates these data empirically into design equations to

i n packed beds. Pressure drop data obtained by Weekman give a consistent design procedure. The accuracy of this

and Myers (1964) were also correlated using the Larkins procedure is adequate for preliminary design leading to initial

approach, and additional pressure loss data are presented by cost estimates.

Dodds et al. (1960b). McIlvroid (1956) presents pressure drop

and liquid phase controlling mass-transfer data for cocurrent

Experimental Equipment

contacting in beds of small dumped packing. Wen (1963)

measured pressure loss and mass-transfer rates using the ab5orp- Columns. Design data for cocurrent gas-liquid contacting

tion of water vapor from air into calcium chloride solutions. were obtained on two packed column scales. T h e small-

Wen’s (1963) and McIIvroid’s (1956) papers represent the only scale equipment consisted of two columns, 3 and 4 inches in

i.d., and the large-scale column was 16 inches in i.d. T h e

data on mass transfer i n cocurrent flow which can be used for schematic flow diagram for columns on both scales is shown

design purposes. in Figure 1. Figure 2 is a photograph of the 16-inch column.

Additional design information, relative to cocurrent con- Air and water are introduced into the top of the column

tacting, is the radial distribution of liquid within the packing through a n inlet distributor, which was designed to give good

initial distribution of gas and liquid over the packing. T h e

and the pressure loss for single-phase flow through packing.

gas and liquid flowed cocurrently downward and were sepa-

Very limited data on radial distribution of liquid have been rated in a sump tank. The air was vented to the atmosphere.

reported (Hoftyzer, 1964; Porter and Jones, 1963 ; Weekman The water could be operated as only a once-through flow, a

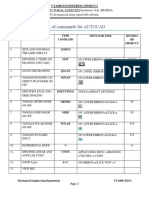

Table 1. Experimental Data Available in the Literature for Cocurrent Gas-liquid Downflow in Packed Beds

Experimental Data Reported

V , Range, Ft./Sec. V , Range, Ft./Sec. - AP

Packing 7 y p e -.- h Liquid k l7a kla Ref.

3in. Max. Min . Max. AZ dik.

Dumped Raschig rings, inches

‘14 1.8 18 0.092 0.25 X x McIlvroid 11956)

’/4 0.35 3.5 0.015 0.051 X X iVen et al. (1963a, b )

”8 0.50 26 0.020 0.87 X X Larkins (1959, 1961)

’I2 0 0 0.0033 0.0033 X Porter and Jones (1963)

‘/2 0.35 3.5 0.015 0.051 X X Tl‘en et al. (1963a, b )

1 0.35 3.5 0.015 0,051 X X TVen et al. (1963a, b )

1 0 2.6 0.0033 0.030 X Hoftyzer (1964)

1.8 12 0.019 0.13 X X a Dodds et al. (1960a, b )

Dumped Pall rings

1 0 0 0,0033 0.0033 X Porter and Jones (1963)

Berl saddles, inches

‘12 0 0 0.0033 0.0033 X Porter and Jones (1963)

‘/z 0.70 4.5 0.0074 0.051 X TVen et al. (1963b)

1 1.8 12 0.019 0.13 Y X Dodds et al. (1960a, b )

1 1.8 12 0.019 0.13 X X Dodds et al. (1960a, b )

Intalox saddles, inches

‘12 0.70 4.5 0,0074 0.051 X TVen et al. (1963b)

1 0.70 4.5 0.0074 0.051 X \Yen rt al. 11963b)

1 1.8 12 0.019 0.13 X X a Dodds et al. (1960a, b )

1‘/2 1.8 12 0.019 0.13 X X Dodds et al. (1960a, b )

Dumped spheres, mm.

3 0.089 1.3 0.0027 0.081 X X Larkins (1959, 1961)

1.8 18 0.031 0.42 X x McIlvroid (1956)

1.8 18 0.031 0.42 X x McIlvroid (1956)

0.17 4.1 0.0055 0.11 X Tl’eekman and Myers

(1964, 1965)

4.75 0.17 4.1 0.0055 0.11 X LVeekman and Myers

(1964, 1965)

6.48 0.17 4.1 0.0055 0.11 X Tt’eekman and Myers

11964, 1965)

3 1 8 inch 0.50 26 0.020 0.87 X X Larkins (1959, 1961)

Pellets

inch 0.50 26 0.020 0.87 X X Larkins 11959, 1961)

a Statistical analyses of variables afecting GO? absorption into ‘VaaOH solutions; no design data Data f o r heat transfer through column wall to gas-liquid

cocurrentj7ow available f r o m Weekman and Myprs (1965).

VOL. 6 NO. 4 OCTOBER 1967 487

completely recycling flow, or a combination of each, where a I n the small columns quick-dosing valves were arranged so

fraction of the recycling water flow was continuously replaced that holdup of liquid could be measured. The technique for

by fresh make-up water. holdup measurement was similar to that ofLarkins (1959).

Provisions were made far mixing ammonia with the incoming Packing. T h e packing used in this study was predominantly

air Stream and for saturating the recycling water stream with thin-walled polyethylene R a x h i g rings ranging from '/z to

I;;

oxygen. Temperature control was provided by cooling coils 3 inches. The packed beds were made by both stacking and

located in the sump, Pressure loss was measured across dumping the rings. One series of experiments utilized a bed of

various segments of the packed bed by pressure taps located a t dumped 1-inch Intalox saddles. The packing data are sum-

different points around the column circumference a t each marized in Table 11.

elevation. Gas-phase and liquid-phase samplers were located The beds of stacked 1- and 3-incb rings were ~iiaocuy srack-

-

a t various axial and radial positions within the packed bed. ing the polyethylene rings on triangular centers. A layer of

packing was offset from the layer below, so that every third

layer was identically oriented. The rings were held together

.

r Packed Taps

in an array by fusing their points of contact with 'a warm

soldering iron. After the array was properly oriented and

assembled, it was cut to fit the inside diameter of the 4- or

16-inch column. As a result, there were fractional segments of

rings next to the column wall, and in effect, these packed

beds were merely a core from a larger bed. A core of 1-inch

rings from the 4-inch column is shown in Figure 3. Figure 4

shows the stacked array of '/$-inch rings in a section of the 3-

inch column. For this case only, whole rings were stacked in

mop

randomly offset layers. The resulting radial distribution of

voidage was not uniform.

Radial Liquid Distribution. The 16-inch column was

equipped to measure the radial liquid distribution. A liquid

i

vgnt

I

. -.

mown m Figure ~

3.

-.

collector was assembled with individual compartments as

?* . was ,mcatea

i n e couecmr . ~oirecriy

1. .

, ., O ~1~ O W

U Sump

the packing, so that each compartment received the liquid

falling from the packing immediately above it. T h e outlet

Cooling

Tank from each compartment was connected to a two-way, 13-port

water valve. T h e gas-liquid flaw through each compartment could

flow directly to the sump tank or be diverted for a short interval

to 13 individual collecting drums (see Figure 2). The liquid

Drain

I flow through each compartment could he measured by deter-

mining the volume of water in each drum after a short interval

of diverted flaw.

The gas and liquid inlet distributor is shown in Figure 6.

Air and water could be introduced bv a series of concentric

Figure

column

' ' Genera' "Ow diagram Of packed 'Ocurrent

air jets with water in the surraundihg annulus. This dis-

tributor configuration was known as the water-in-annulus

distributor. The discharge of the concentric nozzles was about

2 inches above the packed bed. A large-scale single-concen-

tric nozzle is shown in Figure 7. Measurements of liquid

distribution for this nozzle were made to evaluate its per-

formance, as its dimensions are similar to a single nozzle

which might he used as part of a waler-in-annulus distributor

a n a commercial scale.

A scaled-down version of the water-in-annulus distributor

was used in the 3- and 4-inch columns.

Mass Transfer. In establishing the technique for mass-

transfer measurements, two objectives were kept in mind.

First, the measurements of concentration should be made

within the packed bed to give a profile along the bed length

and not just inlet and outlet concentrations. This eliminates

"entry effects" resulting from mass transfer in the inlet and

outlet of the packed column. Second, measurements of

concentration should be continuous and instantaneous. This

ensures that conditions are a t steady state when measurements

are made.

