Академический Документы

Профессиональный Документы

Культура Документы

000-A-Ee-0190469 Rev1 Painting Repair Procedure

Загружено:

onur gunesОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

000-A-Ee-0190469 Rev1 Painting Repair Procedure

Загружено:

onur gunesАвторское право:

Доступные форматы

STAR RAFİNERİ, A.Ş.

CONTRACT Nº UNIT Nº

AEGEAN REFINERY PROJECT (ARP) STAR-C-01 000

CONTRACTOR DOC No: SH/OF

2248-000-A-EE-0190469 2/14

PAINTING REPAIR PROCEDURE STAR DOCUMENT No.

FOR STEEL STRUCTURE 000-A-EE-0190469

REV 0 1

TABLE OF CONTENTS

1. PURPOSE 3

2. SCOPE 3

3. DEFINITIONS 3

4. REFERENCES 4

5. PAINTING REPAIR PROCEDURE FOR STEEL STRUCTURE 6

6. GENERAL APPLICATION CONDITIONS 14

7. ATTACHMENTS AND TEMPLATES 14

This document is the property of TSGI Mühendislik İnşaat Limited Company. Its reproduction without a written permission is strictly forbidden.

000-A-EE-0190029_Tmp.05 Document Template

STAR RAFİNERİ, A.Ş. CONTRACT Nº UNIT Nº

AEGEAN REFINERY PROJECT (ARP) STAR-C-01 000

CONTRACTOR DOC No: SH/OF

2248-000-A-EE-0190469 3/14

PAINTING REPAIR PROCEDURE STAR DOCUMENT No.

FOR STEEL STRUCTURE 000-A-EE-0190469

REV 0 1

1. PURPOSE

This procedure defines the type, materials and methods of application for the repair works which will be

carried out at Steel Structures at ARP Project.

2. SCOPE

This method statement covers the guidelines for surface preparation, paint materials, painting systems

and application of paints during the repair works for Steel Structures. The protective coating systems

specified include Surface preparation, paint material selection, paint application methods.

3. DEFINITIONS

OWNER: STAR RAFİNERİ, A.Ş. (STAR)

CONTRACTOR: Joint Venture between Técnicas Reunidas (TR), Saipem (SP), GS E&C

and Itochu.

PROJECT: Means the Aegean Refinery (AR) Project, being executed by OWNER or its

affiliates.

SUBCONTRACTOR: Entity (and its legal successors in title) named as Subcontractor in the Contractor

purchase order and/or the contract awarded to the Subcontractor to perform

specific services and/or works

TANK “EC” The party which shall carry out all engineering, design and mechanical

CONTRACTOR : fabrication for the storage tanks (except sphere tanks) as per the work spit

between Tank EC contractor and Tank P contractor. In addition, it shall carry

out all the material procurements, surface preparation, installation, inspection

and testing of the lining systems.

TANK “P” The party which shall supply materials for tank fabrication in the site as per

CONTRACTOR : the work split between Tank EC contractor and Tank P contractor.

INSPECTOR: The individual responsible for implementing the inspection function specified

in the contract documents in order to minimize or eliminated defects or failures.

MANUFACTURER: The manufacturer of the lining system(s) and paint materials.

This document is the property of TSGI Mühendislik İnşaat Limited Company. Its reproduction without a written permission is strictly forbidden.

000-A-EE-0190029_Tmp.05 Document Template

STAR RAFİNERİ, A.Ş. CONTRACT Nº UNIT Nº

AEGEAN REFINERY PROJECT (ARP) STAR-C-01 000

CONTRACTOR DOC No: SH/OF

2248-000-A-EE-0190469 4/14

PAINTING REPAIR PROCEDURE STAR DOCUMENT No.

FOR STEEL STRUCTURE 000-A-EE-0190469

REV 0 1

4. REFERENCES

The Society for Protective Coating (SSPC)

ISO 4628 Standard

ASTM - American Society for Testing and Materials

Colors in accordance with RAL-F2 color card

Paint Manufacturer's Instructions

ISO 1461 Standard

ISO 12944-4 Standard

NACE RP0198-2010: Control of Corrosion Under Thermal Insulation and Fireproofing Materials

“RAL 840 HR" issued by "DEUTSCHER NORMENAUSSCHUSS”

STGPS-N1-6

SSPC-VIS 2

ASTM D610

Request for Information (RI’s)

RI-DIR-0004: Painting System for Bulk Valves

RI-DIR-0007 : Painting System for Piping subject to Sea Water Spray and Slashes

RI-DIR-0008 : Final Color for Pressure Vessel >120ºC

RI-DIR-0011 : Painting System for Static Equipment to be insulated for personnel protection

WR-DIR-0002: Painting General Specification

Code: ASME Section VIII Division 1 & Division 2, ASME Sec. V, ASME Sec IX

Painting Spec – Turkey (STGPS – N1)

American Steel Structures Painting Council Standards

SSPC - PA1 Shop, Field and Maintenance Painting

SSPC - PA2 Measurement of Dry Paint Thickness with Magnetic Gauges

SSPC - SP1 Solvent Cleaning

SSPC - SP2 Hand Tool Cleaning

SSPC - SP3 Power Tool Cleaning

SSPC - SP5 White Metal Blast Cleaning

SSPC - SP7 Brush-off Blast Cleaning

This document is the property of TSGI Mühendislik İnşaat Limited Company. Its reproduction without a written permission is strictly forbidden.

