Академический Документы

Профессиональный Документы

Культура Документы

US6564566656

Загружено:

aversifuncaesto0 оценок0% нашли этот документ полезным (0 голосов)

1 просмотров5 страницhghgfhfhgfhgfh5

Авторское право

© © All Rights Reserved

Доступные форматы

PDF или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документhghgfhfhgfhgfh5

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

1 просмотров5 страницUS6564566656

Загружено:

aversifuncaestohghgfhfhgfhgfh5

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

Вы находитесь на странице: 1из 5

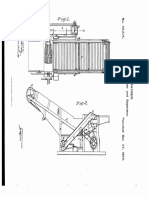

No. 656,469, Patented Aug. 21, 1900.

W. MCHAFFIE.

POWER TRANSMITTER FOR SEWING MACHINES,

(applies fed Fen 91, $000

(to Model) 2 Shoots—Sheet 1.

No. 656,469. Patented Aug. 21, 1900.

W. McHAFFIE.

POWER TRANSMITTER FOR SEWING MACHINES.

(pplication et 4 21, 1900)

(Mo Model.) 2 Shoots—shoot 2,

MAG. 2. 5

RA atte Wr ho

By Rue Attorney,

SL Bee

as

39.

38

40

45

so

Unrrep States Patent Orrice.

WILLIAM MoHAPTIE, -OF NEW YORK, N. ¥.

POWER-TRANSMITTER FOR SEWING-MACHINES.

SPECIFICATION forming part of Letters Patent No, 656,469, dated Augiist 21, 1900.

Appllction ad Fobrasry 21,2000, Serial o.6,022, io mots)

fo all whom it. may concern:

Boit known that I, Witiiam McHAarere, a

citizen of the United States, and a resident of

the borough of Manhattan, in thecity, county,

and State of New York, have invented cer-

tain new and useful Improvements in Power-

‘Transmitters for Sewing-Machines, of which

the following is a specifieation, reference be-

ing had to the accompanying drawings, form-

ing part thereof.

‘My invention relates to improvements in

mechanism for transmitting power from a

main driving shaft, which isconstantly in mo-

tion, to sewing or other similar machines,

whichareadapted to alternately ram and stop.

‘The most usual means employed for such pur-

pose is a belt arranged to ran either alter-

ately upon fast and loose pulloys or upon a

pulley which is movable to and from position

forfrictional engagement with the hand-wheel

of the machine. ‘These belts, however, soon

Decome stretched more or less and require a

great deal of care in keeping the same prop-

erly adjusted to provent undue slack in the

same, and it has been the object of my pres-

ent invention to provide a simple and elfect-

ive power-transmittor by which the use of

elts and the attendant trouble will be avoid-

ed and which may be readily adjusted to ma-

chines of different heights, sizes, and posi

tions and also be eapable of quick and con-

venient adjustment to communicate mov

mentof varying speeds to the machine. ‘This

object I secure by means of the novel con-

straction and combination of parts embody-

ing my invention, as hereinafter set forth in

Geiail, and pointed out in the claims.

In the accompanying drawings, Figure 1

vepresentsan end orside view of my improved

transmitter mechanism with the fable in sec:

tion. Fig. 2 represents a front elevation of

the Samo with the sewing-machine head in

dotted lines and the usual hand-wheol at one

end thereof in full lines; and Fig. 3 repre-

sents a detail view in perspective, to be here-

inafter referred to,

Tn said drawings, 1 indicates a: power-ma-

chine table of ordinary construction; 2, asew-

ing-machine head (in dotted outline) support-

ed iipon said table; 8, the usual hand-wheel

or disk, whieh is made fast upon the eud of

‘the driving-shaft supported in the upper arm

of the machine, and 4 the main power-shaft;

Supported in shitable bearings beneath thé

table 1 and provided with a driving disk or

wheel 5, which rotates therewith.

According tomy invention I provideaframe

or bracket 6, having an opening 7 extending

Iongitudinally therethrough, (see Fig. 8,) in

which a shaft 8, having friction-disks af op-

posite ends thereof, is loosely supported to r

volve. This frame or bracket 6 is provided

at a point between its ends with a pivotally-

connected supporting arm or pin 9, which, as

herein shown, is provided with a forked énd

10, which ombraces a flange or web 11 of the

bracket and is pivotally connected therewith

by means of a pivot-pin 12. The said pin 9

has a sliding adjustable connection with a

tubular head or sleeve 19, located on the end

ofa bracket-arm I, which latter is supported

to slide within a tubular bracket 15, secured

upon one of the table-supporting ‘legs 16.

