Академический Документы

Профессиональный Документы

Культура Документы

Purchasin Full Flowchart

Загружено:

RuturajPatilИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Purchasin Full Flowchart

Загружено:

RuturajPatilАвторское право:

Доступные форматы

BHARATI VIDYAPEETH’S COLLEGE OF ENGINEERING,

KOLHAPUR

CASE STUDY: PURCHASING ACTIVITIES

Introduction

Purchase Management is a function of materials management in a company. Their basic function

is procuring the inputs for production function. This function encompasses suppliers in the

market external to the organization and several internal to the organization.

Till recently, the purchasing process simply involved placing an order with the supplier who

offered the lowest price. Nowadays, increase in competition and market demand and scarcity of

resources have forced organizations to reexamine their purchasing activities. The purchasing

department functions have expanded considerably and include activities such as verifying the

credentials of suppliers, inspecting the quality of the material to be purchased, ensuring the timely

delivery of the material, etc.

While the value of purchased items varies from industry to industry, it adds up to more than fifty

percent of sales in all industries. Purchase management is regarded as a significant activity in

many organizations because of the high cost involved in carrying out purchasing activities,

increasing quality benchmarks, and increasing global competition. Purchase departments buy raw

materials, parts, machinery, and services used by production systems. The objective of purchase

management is to procure the right equipment, materials, supplies and services in the right

quantity, of the right quality, from the right suppliers, at the right time, at the lowest price.

OBJECTIVES OR GOALS OF PURCHASING

Primary objective or goal of purchasing function is making inputs available to the conversion

process at minimum cost to the final output of the company. Thus focus is on system output

rather than on micro level objectives.

The inputs to be made available are raw materials, semi finished items, bought out items etc.

There are certain parameters to be monitored for fulfilling the system objectives. We can call

them goals of purchasing. These goals are popularly known as 5R’s of purchase namely, right

price, right quantity, right quality, right place and right time. In simple terms, if the above 5Rs are

Case Study: Purchasing Activities Page 1

BHARATI VIDYAPEETH’S COLLEGE OF ENGINEERING,

KOLHAPUR

achieved primary objective is fulfilled:-

• Right Price: Right price is determined by costing the production process of the supplier.

Right price is determined by allowing reasonable profit for the supplier and insisting and

helping to reduce cost. Tender system should be used to identify lowest responsible bidder

rather than lowest bidder. Principles normally used to ensure right price are cost structure

and learning curve.

• Right Quantity: Right quantity of purchase is the one that ensures no excess and no

shortage. High priority items are subjected to determine the right quantity for purchase. This

ensures overall minimum cost for inventory.

• Right Quality: In an item purchased should ensure adhering to mutually accepted

standard by supplier and customer at the time of finalizing the purchase order. The accepted

standard may be a drawing, a sample, a grade or a universal standard like DIN, IS, BS,

ASTM etc.

• Right Place: is the one where the item is going to enter the value stream. If the item is not

available here, when needed, it is in short supply for the process.

• Right Time: is as decided by production schedule for meeting customer’s requirements.

THE PROCESS OF PURCHASING

The purchasing process mainly carried out in three segments.

• Pre purchasing

• Purchase order

• Post purchasing

Steps involved in Purchasing

A. Pre-Purchase activities:

1. Recognizing need

2. Purchase requisition(PR)

Case Study: Purchasing Activities Page 2

BHARATI VIDYAPEETH’S COLLEGE OF ENGINEERING,

KOLHAPUR

3. Make copies of PR as per department requirement

4. Identifying a supplier.

5. Send copies of PR to supplier

6. Getting the quotations from supplier

7. Analyzing the quotations

8. Finalize the quotations

B. Purchase Order

9. Qualifying and placing an Purchase Order(PO)

10. Getting Order Acceptance(OA).

C. Post Purchase Activities

11. Follow up procedures

12. Receipt

13. Invoice checking

14. Monitoring and managing delivery process.

Detailed Analysis of Purchasing activity

Recognizing the need:

All departments need to buy something or the other. So first need can be recognized for placing

the order. Whenever a department needs an item (material), it informs the purchasing

department.

Purchase requisition:

1. A form called as “purchase requisition” is filled by the production/planning

department and forward to the purchasing department.

2. The purchasing requisition contains the following:

- Name of requestor

- The planned use of the item.

- The specification of the item.