000-A-EE-0190029_Tmp.05 Document Template

STAR RAFİNERİ, A.Ş. CONTRACT Nº UNIT Nº

AEGEAN REFINERY PROJECT (ARP) STAR-C-01 000

CONTRACTOR DOC No: SH/OF

2248-000-A-EE-0190469 5/14

PAINTING REPAIR PROCEDURE STAR DOCUMENT No.

FOR STEEL STRUCTURE 000-A-EE-0190469

REV 0 1

ISO 12944-6- Paints and varnishes -- Corrosion protection of steel

Structures by protective paint systems -- Part 6: Laboratory performance test methods.

OWNER SPECIFICATIONS AND PROCEDURES

000-A-PE-0020008 Authority Requirements and Technical Standards.

000-A-EE-0190137 Tank internal lining.

STGPS-N1 Painting – General project design specification.

STGPS-W1 Field construction, supervision, inspection and testing requirements.

PROJECT PROCEDURES

000-A-EE-0190410 Construction Quality Plan.

000-A-EE-0190407 Construction Subcontractors Quality Requirements.

000-A-EE-0190406 Control Procedure for Inspection, Measuring and Testing Equipment.

000-A-EE-0190403 Material Identification and Traceability Procedure.

000-A-EE-0190605 Site Inspection Procedure.

000-A-EE-0190414 Site Non-conformity Control and Corrective Action Procedure.

000-A-EE-0190608 Material Control Procedure.

000-A-EE-0190611 Preservation Control Procedure.

000-A-EE-0190502 Site Quality Records.

TERMS AND ABBREVIATIONS

Abrasive Blast Cleaning: Also called abrasive-blasting, a surface preparation method that uses

an abrasive propelled by air pressure, centrifugal force, or water pressure to clean and usually to

add a profile (anchor pattern) to a surface.

Anchor Pattern (Profile): contour of a blast-cleaned surface, it is classified by peaks-to-valleys

depth (amplitude) and texture (dense, rounded or angular).

Dry-Film Thickness: Thickness of cured film, usually expressed in micrometres (or micron,

millionth of a meter).

This document is the property of TSGI Mühendislik İnşaat Limited Company. Its reproduction without a written permission is strictly forbidden.

000-A-EE-0190029_Tmp.05 Document Template

STAR RAFİNERİ, A.Ş. CONTRACT Nº UNIT Nº

AEGEAN REFINERY PROJECT (ARP) STAR-C-01 000

CONTRACTOR DOC No: SH/OF

2248-000-A-EE-0190469 6/14

PAINTING REPAIR PROCEDURE STAR DOCUMENT No.

FOR STEEL STRUCTURE 000-A-EE-0190469

REV 0 1

Holding Primer: A thin-film primer applied to prevent rust blooming prior to the application of the

subsequent build-up lining system.

Holiday: A discontinuity in a protective lining that exposes an unprotected surface to the

environment.

Holiday Detector, Low-Voltage Wet-Sponge Type: An instrument that uses 5 to 90V DC for

detecting holidays in a lining. It is typically used for linings less than 500 micron (dry film

thickness) thick.

Holiday Detector, High-Voltage Type: Also called spark-tester, it’s an instrument for detecting

holidays in a non-conductive coating applied over a conductive substrate. A spark-test instrument

applies a high-voltage (thousands of volt) to the surface with a probe that creates a spark

whenever a holiday, pinhole, or other film defect is found.

The spark triggers an alarm or light on the instrument.The voltage used depends on the lining

type and thickness. It is typically used for linings thicker than 500 micron (dry film thickness).

Manufacturer’s Technical Data Sheet: Sheet printed by the supplier of a product to provide

instructions and information on its use.

Operating Temperature: Means “Maximum operating temperature”

Pot-Life: the elapsed time within which a coating can be effectively applied after all components

of the coating have been thoroughly mixed.

Shelf-Life: the maximum length of time packaged materials (e.g. coating materials) can be

stored at specified conditions and remain in usable conditions.

Shop-Primer: synonymous of Prefabrication Primer (see above).

5. PAINTING REPAIR PROCEDURE FOR STEEL STRUCTURE

5.1. REPAIR WORKS FOR 2.1 SYSTEM (NON-FIREPROOFED AREA’S)

Primer and finish coats for a particular system shall be from the same manufacturer to assure

compatibility.

