Академический Документы

Профессиональный Документы

Культура Документы

'Documentslide - Com - Beer and NMR Carolina NMR Symposium PDF

Загружено:

valerius69Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

'Documentslide - Com - Beer and NMR Carolina NMR Symposium PDF

Загружено:

valerius69Авторское право:

Доступные форматы

From Mash to Bottle: Chemistry of the Brewing Process and NMR-based Quality Control

Adam J. DiCaprio and John C. Edwards

Process NMR Associates, 87A Sandpit Road Danbury, CT 06910

Step 3: Fermentation

Introduction Materials & Methods Succinic Acid Acetic Acid

Alanine Ethanol

Fusel

Pyruvic Acid

Citric Acid Alcohols

Beer is one of the oldest produced beverages in the world, and has Beer was acquired directly from an East coast brewery. Sample volumes were 175µL (straight runs) & 500µL Pyruvic Acid

(hyd.)

been made from barley for at least 5,500 years[1]. Though modern (lyophilized) . Degassed beer samples were brought to a final sample volume of 0.75mL with deuterated water.

beer is a far-cry from its ancient predecessor, the overall process Exactly 10mg of internal quantitation standard (maleic acid) was added to samples for quantitation. Lactic Acid

Malic Acid

remains the same: fermentation of sugars derived from Samples were run on a Mercury-VX 300 spectrometer operating at 299.681 MHz. Spectral Parameters: pw=67.5°,

saccharification of cereal grains. d1=7s, at=8s, T=27°C, nt=256 (straight runs) & nt=128 (lyophilized)

The first step in modern brewing is the mash, in which crushed Spectra were processed in Mnova (ver. 8.2.0-12621) and Chemometrics were performed in Eigenvector (ver. 6.1)

grains are mixed with hot water to activate native barley amylases.

These enzymes then convert complex polysaccharides into smaller, Results & Discussion

fermentable oligosaccharides. The mixture of water and sugars

Step 1: The Mash

(wort) is separated from the spent grains and transferred to a α(1-4) Leucine,

α-reduced Β-reduced Citric Acid Acetic Acid Alanine Lactic Acid

boiling kettle, and is then boiled. Hops are added to the boiling 1 ends ends

Isoleucine,

Valine

wort , which causes the isomerization of alpha acids, lending

bitterness to beer, which balances the sweetness caused by residual

sugars. 2

After boiling, the wort is cooled and transferred to a fermentation

Figure 3: Changes occurring in beer during fermentation. Throughout fermentation, the relative amounts of pyruvic acid (and it’s hydrate), acetic acid,

vessel, where a yeast culture is added to ferment the wort into lactic acid, ethanol, succinic acid and higher alcohols increased. Amino acids (alanine, leucine, isoleucine, valine) decreased throughout fermentation.

Higher carboxylix acids, e.g. citric and malic acid remained the same throughout fermentation.

“green beer.” This unfinished beer is then filtered, carbonated,

bottled/kegged and aged. This entire process is outlined below 3

The fermentation of beer samples followed a predictable course as the concentrations of ethanol and fusel alcohols

(Figure 1). increased dramatically. Malt oligosaccharides decreased in a predictable way, as the glucose and maltose were

preferentially fermented, leaving residual maltotriose and longer chain dextrins. This data gives insight into the final

gravity of a beer, which impacts its body and mouthfeel.

4 In addition to the increase in alcohols, acetic and pyruvic acids increased in relative concentrations, both of which are

intermediates in the ethanol fermentation pathway of S. cerevesiae. Because acetic acid is a precursor to the

tricarboxylic acid cycle, and the relative concentrations of succinic, citric and malic acid stayed constant, it would be

reasonable to infer that this process was completely anaerobic. The concentrations of these acids could be used to

determine if there was an introduction of oxygen to the brewing stream.

The increase of lactic acid was marginal, and could be attributed to the metabolic activity of introduced yeast or

Figure 1: Changes in carbohydrates (left) and amino & organic acids (right) over the course of the mash. Mash-in (red/4), first runnings (green/3), sweet wort after 40 barrel run off (blue/2), end of

sparge (purple/1). Relative to the initial mash(4), the first runnings (3) had larger amounts of all maltooligosaccharides (left panel), all of which decreased continuously to the end of the mash (1). resident lactic acid bacteria. In the event that production was due to lactic acid bacteria, the amounts were minimal

The relative amounts of maltose (β-reduced ends, left doublet) and glucose (β-reduced ends, right doublet) were equivalent throughout steps 1-4. The amino and organic acids all decreased and could be easily measured and assessed by NMR. Chemometrics

throughout steps 1-4, with the exception of lactic acid, which increased in relative concentration throughout the mash.

