Академический Документы

Профессиональный Документы

Культура Документы

Hoist Type Crane Inspection Standard Table

Загружено:

JESUSCALVILLO0 оценок0% нашли этот документ полезным (0 голосов)

43 просмотров3 страницыThe document provides inspection standards for various parts of a hoist type crane. It lists specific inspection items and allowable limits for things like rail wear, wheel wear, gear wear, brake wear, and hook condition. Maintenance technicians should use these standards to inspect cranes on a regular basis and check that components are within the prescribed limits for safe operation.

Исходное описание:

inspeccion del gancho

Оригинальное название

Hoist Inspection

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThe document provides inspection standards for various parts of a hoist type crane. It lists specific inspection items and allowable limits for things like rail wear, wheel wear, gear wear, brake wear, and hook condition. Maintenance technicians should use these standards to inspect cranes on a regular basis and check that components are within the prescribed limits for safe operation.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

43 просмотров3 страницыHoist Type Crane Inspection Standard Table

Загружено:

JESUSCALVILLOThe document provides inspection standards for various parts of a hoist type crane. It lists specific inspection items and allowable limits for things like rail wear, wheel wear, gear wear, brake wear, and hook condition. Maintenance technicians should use these standards to inspect cranes on a regular basis and check that components are within the prescribed limits for safe operation.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 3

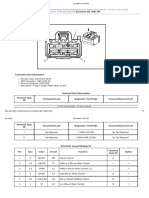

HOIST TYPE CRANE INSPECTION STANDARD TABLE

Inspection item Inspection standard

Foreign matter on rail surface Foreign matter is not to be accumulated.

Oil adhesion on rail surface Unnecessary oil is not to be adhered.

Loosening of rail mounting bolts No to be loosened.

Allowable limit ±5mm (Suspension type)

Measuring of span

Allowable limit ±10mm (Top running type)

1/300 or less (Suspension type)

Measuring of rail slope

1/500 or less (Top running type)

Traveling rail Traveling rail

Difference of elevation between 1/500 × (Span) or less

traveling rails

Rail joint offset 0.5mm or less on both surface and side

Gap of rail joint 5mm or less on surface

Rail crack and deformation rail is not to be cracked and deformed.

rail surface wear: 10% or less of full size

Rail wear

I-beam rail side wear: 5% or less of full

Saddle is to be correctly mounted to main

Slippage of saddle and main girder

girder in right angle.

Appearance of construction material Not to be deformed and damaged.

Condition of jointed part Not to be loosened and cracked.

5% or less of max. dia. On wheel surface

Wear of trolley wheel surface

(φ300 or less) 3% or less (Over φ300)

Out of roundness for trolley wheel 0.8mm or less at surface dia.

Saddle Wear of flange 50% or less of full size thickness

Gap between traveling rail and both 50% or less of wheel surface width

flanges (suspension type)

Diameter difference of right and left 1% or less at surface diameter

wheels

Wear of wheel 2% or less of shaft dia.

Clearance between shaft and 4% or less of shaft dia.

bearing metal

Wear of roller bearing Not to be damaged or remarkably marked.

Appearance of construction material Not to be damaged or deformed.

Condition of jointed part Not to be loosened.

Condition of welded part Not to be cracked.

Corrosion is not to be exceeded 10% of

Situation of corrosion

original plate.

Girder

Painting condition Not to be peeled.

Crane girder Wear of cross travel 10% or less on both surface and side face

Cross travel rail gauge Allowable limit ±5mm

Mounting condition of cross travel Not to be cracked and loosened.

rail

Driving shaft is to be paralleled to

Parallelism of reduction gear shaft

reduction gear shaft.

Mounting condition of reduction gear Mounting bolts, etc., are not to be

Appearance of reduction gear Casing is not to be damaged.

Engaged gear face condition Not tot be abnormally worn.

Inside of gear case of full size thickness:

Wear of gear tooth 20%

Exposed tooth: 40%

Condition of key and key groove Not to be deformed and loosened.

Traveling Wear of shaft 2% or less of shaft dia.

equipment Clearance between shaft and Gear shaft on dia.: 2% or less

bearing metal Other shaft: 4% or less

Wear of roller bearing Not to be damaged or remarkably marked.