5.1.1 PAINT SYSTEM DESCRIPTIONS

PAINT SYSTEM 2.1 – (temp. up to 120 °C);

Primer: ZINC RICH EPOXY ……………………………….….75 mµ

Intermediate: POLYAMIDE EPOXY ………………………..125 mµ

Finish: ALIPHATIC ACRYLIC POLYURETHANE.……...…..50 mµ

This document is the property of TSGI Mühendislik İnşaat Limited Company. Its reproduction without a written permission is strictly forbidden.

000-A-EE-0190029_Tmp.05 Document Template

STAR RAFİNERİ, A.Ş. CONTRACT Nº UNIT Nº

AEGEAN REFINERY PROJECT (ARP) STAR-C-01 000

CONTRACTOR DOC No: SH/OF

2248-000-A-EE-0190469 7/14

PAINTING REPAIR PROCEDURE STAR DOCUMENT No.

FOR STEEL STRUCTURE 000-A-EE-0190469

REV 0 1

SPECIFIED TOUCH UP SYSTEM FOR SYS 2.1;

Primer: SURFACE TOLERANT EPOXY………….…..100~125 mµ

Intermediate: POLYAMIDE EPOXY ………………….……..125 mµ

Finish: ALIPHATIC ACRYLIC POLYURETHANE.……...…..50 mµ

A. SPECIFIED SYSTEM by JOTUN MANUFACTURER (SYS 2.1 temp. up to 120 °C);

BARRIER 80……………………………….………………........75 mµ

PENGUARD EXPRESS XT……...…………………………...125 mµ

HARDTOP XP……………………………………………….…...50 mµ

B. RECOMMENDED TOUCH UP REPAIR SYSTEM by JOTUN;

JOTAMASTIC 80…………………….……………...……100~125 mµ

PENGUARD EXPRESS XT…………………………….……..125 mµ

HARDTOP XP……………………………………………….……50 mµ

C. SPECIFIED SYSTEM by KANAT MANUFACTURER (SYS 2.1 temp. up to 120 °C);

KANEPOX ZINC RICH 80 (11420)………………………….....75 mµ

KANEPOX UNIFAST (12200)……………………………..…..125 mµ

KANPOLY ACR ENAMEL HS (37770)………………………...50 mµ

D. RECOMMENDED TOUCH UP REPAIR SYSTEM by KANAT;

KANEPOX MASTICOAT (15550)…………..…….……. 100~125 mµ

KANEPOX UNIFAST (12200)…………………………..……..125 mµ

KANPOLY ACR ENAMEL HS (37770)……………….…..……50 mµ

E. SPECIFIED SYSTEM by CIN MANUFACTURER (SYS 2.1 temp. up to 120 °C);

C-Pox Primer ZN800………………………………………….....75 mµ

C-Pox S100……………………………..……………………....125 mµ

C-Thane S258……………………………….…………………...50 mµ

F. RECOMMENDED TOUCH UP REPAIR SYSTEM by CIN;

This document is the property of TSGI Mühendislik İnşaat Limited Company. Its reproduction without a written permission is strictly forbidden.

000-A-EE-0190029_Tmp.05 Document Template

STAR RAFİNERİ, A.Ş. CONTRACT Nº UNIT Nº

AEGEAN REFINERY PROJECT (ARP) STAR-C-01 000

CONTRACTOR DOC No: SH/OF

2248-000-A-EE-0190469 8/14

PAINTING REPAIR PROCEDURE STAR DOCUMENT No.

FOR STEEL STRUCTURE 000-A-EE-0190469

REV 0 1

C-POX® ST170…………….…………..………….……. 100~125 mµ

C-Pox S100……………………………..……………………....125 mµ

C-Thane S258……………………………….…………………...50 mµ

G. SPECIFIED SYSTEM by PPG / SIGMA MANUFACTURER (SYS 2.1 temp. up to 120 °C);

SigmaZinc 109 HS or Amercoat 68A……………………….....75 mµ

Sigmafast 278 or Sigmacover 456………………...………....125 mµ

SigmaDur 550, 550H or 520 (Alu Color)………….…………...50 mµ

H. RECOMMENDED TOUCH UP REPAIR SYSTEM by PPG / SIGMA;

Sigmacover 350.………………………..………….……. 100~125 mµ

Sigmafast 278 …………………….………………...………....125 mµ

SigmaDur 550, 550H or 520 (Alu Color)………….…………...50 mµ

5.1.2. Completely Stripped Surfaces until the Steel for Cycle No 2.1;

Surface Preperation & Paint Applicaiton Method

For small defects;

Small defects defined as less than 50cm X 50cm dimensions can be power tool cleaned

to a minimum of ISO St 3 standard with a profile of no less than 25 microns.

For large defects;

The defects which are larger than 50cm X 50cm dimensions shall be spot blasted either

by vacuum blasting, or other suitable blasting equipment,

Blast cleaning shall be made in a covered area, provided by Contractor, to prevent dust spread

on the surrounding areas. For blast cleaning the approval of Owner is required.

