Академический Документы

Профессиональный Документы

Культура Документы

LRFD Design Requirements For Precast & Cast-In-Situ Concrete Box Culverts (Skew)

Загружено:

Mohak Nagrani0 оценок0% нашли этот документ полезным (0 голосов)

10 просмотров4 страницыLRFD Design Requirements for Precast & Cast-In-Situ Concrete Box Culverts (Skew)

Оригинальное название

LRFD Design Requirements for Precast & Cast-In-Situ Concrete Box Culverts (Skew)

Авторское право

© © All Rights Reserved

Доступные форматы

PDF или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документLRFD Design Requirements for Precast & Cast-In-Situ Concrete Box Culverts (Skew)

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

10 просмотров4 страницыLRFD Design Requirements For Precast & Cast-In-Situ Concrete Box Culverts (Skew)

Загружено:

Mohak NagraniLRFD Design Requirements for Precast & Cast-In-Situ Concrete Box Culverts (Skew)

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

Вы находитесь на странице: 1из 4

Illinois Department of Transportation

Memorandum

To: ALL BRIDGE DESIGNERS 11.3 (REV)

From: D, Carl Puzey ACM

Subject: LRFD Design Requirements for Precast and Cast-In-Place

Concrete Box Culverts

Date: November 2, 2011 (Revised January 27, 2012)

‘The Department is beginning implementation of AASHTO Load and Resistance

Factor Design (LRFD) for buried structures, which includes culverts, pipes and

three sided structures. This memorandum addresses conorete box culverts.

PRECAST CONCRETE BOX CULVERTS.

Effective with the 2012 Standard Specifications for Road and Bridge Construction

and beginning with the January 20, 2012 letting, all precast concrete box culverts

and precast extensions of existing culverts shall utilize LRFD by applying the

standard designs of ASTM C 1577. Precast box configurations and loadings not

addressed in ASTM C 1577 may be designed utilizing LRFD with the latest version

of the BOXCAR program, provided similar slab and wall thicknesses of the nearest

standard geometric configurations from ASTM C 1577 are used. These non-

standard precast box culvert sections shall have the design shown on the contract

plans, similar to a cast-in-place box, and shall be sealed by an Illinois Licensed

Structural Engineer. The following table is a list of standard precast box

configurations that may be found in ASTM C 1577. Standard configurations are

encouraged for new culvert designs. If the closest standard configuration is too tall

for a specific application, consider setting the box invert deeper or utilizing more

culvert barrels of a shallower configuration before using a non-standard

configuration.

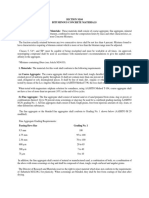

Standar it Concrete Box Culvert Configurations

‘Span x Rise - ft

3x2 8x4 Oxo 1x6

aeeeg 9 GHEE [PEGE 8x5 1x8

8x6 0x5 11x10

4x2 6x6 8x7 10x6 txt

4x3 8x8 10x7

4x4 Zi aires [ieee 10x8 2x Aneel

7x5 ox5 10x9 12x6

5x3 7x6 9x6 10x 10 12x8

5x4 7x7 9x7 12x10

5x5 9x8 Tix4 12x12

Itis important to note there are a few design limitations associated with ASTM C

1677. First, the design tables are adequate for skews up through 30 degrees

and also for larger skews when the design fill is greater than 5 feet. Skews larger

than 30 degrees with design fills less than or equal to 5 feet shall be handled with

design tables that IDOT will provide through a (BDE) special provision entitled

ALL BRIDGE DESIGNERS

Page 2

November 2, 2011 (Revised January 27, 2012)

“CONCRETE BOX CULVERTS WITH SKEWS > 30 DEGREES AND DESIGN

FILLS <5 FEET (BDE)' prior to the January letting. Designs from this special

provision or ASTM C 1577 do not require a seal by an Illinois Licensed Structural

Engineer. This policy is summarized in the following chart.

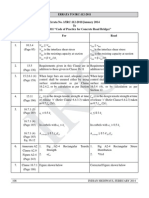

Skew* Design Fil | Specificat

$30 Al Fills ‘ASTM C

>30 eae —__ASTMC 1577

>30 <5it IDOT Special Provision

*The skew is the angle between a perpendicular line to the box culvert and the

centerline of the roadway.

Second, the design tables of ASTM C 1577 are based on a live load distribution

of 1.15 in both directions through design fills 2 2 feet. To achieve this

distribution, Porous Granular Embankment (PGE) backfill is required for all boxes

meeting either of the following two conditions:

+ Depth of fill= 2 ft. and <8 ft

+ Depth of fill s span of largest box in configuration

The limits and quantities of the PGE necessary for the box installation shall be

shown and included in the roadway plans.