Not to be remarkably damaged on lip or its

Wear of oil seal

shaft surface.

Safety cover is not to be damaged and

Mounting conditions of safety

fallen.

covers for gear and other

Mounting bolts are not to be loosened.

Mounting condition of driving shaft Bearing is not to be loosened.

bearing

20% or less of full size thickness at pitch

Wear of winding gear teeth

circle

40% or less of full seize thickness at pitch

Gear Wear of cross travel gear teeth

circle

Engaged gear tooth condition Not to be abnormally worn.

wear of gear shaft 1% or less of shaft dia.

Wear of other shafts 2% or less of shaft dia.

Gear shaft on shaft dia. : 2% or less

Clearance between shaft and

Motor pinion & drum shaft: 1% or less

Shaft, bearing bearing metal

Other shafts: 4% or less

and oil seal

Wear of roller bearing Not to be damaged or remarkably marked.

Not to remarkably damaged on lip or its

Wear of oil seal

shaft surface.

Full size thickness of dry type: 50% or less

Wear of lining

of wet type: 20% or less

Brake Wear and deformation of brake type Not to be cracked and deformed.

wheel

Wear of brake mechanism Brake is to be adequately operated.

Wear on wheel surface 5% or less of max. dia. on full wheel surface.

Electric hoist

roundness of wheel surface 0.8mm or less at wheel surface dia.

Cross travel Diameter difference of right and left 1% or less at wheel surface dia.

wheel wheels

50% or less of full size thickness. However,

Wear of flange width monorail type is 50% or less of wheel

surface for max gap between flange and

Wear of sling loop 10% or less of full size

Opening of hook not to be deformed.

Hook

Hook damage Not to be cracked on hook surface.

Thread part condition of hook Not to be cracked and worn.

Wear of groove 30% or less of wire rope dia.

Deformation corrosion etc, Not to be remarkably deformed and corroded.

Wire rope Rope end condition Not to be cut and corroded.

Length of wire rope Specified length is to be ensured.

Load chain Corrosion, etc. Not to be remarkably corroded.

Chain end condition End metal is to be correctly fixed.

Shaft joint Conditions of key, key groove and Not to be deformed, loosened and worn.

spline

Joint damage Not to be remarkably worn.

Wear of contact 50% or less of full size thickness

Switches

Wear of mechanism To be correctly operated.

Wear of wheel contact face 20% or less of full dia.

Collector

wheel Gap between wheel hole dia. and 20% or less of full shaft dia.

shaft

Cabtyre cable Not to be damaged, deteriorated and

Cable Lead wires interrupted. Other abnormal conditions are

Cable hangers not to be found.

Electric part Electric wire on trolley wire routing Check operation coil end of magnet SW is

side connected to trolley install side.

Power circuit Power switch conditions Not to be damaged.

Connection lines are not to be loosened

Inside of power switches and damaged. Suitable fuses are to be

connected.

Insulation resistance value of entire Class 200V 0.2KΩ or more

Insulation circuit Class 400V 0.4MΩ or more

Grounding Grounding of traveling rail To be well grounded.

Lubrication oil (oiling) Specified oil is to be adequately lubricated.

Assembly Assembly

Assembly To be assembled as specified.

Condition of inspection scaffold Not to be shaken and damaged.

Inspection

ladder

scaffold on

construction Mounting condition of inspection Not to be shaken and damaged.

side scaffold

Inspection Floor condition of inspection scaffold Not to be slipped and stumbled.

scaffold Conditions of carrying and elevating Not to be abnormal.

Movable devices

inspection Brake condition Not to securely locked.

table Hand rails and other protecting Not to be damaged, and to be safety.

devices

Inspection before trial run To be free from obstruction.

To be run in accordance with indications of

No-load run No-load operation

push buttons. Not to be noise.

To be correctly stopped on upper limit

Limit SW

position.

With the rated load hoisted at Deflection of 1/800 or less of span is to be

center of crane span, measure completely reversed.

deflection and reversion of crane

girder.

Trial run

Wind and unwind hoist. Noise and vibration are not to be occurred.

Rated load

test Hook slippage is to be 1% or less of winding

Electromagnetic brake distance for 1 minute after releasing push

button SW while hoisting.

Cross travel of hoist Noise and vibration are not to be occurred.