After blasting all spent abrasive or grit must be removed

For areas Sa 2½ (ISO 8501-1) blasting is not possible due to site conditions after erection,

surface tolerant mastic epoxy which may be applied on top of mechanical surface preparation

as primer prefered instead of zinc rich epoxy for minor touch-up applications.

Completely stripped surfaces until the steel shall be cleaned mechanically by using power

tools (floppy, cup wire brush etc.) in St 3 level according to ISO 8501-1 standard.

Dusts occurred at the end of mechanical cleaning process shall be removed from surfaces by

using compressed air and scrubber. Also, other contaminations such as dirt, mud, oil etc.

remained on the surfaces shall be cleaned with suitable cleaning agent or solvent.

This document is the property of TSGI Mühendislik İnşaat Limited Company. Its reproduction without a written permission is strictly forbidden.

000-A-EE-0190029_Tmp.05 Document Template

STAR RAFİNERİ, A.Ş. CONTRACT Nº UNIT Nº

AEGEAN REFINERY PROJECT (ARP) STAR-C-01 000

CONTRACTOR DOC No: SH/OF

2248-000-A-EE-0190469 9/14

PAINTING REPAIR PROCEDURE STAR DOCUMENT No.

FOR STEEL STRUCTURE 000-A-EE-0190469

REV 0 1

Feathering the edges of existing undamaged coating (Sharp edges of intact coating should be

feathered), followed by application of repair paint system.

Mechanically cleaned surfaces shall be primed with Surface Tolerant Epoxy Primer defined in

touch-up paint system table in one coat with airless spray equipment or in 2 coats (50 microns

for each coat) by using roller & brush equipment in total 100 microns dry film thickness within

the shortest time (in 5 hours at the latest) after mechanical cleaning process was completed.

Care should be taken to prevent overlapping of surface tolerent mastic epoxy on intact with

Polyurethane film.

After 10 hours at the earliest and 30 days at the latest (at 20°C) when Surface Tolerant Epoxy

Primer application was completed, High Build Epoxy Midcoat shall be applied in one coat with

airless spray equipment or in 2 coats (65 microns for first coat+60 microns for second coat) by

using roller & brush equipment in total 125 microns dry film thickness.

After 4 hours at the earliest and 90 days at the latest (at 20°C) when High Build Epoxy Midcoat

application was completed, Aliphatic Acrylic Polyurethane Topcoat shall be applied in one coat

with airless spray or roller & brush equipment in 50 microns dry film thickness.

Ambient temperature, relative humidity and dew point should be checked out prior to each

surface preparation and each paint application. Ambient temperature should be at the values,

that the paint manufacturer recommended, and the relative humidity should be maximum 80%.

Temperature of the surface, to which paint application and surface preparation shall be done,

should be at least 5°C above the dew point.

5.1.3. Damaged Mid-coated Surfaces for Cycle No 2.1;

Damaged mid-coated surfaces shall be roughened by using sandpaper.

Dusts occurred at the end of sanding process shall be removed from surfaces by using

compressed air and scrubber. Also, other contaminations such as dirt, mud, oil etc. remained on

the surfaces shall be cleaned with suitable cleaning agent or solvent.

This document is the property of TSGI Mühendislik İnşaat Limited Company. Its reproduction without a written permission is strictly forbidden.

000-A-EE-0190029_Tmp.05 Document Template

STAR RAFİNERİ, A.Ş. CONTRACT Nº UNIT Nº

AEGEAN REFINERY PROJECT (ARP) STAR-C-01 000

CONTRACTOR DOC No: SH/OF

2248-000-A-EE-0190469 10/14

PAINTING REPAIR PROCEDURE STAR DOCUMENT No.

FOR STEEL STRUCTURE 000-A-EE-0190469

REV 0 1

Feathering the edges of existing undamaged coating (Sharp edges of intact coating should be

feathered), followed by application of repair paint system.

Roughened surfaces with sandpaper shall be painted with High Build Epoxy

Midcoat shall be applied in one coat with airless spray equipment or in 2 coats (65 microns for

first coat+60 microns for second coat) by using roller & brush equipment in total 125 microns dry

film thickness within the same day after roughening process with sandpaper was completed.

Care should be taken to prevent overlapping of surface tolerent mastic epoxy on intact with

Polyurethane film.

After 4 hours at the earliest and 90 days at the latest (at 20°C) when High Build Epoxy Midcoat

application was completed, Aliphatic Acrylic Polyurethane Topcoat shall be applied in one coat

with airless spray or roller & brush equipment in 50 microns dry film thickness.

Ambient temperature, relative humidity and dew point should be checked out prior to each

surface preparation and each paint application. Ambient temperature should be at the values,

that the paint manufacturer recommended, and the relative humidity should be maximum 80%.

Temperature of the surface, to which paint application and surface preparation shall be done,

should be at least 5°C above the dew point.