T o accomplish the first objective, small gas-liquid separators

were made from individual rings in the packed bed. To

obtain a liquid-free gas sample, a ring was located with its

axis parallel to the column axis and the upper end capped off.

A hypodermic tube was introduced through the ring wall just

under the capped-off end; the other end of the tube extended

out through the column wall. For dumped beds these ring

samplers were installed in the empty column and the packing

was carefully dumped around them. Far stacked packing,

one of the rings in the array was used directly as a sampler.

The rate of gas flow through these samplers was carefully con-

trolled so that no liquid was entrained. Thus a continuous

liquid-free gas sample could be withdrawn from any point in

the bed. jvithout mass transieer taking place in the sample line.

l o obtain a liquid sample the whole packed bed was simply

Figure 2. 16-inch diameter cocwrent packed column inverted so that the ring samplers had their bottoms capped off.

488 l&EC PROCESS DESIGN A N D DEVELOPMENT

Figure 3. 4-inch core

of stacked 1-inch

Raschig rings

I'igure 4. 3-inch cob

Jmn with stacked %-

irich Roschig rings

@ @ I @ @

tigure 6. Gas-liquid inlet distributor

Figure 5. Collector for 16-inch column

Fractional Area

Radius, of Individual

Inches Comportment

Wall ring 8.00 0.0321

First ring 7.47 0.1089

Second ring 5.28 0.0802

Center ring 2.71 0.1150 Figure 7. Commercial scale water in annulus nozzle

VOL. 6 NO. 4 OCTOBER 1 9 6 7 489

Liquid collected in these samplers and was slowly drained off, values are tabulated in Table I1 along with the packed bed

giving a gas-free liquid sample. properties.

Ammonia absorption was chosen to represent a gas-phase

resistance controlling mass transfer system and oxygen desorp- The constants in the Ergun equation have different values

tion was used for liquid-phase controlling transfer. Therefore, for each packing material. This is i n agreement with the

to satisfy the second objective, procedures for continuous results of Larkins (1959) ; however, Ergun (1952) suggested

analysis of ammonia in air and oxygen in water were required. that a and p were constant for all packed beds of granular

Ammonia concentrations were first analyzed by a @ray material.

ionization probe which utilized the principle of cross-section

ionization (Deal et al., 1956; Lovelock, 1961; Otvos and Two-Phase Pressure Loss. The method proposed by

Stevenson, 1956). A cross-section ionization probe was con- Larkins (1959) for correlating two-phase pressure loss data

structed using tritium foil as a source of 0 radiation to ionize in packed columns was used to correlate the two-phase pressure

the sample. The ammonia-air sample flowed through a gap loss data obtained in this investigation. Larkins reduced the

in this probe, across which a potential of 120 volts was imposed.

The small electrical current flowing through the gap of ionized momentum equation for steady two-phase vertical downflow to

gas was measured with a Keithley Model 417 picoammeter.

This probe was calibrated with known ammonia-air samples,

so that the current flow was a direct continuous measurement (3)

of the ammonia concentration. This technique was adequate

in the range 0.001 to 0.1 mole fraction of ammonia in air.

An improved technique for ammonia-air analysis was

developed which extended the range of concentration down to

0.000050 to 0.010 mole fraction (50 to 10,000 p.p.m.), enabling The effective density, p m , for vertical two-phase flow in

large scale experiments to be operated safely with the gas packed beds may not be described as simply as expressed by

discharge directly to atmosphere. This technique utilized

the ultraviolet absorption characteristics of ammonia a t 204.3 Equation 4, in that Equation 4 assumes that all downflowing

mp (Gunther et al., 1956, 1958; Kolbezen, 1964). A Beck- liquid contributes to the effective density or “head.” I n a

man Model D U R recording spectrophotometer was used with packed column much of this liquid is not free falling but runs

flow through ultraviolet quartz sample cells of 10- and 100- over the packing surface. Consequently, only a small fraction

mm. optical length. Temperature control assured that the of the total liquid holdup actually is contributing to the effec-

sample and cell temperature remained constant a t 24.5’ =k

0.5’ C. Standard ammonia-air samples were used for calibra- tive density or head. As a result, the effective density may be

tion and the per cent light transmittance, which could be smaller than given by Equation 4 and indeed the “head”

continuously recorded, deviated only slightly from the Lambert- term gpnl/gC in Equation 3 may be small compared to the

Beer law over the whole range of concentration. other two terms.

The concentration of dissolved oxygen in the water was

continuously measured by means of a Beckman Model 260 The maximum numerical value of the effective density

physiological gas analyzer. The macroprobes supplied with calculated by Equation 4 for total holdup values measured in

this instrument were inserted in special flow through probe packed beds is about 0.12 p.s.i. per foot. Hence, if ( h P / A Z ) , ,

holders which were attached to the discharge lines of the liquid is greater than ca. 0.6 p.s.i. per foot the effective density term

samplers. Reference baths of saturated water solutions of Nz, or head effect can be neglected without serious error. A care-

air, and O2held a t column temperature were used for calibra-

tion. ful review of Larkins’ data (1959) shows that the measured

pressure loss was less than 0.6 p.s.i. per foot for only four out of

Experimental Results 190 runs. Hence, there is no conclusive evidence as to the

correctness of applying Equation 4 to calculate the effective

Single-phase Pressure Loss. Single-phase pressure loss density of gas-liquid cocurrent downflow in packed beds.

was measured with both air and water flowing singly in the For the two-phase pressure loss data of this study, the effec-

small columns, while air alone was used in the 16-inch column. tive density or head effect was neglected for all runs. For

T h e experimental data were expressed in the form of the large liquid flow rates where liquid was observed to be free-

Ergun (1952) equation falling, the effective density could possibly be given by Equa-

tion 4. But the measured pressure loss for these cases usually

exceeded 0.6 p.s.i. per foot. For lower liquid flow rates where

the pressure loss was less than 0.6 p.s.i. per foot the liquid was

where observed to flow mainly over the packing surface, and Equation

4 is probably not valid. These conclusions have also been

reported by Weekman and Myers (1964).

The form of the Larkins (1959) pressure drop formula may be

Constants a and p were determined by least squares and the expressed as

Table II. Dimensions of Packing and Properties of Packed Beds

‘/*-inch ‘/*-inch 1-inch 1-inch 3-inch I-inch

Packing dumped stacked dumped stacked stacked Intalox

Ring height, inches ’12 ‘12 1 1 3

Ring o.d., inches ‘ I 2 ‘/2 1 1 3

Ring wall thickness, inch 3/84 3/84 1/16 1/~6 3i16

Column i.d., inches 3 3 16 4 and 16 16

16

E 0.783 0.726 0.883 0:787 0.787 0.682

a,, sq. ft./cu. ft. 117 153 47.8 86.7 28.9 78.0

D,,ft. 0.0105 0.0105 0.0147 0,0147 0.0442 0.0245

01 110 83.8 920 129 122 135

P 2.04 0.234 5.51 0.117 0.108 2.00

490 l & E C PROCESS D E S I G N A N D DEVELOPMENT

where

x = (6L/6,)"2

Experimental data for all packing types except 3-inch rings

are shown i n Figure 8 in comparison with Equation 5. T h e

+ 5 0 ~ 0lines are ale7 shown and the majority of the data lie

within these limits.

The experimental data on stacked 3-inch rings showed large

deviations when corrrelated i n this fashion. T h e contribution

of the effective density is more important for 3-inch stacked

rings than for any other packing types investigated, because

measured values of two-phase pressure loss are small and the

packing surface area is lower than for other types used. Hence,

for any liquid flow rate, the fraction of free-falling liquid will be

larger and the effective density contribution probably cannot

be neglected. As holdup could not be measured in the 16-

inch column, the effective density could not be evaluated.

T h e actual experimental pressure loss data for stacked 3-inch

rings are shown in Figure 9.

