Академический Документы

Профессиональный Документы

Культура Документы

Implementation of The Mega Reg

Загружено:

bhaskar0 оценок0% нашли этот документ полезным (0 голосов)

10 просмотров3 страницыmega

Оригинальное название

Implementation of the Mega Reg

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документmega

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

10 просмотров3 страницыImplementation of The Mega Reg

Загружено:

bhaskarmega

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 3

ADVANCES IN PATHOGEN REDUCTION

Implementation of the Mega Reg

DELL M. ALLEN *

Introduction • Mandated written HACCP system adoption. Plants will

be phased in depending on size, large plants (> 500 em-

On July 25, 1996, the long-awaited “Pathogen Reduc-

ployees) in January ’98; Medium-sized plants (10 to 499

tion; Hazard Analysis and Critical Control Point (HACCP)

employees) in January ’99; and small plants (< 10 em-

Systems;” final rule was published by the USDA. This rule is

ployees) in January of 2000.

commonly referred to as the “Mega Reg,” probably because

• Mandated FSIS inspection performance standard based

it was a major attempt at rewriting the rules, regulations,

on salmonella incidence levels dependent upon species

and guidelines under which federal meat inspection is car-

and/or raw ground product.

ried out. The mega reg is the beginning of shifting the prin-

ciples of meat inspection from a system relying almost solely

HACCP Development

on organolyptic methods to one incorporating science with

organolyptic methods. While the current system relies heavily Before a HACCP system for food safety can be imple-

on FSIS inspectors to detect and correct establishment food mented, it must be designed, developed, and put in the form

safety problems, the new regulations will move that respon- of a plan. According to the mega reg, the following must be

sibility to the establishment management. The Hazard Analy- done as a part of the design and plan development:

sis and Critical Control Point (HACCP) system is the method I. All establishments shall conduct, or have conducted for

mandated for the meat industry to use under the new final them, a hazard analysis to determine the food safety

rule. FSIS’s stated goal under the new rule is as follows: hazards that may occur in the production process. Pre-

“FSIS believes its food safety goal should be to re- ventative measures must also be defined that reduce or

duce the risk of foodborne illness associated with control the identified food safety hazards.

the consumption of meat and poultry products to II. Flow charts must be done that describe the steps of each

the maximum extent possible by ensuring that ap- process and the product flow in the establishment. The

propriate and feasible measures are taken at each products produced, their intended use, and/or consum-

step in the food production process where hazards ers of the finished product will be identified.

can enter and where procedures and technologies III. HACCP plans will be developed and written by the es-

exist or can be developed to prevent the hazard or tablishment for each product or similar groups of prod-

reduce the likelihood it will occur (60 FR 6785).” ucts produced by that plant.

As a part of the final rule, FSIS also clarified and outlined A. A single HACCP plan may encompass multiple prod-

the responsibilities of establishments for maintaining effec- ucts within a processing category if the hazards, criti-

tive sanitation programs, following sound food safety proce- cal control points (CCP’s), critical limits and proce-

dures, and producing solid food safety performance results. dures required are essentially the same.

IV. HACCP plans must include a list of the following:

Key Points of the Mega Reg A. The food safety hazards identified. These may be

chemical, microbiological and/or foreign material.

• Mandated SSOP’s (Sanitation Standard Operating Proce-

B. The critical control points for each of the identified

dures) adopted, January 27, 1997.

food safety hazards.

• Mandated performance criteria based on E.coli testing of

C. The critical limits that must be met for each critical

carcasses adopted January 27, 1997.

control point.

D. The monitoring procedures for all critical control

points and the frequency of monitoring for each.

*Dell M. Allen, Excel Corporation, 151 N. Main, Wichita, E. The corrective actions that have been developed and

Kansas 67201. are to be followed if critical limits are exceeded.

Reciprocal Meat Conference Proceedings, Volume 50, F. A record-keeping system that documents the moni-

1997. toring of the critical control points.

78 American Meat Science Association

G. The verification procedures and the frequency that edge and commitment to making a HACCP system work is

each will be performed. critical if it is to be effective.

