Академический Документы

Профессиональный Документы

Культура Документы

7 - PRILOG - Manuale 12 Puntelli e Torri Tralicciate in Alluminio-Ver 02-16-ENG PDF

Загружено:

Snezana RaicevicОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

7 - PRILOG - Manuale 12 Puntelli e Torri Tralicciate in Alluminio-Ver 02-16-ENG PDF

Загружено:

Snezana RaicevicАвторское право:

Доступные форматы

12

PROPS AND TRESTELED TOWERS

ALU-UP2

USE AND MAINTENANCE MANUAL

Ver. 02.16 ENG

READ THIS MANUAL CAREFULLY

BEFORE USING THE PRODUCTS

Ver. 02.16 ENG PROPS AND TRESTELED TOWER ALU-UP Page 1 of 38

All rights to this manual are reserved. This publication may not be communicated , reproduced or revealed to third parties

without written permission

CONTENTS

CONTENTS.................................................................................................... 2

GENERAL ...................................................................................................... 3

DEFINITIONS ................................................................................................ 4

PROPS ALU-UP2 ........................................................................................... 5

ELEMENTS ALU-UP2 .................................................................................... 6

MOUNTING THE EXTENSION....................................................................... 9

ALU-UP2 PROP BEARING CAPACITY ........................................................ 10

MOUNTING THE UNIVERSAL TRIPOD ....................................................... 13

MOUNTING THE EXTENSION END ............................................................ 14

MOUNTING THE JUNCTION TRESTLE ...................................................... 15

USE OF THE TOWERS ................................................................................ 18

TOWERS ERECTED WITH A SET OF LATTICES ......................................... 21

TOWERS ERECTED WITH TWO SETS OF PROPS ...................................... 27

ADJUSTING THE ALU-UP2 PROP............................................................... 28

CHECKING THE PROPS .............................................................................. 30

BEARING SURFACE .................................................................................... 31

GIRDER COUPLING .................................................................................... 32

INSTALLATION ........................................................................................... 33

SAFETY ON THE CONSTRUCTION SITE .................................................... 34

STRIPPING .................................................................................................. 35

HANDLING .................................................................................................. 36

GENERAL SAFETY GUIDELINES ................................................................ 37

Ver. 02.16 ENG PROPS AND TRESTELED TOWER ALU-UP Page 2 of 38

All rights to this manual are reserved. This publication may not be communicated , reproduced or revealed to third parties

without written permission

GENERAL

Faresin Building S.p.A. is constantly committed to guaranteeing the highest quality

products, and providing an extensive after sales service. The continuous upgrading of our

products is a company policy objective which is also pursued in collaboration with our

customers. For more detailed information or information not contained in this manual, and

to utilize our after sales service contact our technical service department and the staff will

be sure to find a solution for even the most demanding needs.

FARESIN BUILDING S.p.A.

Technical Service

Via della Meccanica 1

36042 Breganze (VI)

tel. +39 0445 306 600

fax +39 0445 874 748

www.faresinbuiding.com tecnico@faresinbuilding.com

Faresin Building S.p.A. guarantees its products only if they are used correctly as described

in this manual. If the products do not conform to the description given in the manual inform

the company's Technical Service immediately, providing all the details requested, to

ensure that the product is suitable for use.

This manual points out the hazards due to the sole use of systems for poker columns and

their accessories, in standard predefined conditions, and does not consider specific

construction site conditions and/or interferences with other operations . Therefore,

interferences with other operations and situations of use that could expose operators to

specific risks or that can in any way lower the performance of the supplied product, must

be subjected to prompt analysis within the sphere of the specific construction site .

Faresin Building S.p.A. can supply, on request, a service to assemble, inspect and

dimension the Poker column systems for specific applications.

This user's manual is subject to constant updating and review without prior notice; the

user must ensure that he is in possession of the most up to date version before beginning

to use the equipment.

Ver. 02.16 ENG PROPS AND TRESTELED TOWER ALU-UP Page 3 of 38

All rights to this manual are reserved. This publication may not be communicated , reproduced or revealed to third parties

without written permission

DEFINITIONS

Description: Compressed element normally used as a temporary vertical support

in construction works. Consisting of two telescopic interfitting tubular elements. A

prop is fitted with a system for approximate and precise adjustment of the

extension.

Operating cycle: the cycle comprises an erection phase followed by use,

dismantling and transporting phases.

Standard conditions for use: conditions in which the products are correctly

erected, as illustrated in this manual, by qualified, trained personnel, correctly

connected to each other and tightened appropriately so that they are capable of

absorbing the actions transmitted by the concrete.

Configuration: assembly of elements in standard conditions for use with a precise

identification of elements, accessories, bracing, etc....

PPE : personal protective equipment

Use: in the phase of use and resistance to the pressure of the concrete after correct

erection .

Erection: sequenced assembly of all the elements required to correctly erect the

structure in the most appropriate configuration to ensure its safe use.

Dismantling: ordered removal of the individual elements utilized

In this manual information is highlighted as explained below:

Mandatory instructions that must be implemented in order to ensure correct use of

the products and to avoid potentially dangerous situations are printed in bold italic

font.

This symbol indicates PAY SPECIAL ATTENTION to the instructions to ensure

correct use of the products.

Ver. 02.16 ENG PROPS AND TRESTELED TOWER ALU-UP Page 4 of 38

All rights to this manual are reserved. This publication may not be communicated , reproduced or revealed to third parties

without written permission

PROPS ALU-UP2

Description Code Weight Kg.

