Академический Документы

Профессиональный Документы

Культура Документы

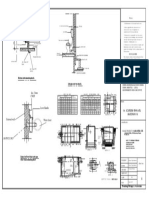

AWP Fold Out, Horz Vert Final

Загружено:

Srdjan KosoricОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

AWP Fold Out, Horz Vert Final

Загружено:

Srdjan KosoricАвторское право:

Доступные форматы

I n s u l a t e d Pa n e l s

Note: Ensure steelwork is suitably lined, levelled and within tolerance.

November 2008 Min. bearing face for vertical joint steelwork is 130mm subject to joint d c Horizontal intermediate support k

option. Refer to Kingspan Design and Construction Guide.

Min. bearing face for intermediate support is 50mm. 1 Fit panel bearers, located

maximum 150mm from panel Ensure vertical secondary steel Lower the next panel (P2) into position ensuring that the

Where long runs of integrated ribbon windows are installed in conjunction ends and at maximum 1500mm face at horizontal and vertical factory applied weather seal is compressed and that the AWP

with horizontal laid architectural wall panels, the vertical panel joints

should terminate above and continue below the window units. Contact

centres. Ensure that bearers are

accurately lined and levelled

interface is continuous to

provide a support for the VJ2 i 3 filler remains in position. Ensure that the panel is evenly

spaced and correctly positioned between vertical joint

Kingspan envirocare technical services for shoe and deflector details.

®

EPDM bubble gasket air seal. centres. Install main fasteners at each panel end and

Vertical rail VJ2 bubble Vertical rail Install 2 No. main fasteners

Gun-grade sealant type - non-setting butyl sealant Cover flashings required where gasket intermediate vertical steel member as previous

I N S U L AT E D W A L L S Y S T E M S - silicone sealant. gap is greater than 20mm at intermediate support

<20mm

position (minimum)

Note: Some installations may require

additional fasteners depending on wind

loadings/specification. Check project

specific details.

P2

h

Install main fasteners through the

male joint at each panel end into

vertical rail location

= =

Evenly spaced and

correctly located

= =

g

Locate first panel (P1) on panel

Installation Guide Note: Some installations may require additional

fasteners depending on wind

loadings/specification. Check project

bearers ensuring panel is evenly

spaced and correctly positioned

KS600/900/1000 AWP Wall Panel specific details. between vertical joint centres P1

Horizontally Laid 2

b

Line, level and fix drip flashing

Factory applied

using low profile fasteners. Joints weather seal

in the drip flashing to incorporate

butt straps sealed with two runs P1

of gun-grade sealant Run a gun-grade

air seal across

Column face Column face male joint

Air seal - VJ2 Air seal - gun-grade

Vertical rail EPDM bubble sealant to male joint

Vertical rail gasket 95 x 10mm AWP filler beaded

Galvanised drip f j

AWP joint filler and

silicone sealant AWP joint filler and

on silicone sealant

at every horizontal

support angle

Site applied PIR insulation

a e Apply an unbroken 6mm Ø bead of gun-grade

KS1000 AWP insulated

wall panel horizontally laid

silicone sealant panel joint

or gun applied fire rated

sealant to provide an air seal between back of Bed an AWP filler in silicone

foam insulation Fit galvanised drip support angle A VJ2 EPDM bubble gasket is required at each vertical

panel and drip support angle. This air seal should sealant at panel ends, and

Panel bearer at ends of using low profile fasteners. An air panel joint detail to provide an air seal. Apply gasket to the Air seal - 6mm bead of

panel & max. 1500mm meet the previously installed bubble gasket gun-grade sealant run a gun-grade air seal

centres between seal consisting of an unbroken vertical steel member, ensure that it overlaps the vertical

across male joint

6mm Ø bead of gun-grade sealant leg of the drip flashing

Drip flashing

is required between support angle Gap subject to

vertical joint option

Air seal - 6mm bead and floor

of gun-grade sealant

Note: Panels can be installed in either a tiered or coarsed q Components

sequence.

Visually check internal liner joint to ensure panels are joined fully.