Liquid Holdup. Liquid holdup measurements were

made in the small 3- and 4-inch columns by sudden closing

of ball valves on the liquid and gas inlets and the column

outlet. End effect corrections were estimated by bolting the

inlet and outlet flanges together with the packed bed sections

removed. T h e liquid held up in the entry and exit sections IO-'

1

d

v

I I I I I l l 1

10

I I I I I I I I

was subtracted from total holdup when the column was in Vg,f t / s e c

place.

Holdup data from stacked and dumped '/'-inch rings and Figure 9. Two-phase pressure drop for stacked 3-inch

stacked 1-inch rings are shown in Figure 10. T h e Larkins Raschig rings

(1959) holdup correlation

log h = -0.774 + 0.525 (log x) - 0.109 (log x ) ~ (6)

Establishing a good initial liquid distribution resolves only

part of the liquid distribution problem. As the flow proceeds

is also shown. Most (data points are within &5070 limits through the bed, liquid migrates toward the wall. If this is

shown. T h e largest deviations are with stacked 1-inch rings severe, liquid redistributors may be required. As a result,

a t high liquid rates. (Caution should be exercised if Equa- liquid distribution after flow through various bed lengths of

tion 6 is used for stacked packing much greater than l-inch stacked 1-inch rings was also measured.

rings. No data are available on larger rings, because of the To evaluate the performance of initial distributors and

impossibility of making holdup measurements with the 16-inch measure distribution after flow through the bed, a quantitative

column. definition of distribution is required. The definition is, of

Radial Liquid Distrilbution. A rather pragmatic investiga- course, determined by the design of the collecting device.

tion of a number of different inlet distributor configurations T h e collecting device i n this case consisted of 13 compartments

was carried out in the 16-inch column. T h e water-in-annulus made from concentric rings partitioned off into quarters as

configuration (Figure 6) proved to give adequate results and shown in Figure 5. The area of each of the nine compart-

was used for the majority of the pressure drop and mass- ments in the central part was designed to be 10% of the total

transfer experiments. area, with the four-wall compartment totaling the remaining

0 Stacked %" Rings

0 Dumped %" Rings

0

S t a c k e d 1" Rings

D u m p e d 1" Rings

A

-0 D u m p e d I" "Intalox"

-

4-

Figure 8. Two-phase pressure

Larkins correlation

A*------

-50% 0

0

r '. 'k.

1 ,

4

I I I I I I I I I 1 I I T-,. I I I

VOL. 6 NO. 4 OCTOBER 1 9 6 7 491

1.

150%

0 Stacked Ib" Rings

0 Dumped 'b" Rings

0 Stacked 1" Rings

lo-'[ J I I 1 I I I I / I I I I I I I I I I I I I l l l l

10-1 I 10 1

x

Figure 10. Liquid holdup correlation

10%. T o simplify construction from standard parts the actual plotted against the center radius of the respective ring and a

areas of the compartments are as indicated i n Figure 5. A smooth curve was drawn through the points.

fractional standard deviation of the liquid superficial velocity The fractional standard deviation could be plotted as a

is defined as follows : function of the two-phase parameter x (see Equation 5) and

the data for different gas and liquid rates were reduced to a

(7) single curve. Figure 11 shows this type of plot for the initial

distribution and for the liquid distribution after flow through

T h e fraction of the superficial liquid velocity in the nth com- three different lengths of packed bed. A fractional standard

partment is deviation of 0.2 was arbitrarily chosen as "good" liquid dis-

tribution. Figure 12 shows the smoothed profiles for a value

of x = 0.44. For this case, a good initial distribution de-

teriorates somewhat, because of water migration to the wall as

where Qn is the liquid collected from the nth compartment with the flow proceeds down through the packed bed.

area A n and Q I as the total liquid collected in all 13 compart- For values of x greater than 1 the initial distribution was

ments with total area A , . poor, because of high liquid flow near the column center and

Another more graphic means of displaying liquid distribution almost no liquid near the wall. The distribution improved

is using smoothed distribution profiles. The average velocity with flow down through the bed because of migration of liquid

for each of the three annular rings and for the center compart- to the wall. H a d the bed been longer than 7 5 inches, the dis-

ment was calculated by tribution would tend to worsen because of increased liquid flow

near the wall.

(9) The performance of a single commercial-scale nozzle (Figure

6) can be seen from the smoothed profile in Figure 13. For

where Q r is the total liquid collected from all four quadrants these tests the nozzle sprayed into empty column sections 26

of one annular ring of area A , (or the liquid collected from the and 49 inches long. Figure 13 shows that a t these flow rates

single center compartment). These average velocities were this type of nozzle could be spaced on about 10-inch centers if

:::;

0.6 1

L

B e d Length,

Figure 1 1 . Liquid inches

d i s t r i b u t i o n for 0.4

-

s t a c k e d 1-inch f 0 0

26

Raschig rings c

0 49

W a t e r in annulus dir- 75

tributor, standard de- .- .

0.2

-

viation

/

0.1 I I 1 I I I I I I I 1 I I I 1 1 1

492 I & E C PROCESS D E S I G N A N D D E V E L O P M E N T

the distance of nozzle to packing is about 2 feet and a reason- Mass Transfer. Mass-transfer data for packed beds are

ably flat profile would result from the overlapping of successive usually presented either in the form of a capacity coefficient,

nozzle spray patterns. Further increasing the gas velocity the product of the mass-transfer coefficient, and the interfacial

causes wider spreading of the liquid to the point where there is area per unit volume of packing, or koa or kla,or as the height

very little liquid below the gas jet center line. of a transfer unit, H T U , or HTUI, where

x 9 0.44

These quantities were calculated from the experimental

ammonia absorption data based on Equation 12.

BedLength 2

inches VP

- 0 0.142 where

-.-

-- 264975 0.616

0.573

-----a 0.430

and

These relationships are valid because the following conditions

are met by the ammonia absorption experiments.

1. Very dilute concentrations of ammonia, y < 0.05.

2. Gas phase is an ideal gas.

3. Ideal mixtures.

4. Linear equilibrium relationship (Henry's law).

5. Liquid film resistance was less than 5%; hence koa is con-

- 1 I I I I sidered to be the gas-phase resistance-controlling capacity

7 6 5 4 3 2 1 coefficient.

all

Radtue, inches E.

Figure 1 2. Liquid distribution for stacked 1 -inch Raschig If the ammonia concentration measurements made along

rings the length of the column are plotted as (y - y *) us. Z on semilog

W a t e r in annulus distributor, smoothed profiles paper, a straight line with slope of (1 +

A)kua/2.303 Vushould

result (Figure 14). The measured gas phase mole fraction,

y , the calculated (Equation 13) equilibrium mole fraction,

y*, and the difference, y - y*, are shown. y approaches y *

-

ftlsec a t the column exit, indicating the one equilibrium stage

Air Nozzle Velocity 480 limiting condition of cocurrent operation. Conditions 1 and 4

Water Nozzle Velocity 6.1

are shown to be valid over most of the column length. Figure

- -26" Void 14 also shows an entry effect. The inlet concentration falls

- ---4?" Void

*

on a smooth curve, but the first sampler reads low. For most

of the runs, the transfer rate in the inlet section and the upper

portion of the packed bed differed significantly from that in the

lower portion of the packed bed. This phenomenon could be

due partially to a sampling problem and partially to a true

entry effect. This again emphasizes the value of taking sam-

ples from within the packed bed away from the inlet rather

than just inlet and outlet samples.