Noise is not to be occurred on run-way

Traveling of crane

and crane.

Mechanical Hoisted load is to be maintained after

Function suspended in midair

brake loosening electromagnetic brake.

Вам также может понравиться

- The Principles of Glass Cutting: A Comprehensive Technical Guide To Successful Glass Scoring and Cutting TechniquesДокумент15 страницThe Principles of Glass Cutting: A Comprehensive Technical Guide To Successful Glass Scoring and Cutting TechniquesAmir BakhshiyanОценок пока нет

- Gear ContactДокумент3 страницыGear ContactAli Ali AsjariОценок пока нет

- C10836834 PDFДокумент1 страницаC10836834 PDFFabian LopezОценок пока нет

- Daramic's Business of Making Pockets Training PDFДокумент60 страницDaramic's Business of Making Pockets Training PDFSibashish Paul100% (1)

- Rope CouplingДокумент4 страницыRope CouplingKamal KapaОценок пока нет

- Maintenance of Gears and Gear DrivesДокумент44 страницыMaintenance of Gears and Gear Driveskapun kumar nayak100% (1)

- Basic Mechanical Seal Installation: By: Dewi Tri HandayaniДокумент9 страницBasic Mechanical Seal Installation: By: Dewi Tri HandayaniPermana DediОценок пока нет

- Specification: 1) Appearance of WheelsДокумент6 страницSpecification: 1) Appearance of WheelsKada Ben youcefОценок пока нет

- Wheels Defects in Indian RailwaysДокумент25 страницWheels Defects in Indian RailwaysTapas kumarОценок пока нет

- 204-00 Suspension System - General Information PICKUP JMCДокумент27 страниц204-00 Suspension System - General Information PICKUP JMCRusonegroОценок пока нет

- Types of Flexible CouplingsДокумент11 страницTypes of Flexible Couplingsdfz138Оценок пока нет

- Vitro TD 119Документ9 страницVitro TD 119Eslam NaseebОценок пока нет

- RR - RJ VisherДокумент12 страницRR - RJ VisherTheo Mahendra WijayaОценок пока нет

- Inspect Forklift BladesДокумент5 страницInspect Forklift BladesElizaberthsОценок пока нет

- Technical Data - Ocean Stone 60x60x1cmДокумент1 страницаTechnical Data - Ocean Stone 60x60x1cmarqsusanlarahОценок пока нет

- Eng Shimano Manu 07218Документ1 страницаEng Shimano Manu 07218Ken SidhartaОценок пока нет

- Excavadoras Hidráulicas DemoliciónДокумент1 страницаExcavadoras Hidráulicas DemoliciónJoel RodríguezОценок пока нет

- Robo3d Z Ribbing Notes V3Документ18 страницRobo3d Z Ribbing Notes V3Adam MartinОценок пока нет

- Grinding Wheel Safety POSTER-BondedДокумент2 страницыGrinding Wheel Safety POSTER-BondedThiru kaОценок пока нет

- Derailment Due To Track DefectsДокумент58 страницDerailment Due To Track DefectsDasari RamamohanaОценок пока нет

- Tires Specification and Maintenance: Prepared byДокумент11 страницTires Specification and Maintenance: Prepared byIbrahim FaqaihОценок пока нет

- Backhoe English PDFДокумент1 страницаBackhoe English PDFGino AndersonОценок пока нет

- Group 2 Major Component: 1. Main PumpДокумент11 страницGroup 2 Major Component: 1. Main PumpChristian VicenteОценок пока нет

- Safety & Maintenance Checklist - D7E Track-Type Tractors V0611.2 PDFДокумент1 страницаSafety & Maintenance Checklist - D7E Track-Type Tractors V0611.2 PDFcherifОценок пока нет

- 06 Gear FailuresДокумент43 страницы06 Gear FailuresrudisamosirОценок пока нет

- 01 Fifth WheelДокумент105 страниц01 Fifth WheelAples Thoeram NdОценок пока нет

- ESTANDAR 01 English-Failure AnalysisДокумент19 страницESTANDAR 01 English-Failure AnalysisDavid FestusОценок пока нет