Vertical rail VJ2 bubble

gasket

Vertical rail p 5 Apply 4mm Ø butyl sealant (site r

KS1000 AWP Wall Panel

Air seal - VJ2

applied) to internal legs of top hat EPDM bubble

Air seal - gun-grade

Check panel cover width module as works progress to ensure Prior to installation of the top hat Incorporate a butt strap into the gasket 95 x 10mm

sealant to male joint

Note: When using WV (Wave) profile, use Primary/Main Silicone Gun-Grade Top Hat

"creep" does not occur, particularly important when windows are 9 x 6mm PVC foam tape. top hat joint sealing with two

incorporated into the elevation.

apply a silicone sealant to horizontal

panel joint at panel ends, in line with runs of gun-grade sealant t AWP joint filler

and silicone sealant AWP joint filler and

silicone sealant

Fastener Sealant Sealant Top Hat Insert

This is a generic AWP installation guide, however details may differ AWP filler Push fit top hat

from project to project. Project specific construction details must be insert into position

used. Please refer to the Kingspan Design and Construction Guide Silicone sealant

for further information.

= = = = 4mm Ø rubber

Evenly spaced and Site applied PIR insulation or gun

m correctly located

P2

sealant

Top hat applied fire rated foam insulation

Install air seals and 4 Top hat insert for

flush option

Top hat insert for

recessed option

AWP filler at panel

ends as previous.

Refer to items j

C2 PIR Galvanised Drip

P1 6 Insulation Support Angle Panel Bearer

P2

Low Profile

Fastener

Drip Flashing

C1 s

P1 Place the top hat in to the vertical joint, aligned to the

bottom of the panel. Fix through the insulation infill to the

vertical steel member at max. 500mm centres, ensuring

top hat is pulled tightly against panel to ensure effective VJ2 EPDM Butyl Rubber Tape AWP

weather seal. Care must be taken not to overdrive Bubble Gasket Sealants Filler Butt Strap

o

C1 The gap between the panel ends is to be filled with PIR

Fire-rated

Canister

6mm 4mm Ø

insulation board or gun applied fire rated canister insulation Insulation

Air seal - VJ2

EPDM bubble

Air seal - gun-grade

sealant to male joint

to a depth to suit the top hat section. If PIR board is used,

ensure that continuity of insulation is achieved by filling any

n This installation guide should be read in

conjunction with the ‘project specific’

gasket 95 x 10mm

gaps with fire rated canister applied insulation Lower the preformed corner panel (C2) into position ensuring design drawings and method statements.

l AWP joint filler and

silicone sealant AWP joint filler and

silicone sealant Note: There are several types of vertical joint options. This guide assumes that an

Option A top hat detail is being used.

that the factory applied weather seal is compressed and that

the AWP filler remains in position. Ensure that the panel is Note: For firewall specifications

Although this ‘installation guide’ is deemed

to be correct at the time of publication,

Locate the preformed corner panel (C1) evenly spaced and correctly positioned between the vertical an internal fastener at maximum Kingspan reserve the right to amend the

on panel bearers ensuring panel is evenly joint centres and install main fasteners into each vertical steel 250mm centres is required. information at any time in the future.

spaced and correctly positioned between member as previous. Refer to h and i Refer to envirocare update EU38® Installation Guides are available for the full

the vertical joint centres and install main range of Kingspan Insulated Roof, Wall and

revision A for further information. Façade Systems.

fasteners through the male joint

envirocare updates can be

®

Gap subject to Please call Kingspan on:

vertical joint option found on our website at UK: +44 (0) 1352 716100

www.kingspanpanels.com. Ire: +353 (0) 42 96 98500

I n s u l a t e d Pa n e l s

Note: Ensure steelwork is suitably lined, levelled and

within tolerance. e i

Cleader angle by steel sub-contractor

with air seal Vapourflex sealant

November 2008

Visually check internal liner joint to ensure panels are 1 Apply an unbroken 6mm Ø

2 3 Site applied PIR

insulation or

Verge flashing with

150mm sealed butt straps applied at joints

KS1000 LP

joined fully. bead of gun-grade sealant to Install min. 1 No. main fasteners through gun applied fire

insulated roof panel

the male joint at the top and bottom, and rated canister

Check panel cover width module as works progress to top rail to provide an air seal insulation

also min. 2 No. at intermediate locations

ensure "creep" does not occur, particularly important when

windows are incorporated into the elevation. f Note: Some installations may require additional fasteners

depending on wind loadings/specification. Check project

20mm x 3mm butyl

rubber sealant

Joints need to be aligned correctly during installation to Install internal corner flashing specific details.