V. The HACCP plan, once written, will be signed and dated Training and educating all employees in the facility must

by the responsible establishment official. This will be occur. Employees should be empowered to initiate a cor-

done upon each of the following occurrences: rective action any time they witness a food safety problem.

A. Upon initial acceptance. When they become involved, safer food will be produced

B. Upon any modification. and new ideas will be generated to continually improve the

C. At least annually, following a required reassessment. HACCP plan.

Implementation Developing the Monitoring Documents/Procedures

Implementation is defined as “to put into practice, carry The employees who will actually have to perform the

out.” This becomes the challenge following the design, de- monitoring, along with their supervisor, should be involved

velopment and the writing of the HACCP plan. What is the in the development of the monitoring documents and pro-

most effective way to get it implemented? There is no “one” cedures. By involving them, the document will tend to be

effective method of implementation; however, there are sev- useable, easy to fill out, and easily understood by the per-

eral key points that are common in the implementation of son doing the monitoring. Likewise, the procedures that are

any plan. These key points include the following: developed are more apt to be the actual ones used. The

most important thing to remember in developing the moni-

Management Support toring documents and procedures is to keep them as simple

and easily used as possible.

Senior management must approve and support an orga-

nized plan of HACCP implementation. The commitment of

Records

senior management is crucial to successful implementation.

Attempting to implement a plan without that support is largely A vital part of implementing a HACCP system is to de-

a waste of time, money, and effort. Target dates for imple- velop a system of collecting, organizing, and maintaining

mentation should also be established. This emphasizes the documentation records generated. Without this, a HACCP

management’s commitment to HACCP implementation and system is incomplete. The manner in which this is done is

gives a clear signal to all employees involved of their expec- dependent upon management. In some cases, facility size,

tations. layout, and/or number of employees may dictate that records

are maintained at more than one site. The important thing is

HACCP Team that a system is in place, functional, and can be easily ac-

cessed as needed by either plant and/or regulatory person-

Once senior management support is obtained, a HACCP

nel.

implementation team and a HACCP coordinator should be

named. The members of this team should be from multiple

Going Operative

disciplines. Each job family with a stake in producing and/

or selling the products being made should be represented In the implementation of a HACCP, it is advisable to first

on the team. A HACCP team representing all disciplines gives identify one critical control point (CCP) in one HACCP plan

maximum input of ideas on plan implementation as well as and then perform a trial run. This will allow the HACCP

causing “ownership” of the project to be shared by all. Team team and the responsible employees the opportunity to fo-

members should be experienced in their respective areas of cus on any potential problems that may evolve unexpect-

expertise, have good supervisory skills, and have had expe- edly. Once the successful implementation of the first CCP

rience in implementing major projects. has occurred, any remaining CCP’s in that HACCP should

be implemented one at a time until the entire HACCP plan

Education/Training for that product is in place. This allows the HACCP team

and employees to identify potential implementation prob-

The HACCP team and coordinator must be trained and

lems and to hopefully avoid them as later HACCP plans are

completely familiar with the HACCP system before attempt-

added. Assuming there is adequate time, the HACCP team

ing to implement the plan. One of their responsibilities and

may prefer to implement each product-specific HACCP plan

a vital part of implementation is to educate all employees

one at a time until the entire system is in place. Regardless

about HACCP and its use. Every employee in a food plant

of the implementation schedule, a trial run implementing

should have a basic understanding of the use of a HACCP

the simplest plan first is recommended.

system for preventing food safety problems. Those directly

involved in monitoring or verifying a critical control point

Recall System

should understand the hazard(s) being controlled, the criti-

cal limits, and what actions are to be taken if the critical An important part of any HACCP food safety system is

limits are violated. The actual production employees knowl- one of having a product recall method in place. This neces-

50th Annual Reciprocal Meat Conference 79

sitates that all product is code dated such that production the importance and their endorsement of the HACCP sys-

date and time is on the product package and/or box. Man- tem if it is to be implemented effectively. Senior manage-

agement must decide how this is to be done. Key consider- ment should name a HACCP team and team leader (HACCP

ations in making this decision include: 1) How likely is there Coordinator) and clearly commission them to implement the

to be a food safety problem with this product? 2) How much system. A key ingredient in a successful implementation is

product do you want to risk having to recall? For example, the education and training of all employees who will be in

in raw beef products, ground beef is more likely to be in- any way involved with the HACCP system of food safety.