Aluminium prop ALU-UP2 7162445 19,1

Size 1500-2500

Aluminium prop ALU-UP2 9168438 22,2

Size 1780-3000

Aluminium prop ALU-UP2 9168568 24,2

Size 1970-3500

Aluminium prop ALU-UP2 9168440 25,0

Size 2780-4000

Aluminium prop ALU-UP2 9168442 30,6

Size 3780-5000

Aluminium prop ALU-UP2 9168530 36,3

Size 5050-6250

Ver. 02.16 ENG PROPS AND TRESTELED TOWER ALU-UP Page 5 of 38

All rights to this manual are reserved. This publication may not be communicated , reproduced or revealed to third parties

without written permission

ELEMENTS ALU-UP2

PRODUCT DESCRIPTION Code Weight kg

PROP EXTENSION 9168448 5,8

END SIZE 12

EXTENSION ALU-UP2 9168445 5,6

SIZE 100

EXTENSION ALU-UP2 9168447 6

SIZE 150

PROP EXTENSION 9168505 7,6

L=150 STANDARD

PLATES

UNIVERSAL TRIPOD 8168789 12,4

JUNCTION TRESTLE

SIZE 75 9168801/C 11,1

JUNCTION TRESTLE

SIZE 100

9168802/C 12,6

Ver. 02.16 ENG PROPS AND TRESTELED TOWER ALU-UP Page 6 of 38

All rights to this manual are reserved. This publication may not be communicated , reproduced or revealed to third parties

without written permission

JUNCTION TRESTLE

SIZE 125

9168803/C 14,1

JUNCTION TRESTLE

SIZE 150

9168804/C 15,6

JUNCTION TRESTLE

SIZE 155

9168805/C 16,0

JUNCTION TRESTLE

SIZE 230 9168806/C 22,1

JUNCTION TRESTLE

SIZE 305

9168807/C 26,8

KEY FOR ALU UP

9168497 1,9

RING

ALU-UP PROP BOX 8168604 130,6

Ver. 02.16 ENG PROPS AND TRESTELED TOWER ALU-UP Page 7 of 38

All rights to this manual are reserved. This publication may not be communicated , reproduced or revealed to third parties

without written permission

TRESTLE BOX 8168763 106.7

SIZES 1500-1550-

2300-3050

TRESTLE BOX 8168764 116.6

SIZE 750

Ver. 02.16 ENG PROPS AND TRESTELED TOWER ALU-UP Page 8 of 38

All rights to this manual are reserved. This publication may not be communicated , reproduced or revealed to third parties

without written permission

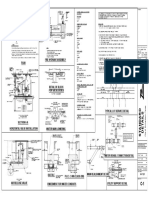

MOUNTING THE EXTENSION

Fix the extension to the end (100-150).

N°4 N°4

SCREW M12X40

Ver. 02.16 ENG PROPS AND TRESTELED TOWER ALU-UP Page 9 of 38

All rights to this manual are reserved. This publication may not be communicated , reproduced or revealed to third parties

without written permission

ALU-UP2 PROP BEARING CAPACITY

Faresin Building S.p.A. declares that the load-bearing capacity of the alu-up2 series props

has been determined through tests in accordance with the directions of the German

standard DIN EN 16031:2012-09.

These tests have been carried out internally as well as in the testing laboratories of the

University of Padova and the polytechnic of Munich.

The resulting values reduced by a suitable safety factor are set out in the following tables

and they are also available in the Faresin use and maintenance manual for Alu-up2

products, in the Alufort product catalogue and in the general Faresin catalogue.

Ver. 02.16 ENG PROPS AND TRESTELED TOWER ALU-UP Page 10 of 38

All rights to this manual are reserved. This publication may not be communicated , reproduced or revealed to third parties

without written permission

USEFUL LOAD-BEARING CAPACITY OF ALU-UP2 SERIES

PROPS

Alu-Up2 250 Alu-Up2 300 Alu-Up2 350 Alu-Up2 400 Alu-Up2 500 Alu-Up2 625

Estension

kN kN kN kN kN kN

cm

Inner Inner Inner Inner Inner Inner Inner Inner Inner Inner Inner Inner

pipe at pipe at pipe at pipe at pipe at pipe at pipe at pipe at pipe at pipe at pipe at pipe at

top bottom top bottom top bottom top bottom top bottom top bottom

150 75,0 88,2

160 72,5 84,7

170 70,0 81,2

178 75,0 88,2

180 67,5 77,6 73,5 85,9

190 65,0 74,1 71,9 83,6

198 98,0 98,0

200 62,5 70,6 70,4 81,3 98,0 98,0

210 60,0 67,1 68,9 80,2 95,0 98,0

220 57,5 63,6 67,4 79,2 94,0 98,0

230 55,0 60,0 65,8 76,3 92,0 98,0

240 52,5 56,5 64,3 72,6 90,0 98,0

250 50,0 53,0 62,8 70,2 88,0 96,8

260 61,2 68,5 84,0 93,3

270 59,7 64,8 80,0 88,8

280 58,2 62,5 75,0 82,5 77,2 85,3

290 56,6 59,8 72,0 78,5 73,8 81,2

300 55,0 58,2 68,0 74,1 70,3 78,2

310 64,0 69,8 66,9 73,2

320 60,0 64,2 63,5 70,1

330 56,0 59,8 60,0 64,5

340 52,0 55,1 56,6 61,1

350 48,0 50,8 53,2 57,5

360 49,7 55,6

370 46,3 48,8

380 42,9 45,4 44,5 49,2

390 39,4 41,9 43,5 47,1

400 36,0 38,5 42,6 46,2

410 41,6 44,1

420 40,7 43,2

430 39,7 42,3

440 38,7 41,2

450 37,8 40,1

460 36,8 39,4

470 35,9 37,5

480 34,9 38,0

490 33,9 36,5

500 32,9 35,0

505 41,0 43,2

515 40,0 42,0

525 38,1 40,2

535 36,3 38,4

545 34,4 36,3

555 32,5 34,5

565 30,7 32,7

575 29,1 31,0

585 27,5 29,0

595 26,0 28,1

605 24,8 26,6

615 23,6 25,6

625 22,4 24,4

Ver. 02.16 ENG PROPS AND TRESTELED TOWER ALU-UP Page 11 of 38

All rights to this manual are reserved. This publication may not be communicated , reproduced or revealed to third parties

without written permission

LOAD-BEARING CAPACITY OF ALU-UP2 PROPS WITH

EXTENSIONS OF 1m AND 1.5m

Faresin Building Division declares that the useful load-bearing capacity of the alu-up2

props with extensions mounted without lattices are the following.