I N S U L AT E D W A L L S Y S T E M S prevent the 'saw tooth' effect at the drip. with low profile fasteners 4mm Ø butyl

rubber sealant

Gun-grade sealant type - non-setting butyl sealant Air seal - 6mm Ø bead

Air seal - 8mm Ø

- silicone sealant. of gun-grade sealant

approx. gun-

Run of gun-grade air KS1000 AWP insulated grade sealant

This is a generic AWP installation guide, however details may

differ from project to project. Project specific construction

seal across male joint

l wall panel vertically laid

details must be used. Please refer to the Kingspan Design

and Construction Guide for further information. d g Bed an AWP filler in silicone

Apply an unbroken 6mm Ø sealant at top of panel only,

Install cladding rail extension plate bead of gun-grade sealant and run a gun-grade air seal

c to open ends of sheeting rails to

provide suitable bearing for fixing

to internal corner flashing

ensuring it meets the

across male joint ensuring it

meets previously installed

Apply an unbroken 6mm Ø bead of gun-grade of panels on return elevation previously installed air seals air seal

Installation Guide sealant to provide an air seal between back of

panel and closure flashing

AWP filler bedded

on silicone sealant

at every horizontal

Note: Position of AWP filler at top

of panel (parapet/bottom of window)

panel joint

KS600/900/1000 AWP Wall Panel needs to reflect project specific

details in order to achieve

Vertically Laid airtightness performance.

b Air seal - 6mm Ø

bead of gun-grade

P1 P2

Line, level and fix drip flashing using low profile

fasteners. Joints in the drip flashing to incorporate j sealant, as per item l

butt straps sealed with two runs of gun-grade sealant At corner positions through fix min.

h P1

2 No. countersunk fasteners

into female panel joint at each

Stanchion

Sheeting rail

Locate first panel (P1)

ensuring it is correctly

horizontal rail location

Note: Fasteners to be suitably located to ensure

m

Optional internal closure positioned lined and levelled they are covered by external corner flashing. Locate next panel (P2) into position ensuring

flashing to mask

insulation from view a Run of gun-grade air

that the factory applied weather seal is

compressed and that the AWP filler remains

seal across male joint

Air seal - 6mm Ø bead

of gun-grade sealant

Closure flashing with

Fit closure flashing

using low profile k in position. Ensure panel is lined and levelled

correctly in line with adjacent panel and

lap joints air sealed fasteners. An air seal Run a gun-grade air seal install min. 1 No. main fasteners through the

PIR insulation board

consisting of an across male joint ensuring male joint at the top and bottom, and also

The gap between the

panel and the drip unbroken 6mm Ø it meets previously min. 2 No. at intermediate locations

flashing needs to be

6mm minimum bead of gun-grade installed air seal

Drip flashing

Air seal - continuous bead

of gun-grade sealant

sealant is required

between support n

angle and floor Repeat processes k to m to

complete elevation

Components

KS1000 AWP Wall Panel

4 Direct

ion of

lay

ion of

lay

5 Direct

r Primary/Main Counter Sunk PIR

Fastener

Gun-Grade Silicone

Main Fastener Insulation Sealant Sealant

At corner positions through fix min. 2 No.

countersunk fasteners in to panel (P5) cut Stack Joint Detail

joint at each horizontal rail location

Cleader angle by steel sub-contractor

Note: Fasteners to be suitably located to ensure they are KS1000 AWP insulated Air seal - 6mm bead Verge flashing with with air seal Vapourflex sealant

covered by external corner flashing. wall panel vertically laid of gun-grade sealant 150mm sealed butt straps applied at joints