Similar techniques were used for the oxygen desorption

mass transfer. T h e transfer rate equations are

(x - x*) - 1 kza

z

log ( x - x*), 2.303 V i

where

x* = z*

1

(Xl - + ptg y 1

x)

However, because of the low solubility of oxygen, the amount

-1 I I I 1 of oxygen desorbed from the liquid phase did not affect the gas

8 7 6 4 3 2 1

Wall Radius, inches phase concentration. Hence, Equation 16 becomes

Figure 1 3. Liquid distribution, smoothed profiles P2

x* =

Commercial scale water in annulus nozzle H y1

VOL. 6 NO. 4 OCTOBER 1967 493

h

loo0 r I

800 1

A

Dumped ’1;‘ Rings

V, 1.67 ftlsec

v, 0.141 f t / s e c

Slope 0 . 0 5 3 3 in-’

HTUp 8.15 in

kea 0.207 s e B ‘

600

“\ Slope 0.0533

2oo/

1v‘

0 4 8 I2 16 20 24

Z, Inches 2. inches

Figure 14. Concentration profiles for ammonia absorp- Figure 15. Concentration profiles for oxygen desorp-

tion tion

The Beckman oxygen analyzer reads in terms of partial pres-

sure over the liquid, which from Henry’s law is

p = Hx

Equation 15 in terms of partial pressure is

(1 8)

’

v

i A , [K

gc P I 4- ($)zj = El, (21)

(P - P*) 1 kla The fractional areas for gas, A o / A t , and liquid, A l / A , , are not

2 simply the gas and liquid holdup, respectively, for a packed

l o g( -P 7- P ) = - Vi

2.303 -

~-

bed. As discussed previously, the liquid flows partially over

Graphs of p - p* us. 2 were prepared from experimental data the packing and partially in free fall. Hence, the terms in

and the slope on semilog paper gives -kza/2.303 V 2 . Figure Equation 21 cannot be evaluated without a better understand-

15 shows the oxygen profiles for one of the experimental runs. ing of the flow mechanism in the packed bed.

Many of the comments made about the ammonia profiles apply The effective density or “head” effect was shown earlier to

here also. ‘The entry effect can be seen as the larger slope have negligible effect on measured pressure loss for the majority

through the first two sample points. of the experimental runs. With this in mind, a modified

A concept, which has been used with some degree of success, definition of energy dissipation for each phase was made:

to correlate mass-transfer data is to relate the capacity co-

efficient to the energy dissipation per unit volume of the E , = Vo($) gas phase

system. This approach has been used to correlate gas-liquid lo

transfer data for stirred tank contactors (Calderbank and

Moo-Young, 1961; Cooper et al., 1944). liquid phase

A similar approach was suggested for correlating the experi- EI = Vi($) 20

mental transfer data from this study (Sternling, 1963). For a

Experimentally measured gas-phase controlling mass-trans-

single-phase vertical flow system, when kinetic energy effects,

fer capacity coefficients were correlated with E, and the liquid

heat input, and shaft work are neglected, the mechanical

coefficients with El. T h e two-phase pressure loss, ( A P / A Z )I,,

energy balance reduces to

was measured concurrently with the mass-transfer coefficients

and used in evaluating the energy dissipation term.

T h e mass-transfer capacity coefficients for all ammonia-

absorption runs a t 70’ F. are shown as a function of the gas-

T h e analogous equation for a two-phase vertical flow system phase energy dissipation in Figure 16. A dimensional equa-

derived by Standart (1 964) is tion of the following form represents these data within zk.2501,.

494 I&EC PROCESS DESIGN AND DEVELOPMEN1

p&" Equation 24

0 Stacked

0 Dumped

0 Stacked 1"

0

%" Rings

vi' Rings

Rings

A D u m p e d 1" Rings

S t a c k e d 3" Rings

0 D u m p e d 1" " I n t a l o x "

1 1 I I I11111 I I I I I Ill1 1 i I 1 1 1 1 1 1 I I 1 I I I l l

10-1 1 10 10'

Eg ft-lbr Force/sec f t 3

Figure 1 6. Ammonia absorption mass transfer-energy dissipation correlation

koa = 2.0 + 0.91 (Eg)2/3 (24) ing. I n this work, improved liquid distribution was observed

k,a = set.-' as liquid rates were increased. Consequently, k,a should

increase with increasing liquid rate, as was observed in these

E , = ft.-lb. force/sec. cu. ft. experiments.

T h e gas-phase controlling transfer data measured by Wen T h e mechanism of liquid distribution is different in these

(1963a) for absorption of water vapor i n calcium chloride solu- two experiments. This could be the result of completely

tions could possibly be comparable to the experimental results different ranges of liquid rates studied in the two experiments.

presented here for ammonia absorption. T h e Schmidt number However, the wetting characteristics of the packing become

for ammonia in air is about the same as for water vapor i n air. important a t low liquid rates. T h e wetting of ceramic packing

Hence, k , for Wen's (1 963a, b) data should be similar to k , mea- by calcium chloride could be the dominant factor determining

sured for ammonia. If the interfacial area for mass transfer is interfacial area in Wen's (1963a, b) experiments, whereas in the

similar in both experiments for similar flow rates and packing higher rates of this experiment wetting effects are less im-

type, the capacity coefficients should be similar for each experi- portant.

ment. Wen's (1963a, b) data have been carefully compared with I t is concluded that the results of these two experiments are

the present results. The only case where cotlditions of Wen's not directly comparable. Caution should be exercised in

(1963a, b) experiments were similar to those of this work were a t extrapolating the results of this work to liquid rates lower than

his highest liquid rate, which was nearly equal to the lowest studied.

liquid rate of the present experiments. T h e values of k,a T h e experimental capacity coefficients for oxygen desorption

reported by Wen for dumped l / z - and 1-inch Raschig rings are a t 77' F . are shown in Figure 17. The empirical dimensional

considerably lower than the values reported here for similar equation representing these data within +25% is

conditions.

Wen (1963a, b) noted increased channeling of liquid as liquid kla = 0.12 (El)1/2 (25)

flow rate increased up to the maximum studied. Hence, he kla = sec.3

concluded that k,a would decrease with increasing liquid rate

by virtue of less effective transfer area due to the liquid channel- E L = ft.-lb. force/sec. cu. ft.

0 Stacked %" Rings

0 Dumped %" Rings

0 Stacked 1" Rings

0 S t a c k e d 3" Rings

3

E a , ft-lbs F o r c e l s e c f t 3

Figure 17. Oxygen desorption mass transfer-energy dissipation correlation

VOL. 6 NO. 4 OCTOBER 1 9 6 7 495

Data for cocurrent oxygen desorption were obtained by on liquid holdup for cocurrent flow. I n none of these investi-

McIlvroid (1956) for packed beds of dumped l/r-inch Raschig gations have the important properties of surface tension and

rings, and dumped 4- and 6-mm. spheres. These data have packing wettability been adequately taken into consideration.

been recalculated into the form of the energy dissipation corre- Practically no physical property effects have been accounted

lation suggested here. The data are compared with Equation for in the limited experimental work on radial liquid dis-

25 in Figure 18 and the agreement is good. This appears to tribution.

extend the range of packing sizes to which Equation 25 is A means of considering the effect of fluid properties on the

applicable. mass-transfer capacity coefficients, koa and k la,involves separat-

ing the coefficients into the factors k and a and estimating the

Estimates of Effect of Physical Properties of Fluids effect of fluid properties o n each factor. The value of k , will

depend on the Schmidt and Reynolds numbers of the gas

The scope of this investigation was limited to the study of the

phase, while k i will be influenced by the Srhmidt and Reynolds

air-water system with packings made of polyethylene (except

numbers in the liquid phase. The interfacial area will be

for the Intalox saddles, which were ceramic). T h e mass-

influenced mainly by the liquid density, viscosity, interfacial

transfer measurements were made with the ammonia absorp-

tension, and wettability of the packing. The mass-transfer

tion and oxygen desorption systems. T o use the results of

data from this investigation as \\ell as those from previous

this investigation for design of systems involving other fluids,

investigations (McIlvroid, 1956; \Veri et al., 1963a) are in-

the effects of fluid physical properties must be known. How-

adequate to define these physical property effects.

ever, it was beyond the scope of the present investigation to

I t can be concluded that further experimental work is re-

study the effects of physical properties of the fluids systemat-

quired to define adequately the effects of fluid physical proper-

ically. Some qualitative remarks on physical property

effects can be made. ties on liquid holdup, radial liquid distribution, and mass-

transfer capacity coefficients for cocurrent gas-liquid flow in

The fluid properties which will probably most significantly

packed columns.

influence the pressure drop, dynamic liquid holdup, and

radial liquid distribution are gas and liquid density, gas and

Summary of Design Procedure for

liquid viscosities, the surface tension of the liquid, and the Cocurrenl Contacting in Packed Columns

contact angle between the liquid and the solid packing-Le.,

the wettability of the packing. All these properties and in Based on the preceding results, a design for a cocurrent

addition the gas-phase and liquid-phase diffusivities of the packed column can be made if the Ergun constants are known

transferring component will influence the mass-transfer capac- for the packing material. If the packing material is not the

ity coefficient. same as, but similar to that used here, a few simple single-phase