Design fills less than 2 feet shall satisfy the requirements of AASHTO LRFD

Article 4.6.2.10. The Department recommends PGE or a continuation of the

roadway sub base up to the 2 feet of fill. Note that for Case 1, parallel to the

span, the LLDF shall then be 1.15.

Roadway Plan Presentation

Over the years, many Districts have developed their own unique contract plan

details for precast box culverts, some by repeating portions of the AASHTO

details and tables and others by developing their own notes, tables and details.

This transition from Load Factor Design (LFD) to LRFD design is a good

opportunity to unify and promote consistent details throughout the State.

Therefore, in lieu of the various past practices, we are recommending the

following:

1. Each culvert shall be identified on the plan/profile sheets of roadway

plans with the following information:

ASTM C 1577; Station; Size; Skew; Design Fill

Fabricators will be instructed in the Bureau of Materials and Physical

Research (BMPR) policy memorandum “Quality Control/ Quality

Assurance Program for Precast Concrete Products" to identify each

precast box culvert section in the same way for easy identification and

location in the field. Additionally, the policy memorandum requires

fabricators to include their producer mark and the date of manufacture

on each precast box culvert section.

ALL BRIDGE DESIGNERS

Page 3

November 2, 2011 (Revised January 27, 2012)

2. Each set of applicable roadway plans shall have a Culvert Schedule

including the following minimum information. The designer shall

determine the design fill heights, and shall note whether PGE backfill is

required.

Precast Box Culvert Schedule (ASTM C 1577)

Design Fil (f.)

: Size sgn EL PGE backfill

Station ant) | Skew" | Edge of shidr. | Maximum :

(Span x Height) (cinmam) "| required

*Skews > 30° with design fils < 5 ft. require a special design. See BDE Special Provision

"CONCRETE BOX CULVERTS WITH SKEWS > 30 DEGREES AND DESIGN FILLS = 5

FEET (BDE)’. The skew is the angle between a perpendicular line to the box culvert and

the centerline of the roadway.

3. The roadway plans shall clearly illustrate the intended limits, pay item

and quantity of the PGE necessary for the box installation.

CAST-IN-PLACE (CIP) BOX CULVERTS

In order to allow some time for plan preparation, all CIP concrete box culverts and

CIP extensions of existing culverts, beginning with the June 15, 2012 letting and

beyond shall utilize LRFD according to the latest version and interims of the

AASHTO LRFD Bridge Design Specifications. The Department anticipates issuing

Standardized Design Tables of single span box culverts for the Culvert Manual

Until these tables become available, all CIP simple span box culverts, on the

June 15, 2012 letting and beyond, will require a design sealed by an Illinois

Licensed Structural Engineer. All multi-span CIP boxes will continue to require a

design sealed by an Illinois Licensed Structural Engineer similar to our current

policy.

Design Preferences

The same live load distribution of 1.15, as previously discussed for precast

concrete box culverts, shall also be used for CIP boxes. As such, PGE will also

be required for the same ranges of design fill.

CIP concrete box culverts shall be designed for the perpendicular span between

the culvert walls. The main flexure reinforcement is therefore also placed at right

angles to the wall. On skewed structures, the skewed areas near staged

construction lines or end sections shall preferably be addressed with an edge

beam design satisfying Article 4.6.2.1.4 of the AASHTO LRFD Bridge Design

Specifications. However, there are circumstances where it may be more

advantageous to place the flexure reinforcement along the skew rather than

perpendicular to the walls. Examples may be culverts with short lengths, staged

construction and large skew or shallow fills where an edge beam design requiring

more slab depth may interfere with the roadway sub base. In these cases, the

perpendicular span shall be used to design the slab thickness and the steel area.

ALL BRIDGE DESIGNERS

Page 4

November 2, 2011 (Revised January 27, 2012)

The stee! area shall then be increased by the multiplication of sec’@ and the

resulting area of steel placed along the skew. The skew, 8, is defined as the

angle between a perpendicular line to the box culvert and the centerline of the

roadway. Additionally, Article 5.5.4.2.1 of the AASHTO LRFD Bridge Design

Specifications shall be satisfied such that the slab remains “tension controlled”.

IMPLEMENTATION

In summary, all precast concrete box culverts and precast extensions of

existing culverts, beginning with the January 20, 2012 letting, shall utilize LRFD

by applying the standard designs of ASTM C 1577 and all CIP concrete box

culverts and CIP extensions of existing culverts on the June 18, 2012 letting

and beyond shall utilize LRFD according to the latest version and interims of

the AASHTO LRFD Bridge Design Specifications.