5.1.4 Damaged Top-coated Surfaces for Cycle No 2.1;

Damaged top-coated surfaces shall be roughened by using sandpaper.

Dusts occurred at the end of sanding process shall be removed from surfaces by using

compressed air and scrubber. Also, other contaminations such as dirt, mud, oil etc. remained on

the surfaces shall be cleaned with suitable cleaning agent or solvent.

Feathering the edges of existing undamaged coating (Sharp edges of intact coating should be

feathered), followed by application of repair paint system.

This document is the property of TSGI Mühendislik İnşaat Limited Company. Its reproduction without a written permission is strictly forbidden.

000-A-EE-0190029_Tmp.05 Document Template

STAR RAFİNERİ, A.Ş. CONTRACT Nº UNIT Nº

AEGEAN REFINERY PROJECT (ARP) STAR-C-01 000

CONTRACTOR DOC No: SH/OF

2248-000-A-EE-0190469 11/14

PAINTING REPAIR PROCEDURE STAR DOCUMENT No.

FOR STEEL STRUCTURE 000-A-EE-0190469

REV 0 1

Roughened surfaces with sandpaper shall be painted with Aliphatic Acrylic Polyurethane

Topcoat shall be applied in one coat with airless spray or roller & brush equipment in 50 microns

dry film thickness within the same day after roughening process with sandpaper was completed.

Care should be taken to prevent overlapping of surface tolerent mastic epoxy on intact with

Polyurethane film.

Ambient temperature, relative humidity and dew point should be checked out prior to each

surface preparation and each paint application. Ambient temperature should be at the values,

that the paint manufacturer recommended, and the relative humidity should be maximum 80%.

Temperature of the surface, to which paint application and surface preparation shall be done,

should be at least 5°C above the dew point.

5.2. REPAIR WORKS FOR 2.5 SYSTEM (FIREPROOFED AREA’S)

5.2.1 PAINT SYSTEM DESCRIPTIONS

PAINT SYSTEM 2.5 – TEMP. up to 150 °C;

Primer: PHENOLIC EPOXY ……………………………….….200 mµ

SPECIFIED TOUCH UP SYSTEM FOR SYS 2.5;

Primer: PHENOLIC EPOXY ………….………………………200 mµ

OR

Primer: SURFACE TOLERANT EPOXY………………….….100 mµ

Finish: PHENOLIC EPOXY ………….………………………100 mµ

A. SPECIFIED SYSTEM by JOTUN MANUFACTURER (SYS 2.5 temp. up to 150 °C);

EPOXY HR………………………………….……………….......200 mµ

This document is the property of TSGI Mühendislik İnşaat Limited Company. Its reproduction without a written permission is strictly forbidden.

000-A-EE-0190029_Tmp.05 Document Template

STAR RAFİNERİ, A.Ş. CONTRACT Nº UNIT Nº

AEGEAN REFINERY PROJECT (ARP) STAR-C-01 000

CONTRACTOR DOC No: SH/OF

2248-000-A-EE-0190469 12/14

PAINTING REPAIR PROCEDURE STAR DOCUMENT No.

FOR STEEL STRUCTURE 000-A-EE-0190469

REV 0 1

B. RECOMMENDED TOUCH UP REPAIR SYSTEM by JOTUN;

EPOXY HR………………………………….……………….......200 mµ

C. SPECIFIED SYSTEM by KANAT MANUFACTURER (SYS 2.5 temp. up to 150 °C);

KANEPOX HYGIENIC (19570)…………………….……….....200 mµ

D. RECOMMENDED TOUCH UP REPAIR SYSTEM by KANAT;

KANEPOX MASTICOAT (15550)…………..…….………….. 100 mµ

KANEPOX HYGIENIC (19570)…………………….……….....100 mµ

E. SPECIFIED SYSTEM by CIN MANUFACTURER (SYS 2.5 temp. up to 150 °C);

C-POX TL 735 / C-POX TL740…………………….…...…….....200 mµ

F. RECOMMENDED TOUCH UP REPAIR SYSTEM by CIN;

C-POX TL740…………………….……………..…….……...….. 200 mµ

G. SPECIFIED SYSTEM by PPG / SIGMA MANUFACTURER (SYS 2.5 temp. up to 150 °C);

SIGMAGUARD 730 or SIGMATHERM 230…………...…….....200 mµ

H. RECOMMENDED TOUCH UP REPAIR SYSTEM by PPG / SIGMA (up to 40 °C);

SIGMAGUARD 350………………………….………..……...….. 100 mµ

SIGMAGUARD 730………………………….………..……...….. 100 mµ

I. RECOMMENDED TOUCH UP REPAIR SYSTEM by PPG / SIGMA (between 40~150 °C);

SIGMAGUARD 730………………………….………………...….. 50 mµ

SIGMAGUARD 730………………………….………..……...….. 150 mµ

5.2.2. Completely Stripped Surfaces until the Steel for Cycle No 2.5;

Surface Preperation & Paint Application Method

For small defects

Small defects defined as less than 50cm X 50cm dimensions can be power tool cleaned

to a minimum of ISO St 3 standard with a profile of no less than 25 microns.