Estensi Alu-Up2 Alu-Up2 Alu-Up2 Alu-Up2 Alu-Up2 Alu-Up2 Alu- Alu-

one cm 3m+1,0m 3m+1,5m 3,5m+1,0 3,5m+1,5 4m+1,0m 4m+1,5m Up2 Up2

m m 5m+1,0 5m+1,5

m m

278 75.0 kN

280 73.5 kN

290 72.5 kN

300 69.0 kN 85,0 kN

310 65.0 kN 85,0 kN

320 62.0 kN 83,7 kN

330 59.0 kN 44.5 kN 81,6 kN

340 55.0 kN 43.5 kN 79,5 kN

350 52.0 kN 42.6 kN 77,4 kN 70,4 kN

360 48.0 kN 41.6 kN 72,9 kN 70,4 kN

370 45.0 kN 40.7 kN 68,4 kN 66,8 kN

380 41.5 kN 39.7 kN 63,8 kN 63,4 kN 43.5 kN

390 38.5 kN 38.7 kN 59,3 kN 60,1 kN 43.0 kN

400 35.0 kN 37.0 kN 54,8 kN 56,7 kN 41.6 kN

410 35.6 kN 50,8 kN 53,4 kN 40.5 kN

420 34.0 kN 46,7 kN 50,0 kN 39.5 kN

430 32.6 kN 42,6 kN 46,6 kN 38.7 kN 40,0 kN

440 31.2 kN 38,5 kN 43,3 kN 37.5 kN 38,7 kN

450 30.0 kN 34,4 kN 39,3 kN 36.0 kN 37,9 kN

460 37,7 kN 35.0 kN 37,0 kN

470 35,5 kN 34.0 kN 36,5 kN

480 33,3 kN 33.0 kN 35,5 kN 42.0 kN

490 31,0 kN 32.0 kN 34,0 kN 40.0 kN

500 28,8 kN 31.0 kN 33,0 kN 38.8 kN

510 31,5 kN 37.2 kN

520 30,0 kN 35.4 kN

530 29,0 kN 34.0 kN 35,0 kN

540 27,5 kN 32.7 kN 33,5 kN

550 26,0 kN 31.0 kN 32,0 kN

560 29.5 kN 31,0 kN

570 28.0 kN 30,0 kN

580 26.8 kN 28,5 kN

590 25.6 kN 27,0 kN

600 24.0 kN 26,0 kN

610 25,0 kN

620 24,0 kN

630 23,0 kN

640 22,0 kN

650 21,0 kN

N.B. = The above load-bearing capacities are guaranteed if the extensions are

mounted on the external pipe of the prop with 4 screws + nut M12x40 mm class 8.8.

N.B. = The above load-bearing capacities are not guaranteed if the extensions are

mounted on the internal pipe of the prop.

Ver. 02.16 ENG PROPS AND TRESTELED TOWER ALU-UP Page 12 of 38

All rights to this manual are reserved. This publication may not be communicated , reproduced or revealed to third parties

without written permission

MOUNTING THE UNIVERSAL TRIPOD

Adjust the tripod's threaded bar and fasten the prop with the wing nut.

Ver. 02.16 ENG PROPS AND TRESTELED TOWER ALU-UP Page 13 of 38

All rights to this manual are reserved. This publication may not be communicated , reproduced or revealed to third parties

without written permission

MOUNTING THE EXTENSION END

Fasten the extension end then the ring nut plate unit to the extension

(100-150) with screws.

9168436/C

N°4 N°4

SCREW M8x16 SCREW M12X40

Ver. 02.16 ENG PROPS AND TRESTELED TOWER ALU-UP Page 14 of 38

All rights to this manual are reserved. This publication may not be communicated , reproduced or revealed to third parties

without written permission

MOUNTING THE JUNCTION TRESTLE

Use the junction trestle to brace the aluminium props by pinching the

prop ribbing and fasten with a wedge.

MOUNTING THE TOWERS

Ver. 02.16 ENG PROPS AND TRESTELED TOWER ALU-UP Page 15 of 38

All rights to this manual are reserved. This publication may not be communicated , reproduced or revealed to third parties

without written permission

Before erecting the towers the bearing surface must be verified as capable of supporting

the loads transmitted to the tower bearing points.

The following conditions must be verified to determine the suitability of the bearing

surface:

1. flatness of the surface: the surface must be flat and free from any irregularities

such as indentations, etc.... Load distribution planking having a minimum

thickness of 40 mm and a minimum width of 400 mm will be positioned on the

bearing surface.

2. resistance of the bearing surface suitable for the transmitted loads: the

pressure at the base is distributed to the surface of the bearing plate and

therefore creates a concentrated load condition. A concrete slab with a suitable

thickness to distribute the load to the ground below without causing any sagging

is considered suitable for distribution of the load (min.15-20 cm). For loads that

are not particularly heavy, a bearing surface could also be made on a suitably

compacted and stabilised scree surface (the load per foot must be compatible

with the ground bearing capacity).

3. uniformity of rigidity and strength of the bearing surface: the bearing

surface must not comprise elements with different rigidity (for example, pebbles).

4. no possibility of differential or uniform sagging of the bearing surface : the

bearing surface must not be subjected to notable yielding, caused by the applied

loads, that could affect the capacity of the towers or the load distribution.

The quality of the bearing directly influences the capacity of the towers, the

greater the applied load the greater the care required to ensure rigid and stable

bearing conditions.

The towers can be stabilised, in the following phases, in several ways:

1. by connecting the tower to the ground at various heights as it grows upwards with

ropes or pipe and coupler, in an adequate number of directions to guarantee its

stability.

2. by connecting the towers to preexisting structures that are strong enough to

stabilize the towers.

3. by connecting several towers together as they grow upwards simultaneously to

guarantee:

a. during the construction of the towers extension in both directions

simultaneously with the upward extension

b. connection between towers with pipe and coupler or with longitudinal and

diagonal braces to create triangular shapes that are always extended in both

directions on the plane. Connecting the towers with horizontal braces without

using diagonal elements is totally ineffective.

Ver. 02.16 ENG PROPS AND TRESTELED TOWER ALU-UP Page 16 of 38

All rights to this manual are reserved. This publication may not be communicated , reproduced or revealed to third parties

without written permission

When an erection diagram is provided it must be scrupulously adhered to, with the

awareness that in the flat drawing of one surface of the tower it is understood that the

bracing elements are set up the same way on the other faces that are not shown in the

drawing.

When the structure has been completely erected, a careful control must be made to

ensure that all the elements required to guarantee the stability of the towers before

and during the application of the overload, have been positioned correctly.

Do not use force to adjust the position of the towers; if necessary, disassemble then

re-erect the towers.

If the towers are erected on a slab or floor the user must verify the static

suitability of the floor for the loads applied by the load-holding towers.

Ver. 02.16 ENG PROPS AND TRESTELED TOWER ALU-UP Page 17 of 38

All rights to this manual are reserved. This publication may not be communicated , reproduced or revealed to third parties

without written permission

USE OF THE TOWERS

The following controls must be verified before a load can be applied to the

towers:

1. ensure that all the main and secondary elements have been positioned for

a correct erection of the towers

2. ensure that all the bracing has been added to guarantee stability of the

towers

3. ensure that the bearing surface is uniformly resistant and capable of

supporting the loads transmitted by the towers without deforming

4. ensure the verticality of all the towers in all directions and the horizontality

of the lattices.