Due to these time frames, itis possible to have a few scenarios that will require

additional action. First, a LFD designed CIP box culvert may appear on some

of the early 2012 lettings. If there is not a note stating otherwise on the plans,

the contractor may still have the option to substitute a precast box culvert as,

permitted by Article 540.04 of the Standard Specifications. In these cases, a

precast box culvert built according to ASTM C 1577 may be substituted

provided the design requirements previously described are satisfied. To

ensure all potential additional costs, such as PGE, are covered by the contract,

for this scenario, a BDE special provision of either “CONCRETE BOX

CULVERTS WITH SKEWS < 30 DEGREES REGARDLESS OF DESIGN FILL

AND SKEWS > 30 DEGREES WITH DESIGN FILLS > 5 FEET (BDE)' or

*CONCRETE BOX CULVERTS WITH SKEWS > 30 DEGREES AND DESIGN

FILLS <5 FEET (BDE)’ shall be inserted into each applicable contract

document.

Second, the contract plans may originally have detailed @ precast concrete box

based on the old AASHTO M 259 or M 273 (LFD design) but the equivalent

standard ASTM C 1577 (LRFD designed) precast concrete box culvert may

require PGE, depending on the design fill. To ensure all potential additional

costs, such as PGE, are covered by the contract for this scenario, the

appropriate BDE special provision as mentioned in the previous paragraph,

shall be inserted into each applicable contract document.

The Bureau of Bridges and Structures will coordinate with the Bureau of Design

and Environment to insure contracts with culverts, let before June 15, 2012, have

the appropriate special provisions inserted. If there are any questions regarding

these policies please contact Gary Kowalski at (217) 785-2914,

KLR/KKtABD11.3LRFDrevised-20111102

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Roundabout PDFДокумент34 страницыRoundabout PDFMohak NagraniОценок пока нет

- Unified Facilities Criteria (Ufc) : Pavement Design For Roads, Streets, and Open Storage Areas, Elastic Layered MethodsДокумент53 страницыUnified Facilities Criteria (Ufc) : Pavement Design For Roads, Streets, and Open Storage Areas, Elastic Layered MethodsMohak NagraniОценок пока нет

- Section M.04 Bituminous Concrete MaterialsДокумент6 страницSection M.04 Bituminous Concrete MaterialsMohak NagraniОценок пока нет

- Traffic Manual: March 2008Документ176 страницTraffic Manual: March 2008Mohak NagraniОценок пока нет

- Index - IRC-No. With DescriptionДокумент5 страницIndex - IRC-No. With DescriptionMohak NagraniОценок пока нет

- IRC SP 99 - 2013 Manual of Specification and Standard For ExpresswaysДокумент152 страницыIRC SP 99 - 2013 Manual of Specification and Standard For ExpresswaysMohak NagraniОценок пока нет

- Irc Code Books S.No. AA Code IRC Code/TitleДокумент4 страницыIrc Code Books S.No. AA Code IRC Code/TitleMohak NagraniОценок пока нет

- AV Assignment: By-Kinshuk Snehi (224), Ravindra PurohitДокумент2 страницыAV Assignment: By-Kinshuk Snehi (224), Ravindra PurohitMohak NagraniОценок пока нет

- Machchundri (PW) Water Resource - Dams and Canals - Data Bank - Narmada (Gujarat State)Документ1 страницаMachchundri (PW) Water Resource - Dams and Canals - Data Bank - Narmada (Gujarat State)Mohak NagraniОценок пока нет

- Grillage Analogy C.S.surana R.agrawal - For WordДокумент283 страницыGrillage Analogy C.S.surana R.agrawal - For WordMohak Nagrani100% (1)

- L&T Construction Transportation Infrastructure: Design of Shear ConnectorДокумент4 страницыL&T Construction Transportation Infrastructure: Design of Shear ConnectorMohak NagraniОценок пока нет

- Errata - Irc 112 2011, Jan 2014Документ2 страницыErrata - Irc 112 2011, Jan 2014Mohak NagraniОценок пока нет

- Green Concrete: K.L.E. College of Engineering and Technology 1Документ26 страницGreen Concrete: K.L.E. College of Engineering and Technology 1Mohak NagraniОценок пока нет

- Technical Seminar On: GreenДокумент17 страницTechnical Seminar On: GreenMohak Nagrani100% (4)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- (Integrative Activity 3) : Be My GuestДокумент7 страниц(Integrative Activity 3) : Be My GuestMonik Rossainz CasasОценок пока нет

- MOMA 1970 July-December 0079Документ3 страницыMOMA 1970 July-December 0079saladidulceОценок пока нет