For large defects;

This document is the property of TSGI Mühendislik İnşaat Limited Company. Its reproduction without a written permission is strictly forbidden.

000-A-EE-0190029_Tmp.05 Document Template

STAR RAFİNERİ, A.Ş. CONTRACT Nº UNIT Nº

AEGEAN REFINERY PROJECT (ARP) STAR-C-01 000

CONTRACTOR DOC No: SH/OF

2248-000-A-EE-0190469 13/14

PAINTING REPAIR PROCEDURE STAR DOCUMENT No.

FOR STEEL STRUCTURE 000-A-EE-0190469

REV 0 1

The defects which are larger than 50cm X 50cm dimensions shall be spot blasted either

by vacuum blasting, or other suitable blasting equipment,

Blast cleaning shall be made in a covered area, provided by Contractor, to prevent dust spread

on the surrounding areas. For blast cleaning the approval of Owner is required.

After blasting all spent abrasive or grit must be removed.

For areas Sa 2½ (ISO 8501-1) blasting is not possible due to site conditions after erection,

Completely stripped surfaces until the steel shall be cleaned mechanically by using power tools

(floppy, cup wire brush etc.) in St 3 level according to ISO 8501-1 standard.

Dusts occurred at the end of mechanical cleaning process shall be removed from surfaces by

using compressed air and scrubber. Also, other contaminations such as dirt, mud, oil etc.

remained on the surfaces shall be cleaned with suitable cleaning agent or solvent.

Feathering the edges of existing undamaged coating (Sharp edges of intact coating should be

feathered), followed by application of repair paint system.

Mechanically cleaned surfaces shall be primed with Surface Tolerant Epoxy Primer defined in

touch-up paint system table in one coat with airless spray equipment or in 2 coats (50 microns

for each coat) by using roller & brush equipment in total 100 microns dry film thickness within

the shortest time (in 5 hours at the latest) after mechanical cleaning process was completed.

Care should be taken to prevent overlapping of surface tolerent mastic epoxy on intact with

Polyurethane film.

After 10 hours at the earliest and 30 days at the latest (at 20°C) when Surface Tolerant Epoxy

Primer application was completed, Solvent-free Phenolic Epoxy shall be applied in one coat

with airless spray equipment or in 2 coats (50 microns for each coat) by using roller & brush

equipment in total 100 microns dry film thickness.

Ambient temperature, relative humidity and dew point should be checked out prior to each

surface preparation and each paint application. Ambient temperature should be at the values,

This document is the property of TSGI Mühendislik İnşaat Limited Company. Its reproduction without a written permission is strictly forbidden.

000-A-EE-0190029_Tmp.05 Document Template

STAR RAFİNERİ, A.Ş. CONTRACT Nº UNIT Nº

AEGEAN REFINERY PROJECT (ARP) STAR-C-01 000

CONTRACTOR DOC No: SH/OF

2248-000-A-EE-0190469 14/14

PAINTING REPAIR PROCEDURE STAR DOCUMENT No.

FOR STEEL STRUCTURE 000-A-EE-0190469

REV 0 1

that the paint manufacturer recommended, and the relative humidity should be maximum

80%. Temperature of the surface, to which paint application and surface preparation shall be

done, should be at least 5°C above the dew point.

6. GENERAL APPLICATION CONDITIONS

1) Minimum and maximum time, required to be waited between each coat during application,

defined in product technical data sheets should be obeyed.

2) Paint application shouldn’t be applied under the conditions determined below:

i) If the surface is wet.

ii) If relative humidity is above the maximum value defined in product technical data sheets.

iii) If ambient or surface temperature is below/above the temperature defined in product

technical data sheets.

iv) If application environment is extremely dusty.

v) If the velocity of wind is more than 24 km/h.

3) Minor touch-up repair applications should be carried out using brushes. While using brushes more

coats will be required in order to achieve specified DFT.

4) Airless spraying during windy conditions may promote dry- spray formation and uneven thickness. If

a situation may arise it should be rectified prior to following coat application. Site HSE rules has to

be followed.

5) All coating works has to be carried out according to the project specifications and instructions stated

in technical data sheets and Application Guide of the products.

6) Applicators and all related parties are fully responsible to follow all information stated in TDS and

Application Guide documents of the products stated in the paint systems.

7) Depending on site conditions different situations which are not stated in this procedure may occur

during application operations, if such a situation may arise it will be evaluated additionally.

8) Weld fumes to be removed by Fresh water washing.

7. ATTACHMENTS AND TEMPLATES

TEMPLATES NAME REVISION

(FORMS)CODE

IF-PAI-100 Daily Ambient Conditions Record Form 0

IF-PAI-111 Paint Application Inspection Report 3

This document is the property of TSGI Mühendislik İnşaat Limited Company. Its reproduction without a written permission is strictly forbidden.