Site applied PIR KS1000 LP

Air seal - gun-grade insulation or

sealant at male panel joint insulated roof panel

gun applied fire

Air seal - Vapourflex rated canister

insulation

q sealant applied over

joints in supports Gun applied fire

rated canister

insulation 20mm x 3mm butyl

t

Locate panel (P5) in to Drip flashing

rubber sealant

Fix external corner flashing

position ensuring factory 4mm Ø butyl with low profile stitching 4mm Ø butyl

4mm Ø butyl

applied weather seal is Air seal - 6mm bead rubber sealant

rubber sealant screws at max. 450mm

sealant

of gun-grade sealant

compressed and AWP filler Air seal - 6mm Ø bead centres positioned as per

AWP joint filler and Air seal - 8mm Ø

remains in position gun-grade sealant of gun-grade sealant

approx. gun- detail. Joints in the corner

KS1000 AWP insulated KS1000 AWP insulated grade sealant

wall panel vertically laid Air seal - gun-grade

wall panel vertically laid flashing to incorporate butt Closure Low Profile External Corner

P4 sealant at male

panel joint

straps sealed with two runs

Flashing

Secondary/

Fastener Flashing

P3 Stitching Screw

P5

p of gun-grade sealant stitching screws at max.

450mm centres

P2 Cut panel (P5) to size using

P1 an evolution type circular

saw, ensuring it meets the Drip Flashing

outside edge of (P1) Butyl Rubber

Tape Sealants

Note: Do not use abrasive wheel cutter.

All cutting should be done at ground level.

Horizontal sheeting rail

s AWP Filler

Corner stub Apply 4mm Ø butyl sealant

Corner column

Air seal - 6mm bead (site applied) to the internal 6mm 4mm Ø 20 x 3mm

of gun-grade sealant

legs of external corner flashing

o Internal corner flashing

Air seal - 6mm bead

Horizontal sheeting rail

ensure sealant is positioned

weather side of fasteners

Fire-rated

Canister

This installation guide should be read in

conjunction with the ‘project specific’

of gun-grade sealant

Install site applied PIR insulation Insulation design drawings and method statements.

4mm Ø butyl

board and gun applied fire rated rubber sealant Although this ‘installation guide’ is deemed

canister insulation into female low profile fastener to be correct at the time of publication,

joint to fill the gap between Kingspan reserve the right to amend the

External corner flashing

panels (P1) and (P5) to ensure information at any time in the future.

Gun applied fire Installation Guides are available for the full

Dir

continuity of insulation rated canister Dir range of Kingspan Insulated Roof, Wall and

ec insulation 4mm Ø butyl ec

Edge of vertical

tio

n of sheeting site cut

rubber sealant tio

n of

Façade Systems.

lay lay

Please call Kingspan on:

ion of

lay

ion of

lay UK: +44 (0) 1352 716100

Direct Direct

Ire: +353 (0) 42 96 98500

Вам также может понравиться

- IMP Wall Installation GuideДокумент2 страницыIMP Wall Installation Guidebhargav1064Оценок пока нет

- Kingspan Trapezoidal Roof KS1000 RW Installation Guide 012016 NZ enДокумент2 страницыKingspan Trapezoidal Roof KS1000 RW Installation Guide 012016 NZ envincent_devine777dОценок пока нет

- Chi Ti T D2/ D2 Details Chi Ti T Seno D1/ Seno D1 DetailsДокумент1 страницаChi Ti T D2/ D2 Details Chi Ti T Seno D1/ Seno D1 DetailsPhanLạcKhanhОценок пока нет

- IPS Empress Direct OpaqueДокумент2 страницыIPS Empress Direct OpaqueSunita TipmontaОценок пока нет

- Lintel Installation GuideДокумент5 страницLintel Installation GuideAnneBricklayer100% (1)

- Installation guide for horizontally laid europanel panelsДокумент5 страницInstallation guide for horizontally laid europanel panelsJL A100% (1)

- 30 - Vertical Movement JointsДокумент1 страница30 - Vertical Movement JointsChris FindlayОценок пока нет

- Escoramento de ValasДокумент1 страницаEscoramento de ValasPablo OliveiraОценок пока нет

- Keys-3001 en 10032639Документ2 страницыKeys-3001 en 10032639Janos NagyОценок пока нет

- Technical Specification COOLING TOWERДокумент5 страницTechnical Specification COOLING TOWERfwzn_eeОценок пока нет

- Abdominal Organ - Vermiform AppendixДокумент3 страницыAbdominal Organ - Vermiform AppendixayooniaОценок пока нет