- Contractor'S Weekly Progress Report: Project DetailsДокумент7 страницContractor'S Weekly Progress Report: Project DetailsBrille John ReyesОценок пока нет

- Session 3 BTVLCДокумент49 страницSession 3 BTVLCYasichalew sefineh100% (1)

- Average House Construction Cost Philippines - PHILCON PRICESДокумент7 страницAverage House Construction Cost Philippines - PHILCON PRICESjohn reyes0% (1)

- 1 Building Const 2Документ89 страниц1 Building Const 2Justine Rose AngolluanОценок пока нет

- Modelling Building Frame With Staadpro N Etabsrahul Leslie090815 151231065653Документ103 страницыModelling Building Frame With Staadpro N Etabsrahul Leslie090815 151231065653Muhammad Murtaza100% (3)

- Upholstery Catalogue PDFДокумент15 страницUpholstery Catalogue PDFDo Van LuanОценок пока нет

- PC Sheet Piles: DescriptionДокумент1 страницаPC Sheet Piles: Descriptionganiardiansyah adam100% (1)

- RC 2Документ92 страницыRC 2Chrisneil DelosreyesОценок пока нет

- Nabataean Concrete UseДокумент3 страницыNabataean Concrete UseDeemaОценок пока нет

- Right Side Elevation Isometric Viewof Fence: Proposed Perimeter Fencing and Garage Balcony RoofingДокумент1 страницаRight Side Elevation Isometric Viewof Fence: Proposed Perimeter Fencing and Garage Balcony RoofingRonnie Buico Conejos CEОценок пока нет

- Boysen ProductsДокумент2 страницыBoysen ProductsAly MendozaОценок пока нет

- Westinghouse Lighting OV-25 Tu-Dor Flat Glass Series Roadway Spec Sheet 1-79Документ2 страницыWestinghouse Lighting OV-25 Tu-Dor Flat Glass Series Roadway Spec Sheet 1-79Alan Masters100% (1)

- BCM SheetsДокумент5 страницBCM SheetsDeeksha PptОценок пока нет

- Tacboc Details 2012 r001.3Документ76 страницTacboc Details 2012 r001.3Pourang EzzatfarОценок пока нет

- Define of Bridge: Introduction To Bridge EngineeringДокумент4 страницыDefine of Bridge: Introduction To Bridge EngineeringASSEFAGETNETОценок пока нет

- Daily ReportДокумент8 страницDaily ReportAndi Ulil Amri UPОценок пока нет

- BOQ For Clubhouse - GulbargaДокумент18 страницBOQ For Clubhouse - GulbargaDatta Pujari0% (1)

- Intake Retaining Wall Take OffДокумент9 страницIntake Retaining Wall Take OffMesfin DerbewОценок пока нет

- GUIDE TO PRECAST CONCRETE AND PREFABRICATED REINFORCEMENT FOR BUILDINGS Lowres PDFДокумент85 страницGUIDE TO PRECAST CONCRETE AND PREFABRICATED REINFORCEMENT FOR BUILDINGS Lowres PDFabdul khader100% (1)

- Mies Van Der RoheДокумент22 страницыMies Van Der RohesanjanaОценок пока нет

- Manan FINAL REPORTДокумент38 страницManan FINAL REPORTManan PrajapatiОценок пока нет

- IFT Project Brief Final PDFДокумент68 страницIFT Project Brief Final PDFCee Jeon100% (1)

- Kajian Penyebab Keterlambatan Dan Rencana Percepatan (Action Plan) Pekerjaan Pondasi Borepile (Studi Kasus Rekonstruksi Jembatan Palu 4)Документ23 страницыKajian Penyebab Keterlambatan Dan Rencana Percepatan (Action Plan) Pekerjaan Pondasi Borepile (Studi Kasus Rekonstruksi Jembatan Palu 4)Rizal anggiawanОценок пока нет

- Snag ListДокумент6 страницSnag ListVishal Tiwari100% (1)

- Fire Resistance of Flat Plate Voided Slabs - ETN-B-2-16Документ6 страницFire Resistance of Flat Plate Voided Slabs - ETN-B-2-16ali tahaОценок пока нет

- RB 07 2013Документ17 страницRB 07 2013ayanmukherjee1404Оценок пока нет

- Mandani Bay Residential BrochureДокумент38 страницMandani Bay Residential BrochureJan Mitchel B. TaborОценок пока нет

- Roofing Data 25july Without Website Lizze-PavneshДокумент9 страницRoofing Data 25july Without Website Lizze-PavneshPavnesh ChauhanОценок пока нет