000-A-EE-0190029_Tmp.05 Document Template

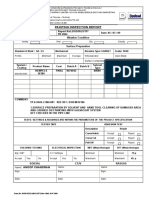

OWNER CONTRACT UNIT

STAR RAFINERI A.S. (STAR) STAR-C-01 XXX

PROJECT QC CODE

AEGEAN REFINERY PROJECT (ARP)

DOCUMENT TITLE N°

SITE QUALITY CONTROL PAINTING AND COATING DATE: _____________

Construction organization PLAN

DAILY AMBIENT CONDITIONS RECORD FORM

Ambient Relative Dew Point Steel Surface

Working Shift Period Time Temperature (0C) Humidity (%Rh) Temperature (0C) Temperature (0C)

START

MID-POINT

END

START

MID-POINT

END

START

MID-POINT

END

START

MID-POINT

END

START

MID-POINT

END

START

MID-POINT

END

START

MID-POINT

END

START

MID-POINT

END

START

MID-POINT

END

NOTES: INSPECTION NOTIFICATION REFERENCE

NFI No.:

CONSTRUCTION ORGANIZATION CONTRACTOR OWNER / PMC REPRESENTATIVE

NAME NAME NAME

SIGNATURE SIGNATURE SIGNATURE

Date Date Date

Form Code: IF-PAI-100_Rev.0

Code: 000-A-EE-0190420-R3 Page 9 of 13

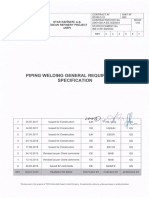

OWNER CONTRACT UNIT

STAR RAFINERI A.S. (STAR) STAR-C-01 XXX

PROJECT QC CODE

AEGEAN REFINERY PROJECT (ARP)

DOCUMENT TITLE N°

SITE QUALITY CONTROL PAINTING AND COATING DATE: _____________

Construction organization PLAN

PAINT APPLICATION INSPECTION REPORT

CODE/SPECIFICATION IDENTIFICATION OF MONITORING AND MEASURING DEVICES

Surface Profile (Roughness) Gauge_____________________ DFT Gauge:______________________________

Paint System : ____________________________ Primer Intermediate Top Coat Repair / Touch-up

Paint Brand Name: _______________________ Colour: ____________ Batch No.: ______________ Manufacture Date: _______________

Thinner Brand Name: _________________________ Batch No.: _______________________ Manufacture Date: ____________________

PAINTING APPLICATION & AMBIENT CONDITION

Application by: Brush/ Roller Conventional (Air) Spray Airless Spray Nozzle Size: _________ Pressure: _________

Ambient Relative Dew Point Steel Surface

Working Shift Period Time Temperature (0C) Humidity (%Rh) Temperature (0C) Temperature (0C)

START

MID-POINT

END

SURFACE PREPARATION

Abrasive Brand: _____________________ Abrassive Type & Size:___________________ Abrassive Batch No.:__________________

Cleaning Method: Blasting Hand Tool Cleaning Power Tool Cleaning

Blasting Nozzle Pressure ____________ Blasting Nozzle Orifice Size _____________ Blasting Air Cleanliness Test_________________

Surface Cleanliness: Sa 2 ½ / SSPC SP 10 St 2 / SSPC SP 2 St 3 / SSPC SP 3 Sweep Blast / SSPC SP 7

Surface Condition: Visual Check_____________ Roughness____________(µm) Chloride Test Result ________________

PAINT THICKNESS CHECK (See Notes Below)

DFT

DFT Req. DFT Actual (µm) Result

Drawing/ ISO/ Area Item/ Spool Average

(µm)

1 2 3 4 5 (µm) Accept Reject

NOTES: INSPECTION NOTIFICATION REFERENCE

Minimum of 5 separate spot measurements (average of 3 gage readings for each spot) spaced

NFI No.:

randomly over each 10m² (100ft²) to be measured.

CONSTRUCTION ORGANIZATION CONTRACTOR OWNER / PMC REPRESENTATIVE

NAME NAME NAME

SIGNATURE SIGNATURE SIGNATURE

Date Date Date

Form Code: IF-PAI-111_Rev.3

Code: 000-A-EE-0190420_R3

Page 12 of 14

Вам также может понравиться

- 000 A Ee 0230028 513 R0Документ13 страниц000 A Ee 0230028 513 R0onur gunesОценок пока нет

- Paint SPECIFICATIONSДокумент21 страницаPaint SPECIFICATIONSonur gunes100% (1)

- 000-A-Ee-0190470 Rev1 Painting Repair ProcedureДокумент34 страницы000-A-Ee-0190470 Rev1 Painting Repair Procedureonur gunes100% (2)

- Paint Coating Stainless SteelsДокумент2 страницыPaint Coating Stainless SteelsSilva NumaОценок пока нет