- Min. 700 MM: Installation Instructions and Safety AdviceДокумент1 страницаMin. 700 MM: Installation Instructions and Safety AdviceregisztralljОценок пока нет

- Design Multistory Buildings Maxi - of It of - , ConДокумент1 страницаDesign Multistory Buildings Maxi - of It of - , ConjosОценок пока нет

- Tension Members in Roof TrussedДокумент23 страницыTension Members in Roof Trussedhegire6013Оценок пока нет

- Spans Over 60' May Require Complex Permanent Bracing. Please Always Consult A Professional EngineerДокумент2 страницыSpans Over 60' May Require Complex Permanent Bracing. Please Always Consult A Professional EngineerhahaerОценок пока нет

- Abcde: To Be Read in Conjunction With PD-ENGRTR103-2Документ1 страницаAbcde: To Be Read in Conjunction With PD-ENGRTR103-2gordonОценок пока нет

- Azimuth Adjustment ToolДокумент1 страницаAzimuth Adjustment ToolscribdninjaОценок пока нет

- Coastal Vinyl Siding ConsiderationsДокумент2 страницыCoastal Vinyl Siding Considerationsbad.wolffieОценок пока нет

- FootingДокумент1 страницаFootingSanjeev VermaОценок пока нет

- Footing ScheduleДокумент1 страницаFooting ScheduleAnonymous cclKewWGVОценок пока нет

- Camara Domo CNB D2000NAДокумент1 страницаCamara Domo CNB D2000NATecnoSmartОценок пока нет

- AC Ducting Sky Air R32 STD - PCSID1913AДокумент3 страницыAC Ducting Sky Air R32 STD - PCSID1913ARhani Dwi AnizarОценок пока нет

- Scaffolding ComponentsДокумент5 страницScaffolding ComponentsrogggОценок пока нет

- Das RF 215 Manual Especificaciones TecnicasДокумент2 страницыDas RF 215 Manual Especificaciones TecnicasJose Perez L.Оценок пока нет

- Drainage Construction Notes ContinuedДокумент1 страницаDrainage Construction Notes ContinuedPaqui MorentОценок пока нет

- Do Not Scale, If in Doubt Please Contact Urban Glass For ClarityДокумент1 страницаDo Not Scale, If in Doubt Please Contact Urban Glass For ClarityErnie ErnieОценок пока нет

- FT-BS EN-F-0604b Intubatt 3 Slab Edge Horizontal SealДокумент1 страницаFT-BS EN-F-0604b Intubatt 3 Slab Edge Horizontal SealTung ThanhОценок пока нет

- Nice Epmb Eplb Photocells ManualДокумент2 страницыNice Epmb Eplb Photocells ManualMFAОценок пока нет

- Annex - II-A (Ii) - B - HAUNA FOUNDATIONДокумент1 страницаAnnex - II-A (Ii) - B - HAUNA FOUNDATIONDumoluhleОценок пока нет

- Jally WindowДокумент1 страницаJally WindowerattakoyaОценок пока нет

- FafnirДокумент3 страницыFafnirGustavo NielОценок пока нет

- BT8380 Spec Sheet 2019-0.6m PDFДокумент2 страницыBT8380 Spec Sheet 2019-0.6m PDFQNet SénégalОценок пока нет

- Insulated roof panel installation guideДокумент2 страницыInsulated roof panel installation guideGabi DanutОценок пока нет

- Kingspan - Architectural Wall Panel KS1000 AWP - Installation Guide - Vertically Laid - January 2020 - AU NZ - ENДокумент12 страницKingspan - Architectural Wall Panel KS1000 AWP - Installation Guide - Vertically Laid - January 2020 - AU NZ - ENBranZzZzZОценок пока нет

- Perfect Mortise and Tenon JointsДокумент8 страницPerfect Mortise and Tenon Jointspiedrahec100% (1)

- H3AC3 English Installation GuideДокумент1 страницаH3AC3 English Installation Guidejmom18_647241209Оценок пока нет

- Drainage Details Sheet 1Документ1 страницаDrainage Details Sheet 1Mohamed AdelОценок пока нет

- Entrance of VIP: Service Path TarmacДокумент5 страницEntrance of VIP: Service Path TarmacfebousОценок пока нет