Physical property effects have been reasonably well ac- pressure loss experiments can be performed to determine these

counted for in the single-phase pressure-loss equation of constants. When these constants are known, single-phase

Ergun (1952) (Equation 1) and the two-phase pressure-loss pressure loss for each phase as if it were flowing alone can be

equation of Larkins (1959) (Equation 5). Effects of surface evaluated from Equations 1 and 2

tension on two-phase pressure loss have been considered by

both Larkins and Weekman and Myers (1964). The effects

of liquid physical properties on liquid holdup in packed beds

with no gas flow have been considered by Jesser and Elgin where

(1943), Shulman et al. (1955), and Standish (1964), while

Larkins (1959, 1961) measured some physical property effects

Figure 1 8. Liquid phase mass transfer-energy dissipation correlation

Data of Mcllvroid (1956)

496 l & E C PROCESS D E S I G N A N D D E V E L O P M E N T

T h e two-phase parameter x is then evaluated:

x = (61/6,)"2

and the two-phase pressure loss calculated from

0.41 6

__-

x )+

~ 0.666 (5)

and holdup from

log h = -0.774 + 0.525 log x - 0.109 (log x)* (6)

T h e individual phase energy dissipation terms can be evaluated

from the two-phase pressure loss by

12

T h e gas-phase controlling mass-transfer coefficient for am- k,a C a l c u l a t e d , rec-'

monia absorption a t 703 F. can be calculated from the dimen-

sional equation Figure 19. Comparison of measured and calculated

koa = 2.0 + 0.91 (E,)2i3 (24) ammonia ahsorption mass transfer

where

koa = set.-'

E, = ft.-lb. forcelsec. cu. ft. T h e example chosen is ammonia absorption a t large liquid-to-

gas ratio (L'IV' = 161). As a result, the liquid-phase con-

The liquid-phase oxygen-absorption capacity coefficient a t

centration of ammonia will be very dilute and nearly constant

77' F. can be evaluated from the dimensional equation

down the length of the column, satisfying the requirement of

k l a = 0.12 ( E l ) 1 / 2 (25) only one equilibrium stage. The number of transfer units for

where this specific example will be nearly the same for both counter-

current and cocurrent flow. T h e packing chosen is dumped

kla = sec.-] '/*-inch Raschig rings, as ammonia absorption data are avail-

El = R.-lb. force/sec. cu. ft. able for this packing from the literature for countercurrent

flow (Cornel1 et al., 1960) and from this report for cocurrent

Each of the above empirical equations has been determined flow.

by fitting experimental data. I n some cases the scatter of The countercurrent design is based on operation a t 70% of

data around these individual equations is as great as =k50%. flooding. The actual gas and liquid rates are calculated

T o show that the accuracy of the over-all design procedure is from the liquid-to-gas ratio using the \\fell known flooding

not significantly different from the accuracy of the individual correlation of Sher\vood et al. (see Leva, 1953). Pressure drop

equations comprising it, experimentally measured gas-phase is determined by extrapolating design charts for '/*-inch rings

capacity coefficients are compared in Figure 19 with those (Leva, 1953) and HTC', is calculated from a generalized

calculated via the above procedure, starting from the known correlation presented by Cornell et ai. (1960).

conditions of each ammonia absorption experiment. T h e T\vo cases of cocurrent operation illustrate that there is no

agreement is Ivithin +507, for most cases, indicating that the flooding with this mode of operation. As the column diameter

fit of the experimental mass-transfer data to the over-all design is reduced, the actual velocities in the column increase if the

procedure is no worse than the fit of the data to any individual total feed rates are kept constant. T h e result is that the

equation comprising the design procedure. This design column diameter is limited only by the available pressure

procedure should produce results which are accurate to within drop. T h e pressure drop and H T U , are determined from the

=t50%,, adequate for most preliminary designs for initial cost data presented in this paper.

estimates. The number of transfer units is the same for both modes of

For more accurate design, additional pilot scale experiments operation; thus the column heights will be directly propor-

may be required, especially if fluid properties are significantly tional to the H T U , and the total column pressure drop \vi11 be

different from the air-water-ammonia-oxygen systems utilized directly proportional to the product (HTL,) X (AP/AZ) lo.

in this study. However, the similarity principle of equal T h e two modes of operation are compared by using the coun-

energy dissipation per unit volume, shown to be valid here, tercurrent operation as a base case. The relative costs are

can be used as a basis for mass-transfer scale-up i n cocurrent calculated assuming that the capital cost of the column is

contacting in packed columns. directly proportional to the product of column diameter and

column height. This assumes that the column cost is deter-

Cocurrent and Countercurrent Gas-liquid mined by the volume of the metal comprising the column shell,

Contacting in Packed Columns

that the wall thickness is constant, and that the column heads

An example of design calculation is presented here for and packing have a negligible cost. The results of this calcula-

operating conditions which are suited to cocurrent contacting. tion are sho\vn in Table 111.

VOL. 6 NO. 4 OCTOBER 1967 497

E = energy dissipation per unit volume, ft.-lb. force/

Table 111. Comparison of Cocurrent Operation with Counter- sec. cu. ft.

current Operation for NHs Adsorption g = gravitational acceleration 32.2, ft./sec.?

gc = conversion constant 32.2, Ib. mass ft./lb. force sec2

(Dumped '/,-inch Raschig rings) H = Henry's law constant, atm.

HTU = height of transfer unit, ft.

Counter-

current h = free draining holdup, fraction of void volume

(cc), 70% -

Cocurrent ( c o ) k = mass-transfer coefficient based on individual film

of Flood Case I Case 2 driving force, ft./sec.

k,a = gas-phase film capacity coefficient, sec. -I

L ' / V ' , moles HpO/mole liquid-phase film capacity coefficient, set.-'

air

L ' , moles HsO/hr. sq.

161 161 161 27 =

= liquid molar velocity, solute free, moles H,O/hr. sq.

ft .

f t. 916 ,680 5550

V', moles air/hr. sq. ft. 5.69 22.8 34.5 P = pressure. atm.

VI, ft./sec. 0.0736 0,294 0.450 p = partial pressure, mm. Hg

V,, ft./sec. 0.611 2.44 3.70 p* = partial pressure in equilibrium with liquid a t inter-

(AP/AZ)l,, p.s.i./ft. 0.072 0.52 1.7 face, mm. H g

HTU,, ft. 0.25 0.12 0.058

= measured pressure gradient, p.s.i./ft.

1. 0 -

1. o

0.50

0.48

0.41

0.23 E;z

1 .o 3.5 5.4 Q = volume of liquid collected, cu. ft.

1. o 0.24 0,094 Re = Reynolds number, Equation 2

V = superficial velocity, ft./sec.

V' = gas molar velocity solute free, moles airihr. sq. ft.

x = liquid-phase mole fraction, moles solute/mole H20 f

mole solute

x* = liquid-phase mole fraction in equilibrium with gas-

I t may be concluded that the capital cost of a cocurrent phase bulk concentration, moles solute/mole H20

column for these conditions is lower than the cost of a counter- + mole solute

current column, but the operating cost will be higher by virtue y = gas-phase mole fraction, moles solute/mole air f

of the increased pressure drop across the column. mole solute

y* = gas-phase mole fraction in equilibrium ivith liquid-

phase bulk concentration, moles solute/mole air

mole solute

+

Conclusions

Z = column length. ft.

cy = Ergun constant Equation 1

Single-phase frictional Dressure loss in packed beds can be Ergun constant Equation 1

p =

predicted from the Ergun (1952) equation (Equation l ) , but 6 = frictional pressure gradient, p.s.i./ft.

the empirical constants are not indzpendent of packing type. t = packing void fraction

The two-phase pressure drop and liquid holdup correlations p = fluid viscosity. 1b.jft. hr.

p = fluid density. Ib.,/cu. ft.

of Larkins (1959, 1961) cover a wide range of packing types u = standard deiriation, Equation 7

with an accuracy of & 50%. x = two-phase parameter, x = (81/8,)'/'

Radial liquid distribution is a function of packed bed height,

SUBSCRIPTS

and gas and liquid rates expressed i n the two-phase parameter

co = cocurrent

X. cc = countercurrent

M iss-transfer capacity coefficients for gas-phase and liquid- g = gas phase

phase resistance-controlling transfer can be correlated with 1 = liquid phase

individual phase energy dissipation per unit volume, and the 1g = gas-liquid phases combined or two-phase flow

rn = mean or effective (Lvith density)

correlation is valid for a wide range of packing type.

n = any compartment in collector

Further experimental work is required to evaluate the effect Y = any annular ring in collector

of flui 1 properties on liquid holdup, radial liquid distribution, t = total in cross-sectional area, pressure, etc.

and both gas-phase and liquid-phase resistance controlling 1 = column inlet

mass-transfer capacity coefficients.