- Steer T-SB-0063-20Документ23 страницыSteer T-SB-0063-20VishyОценок пока нет

- 02 - LSD & LDДокумент5 страниц02 - LSD & LDQuang HuyОценок пока нет

- Norton Article Approved Formatted 1Документ6 страницNorton Article Approved Formatted 1RafaelОценок пока нет

- Elastomeric Bearing Pads & StripsДокумент4 страницыElastomeric Bearing Pads & StripsganmosesОценок пока нет

- Specifications: Description SpecificationДокумент15 страницSpecifications: Description SpecificationmanualОценок пока нет

- Derailment Due To Track DefectsДокумент58 страницDerailment Due To Track Defectskr_abhijeet72356587100% (3)

- TC Cone BrochureДокумент8 страницTC Cone BrochurecarrialdiОценок пока нет

- Grinding Wheel Wear PDFДокумент5 страницGrinding Wheel Wear PDFMira InduОценок пока нет

- Foreign Object Damage Uneven Wear Normal Wear: Radial and Bias TiresДокумент1 страницаForeign Object Damage Uneven Wear Normal Wear: Radial and Bias Tireshpulido33_390009144100% (1)

- Double Ram BOP Intermediate Maintenance Sheet (Yearly)Документ1 страницаDouble Ram BOP Intermediate Maintenance Sheet (Yearly)Gowthamagavaskar EnochОценок пока нет

- Safety & Maintenance Checklist - Demolition Hydraulic Excavators V0611.2Документ1 страницаSafety & Maintenance Checklist - Demolition Hydraulic Excavators V0611.2cherif100% (3)

- Guidelines For Good Glass Edge QualityДокумент12 страницGuidelines For Good Glass Edge QualityAnanthanarayananОценок пока нет

- Wheel DefectsДокумент13 страницWheel Defectsdeep0987654321100% (4)

- Shimano Ultegra 6703 Chainset Instructions PDFДокумент1 страницаShimano Ultegra 6703 Chainset Instructions PDFGabriel PastroОценок пока нет

- DamageДокумент27 страницDamageLuiz SilvaОценок пока нет

- SECTION 1.20: SpecificationsДокумент26 страницSECTION 1.20: SpecificationsLUISA FERNANDA TORRES MANOSALVAОценок пока нет

- RollerДокумент35 страницRollergun100% (1)

- 8 - Iknow Machinery Co., Ltd. (IK)Документ7 страниц8 - Iknow Machinery Co., Ltd. (IK)khan asifОценок пока нет

- Drive Shaft and AxleДокумент4 страницыDrive Shaft and AxleKada Ben youcefОценок пока нет

- SsangYong-Korando 2012 en US Manual de Taller Rueda Neumatico E5a4a452daДокумент20 страницSsangYong-Korando 2012 en US Manual de Taller Rueda Neumatico E5a4a452datsung0466Оценок пока нет

- Camión Minero 777-797Документ1 страницаCamión Minero 777-797Joel RodríguezОценок пока нет

- 001 - Transmision TorqflowДокумент12 страниц001 - Transmision TorqflowRichard Sequeiros Alvarez100% (1)

- LSD Manual PDFДокумент13 страницLSD Manual PDFDaniel CanalesОценок пока нет

- Brake SquakeДокумент5 страницBrake SquakeEdy SupriyantoОценок пока нет

- Expert Tips Hints Off Road Performance Tyres Suspension 1Документ16 страницExpert Tips Hints Off Road Performance Tyres Suspension 1AnupОценок пока нет

- Failure of Mechanical Shaft SealsДокумент17 страницFailure of Mechanical Shaft SealsbederinadmlОценок пока нет

- O RingДокумент89 страницO RingNikolat84Оценок пока нет

- Bearing & LubricationДокумент34 страницыBearing & LubricationRakesh GairolaОценок пока нет

- Safety & Maintenance Checklist - Backhoe Loaders V0611 - 2E2Документ1 страницаSafety & Maintenance Checklist - Backhoe Loaders V0611 - 2E2Abdellatef HossamОценок пока нет

- Maintenance &: Technical ManualДокумент8 страницMaintenance &: Technical Manuallukmanul hakimОценок пока нет

- EX55UR (1937) Y7141hrДокумент4 страницыEX55UR (1937) Y7141hrSyahrizal AlmazsОценок пока нет