5. ensure that all diagrams or integrating instructions provided by the

manufacturer or designer have been observed in full .

The bearing towers are used predominantly to support the load applied by the pour of a

concrete slab. The instructions below refer to this type of use.

The use of the bearing towers to support loads other than those applied by a

uniform concrete pour is not considered in this manual and must in any case be

verified beforehand by FARESIN BUILDING S.p.A.

When pouring the concrete take care to:

1. avoid eccentric loads applied only to some end posts.

2. avoid accumulation of concrete in some points of the slab, the

accumulation could affect the strength of the concrete but also the

stability of the towers.

3. proceed with uniform thin layers and respecting any instructions

concerning pour times provided by FARESIN BUILDING S.p.A.

4. distribute the concrete in such a way that the load configuration is always

stable.

The arrangement of several towers to create scaffoldings must be capable of

withstanding actions applied from all directions.

To stabilize the composition of several towers they must be joined to each other using

longitudinal and diagonal braces or pipe and coupler to construct adequate bracing.

Ver. 02.16 ENG PROPS AND TRESTELED TOWER ALU-UP Page 18 of 38

All rights to this manual are reserved. This publication may not be communicated , reproduced or revealed to third parties

without written permission

Definition of the load-bearing capacity

The bearing towers must be used in total observance of the performance limits indicated

below and they are only guaranteed if employed correctly.

The specified efficiency has been verified state with numeric models, in accordance with

normative indications, and certified with tests on full-scale towers.

It is the user’s responsibility to use the elements correctly in order to prevent

damaging them or compromising safety by using them beyond the specified

performance levels.

A brief outline of the useful data for correct use of the formworks within the performance

limits follows. If considered necessary for a specific use more information can be obtained

by contacting FARESIN BUILDING S.p.A. 's technical assistance service directly.

The performance indicated below does not refer to the erection stages and the

load configurations that could occur before the application of the overload.

The global stability of the individual towers must be guaranteed with suitable bracing

systems or reciprocal connection systems if using several towers.

The towers have been verified for correct erection and use, including ongoing

maintenance of the separate elements.

The specified load bearing capacities refer to a complete product, suitable for use and

consequently without any history of stress that could modify its resistance and erected by

qualified personnel.

The towers are particularly sensitive to the positioning methods and in particular care must

be taken to ensure perfect verticality of the elements as well as the resistance and flatness

of the bearing surface.

The towers have been tested and verified, for the specified loads, under precise

conditions:

1. Vertical load centred on the props;

2. No dynamic load effects;

3. Verticality of towers in position;

4. Flat and non-deformable bearing surface;

5. No material or component defects;

6. Presence of suitable bracing for stabilizing the towers.

Ver. 02.16 ENG PROPS AND TRESTELED TOWER ALU-UP Page 19 of 38

All rights to this manual are reserved. This publication may not be communicated , reproduced or revealed to third parties

without written permission

Use of the structure in the following situations is strictly forbidden:

Placement on a base that is not sufficiently rigid or stable that can deform due

to the effect of the applied loads;

no verification of the verticality of the towers;

use of damaged or deformed elements;

erection in strong wind conditions.

The bearing capacities given refer to standard erection diagrams; use in different

erection conditions must be verified for each individual case.

Ver. 02.16 ENG PROPS AND TRESTELED TOWER ALU-UP Page 20 of 38

All rights to this manual are reserved. This publication may not be communicated , reproduced or revealed to third parties

without written permission

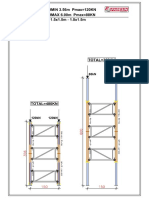

TOWERS ERECTED WITH A SET OF LATTICES

ALU-UP2 PROPS maximum extension 3 m

Tower H Max. bearing capacity

Upright

1,78 M 112.5 kN

1,80 M 110,3 kN

1,90 M 107,9 kN

2,00 M 105,6 kN

2,10 M 103,4 kN

2,20 M 101,1 kN

2,30 M 98,7 kN

2,40 M 96,5 kN

2,50 M 94,2 kN

2,60 M 91,8 kN

2,70 M 89,6 kN

2,80 M 87,3 kN

2,90 M 84,9 kN

3,00 M 82,5 kN

N.B. LOAD-BEARING CAPACITIES APPLY TO TOWERS HAVING:

DIMENSIONS 2300x1500 mm

DIMENSIONS 1500x1500 mm

Ver. 02.16 ENG PROPS AND TRESTELED TOWER ALU-UP Page 21 of 38

All rights to this manual are reserved. This publication may not be communicated , reproduced or revealed to third parties

without written permission

TOWERS ERECTED WITH A SET OF LATTICES

ALU-UP2 PROPS MAXIMUM EXTENSION 3,5 m

Max. bearing

Tower H capacity

Upright

198 m 147 kN

200 m 147 kN

210 m 142 kN

220 m 141 kN

230 m 138 kN

240 m 135 kN

250 m 132 kN

260 m 126 kN

270 m 120 kN

280 m 112 kN

290 m 108 kN

300 m 102 kN

310 m 96 kN

320 m 90 kN

330 m 84 kN

340 m 78 kN

350 m 72 kN

N.B. LOAD-BEARING CAPACITIES APPLY TO TOWERS HAVING :

DIMENSIONS 2300x1500 mm

DIMENSIONS 1500x1500 mm

Ver. 02.16 ENG PROPS AND TRESTELED TOWER ALU-UP Page 22 of 38

All rights to this manual are reserved. This publication may not be communicated , reproduced or revealed to third parties

without written permission

TOWERS ERECTED WITH TWO SETS OF LATTICES

ALU-UP2 PROPS maximum extension 3,5 m

Max. bearing

Tower H capacity

Upright

198 m 157 kN

200 m 157 kN

210 m 152 kN

220 m 150 kN

230 m 147 kN

240 m 144 kN

250 m 141 kN

260 m 134 kN

270 m 128 kN

280 m 120 kN

290 m 115 kN

300 m 109 kN

310 m 102 kN

320 m 96 kN

330 m 90 kN

340 m 83 kN

350 m 77 kN

N.B. LOAD-BEARING CAPACITIES APPLY TO TOWERS HAVING :