Cocurrent columns can be designed within an accuracy of Acknowledgment

i 5 0 y o , starting with only the knowledge of the Ergun con- The valuable assistance of G. H. Ackerman, J. J. Sutfin,

stant$for the single-phase pressure loss equation. J. M. Elliott: and \V. B. Schwenning is gratefully acknowl-

The cocurrent mode of operation may be favored over the edged. The author appreciates the permission to publish

more conventional countercurrent operation when only one this paper granted by the Shell Development Co.

equilibrium stage is required-physical absorption a t large

liquid-to-gas ratios, physical desorption a t small liquid-to-gas literature Cited

ratios, and chemical reaction consuming the transferring com- Calderbank, P. H., Moo-Young, M. B., Chem. Eng. Sci. 16, 39

ponent in one of the phases; when pressure drop can be (December 1961).

tolerated without excessive operating cost; or when capital Cooper, C. hi., Fernstorm, G. A , , Miller, S. A., Znd. Eng. Chem.

36, 517 (1944).

costs of equipment are high-high pressure equipment or Cornell, D., Knapp, \V. G., Fair, J. R., Chem. Eng. Progr. 56, 6 8

corrosive materials involved. i J u-l v, 19601.

~ ~

Deal, C. H., b t v o s , J . I$'., Smith, V. N., Zucco, P. S., Anal. Chem.

28, 1958 (1956).

Nomenclature Dodds, \V, S., Stutzman, I,. F., Solami, B. J . , Carter, R. J.,

A = cross-sectional area, sq. ft. A.Z.Ch.R. .I. 6, 197 (1960a).

A* = absorption factor, Equation 14 Dodds, \V. S., Stutzman, I,. F., Solami, B. J., Carter, R. J., A . I .

a = mass transfer interfacial area per unit volume, ft.-'

Ch.E. J . 6, 390 (1960b).

Ergun, S . , Chem. Eng. Progr. 48, 89 (1952).

a, = packing surface area per unit volume, ft.-l Gunther, F. A , , Barkley, J. H., Kolbezen, M. J., Blinn, R. C.,

d = column diameter, ft. Staggs, E,. A , , Anal. Chem. 28, 1985 (1956).

ZIP = equivalent spherical particle diameter, D, = 6(1 - Gunther, F . A., Rlinn, R. C., Kolbezen, M. J., \Vilson, C. \V.,

€),/a,,

ft. Conklin, R.. A , , Anal. Chem. 30, 1089 (1958).

498 l & E C PROCESS D E S I G N A N D D E V E L O P M E N T

Hoftyzer, P. J., Trans. ZnJt. Chem. Engrs. 42, T109 (1964). Standish, N., Nature 202, 587 (May 9, 1964).

Jesser, B. W., Elgin, J. C., Trans. A.Z.Ch.E. 39, 277 (1943). Sternling, C. V., private communication, 1963.

Kolbezen, M. J., Eckert, J. W.,Wilson, C. W., Anal. Chem. 36, Wen, C. Y., O’Brien, W. S., Fan, L. T., J . Chem. Eng. Data 8,

593 (1964). 42 (1963a).

Larkins, R. P., “Two-F’hase Cocurrent Flow in Packed Beds,” Wen, C. Y., O’Brien, W. S., Fan, L. T., J . Chem. Eng. Data 8,

Ph.D. thesis, University of Michigan, 1959. 47 (1963b).

Larkins, R. P., White, R. R., Jeffrey, D. W., A.Z.CI1.E. J . 7, 231 Weekman, V. W., Myers, J. B., A.Z.Ch.E. J . 10, 951 (1964).

(1961). Weekman, V. W., Myers, J. B., A.Z.Ch.E. J . 11, 13 (1965).

Leva, M., “Tower Packings and Packed Tower Design,” 2nd ed.,

pp. 28-37, U. S. Stoneware Co., 1953. RECEIVED

for review December 5, 1966

Lockhart, R. W., Martinelli, R. C., Chem. Eng. Progr. 45, 39 ACCEPTED May 1, 1967

(January 1949).

Lovelock, J. E., Anal. Chcm. 33, 162 (1961).

Mcllvroid, H. G., “Mass Transfer in Cocurrent Gas-Liquid Flow

through a Packed Column,” Ph.D. thesis, Carnegie Institute Material supplementary to this article has been deposited as

of Technology, 1956. Document 9495 with the AD1 Auxiliary Publications Project,

Otvos, J. W., Stevenson, D. P., J . A m . Chem. SOC.78, 546 (1956). Photoduplication Service, Library of Congress, Washington,

Porter, K. E., Jones, M. C., Trans. Znst. Chem. Engrs. 41, 240 D.C. A copy may be secured by citing the document number

(1963). and by remitting $2.50 for photoprints or $1.75 for 35-mm.

Shulman, H. L., Ullrica, C. F., Wells, N., Proulx, A. Z . , A.Z.Ch.E. microfilm. Advance payment is required. Make checks or

J . 1, 259 (1955). money orders payable to Chief, Photoduplication Service, Library

Standart, G., Chem. Eng. Sci. 19, 227 (1964). of Congress.

C A L C U L A T I O N OF EFFECT OF V A P O R

MIXING O N T R A Y EFFICIENCY

D A V I D A. DIENER

ESSOResearch and Engineering Co., Florham Park, N.J .

The relationship between the point efficiency and the Murphree tray efficiency has been developed for

the case of partial mixing of the liquid and no mixing of the vapor. This is an extension of previous

studies which have assumed the vapor entering each tray to be completely uniform in composition. The

lateral concentration gradient in the vapor rising from the liquid is assumed to be similar to the longitudinal

concentration gradient in the liquid flowing across the tray. This assumption probably approximates the

actual physical situation best at high per cents of flood. The principal application of the results of this

work is to systems where point efficiencies are greater than about 0.80.

HE relationship between the point efficiency and the General Relationships

TMurphree tray efficiency has in general been described in

Application of the eddy diffusion model to describe the

terms of the degree of backmixing of the liquid as it flows

partial mixing of aerated liquid on a distillation tray yields,

across a tray. This has been done using a number of different

in terms of a material balance on a small vertical slice of liquid,

models to characterize the liquid mixing. These models

include mixed pools :in series (Gautreaux and O’Connell,

1955), eddy diffusion (Gerster et al., 1958), recycle stream

(Oliver and Watson, 1956), splashing of the liquid (Johnson

and Marangozis, 1958)., and measurement of residence times with w varying from 1 to 0 as the liquid flows across the tray.

of liquid elements (Foss et al., 1958). In the use of each of these Use of the equilibrium relationship, yn* = m x , + b’, and the

models to develop the relationship between point and tray -

definition of the point efficiency, Eo, = ( y , - Y n - l ) / ( Y n *

efficiencies, however, the assumption has always been made ynv1), to substitute in Equation 1 then gives the relationship

that the vapor entering successive trays is well mixed. Only between the point efficiency and the vapor compositions as

in ‘the extreme case of no backmixing of the liquid has the

relationship between the point efficiency and the tray efficiency

been developed without assuming the vapor to be completely

mixed. This case, for plug flow of the liquid and unmixed

vapor, has been presented (Lewis, 1936) for two different flow

situations.