Case Study: Purchasing Activities Page 3

BHARATI VIDYAPEETH’S COLLEGE OF ENGINEERING,

KOLHAPUR

- Number of units.

- Tentative price per unit.

- Expected of purchase.

Requisition No………………….

Date……………………

Shop: ………………………………

Required for

1. (a)Work order no: ………………………..

(b) Department use: ……………………

(c)To stock: ……………………………………

Sr.no Description Specific Quantity Approx Remarks if any

Of material ation cost

Delivery Required by ………………….. (Date), at ……………………. (place)

Address of probable supplier …………………………………………………………

Signature

Production/Planning

Manager

…………………………………………………………………………………………………………

…………………………………………………

2. Report Of store Keeper

Signature

StoreManager

…………………………………………………………………………………………………………

…………………………………………………

3. For the use of Purchase/Inspection section

Same copy is also Sent to the supplier. Hence 3-6 copies are made as per department requirement.

Part I is filled by the production or planning department. For quick purchasing and monitoring the work of

purchase section should maintain the addresses of probable suppliers who can supply these materials.

Part II is for storekeeper for onward transmission, it is filled by storekeeper in remaining 2 copies and he

reports on it whether the required material is available in the store or not. If the storekeeper also wants this

Case Study: Purchasing Activities Page 4

BHARATI VIDYAPEETH’S COLLEGE OF ENGINEERING,

KOLHAPUR

material for stocking in store he adds demand also.

Part III is for purchase section, they’ll make the necessary arrangement for purchases.

Identifying a supplier and Send copies of PR to supplier:

As per requirement prepare the list of suppliers who deal with the business of the articles to be

purchased and are reliable. If the material to be purchased is of small amount and required

urgently it may be purchased locally.

If necessary prepare and issue N.I.T (Notice inviting tenders) to the concerning suppliers,

mentioning different terms, conditions, date and time of the opening and closing of tenders.

There are two types of tenders: 1. Open Tenders 2. Closed Tenders

Getting the quotations from supplier, Analyzing and Finalize the quotations

Open the tender/Offer/Quotation on the prescribed time on the prescribed date.

Prepare a comparative statement of the rates, terms and conditions mentioned in the tender and study

them. Finalize the quotation in terms of quality, cost and other parameters.

COMPARATIVE STATEMENT

Date of issue of N.I.T. ………………….. Date of receipt of Tenders

………………….

Sr. no. Name of Quantity Firm/Vendor Firm/Vendor 2

article with Reqd 1

Specification

Quoted value Quoted value

Terms and conditions

comparison

1.

2.

Qualifying and placing an Purchase Order(PO)

1. Purchase order is the most important element in ordering system. Purchase manager releases

the purchase order after selecting the supplier and finalizing the price and other conditions of

sale. Once the purchase order is raised and accepted it becomes a legal document.

Case Study: Purchasing Activities Page 5

BHARATI VIDYAPEETH’S COLLEGE OF ENGINEERING,

KOLHAPUR

Contents of the purchase order are:-

Purchase order reference number

Description of materials and specifications

Quantity required and delivery schedule

Price and discounts

Shipping instructions

Location where the material is to be shipped

Signature of the authorized officer

Detailed terms and conditions:-

It includes terms and conditions regarding payment, Transportation, warranties,

limitations and liabilities, Scope of work, replies of Technical questionnaires.

Several numbers of copies made to be forwarded to various recipients. Many companies color

code the copies making the color destination specific.

Original and a copy is sent to the supplier for acknowledgment of the original order. This

acknowledgment is acceptance of terms and conditions of purchase order.

One copy is sent to the receiving department for making necessary receiving arrangement

One copy is sent to the indenting department for information.

One copy is sent to finance department for organizing payment to the supplier.

Case Study: Purchasing Activities Page 6

BHARATI VIDYAPEETH’S COLLEGE OF ENGINEERING,

KOLHAPUR

Case Study: Purchasing Activities Page 7

BHARATI VIDYAPEETH’S COLLEGE OF ENGINEERING,

KOLHAPUR

Post Purchase Activities

1. Follow up procedures

2. Receipt

3. Invoice checking

4. Monitoring and managing delivery process.

• Follow up procedures: Follow up is an expensive activity for an organization. Hence this

should be minimized and made more effective. A sound procedure for follow up is

required to eliminate duplication and ineffectiveness. Follow up responsibility is

assigned to buyers responsible for areas in which suppliers are situated.