DIMENSIONS 2300x1500 mm

DIMENSIONS 1500x1500 mm

Ver. 02.16 ENG PROPS AND TRESTELED TOWER ALU-UP Page 23 of 38

All rights to this manual are reserved. This publication may not be communicated , reproduced or revealed to third parties

without written permission

TOWERS ERECTED WITH A SET OF LATTICES

ALU-UP2 PROPS MAXIMUM EXTENSION 4 m

Tower H Max. bearing capacity

Upright

2,80 M 115,8 kN

2,90 M 110,7 kN

3,00 M 105,5 kN

3,10 M 100,4 kN

3,20 M 95,3 kN

3,30 M 90,0 kN

3,40 M 84,9 kN

3,50 M 79,8 kN

3,60 M 74,6 kN

3,70 M 69,5 kN

3,80 M 64,4 kN

3,90 M 59,1 kN

4,00 M 54,0 kN

N.B. LOAD-BEARING CAPACITIES APPLY TO TOWERS HAVING :

DIMENSIONS 2300x1500 mm

DIMENSIONS 1500x1500 mm

Ver. 02.16 ENG PROPS AND TRESTELED TOWER ALU-UP Page 24 of 38

All rights to this manual are reserved. This publication may not be communicated , reproduced or revealed to third parties

without written permission

TOWERS ERECTED WITH TWO SETS OF LATTICES

ALU-UP2 PROPS maximum extension 4 m

Tower H Max. bearing capacity

Upright

2,80 M 123.5 kN

2,90 M 118.1 kN

3,00 M 112.5 kN

3,10 M 107.0 kN

3,20 M 101.6 kN

3,30 M 96.0 kN

3,40 M 90.6 kN

3,50 M 85.1 kN

3,60 M 79.5 kN

3,70 M 74.1 kN

3,80 M 68.6 kN

3,90 M 63.0 kN

4,00 M 57.6 kN

N.B. LOAD-BEARING CAPACITIES APPLY TO TOWERS HAVING :

DIMENSIONS 2300x1500 mm

DIMENSIONS 1500x1500 mm

Ver. 02.16 ENG PROPS AND TRESTELED TOWER ALU-UP Page 25 of 38

All rights to this manual are reserved. This publication may not be communicated , reproduced or revealed to third parties

without written permission

TOWERS ERECTED WITH TWO SETS OF LATTICES

ALU-UP2 PROPS maximum extension 5 m

Tower H Max. bearing capacity

Upright

3,80 M 71,2 kN

3,90 M 69,6 kN

4,00 M 68,2 kN

4,10 M 66,6 kN

4,20 M 65,1 kN

4,30 M 63,5 kN

4,40 M 61,9 kN

4,50 M 60,5 kN

4,60 M 58,9 kN

4,70 M 57,4 kN

4,80 M 55,8 kN

4,90 M 54,2 kN

5,00 M 52,6 kN

N.B. LOAD-BEARING CAPACITIES APPLY TO TOWERS HAVING :

DIMENSIONS 2300x1500 mm

DIMENSIONS 1500x1500 mm

Ver. 02.16 ENG PROPS AND TRESTELED TOWER ALU-UP Page 26 of 38

All rights to this manual are reserved. This publication may not be communicated , reproduced or revealed to third parties

without written permission

TOWERS ERECTED WITH TWO SETS OF PROPS

Uprights made with two ALU-UP2 opposite props.

H tower Max H tower Max H tower Max H tower Max

bearing bearing bearing bearing

capacity capacity capacity capacity

Prop Uprights Prop Uprights Prop Uprights Prop Uprights

H 3000 H 3500 H 4000 H 5000

3,56 m 120,0 kN 3,96 m 157 kN 5,56 m 123,5 kN 7,56 m 71,2 kN

3,60 m 117,6 kN 4,00 m 157 kN 5,60 m 123,5 kN 7,60 m 71,2 kN

3,80 m 115,0 kN 4,20 m 152 kN 5,80 m 118,1 kN 7,80 m 69,6 kN

4,00 m 112,6 kN 4,40 m 150 kN 6,00 m 112,5 kN 8,00 m 68,2 kN

4,20 m 110,2 kN 4,60 m 147 kN 6,20 m 107,0 kN 8,20 m 66,6 kN

4,40 m 107,8 kN 4,80 m 144 kN 6,40 m 101,6 kN 8,40 m 65,1 kN

4,60 m 105,3 kN 5,00 m 141 kN 6,60 m 96,0 kN 8,60 m 63,5 kN

4,80 m 102,9 kN 5,20 m 134 kN 6,80 m 90,6 kN 8,80 m 61,9 kN

5,00 m 100,5 kN 5,40 m 128 kN 7,00 m 85,1 kN 9,00 m 60,5 kN

5,20 m 97,9 kN 5,60 m 120 kN 7,20 m 79,5 kN 9,20 m 58,9 kN

5,40 m 95,5 kN 5,80 m 115 kN 7,40 m 74,1 kN 9,40 m 57,4 kN

5,60 m 93,1 kN 6,00 m 109 kN 7,60 m 68,6 kN 9,60 m 55,8 kN

5,80 m 90,6 kN 6,20 m 102 kN 7,80 m 63,0 kN 9,80 m 54,2 kN

6,00 m 88,0 kN 6,40 m 96 kN 8,00 m 57,6 kN 10,00 m 52,6 kN

6,60 m 90 kN

6,80 m 83 kN

7,00 m 77 kN

To guarantee the form of the section in the case of tower support scaffolding with heights >7.0 m, a

horizontal diagonal brace (steel or aluminium pipe with 48.3 diameter) with revolving couplers must be

connected to the lattices at mid-height.

N.B. LOAD-BEARING CAPACITIES APPLY TO TOWERS HAVING :

DIMENSIONS 2300x1500 mm

DIMENSIONS 1500x1500 mm

Ver. 02.16 ENG PROPS AND TRESTELED TOWER ALU-UP Page 27 of 38

All rights to this manual are reserved. This publication may not be communicated , reproduced or revealed to third parties

without written permission

ADJUSTING THE ALU-UP2 PROP

Remove the safety bolt.

Extract the threaded part to the desired measurement.

Ver. 02.16 ENG PROPS AND TRESTELED TOWER ALU-UP Page 28 of 38

All rights to this manual are reserved. This publication may not be communicated , reproduced or revealed to third parties

without written permission

Screw the ring nut to the end.

Insert the safety bolt.