In this work, partial mixing of the liquid with no mixing of T o obtain the relationship between the point efficiency

the vapor is considered for the same two flow situations con- and the Murphree tray efficiency, however, it is also necessary

sidered by Lewis in his development. T h e model used to to relate the tray efficiency to the vapor compositions. This

describe the partial liquid mixing is that of eddy diffusion. In can be done by considering the definition of the Murphree

carrying out the development, it is assumed that a lateral tray efficiency, EIMV= (g, - gn- l)/(yo* - gn- l ) . Using this

concentration gradient exists in the vapor similar to the longi- definition, the desired relationship may be expressed as

tudinal concentration gradient which exists in the liquid flow-

ing across the tray. T h e vapor is assumed to rise directly

(without lateral mixing) from the point where it leaves the

EMV =

1’1

(Yn - Yn- ddw

(3)

aerated liquid on one tray to the corresponding point on the

tray above.

VOL. 6 NO. 4 O C T O B E R 1 9 6 7 499

Вам также может понравиться

- Viscous Hypersonic Flow: Theory of Reacting and Hypersonic Boundary LayersОт EverandViscous Hypersonic Flow: Theory of Reacting and Hypersonic Boundary LayersОценок пока нет

- Banerjee&Turney2013 - Air-Water Gas Transfer and Near-Surface MotionsДокумент37 страницBanerjee&Turney2013 - Air-Water Gas Transfer and Near-Surface MotionsLeandro DijonОценок пока нет

- Stability Analysis of Inclined Stratified Two-Phase Gas-Liquid FlowДокумент43 страницыStability Analysis of Inclined Stratified Two-Phase Gas-Liquid FlowanellbmcОценок пока нет

- 10.1007 s11242 004 1407 5 Relative Permeability Estimation For Rich Gas Condensate ReservoirsДокумент27 страниц10.1007 s11242 004 1407 5 Relative Permeability Estimation For Rich Gas Condensate ReservoirsSina ForoudiОценок пока нет

- Passive Scalar Mixing in A Turbulent Jet: Massimo FalchiДокумент6 страницPassive Scalar Mixing in A Turbulent Jet: Massimo FalchiMassimo FalchiОценок пока нет

- Determination of Wetting Efficiency in Trickle-Bed Reactors by A Reaction MethodДокумент10 страницDetermination of Wetting Efficiency in Trickle-Bed Reactors by A Reaction Methoddaymen skiiОценок пока нет

- Progress in The Development of A Reynolds Stress TДокумент31 страницаProgress in The Development of A Reynolds Stress TSmith Diaz VasquezОценок пока нет

- Boundary-Enhanced Sedimentation Due To Settling ConvectionДокумент23 страницыBoundary-Enhanced Sedimentation Due To Settling Convection2306노강민Оценок пока нет

- Rev MTC For PackedДокумент15 страницRev MTC For PackedAldren RebaLdeОценок пока нет

- 1985 Saez CarbonellДокумент11 страниц1985 Saez CarbonellAditya SinghОценок пока нет

- Performance of A Two-Phase Gas/liquid Flow Model in VerticalДокумент17 страницPerformance of A Two-Phase Gas/liquid Flow Model in VerticalDarryan DhanpatОценок пока нет

- Airlift Bioreactors Review of Recent AdvancesДокумент14 страницAirlift Bioreactors Review of Recent AdvancesWilliam Mejia GalarzaОценок пока нет

- A Computer Design Method For Vertical Thermosyphon ReboilersДокумент13 страницA Computer Design Method For Vertical Thermosyphon ReboilersSrihari Kodimela100% (1)

- Wang 2005Документ15 страницWang 2005Edu CordonОценок пока нет

- THE FLOODING TRANSITION WITH GASSED RUSHTON TURBINES - 1984 - Fluid Mixing IIДокумент9 страницTHE FLOODING TRANSITION WITH GASSED RUSHTON TURBINES - 1984 - Fluid Mixing IIvane-16Оценок пока нет

- Hanjalic-Launder JFM Vol52 1972Документ30 страницHanjalic-Launder JFM Vol52 1972LucaОценок пока нет

- Compressible Effects Modelling in Turbulent Cavitating p.8 p.18Документ85 страницCompressible Effects Modelling in Turbulent Cavitating p.8 p.18劉平本Оценок пока нет

- Numerical Simulation of The Gas-Solid Flow in A Fluidized Bed by Combining Discrete Particle Method With Computational Fluid DynamicsДокумент25 страницNumerical Simulation of The Gas-Solid Flow in A Fluidized Bed by Combining Discrete Particle Method With Computational Fluid Dynamicsp ppОценок пока нет

- The Effect of Turbulence On Flow of Natural Gas Through Porous ReservoirsДокумент8 страницThe Effect of Turbulence On Flow of Natural Gas Through Porous ReservoirsAbraham SalihОценок пока нет

- Application of Lattice Gas Techniques To The Study of Sediment Erosion and Transport Caused by Laminar SheetflowДокумент9 страницApplication of Lattice Gas Techniques To The Study of Sediment Erosion and Transport Caused by Laminar SheetflowMarco Antonio Miranda RodriguezОценок пока нет

- Static Liquid Holdup in Packed Beds of Spherical ParticlesДокумент4 страницыStatic Liquid Holdup in Packed Beds of Spherical ParticlesaegosmithОценок пока нет

- Review of Surface ApplicationДокумент42 страницыReview of Surface ApplicationLuis RosesОценок пока нет

- G - D B F: Ravity Riven Ubbly LowsДокумент32 страницыG - D B F: Ravity Riven Ubbly LowsAnkitPatel90Оценок пока нет

- 3.nikora Et Al. (2001)Документ11 страниц3.nikora Et Al. (2001)cntОценок пока нет

- ILASS-16 Karathanassis Et Al Camera-ReadyДокумент10 страницILASS-16 Karathanassis Et Al Camera-ReadyBRICKTOP000Оценок пока нет

- Traduccion Solo TextoДокумент9 страницTraduccion Solo TextoED OGОценок пока нет

- Orell 2005Документ11 страницOrell 2005Rafael SalgadoОценок пока нет

- Mass Transfer in Wetted WallsДокумент9 страницMass Transfer in Wetted WallsRonald Ramirez EspinozaОценок пока нет

- Nonisothermal Multiphase Flow of Brine and Gas Through Saline MediaДокумент23 страницыNonisothermal Multiphase Flow of Brine and Gas Through Saline MediaAlejandra VeraОценок пока нет

- Olivella1994 PDFДокумент23 страницыOlivella1994 PDFAlejandra VeraОценок пока нет

- Hydrodynamics of Gas-Solid FluidizationДокумент53 страницыHydrodynamics of Gas-Solid FluidizationGabriel Cujia QuinteroОценок пока нет

- Gravity Separator Fundamentals and DesignДокумент23 страницыGravity Separator Fundamentals and Designadam_k113Оценок пока нет

- Gravity Separator Fundamentals and DesignДокумент23 страницыGravity Separator Fundamentals and DesignThanh Van Le100% (1)

- Mass Noneq U: Transfer Across A BR M N Te DaceДокумент10 страницMass Noneq U: Transfer Across A BR M N Te DaceGustavo Gabriel JimenezОценок пока нет

- Two Phase FlowДокумент22 страницыTwo Phase FlowAdil Khan100% (1)

- Experimental Investigation of Flow and Energy Dissipation in Stepped SpillwaysДокумент14 страницExperimental Investigation of Flow and Energy Dissipation in Stepped Spillwaysrsiqueirasantos5711Оценок пока нет

- Scaling Considerations For Circulating Fluidized Bed Risers, Patience Et Al. 1992Документ7 страницScaling Considerations For Circulating Fluidized Bed Risers, Patience Et Al. 1992Enivaldo BarbosaОценок пока нет

- FM019040811Документ18 страницFM019040811Jean Carlos D. VidalОценок пока нет

- Redacted For Privacy: TitleДокумент35 страницRedacted For Privacy: TitlelauraОценок пока нет

- Compressed Air Flow Within Aquifer Reservoirs of CAES PlantsДокумент22 страницыCompressed Air Flow Within Aquifer Reservoirs of CAES PlantssasikalasivakumarОценок пока нет