‘The pin 9 is held ina stationary adjusted po-

sition relative to the head or sleeve 13 and

the arm 14 of the latter in a stationary ad-

justed position relative to the bracket 15 by

Imeans of set-serews 17 and 18, respectively,

as shown. ‘The shait S is of greater length

than the bracket 6 and extends at each end

beyond the ends of the latter. Upon these

projecting ends of the shaft 8 aro secured

friction-disks 19 and 20, the disk 19 at the

lower-end of the shaft: being adapted to en-

gage with the adjacent face or side of the

Griving-disk 5 on the shaft 4, so as to receive

motion therefrom, and the disk 20 at the up-

per end of the shaft being adapted to engage

with the face of the hand-wheol 3 of the sew-

ing-machine and transmit motion thereto.

‘AS @ simple means for rocking the bracket

6 apon its pivotal support, 80 as to throw the

disks on the opposite ends. of the shaft

either into or away from contact with the

dtiving-disk 5 and the hand-wheol 3, whereby

the sewing-machine may be either set in mo-

tion or stopped at the will of the operator, T

have provided a bell-crank lever 21, which is

pivotally supported ona floor-braeket22, with

one arm 25 connecting with the forward or

too ond of a treadle 25' and its other arm 24

having a forked arm 25 loosely embracing the

bracket 6, adjacentto its lowerend. By this

arrangement of parts pressure upon the heel

55

60

65

70

15

80

9°

2

end of the treadle will rock the bell-crank.

lever 21 in the proper direction to swing the

bracket 6 upon its pivot and force the lower

friction-disk 19 into contact with the driving-

disk 5 and the upper disk 20 into contact with

the hand-wheel 3 and so set the macbine in

motion. When it is desired to stop the ma-

chine, pressure is simply removed from the

heel of the treadle, thereby permitting the

bracket 6 to swing on its pivot and move the

frietion-disks 19 and 20 from contaet with the

driving and driven parts. A bracket 26,

cured on the upper surface of the table i, is

provided with a forked arm 27, which loosely

embraces the pivoted bracket 6, adjacent to

its upperend,andservestosupportand steady:

the same at Such point.

In order that the bell-crank lever 21 imme-

diately upon removal of pressure from the

heel of the treadle may be automatically

swung back to ils normal position, as shown,

in Fig. 2, to relieve the friction-disks from

contact with the driving and driven parts, I

have provided a coiled spring 28, which is

attached at one end to a hook or staple 28°

on the floor and at its opposite end to the hori-

zontal arm 23 of the bell-erank lever 21 and

acts to yieldingly hold the lever in such nor-

mal position.

In order that the machine may be quickly

brought to a standstill after the transmitter

has been released from operative engagement

therewith, [have pivoted a lever 29 upon the

arm of the machine at 30, with one end hay-

ing a piece of leather or other similar mate-

rial 29° thercon to serve as a frietion-brake

for engaging with the periphery of the hand-

wheel 3 and its opposite end having connec-

tion with the bell-erank lever 21 through the

medium of a connecting-rod 81. By.this eon-

struction and arrangement of parts when

pressure is removed from the heel end of the

treadle and the bell-erank lover 21 is rocked

under the action of the spring 28 to relieve

the pivoted bracket 6 from lateral pressure

such movement of the lever 21 acts upon the

brake-lever 29 through the medium of the

rod 81 and forces the brake end of the same

into frictional engagement with the hand-

wheel, so as to quickly bring the machine to

astop.

It will be understood that the speed of the

machine may be varied, as desired, by simply

adjusting the position of the frietion-disk 19

back and forth on the shaft, so as to engage

with the driving-disk 5 a groater or less dis-

15

25

3°

35

40

45

50

55

tance from its center, a set-scrow 32 in the |

hub of the dist sorving to secure the latter |

‘The

in adjusted position upon its shaft 8,

disk 20 at the upper end of the shaft 8 is

adjustable on tho latter to engage with the

hand-wheel at opposite sides of its center in

a manner and for the purpose, as follows:

‘The disk, as shown, of course engages with

the hand-wheel at one side of its center, $0 as,

to rotate the same and connected driving-

shaft in onedirection; butin the event of the

60

65

| and-accurately adjusted to machines of differ-

656,469

transmitter being applied toa machine the

Ariving-shaft of which is adapted to be ro-

tated in the opposite direction the disk 20

may then be drawn off the end of the shaft

and replaced in a revorsod position, so as to

engage with the hand-wheel at the opposite

same to rotate in the opposite direction, the

side of its center, and consequently cause the

disk being secured on the shaft in adjusted

position by means of the set-screw 20'.

‘The several adjustments of tho frame or

bracket 6 with the supported transmitter

shaft 8 and connected friction-disks allowed

by the sliding and rocking connection of the

pin 9 with the bracket-arm 14, the sliding

‘connection of the latter with the bracket 15

ina direetion transverse to the pin 9, and the

vertical adjustmont of the said bracket 15,

allowed by the clongated slot 15’ therein,

through which its fastening serew or bolt 15”

extends, all permit the said bracket, with its

supported transmitter devices, to be readily

ze

15

80

85,

90

ent sizes and in different posi

readily understood.