Ver. 02.16 ENG PROPS AND TRESTELED TOWER ALU-UP Page 29 of 38

All rights to this manual are reserved. This publication may not be communicated , reproduced or revealed to third parties

without written permission

CHECKING THE PROPS

Do not use props with evident signs of damage.

Ver. 02.16 ENG PROPS AND TRESTELED TOWER ALU-UP Page 30 of 38

All rights to this manual are reserved. This publication may not be communicated , reproduced or revealed to third parties

without written permission

BEARING SURFACE

Avoid uneven and unsafe bearing surfaces !!!!!!

Ver. 02.16 ENG PROPS AND TRESTELED TOWER ALU-UP Page 31 of 38

All rights to this manual are reserved. This publication may not be communicated , reproduced or revealed to third parties

without written permission

GIRDER COUPLING

Couple the girders as illustrated in the drawing

Ver. 02.16 ENG PROPS AND TRESTELED TOWER ALU-UP Page 32 of 38

All rights to this manual are reserved. This publication may not be communicated , reproduced or revealed to third parties

without written permission

INSTALLATION

Verify that the props are completely vertical and suitable for the applied load.

(see attached tables)

Ver. 02.16 ENG PROPS AND TRESTELED TOWER ALU-UP Page 33 of 38

All rights to this manual are reserved. This publication may not be communicated , reproduced or revealed to third parties

without written permission

SAFETY ON THE CONSTRUCTION SITE

Situations to be avoided at all costs.

During the pour do not stand under the slab

Ver. 02.16 ENG PROPS AND TRESTELED TOWER ALU-UP Page 34 of 38

All rights to this manual are reserved. This publication may not be communicated , reproduced or revealed to third parties

without written permission

STRIPPING

Use the correct procedures and do not damage the material.

HANDLING

Ver. 02.16 ENG PROPS AND TRESTELED TOWER ALU-UP Page 35 of 38

All rights to this manual are reserved. This publication may not be communicated , reproduced or revealed to third parties

without written permission

HANDLING

Handle the material with suitable equipment and systems.

Ver. 02.16 ENG PROPS AND TRESTELED TOWER ALU-UP Page 36 of 38

All rights to this manual are reserved. This publication may not be communicated , reproduced or revealed to third parties

without written permission

GENERAL SAFETY GUIDELINES

In order to guarantee a suitable level of safety during the use of the products it is

important for users to note that collective protection devices always predominate

over personal protective devices.

The personal protective equipment (PPE) must be considered supplementary devices, not

substitutes, of the provisional works and work guidelines and instructions.

It is understood from the information given below that all the equipment used in the works

must comply with current regulations.

Remove all the elements or accessories that are obviously defective (damaged,

folded, with cracks, etc...) from the construction site in order to prevent them from being

used.

Use of Personal Protective Equipment (PPE)

Wear protective gloves, safety footwear, suitable work clothes, a safety hat and

suitable safety devices to protect users against falling from a height during all the

phases involving handling, assembly and use of the load-holding towers.

Handling, assembly and dismantling of the towers involve risks of impact with and blows

from heavy, blunt bodies; these operations must be carried out by personnel wearing

suitable personal protective equipment such as gloves, safety hat and footwear.

To protect users against falling from a height, use suitable safety belts hooked at

points that will guarantee a good hold, in all the work phases carried out in elevated

positions and in particular during the erection and dismantling of the towers.

During the concrete pour wear suitable equipment, safety footwear, eye and hand

protection, and any other equipment included in the safety guidelines.

For use of all the elements composing the load-holding towers adhere strictly to the

specific instructions contained in this manual.

Specific regulations concerning safety standards exist for all elements produced by

FARESIN BUILDING S.p.A. designed for use in construction sites.

Ver. 02.16 ENG PROPS AND TRESTELED TOWER ALU-UP Page 37 of 38

All rights to this manual are reserved. This publication may not be communicated , reproduced or revealed to third parties

without written permission

NORMATIVE REFERENCES

For any information not directly recalled in this manual refer to the most recent

safety standards in force in the specific country of use.

The main Italian regulations concerning safety on construction sites are:

D.LGS (Legislative Decree) 494/96 – 528/99

“TRANSPOSED EUROPEAN DIRECTIVE 92/57/EEC CONCERNING THE MINIMUM

SAFETY AND HEALTH STANDARDS TO BE APPLIED IN TEMPORARY OR MOBILE

WORK SITES ”

D.Lgs. (Legislative Decree) 81/08

“CONSOLIDATION ACT ON HEALTH AND SAFETY”

The regulations provide general guidelines and requirements that must also be adhered to

when using Faresin Building S.p.A. products. This manual integrates the standard

requirements that must be applied autonomously.

Note that, pursuant to DPR 164/56, formworks for big works, that are not

included in the current use outlines, must be executed according to a design

prepared by an engineer, with all the stability calculations included. Before setting

the formwork and the framework the ground resistance or the resistance of the

structure on which they are to be placed must be checked in order to prevent

possible yielding.

17 March 2016

Ver. 02.16 ENG PROPS AND TRESTELED TOWER ALU-UP Page 38 of 38

All rights to this manual are reserved. This publication may not be communicated , reproduced or revealed to third parties

without written permission

Вам также может понравиться

- Highway Materials & Mix Design Ppt. MMHДокумент35 страницHighway Materials & Mix Design Ppt. MMHMd Mehedi HasnatОценок пока нет

- Code of Practice for Scaffold SafetyДокумент58 страницCode of Practice for Scaffold Safetyvijayamalraj100% (1)

- BS5400 Part 4 Training Course - TE EpsomДокумент19 страницBS5400 Part 4 Training Course - TE EpsomjologscresenciaОценок пока нет

- UBC ASHRAE Competition Report PDFДокумент34 страницыUBC ASHRAE Competition Report PDFmech118100% (1)

- BH-8 00Документ2 страницыBH-8 00Naveen ChodagiriОценок пока нет

- Time History AnalysisДокумент4 страницыTime History AnalysisYoussef AliОценок пока нет

- ISRM Suggested MethodsДокумент2 страницыISRM Suggested MethodsRed OrangeОценок пока нет

- SN017 (NCCI - Shear Resistance of A Fin Plate Connection)Документ13 страницSN017 (NCCI - Shear Resistance of A Fin Plate Connection)Hamati Rami100% (2)

- Docslide - Us - Geotehnics in Civil Engineering 2013 PDFДокумент484 страницыDocslide - Us - Geotehnics in Civil Engineering 2013 PDFSnezana RaicevicОценок пока нет