volved in a recall than whole-muscle subprimals. Thus, a Product safety is essential to the long term viability of a

facility may want to break the production run of ground beef company and to the industry the product comes from. Mak-

into small lots so that a recall could potentially be confined ing it safe must occur on the production floor and the em-

to an hour or less of production. Since whole-muscle sub- ployees who produce it are the individuals who make that

primals are rarely involved in a recall, these may be code- happen. Management has the responsibility to provide em-

dated in such a manner that if a recall was necessary, an ployees with the tools to produce safe product and also to

entire shift of production would be involved. empower them in utilizing the HACCP system to ensure safe

food results. This entire process of implementing and using

Summary a HACCP system to ensure the integrity of product safety is

a team effort and mandates the involvement of everyone

HACCP system implementation is the putting into use of

associated with its production.

a written plan of process control. It is essential that the se-

nior management of a company send a clear message on

80 American Meat Science Association

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Night Shift Work PlanДокумент23 страницыNight Shift Work PlanArunKumar Ganesan67% (6)

- 800m Training Plan For Sri Vignesh 2019-2020Документ7 страниц800m Training Plan For Sri Vignesh 2019-2020Sunder Veera Karthikeyan100% (1)

- Hazop Study TemplateДокумент3 страницыHazop Study TemplateLunga Dan Patso100% (1)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Risk Register - Trivia NightДокумент1 страницаRisk Register - Trivia Nightapi-514548596Оценок пока нет

- Chapter 1 Introduction To Osha v2Документ40 страницChapter 1 Introduction To Osha v2Izwan SaifudinОценок пока нет

- RM - Basics of Teaching-LearningДокумент12 страницRM - Basics of Teaching-LearningbhaskarОценок пока нет

- Pork PlasmaДокумент6 страницPork PlasmabhaskarОценок пока нет

- Effect of Rinses On Microbial Quality of Commercially Available Eggs and Its Components Before Processing From Ilorin in Western NigeriaДокумент4 страницыEffect of Rinses On Microbial Quality of Commercially Available Eggs and Its Components Before Processing From Ilorin in Western NigeriabhaskarОценок пока нет

- Shami KebabДокумент6 страницShami KebabbhaskarОценок пока нет

- ANS 6288 - Experimental Techniques in Meat Science Spring 2015Документ5 страницANS 6288 - Experimental Techniques in Meat Science Spring 2015bhaskarОценок пока нет

- ICMR JRF Entrance Examination 2016: Information BrochureДокумент15 страницICMR JRF Entrance Examination 2016: Information BrochurebhaskarОценок пока нет

- ICMR-JRF Advertisment 2016Документ1 страницаICMR-JRF Advertisment 2016bhaskarОценок пока нет

- References:: Tetragonoloba) Korma in The Diet of Broiler Chickens. Indian Journal of Poultry Science, 46Документ2 страницыReferences:: Tetragonoloba) Korma in The Diet of Broiler Chickens. Indian Journal of Poultry Science, 46bhaskarОценок пока нет

- MeatДокумент19 страницMeatbhaskarОценок пока нет

- DR S.K. Mendiratta: Contact For Further Details: Course DirectorДокумент2 страницыDR S.K. Mendiratta: Contact For Further Details: Course DirectorbhaskarОценок пока нет

- Utilization of Low Glucosinalate and Conventional Mustard Oilseed Cakes in Commercial Broiler Chicken DietsДокумент7 страницUtilization of Low Glucosinalate and Conventional Mustard Oilseed Cakes in Commercial Broiler Chicken DietsbhaskarОценок пока нет

- Isikjenu J. O-2013 PDFДокумент6 страницIsikjenu J. O-2013 PDFbhaskarОценок пока нет

- IPSACON2013 Proceedings Vol. 2Документ280 страницIPSACON2013 Proceedings Vol. 2bhaskar0% (1)