Having thus sot forth a practical embodi-

ment of my invention, I do not wish to bi

understood as confining myself to the par

ticular details of construction and arrange-

ment of parts as illustrated and deseribed,

as the sane may be more or less materially

modified without departure from the spirit

of my invention, for

‘What I claim, and desire to secure by Let-

tors Patent, is—

1, Thecombination, with drivingand driven

disks or wheels, of a powor-tranamitter ar-

ranged intermediate of said disks, compris-

ing a pivotally-sapported frame or bracket, a

shaft supported in bearings in said frame or

bracket and provided with a frietion-disk at

or adjacent to each ond, one being adapted

to engage with one faco of the driving-disk 110

and the other to engage with the opposite face

of the driven disk, and means for rocking

said frame or bracket to simultaneously move

the frletion-disks either into, or away from,

engagement with tho said delving and driver

disks, for the purpose set forth.

2, Thecombination, withdriving and driven.

disks or wheels, of & power-transinitter ar-

ranged intermediate of said disks, eompris-

ing a pivoted rocking fratie or bracket, a re-

volving shaft supported wholly by said frame

ions, as will be

105

15

| or bracket and provided with friction-disks

at or adjacent to its opposite ends, and means

for shifting said frame or bracket to move

the friction-disks either into, or away from,

engagement with the said driving and deiven

disks, for the purpose set forth.

‘The combination, with drivingand driven

disks or wheels, of & power-transmitter ar-

ranged intermediate of said disks, compris-

ing a revolving shaft having friction-disks

thereon for engagement with the said driv-

ing and driven disks respectively, one-of the

friction-disks being adjustable on its shaft to

135

130

656,469 8

opposite sides of the center of the engaging | disks or wheels, of a power-transmitter at-

disk, for the purpose sot forth, and means for | ranged intermediate of said disks, eompris-

supporting said shaft. ing a frame or bracket provided with a sup-

‘Thecombination, with drivingand driven | porting arm or pin, a vertically and horizon-

5 disks or wheels, of a power-transmitter ar- | tally adjustable bracket-arm having an open- 35

ranged intermediate of said disks, compris- | ing which receives sald arm or pin in adjust

ing a pivoted rocking framo or bracket, a | able connection therewith, a shaft carted by

shaft carried by said frame or bracket and | said frame or braeket and having friction

having friction-disks thereon, means for ad-| disks thereon, and means for shifting said

ro justably supporting said frame or bracket | frame or bracket to move the friction-disks 40

With the parts carried thereby, amd means | either into, or away from, engagement with

for shifting said frame or bracket to move the | the said driving and driven disks,for the pur-

friction-disks either into, or away from, en- | pose set forth.

gagement with tho said driving and driven | 7. Thecombination,with drivingand driven

s, for the purpose set forth. disks or wheels, of a powor-transmitter ar- 45

. Phecombination,with driving and driven | ranged intermediate of said disks, compris-

disks or wheels, of a power-transmittor ar- | ing a frame or bracket provided with a piv-

ranged intermediate of said disks, compris- | otally-connected arm or pin, a bracket-arm

ing.a eentrally-pivoted frame or bracket, a | provided with an opening which receives said

20 revolving shaft carried by said frame or | pivoted arm or pin in adjustable connection so

bracket and being provided with friction- | therewith, a shaft carried by sald frame or

disks thereon, one of said disks being adjust- | bracket and having friction-disks thereon,

able on the shaft and in a radial direction | and means for shifting said frame or bracket

relative to the driving-disk, whereby it will | tomove tho friction-disks eitherinto, oraway

25 transmit different speeds from the latter, and | from, engagement with the said driving aud 55

means for rocking said frame or bracket to | driven disks, for the purpose set forth.

move the friction-disks either into, or away WILLIAM McHAFFIE.

from, engagement with the said driving and | Witnesses:

driven disks, for the purpose sot forth. Citas. F. Daxx,

30 6, Thecombination, with drivingand driven Hersert E, DAnn.

Вам также может понравиться

- UfgdgdgdgДокумент8 страницUfgdgdgdgaversifuncaestoОценок пока нет

- PL6 GHFHFHF 5646 Y1 GFHДокумент4 страницыPL6 GHFHFHF 5646 Y1 GFHaversifuncaestoОценок пока нет

- 65665656Документ4 страницы65665656aversifuncaestoОценок пока нет

- HU2564646505080BДокумент5 страницHU2564646505080BaversifuncaestoОценок пока нет

- 45646Документ3 страницы45646aversifuncaestoОценок пока нет

- NL345343333333333564644CДокумент2 страницыNL345343333333333564644CaversifuncaestoОценок пока нет

- DE45655CДокумент5 страницDE45655CaversifuncaestoОценок пока нет

- US5546466456Документ3 страницыUS5546466456aversifuncaestoОценок пока нет

- US45646464Документ2 страницыUS45646464aversifuncaestoОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)