• Receipt: Receipt system should ensure that defects in receipt process are eliminated

proactively. A systematic record of all receipts, carrier details and descriptions is

maintained. This record is in chronological sequence of arrival of supplies. The system

ensures that inspection of consignments received is arranged in time and payment to

suppliers for accepted consignments is organized. In many organizations a receipt

section handles this activity centrally.

• Invoice checking: supplier sends his invoice to customer’s finance department for

payment for the goods supplied. Invoice checking system ensures that the invoice is

checked against the PO terms, receipt details, quantity received, inspection reports

[accepted quantity and rejected quantity], losses, damages etc. this system helps

materials management to coordinate with finance department for payment to suppliers.

Delivery of Material receipt and material examination

Material supplied by the vendor is received by the receiving department which unpacks the

materials received and checks the quantities and conditions of the materials. A copy of purchase

order is present with the receiving department to check the materials received. A material receipt

is material received report. It is prepared and is sent to purchase department to inform that these

are goods received and also for them to check and compare it with the purchase order.

A material receipt form is as under

Case Study: Purchasing Activities Page 8

BHARATI VIDYAPEETH’S COLLEGE OF ENGINEERING,

KOLHAPUR

Material examination

All items, after they have been received, are inspected and sample tested to ensure that the

purchase order specifications have been met or not. Results of the inspections & tests are

indicated in the testing report, upon the basis of which a clearance report or rejection note is

prepared and sent by the inspection department to purchase department In case of rejection, a part

or whole of the consignment may be returned to the vendor with a request either for complete

cancellation of the order or for replacement. A clearance report or rejection note is as under

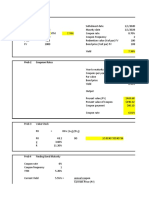

Entire work flow from initial stage to final stage will consist of Five Toll Gates

Case Study: Purchasing Activities Page 9

BHARATI VIDYAPEETH’S COLLEGE OF ENGINEERING,

KOLHAPUR

1st Toll Gate - Work Assessment / Understanding

2nd Toll Gate - Vendor Selection / Evaluation

3rd Toll Gate- Release of Order (Clarity on Technical and Commercial conditions /requirements)

4th Toll Gate - Certificate of Conformance (CoC) form QA

5th Toll Gate - Delivery, Completion of Project and Feedback from Customer

Flowcharts will graphically represent the steps making up the entire process.

Case Study: Purchasing Activities Page 10

BHARATI VIDYAPEETH’S COLLEGE OF ENGINEERING,

KOLHAPUR

Case Study: Purchasing Activities Page 11

BHARATI VIDYAPEETH’S COLLEGE OF ENGINEERING,

KOLHAPUR

Case Study: Purchasing Activities Page 12

BHARATI VIDYAPEETH’S COLLEGE OF ENGINEERING,

KOLHAPUR

Case Study: Purchasing Activities Page 13

BHARATI VIDYAPEETH’S COLLEGE OF ENGINEERING,

KOLHAPUR

Case Study: Purchasing Activities Page 14

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Final Exam-2 AnswersДокумент29 страницFinal Exam-2 AnswersRuturajPatilОценок пока нет

- MId Term Exam-1 AnswersДокумент23 страницыMId Term Exam-1 AnswersRuturajPatilОценок пока нет

- HW3 - Chapter 7 - 8Документ10 страницHW3 - Chapter 7 - 8RuturajPatilОценок пока нет

- Solution Aassignments CH 12Документ7 страницSolution Aassignments CH 12RuturajPatilОценок пока нет

- HW6 Chpters13 14Документ16 страницHW6 Chpters13 14RuturajPatilОценок пока нет

- Solution Aassignments CH 11Документ12 страницSolution Aassignments CH 11RuturajPatilОценок пока нет

- Solution Aassignments CH 14Документ9 страницSolution Aassignments CH 14RuturajPatilОценок пока нет

- Solution Aassignments CH 7Документ5 страницSolution Aassignments CH 7RuturajPatilОценок пока нет

- Solution Aassignments CH 9Документ10 страницSolution Aassignments CH 9RuturajPatilОценок пока нет

- Solution Aassignments CH 13Документ2 страницыSolution Aassignments CH 13RuturajPatilОценок пока нет

- Solution Aassignments CH 5Документ5 страницSolution Aassignments CH 5RuturajPatilОценок пока нет

- Homework 3 Six Sigma - Fq8871Документ6 страницHomework 3 Six Sigma - Fq8871RuturajPatilОценок пока нет