- Piusi Air Operated P60 1 InstructionsДокумент2 страницыPiusi Air Operated P60 1 Instructions673348300 Producto CartesОценок пока нет

- Sustainable Design of Monopile Supported Offshore Wind Turbine SystemДокумент11 страницSustainable Design of Monopile Supported Offshore Wind Turbine SystemAbderraouf KamelОценок пока нет

- Ridge Installation GuideДокумент1 страницаRidge Installation GuideGeorgios PОценок пока нет

- Manhole DetailsДокумент1 страницаManhole DetailsZacharul ShahОценок пока нет

- Vertical Movement Joints: Installation GuideДокумент1 страницаVertical Movement Joints: Installation GuideKelvin bongОценок пока нет

- JMS DRG Ele 000010Документ1 страницаJMS DRG Ele 000010pinakisharma1982Оценок пока нет

- CFSB3 - Permanent Restraint - Bracing of Chords & Web MembersДокумент2 страницыCFSB3 - Permanent Restraint - Bracing of Chords & Web MembersTodd HenryОценок пока нет

- Paraflex Coupling Instruction ManualДокумент4 страницыParaflex Coupling Instruction ManualSuwatchai SittipanichОценок пока нет

- Wall Panel Systems, IncДокумент12 страницWall Panel Systems, IncIrah Kenth Owenson OberaОценок пока нет

- R.C Wall Block Wall Vent Pipe Low Level CisternДокумент1 страницаR.C Wall Block Wall Vent Pipe Low Level CisternAmadi HenryОценок пока нет

- CC20 27Документ1 страницаCC20 27Celular Oil Control 05Оценок пока нет

- Vinyl Siding/Window and Door FlashingДокумент10 страницVinyl Siding/Window and Door FlashingZepol RotcivОценок пока нет

- Inclined Tower Level Unita - Block Wall SectionДокумент1 страницаInclined Tower Level Unita - Block Wall SectionHirushan MenukaОценок пока нет

- Mecalux Pallet Racking Assembly: Guide To Assembly & UsageДокумент6 страницMecalux Pallet Racking Assembly: Guide To Assembly & UsageUni ToolsОценок пока нет

- IMG - 0087 PSME Code 2008 78Документ1 страницаIMG - 0087 PSME Code 2008 78Bugoy2023Оценок пока нет

- Pros. - QuestionsДокумент11 страницPros. - Questionsمهيمن العبيديОценок пока нет

- Cherry ConsoleДокумент11 страницCherry ConsolekathmartinОценок пока нет

- General Notes:: DIVISION 4: Masonry DIVISION 7: Thermal & Moisture DIVISION 9: FinishesДокумент5 страницGeneral Notes:: DIVISION 4: Masonry DIVISION 7: Thermal & Moisture DIVISION 9: FinishesKarim TarekОценок пока нет

- Advanced Dual Pump Controller 3PHДокумент16 страницAdvanced Dual Pump Controller 3PHandrewОценок пока нет

- 2020-0-01 Sokaway DrawingДокумент1 страница2020-0-01 Sokaway DrawingerniE抖音 AI Mobile Phone Based MovieОценок пока нет

- VANTAGE Brochure CENTSYSДокумент2 страницыVANTAGE Brochure CENTSYScharactergatesОценок пока нет

- 00 Proracun 01Документ21 страница00 Proracun 01Srdjan KosoricОценок пока нет

- BC3 BriefДокумент3 страницыBC3 BriefSrdjan KosoricОценок пока нет

- Commentary and Worked Examples To en 1993-1-5 Plated Structural ElementsДокумент242 страницыCommentary and Worked Examples To en 1993-1-5 Plated Structural ElementsMaris VeitsОценок пока нет

- Webinar N°9 Results Connect, Robot API, DynamoДокумент43 страницыWebinar N°9 Results Connect, Robot API, DynamoSrdjan KosoricОценок пока нет

- Webinar N°10 Revit - Robot InteroperabilityДокумент40 страницWebinar N°10 Revit - Robot InteroperabilitySrdjan KosoricОценок пока нет

- Geometry and Structure - The Benefit of The Third DimensionДокумент4 страницыGeometry and Structure - The Benefit of The Third DimensionSrdjan KosoricОценок пока нет