The increase in all carbohydrate resonances indicated that during the mash, amylase enzymes were responsible for Principal component analysis of stream samples

the conversion of insoluble polysaccharides to water soluble oligosaccharides. Of these, malto-oligosaccharides successfully resolved the three separate batches

experienced the largest relative increase, which could be used to determine mash conditions, as variations in based largely on ethanol and oligosaccharide

resonances. Within the expansion of Batch A and

temperature ranges influence proportions of mono- di- and trisaccharides present in the sweet wort. B, Mash In/Out and Preboiled samples were

Despite the relative constant concentration of the labeled organic and amino acids, lactic acid increased separated from Knockout and Postboiled Samples

dramatically throughout the mash and sparge. The increasing amount of this acid could be indicative of an active along PC2. The potential exists that this

population of lactic acid bacteria during the mash, which could potentially directly influence the flavor of a finished discrimination is related to protein and amino acid

beer, as well as the pH of the wort, which could influence fermentation behavior of S. cereviseae. content of wort, as knockout and boiling of worts

involves denaturation and precipitation of

Step 2: The Boil dissolved wort proteins. This could be correlated

Figure 1: Complete brewing process. Image credit: BBC News http://news.bbc.co.uk/2/hi/business/5273828.stm

No observable changes could be deciphered in samples pre- and post-boil. to free amino nitrogen content in wort, which has

a direct influence on yeast fermentation

Because of the complexity of the complete brewing process, there behavior⁴. Despite data point discrimination,

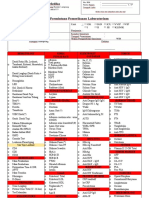

are multiple opportunities for the application of NMR in brewery Figure 4: Principal Component Analysis of brewing stream. Samples were from two separate mash

Batch A and Batch B occurred in close proximity in

quality control. NMR and multivariate analysis have been applied batches (green asterisks & red triangles [left]) which were then combined in the fermenter (blue the PC1 x PC2 projection, suggesting that a simple

Kojibiose circles [left]). Samples were as follows: 2 – Mash in A, 3 – Mash Out A, 4 – 1st Runnings A, 5 – Preboil

as quality control measures previously[2,3], but never throughout Kojibiose A, 6 – Postboil A, 7 – Knockout A, 8 – 1st Runnings B, 9 – Preboil B, 10 – Postboil B, 11 – Knockout B, 12

PCA analysis may not be sensitive enough to

– Fermenter A+B, 13 – 24hr Ferm, 14 – End Ferm, 15 – Prefilter, 16 – Carbonated, 17 – Bottled. discriminate initial brewing steps among multiple

the entire brewing process. streams.

In conjunction with a commercial brewing company, this project

seeks to utilize NMR and chemometrics to describe the full Future Work

chemical changes that occur during the brewing process, as well The first step in future work is to obtain complete data sets for the entire brewing process. The acquisition of data completely documenting

as variations occurring between separate production lots. multiple streams of the brewing process would make chemometric-based quality control schemes possible.

The next step will be to build multivariate batch reaction models to identify outliers in the brewing process. Identification of samples and

Equipped with the knowledge of brewing process variables and review of spectral data would make amelioration of process deficiencies possible, as many of the chemical species present in beer have

their consequential chemical effects, brewers would be able to specific origins and well defined impact on flavor. Instead of using simple PCA, modeling will focus on using multiway chemometrics, which

use NMR as a quality control measure to not only identify when are more useful in analyzing chemical changes batch and stream processes.

Finally, correlations and trends observed in spectral data will be considered in the context of brewing variables (e.g. wort gravity/color, mash

production issues occur, but also where and why they occur. temperatures, hop bittering levels [IBUs]) to improve the brewing process.

Acknowledgements

The following data represent samples taken from multiple batches

We would like to thank Franklin and the brewers responsible for furnishing these samples.

of the same beer. Labeled chemical species serve as Figure 2: Spectra of carbohydrate region of samples pre- (top) and post- (bottom) boil. There were no significant differences in the relative amounts of any resonances displayed. Assigned resonances

are identical to those in Figure 1, excepting the addition of kojibiose.

representatives of identifiable compounds, along with Though no direct trends were observed in pre- and post-boil samples, the potential exists that certain compounds

illustrations of the inferences a chemist can draw by using these

Citations

could be used for quality control measures during the boil step. For example, kojibiose, a product of the 1. Wilford, John N. (1992). Jar in Iranian Ruins Betrays Beer Drinkers of 3500 B.C.

compounds. carmelization of glucose, is a potential indicator for the condition of a beer while boiling, as excessive 2. Almeida, C. et. Al. (2006). Composition of Beer by ¹H NMR Spectroscopy: Effects of Brewing Site and Date of Production.