- ManagementДокумент54 страницыManagementRuturajPatilОценок пока нет

- Knowledge BsedДокумент2 страницыKnowledge BsedRuturajPatilОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Answer Key Bacostmx-3tay2021-Finals Quiz 2Документ8 страницAnswer Key Bacostmx-3tay2021-Finals Quiz 2Marjorie Nepomuceno100% (1)

- Downloable Solution Manual For Managerial Accounting 5th Edition WildWild MA 5e EPPT Ch02Документ70 страницDownloable Solution Manual For Managerial Accounting 5th Edition WildWild MA 5e EPPT Ch02Phan Thị Trúc VyОценок пока нет

- A. $800,000 B. $600,000 C. $440,000 D. $200,000Документ15 страницA. $800,000 B. $600,000 C. $440,000 D. $200,000sino akoОценок пока нет

- Issues in Supply Chain Mangement Lambert and Cooper 2000Документ19 страницIssues in Supply Chain Mangement Lambert and Cooper 2000kriastОценок пока нет

- 2012 Third-Party Logistics Study: The State of Logistics OutsourcingДокумент52 страницы2012 Third-Party Logistics Study: The State of Logistics OutsourcingJJОценок пока нет

- ACC 102 - QuizДокумент11 страницACC 102 - QuizSarah Mae EscutonОценок пока нет

- HPC4 Supply Chain ManagementДокумент6 страницHPC4 Supply Chain ManagementSheena HarrienОценок пока нет

- OM1 Assignment - Flying Exp.Документ6 страницOM1 Assignment - Flying Exp.mukesh chavanОценок пока нет

- Bangladesh Retailing IndustryДокумент33 страницыBangladesh Retailing IndustryStoic_SpartanОценок пока нет

- SC Lead BDGДокумент4 страницыSC Lead BDGfazhia pantheraОценок пока нет

- UNIT 1 LogisticsДокумент10 страницUNIT 1 Logisticsanon_124527471Оценок пока нет

- Inventories: Initial RecognitionДокумент5 страницInventories: Initial RecognitionMary Grace NaragОценок пока нет

- Inventory and Production ManagementДокумент31 страницаInventory and Production ManagementChelsea Anne VidalloОценок пока нет

- Introduction To PeopleSoft v1.0Документ53 страницыIntroduction To PeopleSoft v1.0Anbudan Chandru100% (2)

- Realizing Automotive EDI ProcessesДокумент6 страницRealizing Automotive EDI ProcessesSeenu HkОценок пока нет

- Review of LiteratureДокумент10 страницReview of LiteratureThiru VenkatОценок пока нет

- SWTC 10-182-101 Course DesignДокумент29 страницSWTC 10-182-101 Course DesignLea De leonОценок пока нет

- 7th Sem FeesДокумент1 страница7th Sem FeesMoloy SinhaОценок пока нет

- CH 12 ForecastingДокумент76 страницCH 12 ForecastingDarsh MenonОценок пока нет

- Process Costing Short QuizДокумент5 страницProcess Costing Short QuizGenithon PanisalesОценок пока нет

- A New Look at Management AccountingДокумент14 страницA New Look at Management AccountingWan LingОценок пока нет

- Impacts of Big 2018 2Документ11 страницImpacts of Big 2018 2Lauro SilapanОценок пока нет

- SCM ProjectДокумент15 страницSCM ProjectAnkita GoelОценок пока нет

- Application of Activity-Based Costing To A Land Transportation Company A Case StudyДокумент21 страницаApplication of Activity-Based Costing To A Land Transportation Company A Case StudySafira Adi Nur FirdausiОценок пока нет

- Logistics and Supply Chain ManagementДокумент39 страницLogistics and Supply Chain ManagementSachin DhawaleОценок пока нет

- Daily Report-TQMДокумент24 страницыDaily Report-TQMNieva Asor DomingoОценок пока нет

- 外贸专业术语Документ13 страниц外贸专业术语邱建华Оценок пока нет

- International DistributionДокумент39 страницInternational DistributionPragati MehndirattaОценок пока нет

- Overview of Lean-ManagementДокумент20 страницOverview of Lean-ManagementKarthik ManianОценок пока нет

- The Warehouse Design Assignment: Assignment 1B - GROUP REPORTДокумент20 страницThe Warehouse Design Assignment: Assignment 1B - GROUP REPORTNguyên NguyễnОценок пока нет