- Webinar N°11 Robot Structural Analysis Professional and Advance Steel IntegrationДокумент41 страницаWebinar N°11 Robot Structural Analysis Professional and Advance Steel IntegrationSrdjan KosoricОценок пока нет

- Webinar N°6 Tips and Tricks in RobotДокумент53 страницыWebinar N°6 Tips and Tricks in RobotSrdjan KosoricОценок пока нет

- BS5950 BOLT AND WELD CAPACITIESДокумент1 страницаBS5950 BOLT AND WELD CAPACITIESHelena DomičićОценок пока нет

- 9 Design Examples: Imperfections and Frame AnalysisДокумент1 страница9 Design Examples: Imperfections and Frame AnalysisSrdjan KosoricОценок пока нет

- Webinar N°8 How To Create and Run Code Verification of User Defined SectionДокумент50 страницWebinar N°8 How To Create and Run Code Verification of User Defined SectionSrdjan KosoricОценок пока нет

- FRP Installation InstructionsДокумент6 страницFRP Installation InstructionsFodor ZoltanОценок пока нет

- 9.32 Example: Non-Sway Moment Resisting Frame 505: - 27.8 KNM 27.8 KNMДокумент1 страница9.32 Example: Non-Sway Moment Resisting Frame 505: - 27.8 KNM 27.8 KNMSrdjan KosoricОценок пока нет

- Buckling ExampleДокумент3 страницыBuckling ExampleSrdjan KosoricОценок пока нет

- Kingspan Structural Brochure 1Документ1 страницаKingspan Structural Brochure 1Srdjan KosoricОценок пока нет

- WBH en 0316 EditДокумент4 страницыWBH en 0316 EditSrdjan KosoricОценок пока нет

- Formglas FRP Specification V Sept 2011Документ4 страницыFormglas FRP Specification V Sept 2011Srdjan KosoricОценок пока нет

- PHILIPP Lifting Insert With Cross Hole Installation InstructionДокумент4 страницыPHILIPP Lifting Insert With Cross Hole Installation InstructionSrdjan KosoricОценок пока нет

- Gas Station - L2-ModelДокумент1 страницаGas Station - L2-ModelSrdjan KosoricОценок пока нет

- PHILIPP Lifting Insert With Cross Hole Installation InstructionДокумент4 страницыPHILIPP Lifting Insert With Cross Hole Installation InstructionSrdjan KosoricОценок пока нет

- Humbrol model paint guide for Airfix and other kitsДокумент2 страницыHumbrol model paint guide for Airfix and other kitsALFARMОценок пока нет

- Gas Station - L0-ModelДокумент1 страницаGas Station - L0-ModelSrdjan KosoricОценок пока нет

- Zeds & Cees: Users GuideДокумент40 страницZeds & Cees: Users GuideTee Bun PinОценок пока нет

- DS FlourMilling WBH 0115 ENGДокумент2 страницыDS FlourMilling WBH 0115 ENGSrdjan KosoricОценок пока нет

- Railing WorksheetДокумент3 страницыRailing WorksheetSrdjan KosoricОценок пока нет

- Step Step Step Step: Gettingstarted Picket Installation Glass InstallationДокумент6 страницStep Step Step Step: Gettingstarted Picket Installation Glass InstallationARUMOYОценок пока нет

- Section B-B Drawing DetailsДокумент1 страницаSection B-B Drawing DetailsSrdjan KosoricОценок пока нет

- Forward Fabrication P/L: Section: "B - B"Документ1 страницаForward Fabrication P/L: Section: "B - B"Srdjan KosoricОценок пока нет

- Gas Station - L1-ModelДокумент1 страницаGas Station - L1-ModelSrdjan KosoricОценок пока нет

- 1.0 EngineДокумент278 страниц1.0 EngineSergeyОценок пока нет

- Shin-Etsu LIMS GuideДокумент12 страницShin-Etsu LIMS GuideFira FfirehsОценок пока нет

- Dow CorningДокумент4 страницыDow CorningMukesh PandeyОценок пока нет

- 323 Ta Aerosil200 PDFДокумент2 страницы323 Ta Aerosil200 PDFelektron2010Оценок пока нет