- TII List of Current Documents (June 2017)Документ21 страницаTII List of Current Documents (June 2017)Arabel Vilas SerínОценок пока нет

- Atlanta Housing Construction PracticesДокумент44 страницыAtlanta Housing Construction PracticesDanie RoyОценок пока нет

- UC2013 Book LRДокумент272 страницыUC2013 Book LREric OwusuОценок пока нет

- Elastic Critical Moment For Lateral Torsional BucklingДокумент13 страницElastic Critical Moment For Lateral Torsional BucklingSabina Atencio100% (1)

- Basic Nec Code Rules and Design PracticeДокумент13 страницBasic Nec Code Rules and Design PracticeSiswoyo Suwidji100% (1)

- Greek Code For Seismic Resistant Structures - EAK2000Документ111 страницGreek Code For Seismic Resistant Structures - EAK2000Ratanak SanОценок пока нет

- Proceedings TIL2014Документ204 страницыProceedings TIL2014GogyОценок пока нет

- TN NewДокумент6 322 страницыTN Newdeva nesan83% (6)

- SCI PUBLICATION P387 Steel Building Desi PDFДокумент106 страницSCI PUBLICATION P387 Steel Building Desi PDFSabarishwaran SabariОценок пока нет

- Technical Report: Design of Metal Anchors For Use in Concrete Under Seismic ActionsДокумент16 страницTechnical Report: Design of Metal Anchors For Use in Concrete Under Seismic ActionsJulioGoesОценок пока нет

- ECCS 1994-76 ECCS Manual On Design of Steel Structures in Seismic ZonesДокумент278 страницECCS 1994-76 ECCS Manual On Design of Steel Structures in Seismic ZonesDehumanizerFromHellОценок пока нет

- CA - Oresund BridgeДокумент29 страницCA - Oresund BridgeApoorva SinghОценок пока нет

- 1 Service ManualДокумент486 страниц1 Service ManualАлександрОценок пока нет

- Datwyler-Diagram M 385 44Документ6 страницDatwyler-Diagram M 385 44Mihai GheorghiuОценок пока нет

- Mechanics of masonry vaults: The equilibrium approachДокумент24 страницыMechanics of masonry vaults: The equilibrium approachfukuroxyzОценок пока нет

- Dampers in Bridges 2010Документ16 страницDampers in Bridges 2010IONUT RACANELОценок пока нет

- Cable Loss Analyses and Collapse Behavior of Cable Stayed Bridges (Wolff Starossek) PDFДокумент8 страницCable Loss Analyses and Collapse Behavior of Cable Stayed Bridges (Wolff Starossek) PDFm8r0ocvbs7Оценок пока нет

- En 1993-1-13 Travi Alveolari AcciaioДокумент39 страницEn 1993-1-13 Travi Alveolari AcciaioAndreaBarberisОценок пока нет

- Manual Kangaroo2 BR enДокумент24 страницыManual Kangaroo2 BR enLeandro AthanasioОценок пока нет

- ScimagojrДокумент766 страницScimagojrgurudev001Оценок пока нет

- En 1991 1 7 2006Документ69 страницEn 1991 1 7 2006xuanphuong2710Оценок пока нет

- Clock Towers of MacedoniaДокумент5 страницClock Towers of MacedoniaZoran PavlovОценок пока нет

- En 1051-1Документ13 страницEn 1051-1Hasan OzturkОценок пока нет

- ZollingerДокумент12 страницZollinger董思辰100% (1)

- 5 - VasoflonДокумент16 страниц5 - Vasoflonstavros_stergОценок пока нет

- Hollo-Bolts in Idea Statica: SCI P358Документ3 страницыHollo-Bolts in Idea Statica: SCI P358MartinОценок пока нет

- Architectural Drawing of Proposed Three Storey BuildingДокумент7 страницArchitectural Drawing of Proposed Three Storey BuildingMuhammad Wazim AkramОценок пока нет

- Vie Pc01 STN DWG MP Ppa 01109 0Документ1 страницаVie Pc01 STN DWG MP Ppa 01109 0Ashish BhartiОценок пока нет

- En BRUCHAPaneel Wand Fassade PIRДокумент16 страницEn BRUCHAPaneel Wand Fassade PIRAnjaОценок пока нет

- Design of Continuity Slabs and The Metro Viaduct Designs PDFДокумент6 страницDesign of Continuity Slabs and The Metro Viaduct Designs PDFraviОценок пока нет

- Prestress Loss in SOFiSTiK - R1Документ4 страницыPrestress Loss in SOFiSTiK - R1SASHIN ServiSoftОценок пока нет

- The New Guide To Stability Design Criteria For Metal StructuresДокумент3 страницыThe New Guide To Stability Design Criteria For Metal StructuresBilly BobОценок пока нет

- Extraction of External Force and Wall Reactions From NEMStatik Using Excel VBA MacroДокумент19 страницExtraction of External Force and Wall Reactions From NEMStatik Using Excel VBA MacroRonald Miguel DavidОценок пока нет

- Bullivants HandbookДокумент259 страницBullivants HandbookJoshua Gibbings100% (1)

- ECCS 73 Practice For Composite SlabsДокумент65 страницECCS 73 Practice For Composite SlabsСтефан ЖечевОценок пока нет

- Macau Wind CodeДокумент53 страницыMacau Wind CodeJack WenОценок пока нет

- Min Reinf To - BS 8007 and Crack Width - NZS 3106 - 2009 - MH01 PDFДокумент2 страницыMin Reinf To - BS 8007 and Crack Width - NZS 3106 - 2009 - MH01 PDFAnonymous 9LWbwMZNОценок пока нет

- LTL Galvanizers provides galvanizing certificationДокумент1 страницаLTL Galvanizers provides galvanizing certificationindunilОценок пока нет

- Riodin XEДокумент2 страницыRiodin XEAntónio NôroОценок пока нет

- CMFB Vol 3 Approach Bridge Substructure S1 P1Документ53 страницыCMFB Vol 3 Approach Bridge Substructure S1 P1ani4576100% (1)

- 0302 Wind Loads On The Building With Flat RoofДокумент2 страницы0302 Wind Loads On The Building With Flat RoofFrank George Crema CremaОценок пока нет

- Translated Version of RalДокумент31 страницаTranslated Version of RalsskamalakannanОценок пока нет

- Unien1998 1 2013 - Eit PDFДокумент193 страницыUnien1998 1 2013 - Eit PDFfedecimaОценок пока нет