- Shahbazi., 2012Документ5 страницShahbazi., 2012bhaskarОценок пока нет

- B - Mannanase - Jackson - Practical Applications of Hemicell Feed Enzyme inДокумент9 страницB - Mannanase - Jackson - Practical Applications of Hemicell Feed Enzyme inbhaskarОценок пока нет

- GHS Hazard Comm Labeling & SDS - 1Документ61 страницаGHS Hazard Comm Labeling & SDS - 1Rosiawan Sasambo100% (1)

- Lecture 5 Saftey Customer Service PDFДокумент6 страницLecture 5 Saftey Customer Service PDFhkaqlqОценок пока нет

- Dugayo Activity 1Документ1 страницаDugayo Activity 1Ozen YuОценок пока нет

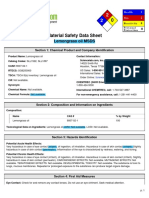

- Safety Data Sheet: Starchem LLCДокумент8 страницSafety Data Sheet: Starchem LLCnailuj9614Оценок пока нет

- Work Well Inspections Sample TemplateДокумент8 страницWork Well Inspections Sample TemplateharishsambiОценок пока нет

- Fire Safety Checklist - 31st July 2018Документ2 страницыFire Safety Checklist - 31st July 2018Raviraj Pishe100% (1)

- Safety: Life-Critical ProcedureДокумент12 страницSafety: Life-Critical ProcedureDharani SriramОценок пока нет

- Philippine Occupational Health and Safety StandardsДокумент14 страницPhilippine Occupational Health and Safety StandardsJudithОценок пока нет

- GRA - Civil Work - WWT HousekeepingДокумент17 страницGRA - Civil Work - WWT HousekeepingMohamad Nazmi Mohamad RafianОценок пока нет

- Sika Multiseal SДокумент9 страницSika Multiseal SnkhhhОценок пока нет

- HSE Training Matrix (Draft)Документ57 страницHSE Training Matrix (Draft)Heri HaryonoОценок пока нет

- CF Products and Services BrochureДокумент20 страницCF Products and Services BrochureMai Thế ToanОценок пока нет

- Backhoe WORK PLAN JsaДокумент1 страницаBackhoe WORK PLAN JsaMax McguireОценок пока нет

- Introduction To Health Vulnerability and Risk Analysis and Mapping (VRAM)Документ20 страницIntroduction To Health Vulnerability and Risk Analysis and Mapping (VRAM)mohamed el amine brahimiОценок пока нет

- How To Prepare A Safety Data Sheet (SDS) For A Synthesized ChemicalДокумент10 страницHow To Prepare A Safety Data Sheet (SDS) For A Synthesized Chemicaljuegosmegaacer aspireОценок пока нет

- Assessing Risk Asimplified Methodology For Prejob Planning in Oil and Gas ProductionДокумент8 страницAssessing Risk Asimplified Methodology For Prejob Planning in Oil and Gas Productionkenoly123Оценок пока нет

- Checklist ERDMP 100919Документ3 страницыChecklist ERDMP 100919varunkumar415Оценок пока нет

- Lemongrass OilДокумент5 страницLemongrass OilMuhammad YogaОценок пока нет

- Tos Household ServicesДокумент3 страницыTos Household ServicesElsie Sumalhay100% (1)

- Risk Assessment (Park Bench)Документ2 страницыRisk Assessment (Park Bench)BaileyОценок пока нет

- 14 Miscellaneous Occupancy ChecklistДокумент4 страницы14 Miscellaneous Occupancy ChecklistSylvester Lastrella YecyecОценок пока нет

- SOP For Fire and Safety Management - For UPDATEДокумент7 страницSOP For Fire and Safety Management - For UPDATEPeracha Engineering33% (3)

- Risk Analysis and ManagementДокумент3 страницыRisk Analysis and ManagementSoudabeh GorjinezhadОценок пока нет

- Hazard Identification Chemical StorageДокумент1 страницаHazard Identification Chemical StorageArdi HardiantoОценок пока нет

- PJHA Minggu 1Документ2 страницыPJHA Minggu 1jumaliОценок пока нет