- Manuel de Service Hotte FIV K-SystemДокумент64 страницыManuel de Service Hotte FIV K-SystemAbdel MUNDENОценок пока нет

- Product guide for silicone textile inksДокумент8 страницProduct guide for silicone textile inksTudo32Оценок пока нет

- Greenery Provisions For Roadside For RefДокумент2 страницыGreenery Provisions For Roadside For Refjhaydhee0331100% (1)

- Polymers: Presented By: Ms - Arti BhatnagarДокумент82 страницыPolymers: Presented By: Ms - Arti BhatnagarSomnath PratikОценок пока нет

- Inorganic Organic CoatingsДокумент9 страницInorganic Organic Coatingstocamdinhvu100% (1)

- DOWSIL™ 1-2620 Dispersion RTV Elastoplastic Conformal CoatingДокумент3 страницыDOWSIL™ 1-2620 Dispersion RTV Elastoplastic Conformal CoatingGreat StuffОценок пока нет

- Spicer Axle 123Документ236 страницSpicer Axle 123Дмитрий ПодвигинОценок пока нет

- Dow Corning Glazing MethodДокумент32 страницыDow Corning Glazing Methody2kareinОценок пока нет

- Quality Industrial Rubber Goods Since 1921Документ22 страницыQuality Industrial Rubber Goods Since 1921bagus handokoОценок пока нет

- Products Made Possible by Chlorine ChemistryДокумент1 страницаProducts Made Possible by Chlorine ChemistrygrasimlookОценок пока нет

- Xiameter MEM-0939 Emulsion: INCI NAME: Amodimethicone and Trideceth-12 and Cetrimonium Chloride Features ApplicationsДокумент2 страницыXiameter MEM-0939 Emulsion: INCI NAME: Amodimethicone and Trideceth-12 and Cetrimonium Chloride Features ApplicationsasmybablooОценок пока нет

- TDS Byk-315 N en PDFДокумент2 страницыTDS Byk-315 N en PDFabusaadОценок пока нет

- H-85317-4 TraSys 428Документ2 страницыH-85317-4 TraSys 428zouhy0442Оценок пока нет

- Company PresentationДокумент36 страницCompany PresentationRajashree PatraОценок пока нет

- Industrial Grade Silicone Sealant for Ducts, Vents and MoreДокумент3 страницыIndustrial Grade Silicone Sealant for Ducts, Vents and MoreDon HowardОценок пока нет

- Design Guide For Rubber Keypads (17-19)Документ19 страницDesign Guide For Rubber Keypads (17-19)Mahmudul Hasan RifatОценок пока нет

- Ottocoll® Hitack: The Hybrid Adhesive With High Initial AdhesionДокумент4 страницыOttocoll® Hitack: The Hybrid Adhesive With High Initial AdhesionJoeОценок пока нет

- Ats192 General Glazing Guidelines 2013102 - Setting Block LocationДокумент8 страницAts192 General Glazing Guidelines 2013102 - Setting Block LocationDave LiОценок пока нет

- JP Vol.16 09-13 PDFДокумент5 страницJP Vol.16 09-13 PDFAndres J AndradeОценок пока нет

- NuSil Technology MED6-161 Silicone PrimerДокумент2 страницыNuSil Technology MED6-161 Silicone PrimerTecothaneОценок пока нет

- Koyo Oil SealДокумент119 страницKoyo Oil Sealvicksgeorge100% (1)

- Silver-Brite Hi-Heat: Protective & Marine CoatingsДокумент4 страницыSilver-Brite Hi-Heat: Protective & Marine CoatingsAida LinaresОценок пока нет

- Apply Appropriate Sealant or AdhesiveДокумент32 страницыApply Appropriate Sealant or Adhesivevillamor niez96% (67)

- Dowsil1080rtvДокумент2 страницыDowsil1080rtvGomathi SankarОценок пока нет

- Insualtion ClassДокумент10 страницInsualtion ClassgoyalmanojОценок пока нет

- Pressure-Sensitive Adhesive Guide for Surface BondingДокумент9 страницPressure-Sensitive Adhesive Guide for Surface BondingRomulo Mayer FreitasОценок пока нет