- 900 263 49 CAT. Demag Gearmotor SystemДокумент12 страниц900 263 49 CAT. Demag Gearmotor SystemJESUSCALVILLOОценок пока нет

- Relay CatalogueДокумент1 страницаRelay CatalogueJESUSCALVILLOОценок пока нет

- Configure One BB3: CTO Model DefinitionДокумент5 страницConfigure One BB3: CTO Model DefinitionJESUSCALVILLOОценок пока нет

- Manual 83510Документ9 страницManual 83510JESUSCALVILLOОценок пока нет

- HPL500 PDFДокумент2 страницыHPL500 PDFJESUSCALVILLOОценок пока нет

- Spare Parts List: Lever Hoists & Chain HoistsДокумент8 страницSpare Parts List: Lever Hoists & Chain HoistsJESUSCALVILLOОценок пока нет

- SNGL GRDR Crane BRDG Kits Electrical-113533-74Документ8 страницSNGL GRDR Crane BRDG Kits Electrical-113533-74JESUSCALVILLOОценок пока нет

- Electric Hoist - June 1973 113534-37Документ28 страницElectric Hoist - June 1973 113534-37JESUSCALVILLOОценок пока нет

- Lever Operated Hoists - Nov 1997 113536-18Документ24 страницыLever Operated Hoists - Nov 1997 113536-18JESUSCALVILLOОценок пока нет

- Lever Operated Hoists - May 1977 113536-10Документ16 страницLever Operated Hoists - May 1977 113536-10JESUSCALVILLOОценок пока нет

- 981101Документ44 страницы981101JESUSCALVILLOОценок пока нет

- Icd Ebdrumbrake CatalogДокумент6 страницIcd Ebdrumbrake CatalogJESUSCALVILLOОценок пока нет

- Lever Operated Hoist - Oct 1997 113536-14Документ16 страницLever Operated Hoist - Oct 1997 113536-14JESUSCALVILLOОценок пока нет

- Folleto de PolipastosДокумент8 страницFolleto de PolipastosJESUSCALVILLOОценок пока нет

- 06 BrakesДокумент31 страница06 BrakesJESUSCALVILLOОценок пока нет

- Flyer FMD1 enДокумент2 страницыFlyer FMD1 enJESUSCALVILLOОценок пока нет

- Index:: 1) Gt09 Wheel Diameter 90 MMДокумент14 страницIndex:: 1) Gt09 Wheel Diameter 90 MMJESUSCALVILLOОценок пока нет

- Crane Kits Specifications CSL1003 0206Документ28 страницCrane Kits Specifications CSL1003 0206JESUSCALVILLOОценок пока нет

- STAHL ST Electric HoistsДокумент5 страницSTAHL ST Electric HoistsJESUSCALVILLOОценок пока нет

- en de 170630Документ16 страницen de 170630JESUSCALVILLOОценок пока нет

- en de 170630Документ24 страницыen de 170630JESUSCALVILLOОценок пока нет

- Demag Spare Part Sets: The Future Starts HereДокумент4 страницыDemag Spare Part Sets: The Future Starts HereJESUSCALVILLOОценок пока нет

- CMXC007 Upgrade Kit ManualДокумент97 страницCMXC007 Upgrade Kit ManualJESUSCALVILLOОценок пока нет

- Polipastos Nippon Hoist CatalogoДокумент5 страницPolipastos Nippon Hoist CatalogoJESUSCALVILLOОценок пока нет

- 203 656 44 Accesorios ElectricosДокумент32 страницы203 656 44 Accesorios ElectricosJESUSCALVILLOОценок пока нет

- MEUS ManualДокумент43 страницыMEUS ManualJESUSCALVILLOОценок пока нет

- Ges4 F07driveДокумент1 страницаGes4 F07driveJESUSCALVILLOОценок пока нет

- QCVN 09-2013 National Technical Regulation On Energy Efficiency Buildings (Eng)Документ56 страницQCVN 09-2013 National Technical Regulation On Energy Efficiency Buildings (Eng)Law ArveyОценок пока нет

- Placa PC Chip M909Документ64 страницыPlaca PC Chip M909michigato100% (1)

- N4 Physics 1.3 - ElectronicsДокумент20 страницN4 Physics 1.3 - ElectronicsNoniОценок пока нет