- DimitriosДокумент29 страницDimitriosisaych33zeОценок пока нет

- 09 Eurocodes Steel Workshop LANDOLFOДокумент119 страниц09 Eurocodes Steel Workshop LANDOLFOAlper KzОценок пока нет

- (ECCE) FootbridgesДокумент210 страниц(ECCE) FootbridgesA. KatsarakisОценок пока нет

- MOST CompleteДокумент286 страницMOST CompleteB Kumar BОценок пока нет

- S257Документ459 страницS257maimy_annОценок пока нет

- BS en 10058-2018 PDFДокумент12 страницBS en 10058-2018 PDFBravo RdОценок пока нет

- Lecture 2 Materials, Cover and Some Definitions CG 28 Sep 2016Документ32 страницыLecture 2 Materials, Cover and Some Definitions CG 28 Sep 2016je311Оценок пока нет

- 98s11 PDFДокумент11 страниц98s11 PDFpaulkohanОценок пока нет

- Frantz & Breen 1980Документ262 страницыFrantz & Breen 1980groger23Оценок пока нет

- 13 Nisa CivilДокумент8 страниц13 Nisa Civilakhlaq_hssainkotaОценок пока нет

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionОт EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionОценок пока нет

- PT 27 - Torch - F 15 203 C PDFДокумент16 страницPT 27 - Torch - F 15 203 C PDFAnonymous jOwMSp5lrkОценок пока нет

- Sales-Bulletin-6572-2019-05Документ2 страницыSales-Bulletin-6572-2019-05Tomás LagosОценок пока нет

- 5200-780 20140813 PartsSpecsДокумент102 страницы5200-780 20140813 PartsSpecsUbaldo Enrique Caraballo EstradaОценок пока нет

- CD RDS Receiver Service ManualДокумент65 страницCD RDS Receiver Service Manualisdi antoroОценок пока нет

- Guide Tech Potences EngДокумент42 страницыGuide Tech Potences EngflasnicugОценок пока нет

- DB Engineering Co-January 2018Документ43 страницыDB Engineering Co-January 2018Snezana RaicevicОценок пока нет

- Props and Tresteled Towers Alu-Up2: Read This Manual Carefully Before Using The ProductsДокумент38 страницProps and Tresteled Towers Alu-Up2: Read This Manual Carefully Before Using The ProductsSnezana RaicevicОценок пока нет

- BS 1139 82 Tubes For Use in Scaffolding PDFДокумент3 страницыBS 1139 82 Tubes For Use in Scaffolding PDFHoang Duc50% (2)

- Allowable Load Bearing Alu Up Tower 300-350-400Документ6 страницAllowable Load Bearing Alu Up Tower 300-350-400Snezana RaicevicОценок пока нет

- 2 - Wind Calculation Report 1Документ14 страниц2 - Wind Calculation Report 1Snezana RaicevicОценок пока нет

- Water: City of RichardsonДокумент15 страницWater: City of RichardsonSnezana RaicevicОценок пока нет

- Parker Pneumatic Stainless Steel FRL Catalogue PDE2504TCUKДокумент24 страницыParker Pneumatic Stainless Steel FRL Catalogue PDE2504TCUKJas SumОценок пока нет

- Installation and Maintenance Guide for Kenmore 2500 15 Gallon Central HumidifierДокумент13 страницInstallation and Maintenance Guide for Kenmore 2500 15 Gallon Central HumidifierjsedlockОценок пока нет

- Heavy-Duty Safety Rope Pull Switches for Long ConveyorsДокумент3 страницыHeavy-Duty Safety Rope Pull Switches for Long ConveyorsMasood NizamОценок пока нет

- Resolve VP ApacДокумент20 страницResolve VP ApacHoang-Vu BuiОценок пока нет

- SUPERCITO MMA Electrodes for Structural and Heavy WorkДокумент1 страницаSUPERCITO MMA Electrodes for Structural and Heavy Workantonio111aОценок пока нет

- Current Composites Testing ReportДокумент4 страницыCurrent Composites Testing ReportMohamed RamzanОценок пока нет

- Detailed Summary of Estimates PDFДокумент6 страницDetailed Summary of Estimates PDFLeslie Cambarijan LumpasОценок пока нет

- Utilisation of Waste Plastic in Bituminous Roads ReviewДокумент14 страницUtilisation of Waste Plastic in Bituminous Roads ReviewCivil StructureОценок пока нет

- Background: The Duct Tape BookДокумент5 страницBackground: The Duct Tape BookCloudine IzonОценок пока нет

- ME - 312, HMT-week 11Документ21 страницаME - 312, HMT-week 11Qazi MaazОценок пока нет

- Cable Tray VantrunkДокумент93 страницыCable Tray Vantrunkvineet57Оценок пока нет

- SteelДокумент8 страницSteelMxoli MbazoОценок пока нет

- Ding 2014Документ4 страницыDing 2014pranav razdanОценок пока нет

- Vivek Sir RCC WorkbookДокумент100 страницVivek Sir RCC WorkbookChodapuneedi SatyanarayanaОценок пока нет

- Sprinkler 2 01 2021Документ2 страницыSprinkler 2 01 2021rajaОценок пока нет

- Bt5 Lecture 1Документ32 страницыBt5 Lecture 1Marrielle BalagotОценок пока нет

- vivaraZON HCP 170 171 EngДокумент1 страницаvivaraZON HCP 170 171 EngMocanu Romeo-CristianОценок пока нет

- ITW Product Catalog39 PDFДокумент1 страницаITW Product Catalog39 PDFjohnОценок пока нет

- Proofex LM: Constructive SolutionsДокумент2 страницыProofex LM: Constructive SolutionsSHAIK ASIMUDDINОценок пока нет

- Sequential Load Analysis For Tall BuildingsДокумент10 страницSequential Load Analysis For Tall BuildingsharisleeОценок пока нет

- Wall Mounted PDFДокумент5 страницWall Mounted PDFAhmed AzadОценок пока нет

- Incinerator VentilationДокумент33 страницыIncinerator VentilationRevati shindeОценок пока нет

- Gan Band STRДокумент18 страницGan Band STRitshotandfreeОценок пока нет

- Castrol BulletinДокумент1 страницаCastrol BulletinHarrier ESОценок пока нет

- Bubble Wrap Manufacturing ProcessДокумент13 страницBubble Wrap Manufacturing ProcessAnonymous a8rdyKOCОценок пока нет