3. Duarte, I. F. (2004). Multivariate Analysis of NMR and FTIR Data as a Potential Tool for the Quality Control of Beer.

carmelization and browning can influence the color and flavor of a finished beer. 4. Lekkas, C. et. Al .(2007). Elucidation of the Role of Nitrogenous Wort Components in Yeast Fermentations.

Вам также может понравиться

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Enzymes 1Документ95 страницEnzymes 1Hawi kelbessaОценок пока нет

- Test Bank For Pharmacology For The Surgical Technologist 4th Edition by SnyderДокумент6 страницTest Bank For Pharmacology For The Surgical Technologist 4th Edition by Snyderroyfideliagxzq6Оценок пока нет

- Gujarat Technological UniversityДокумент1 страницаGujarat Technological UniversityVishesh DwivediОценок пока нет

- Genetic Testing For Autism, Explained: Spectrum - Autism Research NewsДокумент3 страницыGenetic Testing For Autism, Explained: Spectrum - Autism Research NewsTimothyОценок пока нет

- Encyclopediabookchapter PDFДокумент13 страницEncyclopediabookchapter PDFJamesОценок пока нет

- Exiqon Data Analysis Guide PDFДокумент55 страницExiqon Data Analysis Guide PDFwina measОценок пока нет

- Form Lab RSBM NewДокумент2 страницыForm Lab RSBM NewKiki OlivianaОценок пока нет

- Pathology of Nutritional DisordersДокумент15 страницPathology of Nutritional DisordersbumfromjerseyОценок пока нет

- Friedreich 'S Ataxia: Clinical Features, Pathogenesis and ManagementДокумент12 страницFriedreich 'S Ataxia: Clinical Features, Pathogenesis and ManagementVaibhav BhatiaОценок пока нет

- Hofmann 1998Документ8 страницHofmann 1998Sarly FebrianaОценок пока нет

- AP Bio U1Документ92 страницыAP Bio U1朱國修Оценок пока нет

- Enantiomers Evaluation CetirizineДокумент4 страницыEnantiomers Evaluation Cetirizinebebel555Оценок пока нет

- Chem 160.1 Post LabДокумент7 страницChem 160.1 Post LabMarlyn AmanteОценок пока нет

- LAB0016 Covid-19 Molecular Diagnostic Lab Belbas, ButwalДокумент1 страницаLAB0016 Covid-19 Molecular Diagnostic Lab Belbas, ButwalPoonam RanaОценок пока нет

- Structure and Function of HaemoglobinДокумент21 страницаStructure and Function of HaemoglobinEmily HoОценок пока нет

- Detection of Beer Spoilage BacteriaДокумент10 страницDetection of Beer Spoilage BacteriajoeОценок пока нет

- DLP GlycolysisДокумент3 страницыDLP GlycolysisMichelle NicolasОценок пока нет

- Summary 4º ESO - Unit 3 - Genetic Information and Nucleic AcidsДокумент89 страницSummary 4º ESO - Unit 3 - Genetic Information and Nucleic AcidsPILARОценок пока нет

- Handout Week 1Документ8 страницHandout Week 1Vien Lovelle Macanip Cabug-osОценок пока нет

- Macro Molecules Notes Chapter 6Документ3 страницыMacro Molecules Notes Chapter 6lmaureyОценок пока нет

- Garber Lab RNA-seq ProtocolДокумент2 страницыGarber Lab RNA-seq ProtocolVirus GirlОценок пока нет

- Chromosome StructureДокумент10 страницChromosome StructurePhú NguyễnОценок пока нет

- 2402 CH 17 Endocrine System (Part 1) PDFДокумент23 страницы2402 CH 17 Endocrine System (Part 1) PDFHarry RussellОценок пока нет

- Microbial Physiology and Fermentation Technology 2020Документ10 страницMicrobial Physiology and Fermentation Technology 2020fabio.v.mullerОценок пока нет

- Research Director or Biotechnology Consultant or Biochemical EngДокумент5 страницResearch Director or Biotechnology Consultant or Biochemical Engapi-78972323Оценок пока нет

- 04B. Bioinformatics-Lecture 4 (Alternative) - BlastДокумент38 страниц04B. Bioinformatics-Lecture 4 (Alternative) - BlastLinhNguyeОценок пока нет

- Fluorescence Activated Cell SortingДокумент6 страницFluorescence Activated Cell SortingAjit YadavОценок пока нет

- Genetic Engineering Answer Key B5a61 6163ece5Документ2 страницыGenetic Engineering Answer Key B5a61 6163ece5Cassandra CostunaОценок пока нет

- Metabolism Complete Notes #KigogoДокумент145 страницMetabolism Complete Notes #KigogoHesbone AneneОценок пока нет

- Answer Key WorksheetДокумент1 страницаAnswer Key WorksheetDivine Camacho-LanabanОценок пока нет