- Mixing in The Interaction Zone of Two Jets: J, J. J. JДокумент10 страницMixing in The Interaction Zone of Two Jets: J, J. J. JGustavo Gabriel JimenezОценок пока нет

- ++ Drift-Velocity Closure Relationships For Slug Two-Phase High-Viscosity Oil Flow in PipesДокумент9 страниц++ Drift-Velocity Closure Relationships For Slug Two-Phase High-Viscosity Oil Flow in PipesAnonymous H9n5g3aaCEОценок пока нет

- Mathematical Modeling, Numerical Techniques, and Computer Simulation of Flows and Transport in Porous MediaДокумент17 страницMathematical Modeling, Numerical Techniques, and Computer Simulation of Flows and Transport in Porous Mediatomk2220Оценок пока нет

- Jia 2011Документ15 страницJia 2011Rafael SalgadoОценок пока нет

- Material-Balance Analysis of Gas Reservoirs With Diverse DriveДокумент28 страницMaterial-Balance Analysis of Gas Reservoirs With Diverse DriveMuhammad Arif FadilahОценок пока нет

- Dukler 1980Документ10 страницDukler 1980Vassilios KelessidisОценок пока нет

- Turb Free Shear Layer MixingДокумент71 страницаTurb Free Shear Layer MixinghyperlizОценок пока нет

- Two-Phase Flow Behavior and Spinner Data Analysis in Geothermal WellsДокумент8 страницTwo-Phase Flow Behavior and Spinner Data Analysis in Geothermal WellsIrwan JanuarОценок пока нет

- Dispersed Two-Phase Flow in A Gas-Liquid Cylindrical Cyclone SeparatorДокумент12 страницDispersed Two-Phase Flow in A Gas-Liquid Cylindrical Cyclone SeparatorManivannanVenkatesanОценок пока нет

- Three Phase FluidizationДокумент10 страницThree Phase FluidizationHa M ZaОценок пока нет

- Características de Transferencia de Masa de Platos ValvulaДокумент9 страницCaracterísticas de Transferencia de Masa de Platos ValvulaTerry VargasОценок пока нет

- Performance of Packed Extraction TowerДокумент7 страницPerformance of Packed Extraction Towercnaren67Оценок пока нет

- Modelling The Rapid Near-Surface Expansion of Gas Slugs in Low-Viscosity MagmasДокумент21 страницаModelling The Rapid Near-Surface Expansion of Gas Slugs in Low-Viscosity MagmasSimon PetersОценок пока нет

- Herlina & Jirka 2004 Application of LIF To Investigate Gas Transfer Near The Air-Water InterfaceДокумент9 страницHerlina & Jirka 2004 Application of LIF To Investigate Gas Transfer Near The Air-Water InterfaceFrancisco OppsОценок пока нет

- Chapter01 - Flow Pattern Transitions in Gas-Liquid Systems - Measurement and ModelingДокумент94 страницыChapter01 - Flow Pattern Transitions in Gas-Liquid Systems - Measurement and ModelingJose CantorОценок пока нет

- KlinkembergДокумент30 страницKlinkembergZineddine ImaneОценок пока нет

- Porous 5Документ15 страницPorous 5Angel Magaña SolanaОценок пока нет

- A Method of Reaching Extreme Altitudes: The seminal text on rocket science that foretold the Space AgeОт EverandA Method of Reaching Extreme Altitudes: The seminal text on rocket science that foretold the Space AgeОценок пока нет

- Fluid Dynamics Transactions: Symposium · Jabłona · September 1961От EverandFluid Dynamics Transactions: Symposium · Jabłona · September 1961W. FiszdonОценок пока нет

- House Price Estimates Based On Machine Learning AlgorithmДокумент5 страницHouse Price Estimates Based On Machine Learning AlgorithmEditor IJTSRDОценок пока нет

- Sample 5th Grade Lesson PlanДокумент2 страницыSample 5th Grade Lesson PlanJune Lee CamarinОценок пока нет

- Similarity - Similar Triangles Part 2Документ3 страницыSimilarity - Similar Triangles Part 2Ara Herrera100% (1)

- QWE Case StudyДокумент5 страницQWE Case StudyShubhendra vatsaОценок пока нет

- BlastingAKRaina Flyrock Factor of Safety Based Risk AnalysisДокумент14 страницBlastingAKRaina Flyrock Factor of Safety Based Risk Analysisshaik sakeemОценок пока нет

- Cis110 12sp MidtermДокумент8 страницCis110 12sp Midtermdodoman666Оценок пока нет

- Isoparametric Elements.: - Finite Element Method For Structural AnalysisДокумент12 страницIsoparametric Elements.: - Finite Element Method For Structural AnalysisAlvaro Garnica TrujilloОценок пока нет

- Lab Activity 8 and 9 Class IxДокумент4 страницыLab Activity 8 and 9 Class IxSiddhant NarayanОценок пока нет

- Niterói, Volgograd and Trans-Tokyo Bay Steel Bridge Decks Abraham - Sanchez - Corriols - 2de2Документ135 страницNiterói, Volgograd and Trans-Tokyo Bay Steel Bridge Decks Abraham - Sanchez - Corriols - 2de2Miguel PerezОценок пока нет

- s2 TrigonometryДокумент31 страницаs2 TrigonometryClaire PadronesОценок пока нет

- Einstein 1937Документ12 страницEinstein 1937JonathanHdzОценок пока нет

- C Sample Two Mark Question and Answer: 1) Who Invented C Language?Документ13 страницC Sample Two Mark Question and Answer: 1) Who Invented C Language?rajapst91% (11)

- 2003 HSC Notes From The Marking Centre Mathematics Extension 1Документ24 страницы2003 HSC Notes From The Marking Centre Mathematics Extension 1Ye ZhangОценок пока нет

- Sabour & Poulin 2006Документ22 страницыSabour & Poulin 2006ali basyaОценок пока нет

- 14 Ships Service GeneratorsДокумент32 страницы14 Ships Service Generatorsdeep4u2009100% (1)

- Quarter 1: Learner'S MaterialДокумент39 страницQuarter 1: Learner'S MaterialCynara AlexaОценок пока нет

- CH 12Документ41 страницаCH 12Darlene Jewel Ramos100% (2)

- 1 Quarter: 5 Grade Benchmark Scope and Sequence Pacing Guide 2015-2016Документ3 страницы1 Quarter: 5 Grade Benchmark Scope and Sequence Pacing Guide 2015-2016api-292307509Оценок пока нет

- 8 The Chinese Postman ProblemДокумент5 страниц8 The Chinese Postman ProblemWantei Kupar WarjriОценок пока нет

- Linear Algebra With Applications 9th Edition Leon Solutions ManualДокумент32 страницыLinear Algebra With Applications 9th Edition Leon Solutions ManualLafoot BabuОценок пока нет

- The Impact of Firm Growth On Stock Returns of Nonfinancial Firms Listed On Egyptian Stock ExchangeДокумент17 страницThe Impact of Firm Growth On Stock Returns of Nonfinancial Firms Listed On Egyptian Stock Exchangealma kalyaОценок пока нет

- List of Commands For Autocad: Cad Lab Tutorial Exercises Instructor: S.K. Sharma To Be Practiced Using Autocad SoftwareДокумент15 страницList of Commands For Autocad: Cad Lab Tutorial Exercises Instructor: S.K. Sharma To Be Practiced Using Autocad SoftwareShakeelОценок пока нет

- Gann Time Price SquareДокумент5 страницGann Time Price Squareanudora0% (1)

- Maths Y8 4Документ2 страницыMaths Y8 4s100% (1)

- Syllabus Jan09 MAT183Документ2 страницыSyllabus Jan09 MAT183Mike ZakwanОценок пока нет

- Math 9 Q1 Week 3Документ5 страницMath 9 Q1 Week 3John Nino DoligolОценок пока нет

- Solved Problems - Continuous Random VariablesДокумент4 страницыSolved Problems - Continuous Random VariablesDahanyakage WickramathungaОценок пока нет

- Analytical Dynamics - WikipediaДокумент5 страницAnalytical Dynamics - WikipediaHEIN HTETОценок пока нет