- Computer Systems ServicingДокумент13 страницComputer Systems ServicingLoli Gonzales ArtiagaОценок пока нет

- MCT 10 Set-Up Software: Group Folder: ProjectДокумент3 страницыMCT 10 Set-Up Software: Group Folder: Projectjayanta37Оценок пока нет

- ZXM8 TPLDD120 600Документ2 страницыZXM8 TPLDD120 600SOLUCIONES ENERGETICAS Y PROCESOS INNOVADORESОценок пока нет

- Index MBL22-8 MBL40-6 MBL40-8 enДокумент5 страницIndex MBL22-8 MBL40-6 MBL40-8 enMahir PiricОценок пока нет

- Ac 1Документ2 страницыAc 1Alfredo jose Medina revattaОценок пока нет

- Ia Audit Report ExcelДокумент5 страницIa Audit Report ExcelSunil Kumar Gurudutt NanduriОценок пока нет

- Jib Crane 1Документ28 страницJib Crane 1OPAZOSCОценок пока нет

- Skilsaw Sawsquatch ManualДокумент56 страницSkilsaw Sawsquatch ManualAhmedy PОценок пока нет

- A Project Report SSP 1Документ22 страницыA Project Report SSP 120-301 AKSHAYОценок пока нет

- ABB Publication 1MRK509015-BEN C en High Impedance Differential Relay RADHAДокумент5 страницABB Publication 1MRK509015-BEN C en High Impedance Differential Relay RADHAjavedsmg1Оценок пока нет

- Management Guide To AlignmentДокумент3 страницыManagement Guide To Alignmentjonalthan1987Оценок пока нет

- Product Bulletin Fisher Vee Ball v150 v200 v300 Rotary Control Valves en 122994Документ28 страницProduct Bulletin Fisher Vee Ball v150 v200 v300 Rotary Control Valves en 122994Swastik MahapatraОценок пока нет

- Instruction Manual AK-157Документ10 страницInstruction Manual AK-157Kalim KamОценок пока нет

- Detailed Lesson PlanДокумент9 страницDetailed Lesson PlancaifiОценок пока нет

- C002A-Propylene Compressor LLFДокумент1 страницаC002A-Propylene Compressor LLFPwan KhuranaОценок пока нет

- Baldor DC ServoДокумент48 страницBaldor DC Servod3xter100% (1)

- Special Purpose Vehicles: Padhiyar Raj H Automobile Department Saffrony Institute of TechnologyДокумент34 страницыSpecial Purpose Vehicles: Padhiyar Raj H Automobile Department Saffrony Institute of TechnologyBirjesh YaduvanshiОценок пока нет

- Clarity Line AmpДокумент27 страницClarity Line AmpPayphone.comОценок пока нет

- Pilot Circuits: Service Training Manual CM 760/780Документ5 страницPilot Circuits: Service Training Manual CM 760/780victor laraОценок пока нет

- ML411A Solar Marine LanternДокумент12 страницML411A Solar Marine Lanternjetr19754106Оценок пока нет

- NUVE EN 032-055-120 Incubators BrochureДокумент2 страницыNUVE EN 032-055-120 Incubators BrochureDinhtrung TruongОценок пока нет

- Audi A4 B8 VCDS Codings PDFДокумент10 страницAudi A4 B8 VCDS Codings PDFcosteniuc100% (3)

- Cursor: Fpt Cursor 13Te7 (Cr13 Te 7W) Use and Maintenance Бриз МоторсДокумент36 страницCursor: Fpt Cursor 13Te7 (Cr13 Te 7W) Use and Maintenance Бриз МоторсMohammed HamdeenОценок пока нет

- A Study On MicropocessorДокумент12 страницA Study On MicropocessormanaskollamОценок пока нет

- Buscar VyxДокумент22 страницыBuscar VyxDayana OrozcoОценок пока нет

- Motor 60Z02152 - 03 (1) CAT3306 CrankshaftДокумент5 страницMotor 60Z02152 - 03 (1) CAT3306 CrankshaftIsmael De Jesus AndradeОценок пока нет

- Product Information.: Technical Training. N47TU EngineДокумент66 страницProduct Information.: Technical Training. N47TU EngineAndreAPL100% (1)