- SOP - 07 - Sand Blasting - Painting ProcedureДокумент66 страницSOP - 07 - Sand Blasting - Painting ProcedureSuci Yatiningtiyas100% (1)

- Surface Preparation and Painting Procedure Rev 01 PDFДокумент23 страницыSurface Preparation and Painting Procedure Rev 01 PDFNaceur Turki100% (3)

- Inar Profiles Pvt. LTD., Kotturu, Industrial Area, Visakhapatnam, Andhrapradesh, IndiaДокумент14 страницInar Profiles Pvt. LTD., Kotturu, Industrial Area, Visakhapatnam, Andhrapradesh, IndiaSreedhar Patnaik.MОценок пока нет

- Painting Procedure NG SystemsДокумент6 страницPainting Procedure NG SystemsTanveer Rajput EngrОценок пока нет

- (AL Shabab) : Painting Procedure P-04Документ12 страниц(AL Shabab) : Painting Procedure P-04Omar Nabil80% (5)

- NPK 000 N1 GS 6001 K Rev 3 Spesification For Painting and CoatingДокумент33 страницыNPK 000 N1 GS 6001 K Rev 3 Spesification For Painting and CoatingDangolОценок пока нет

- Daily Consumed Productive Hours: Job No: MRT-FRM-304-109 Responsible Engineer: Saif Ullah KhanДокумент4 страницыDaily Consumed Productive Hours: Job No: MRT-FRM-304-109 Responsible Engineer: Saif Ullah KhanSUKhanОценок пока нет

- MNT - QC - BP - 001 Blasting & Painting ReportДокумент1 страницаMNT - QC - BP - 001 Blasting & Painting Reportsivagnanam sОценок пока нет

- Paint Inspection BasicДокумент6 страницPaint Inspection BasicmaddyОценок пока нет

- Blasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateДокумент3 страницыBlasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateLOPA THANDARОценок пока нет

- Marine and Protective Colour Card Tcm60 91091Документ2 страницыMarine and Protective Colour Card Tcm60 91091Trịnh Minh KhoaОценок пока нет

- COATING PROCEDURES AT A GLANCEДокумент10 страницCOATING PROCEDURES AT A GLANCENanang Cesc Utta100% (1)

- Pull Off Test ReportДокумент1 страницаPull Off Test ReportAhmedA.Hassan100% (1)

- Repair Touch-Up Paint ProcedureДокумент10 страницRepair Touch-Up Paint ProcedureLiyakathalikhan Shahjahan100% (1)

- Painting ProcedureДокумент8 страницPainting ProcedureSunday Paul50% (2)

- Pull-Off Test Report - PUB Pedestrian Bridge ProjectДокумент2 страницыPull-Off Test Report - PUB Pedestrian Bridge ProjectErin Williams100% (2)

- Attachment 5 - Painting and Coating System Including Colour CodeДокумент54 страницыAttachment 5 - Painting and Coating System Including Colour CodeVan Anh0% (1)

- 25 - Coating ProcedureДокумент12 страниц25 - Coating ProcedureMOHAMEDОценок пока нет

- CP Painting Revised SpecsДокумент57 страницCP Painting Revised SpecsanilnwaychalОценок пока нет

- ISO 9001, ISO 14001 & OHSAS 18001 Certified Product Data SheetДокумент3 страницыISO 9001, ISO 14001 & OHSAS 18001 Certified Product Data SheetHendri Dwi cahyonoОценок пока нет

- Exova Coating System Compliance StatementДокумент1 страницаExova Coating System Compliance StatementSaravan KumarОценок пока нет

- RasGas Onshore Expansion Project Painting Inspection ReportДокумент1 страницаRasGas Onshore Expansion Project Painting Inspection ReportRahul MoottolikandyОценок пока нет

- Blasting and Painting ProcedureДокумент24 страницыBlasting and Painting ProcedureEnabulele Osakpamwan100% (1)

- Blasting and Painting ProcedureДокумент6 страницBlasting and Painting Procedureanon_994898767Оценок пока нет

- Blasting & Painting ProcedureДокумент10 страницBlasting & Painting ProcedurepraksahОценок пока нет

- Painting ReportДокумент2 страницыPainting ReporthikmahОценок пока нет

- Surface Preparation and PaintingДокумент4 страницыSurface Preparation and PaintingSimbu ArasanОценок пока нет

- Coating Specification PAM EC 50 SP 001 1AДокумент43 страницыCoating Specification PAM EC 50 SP 001 1ADavid Ricardo Diaz0% (1)

- Painting ReportДокумент1 страницаPainting Reportbaidu1980Оценок пока нет

- Procedure for holiday testingДокумент2 страницыProcedure for holiday testingSaptarshi MandalОценок пока нет

- AV650 Petrochemical Fireproofing Application MethodДокумент4 страницыAV650 Petrochemical Fireproofing Application MethodNizarHamrouniОценок пока нет

- CPVC ChecklistДокумент1 страницаCPVC Checklistchakravarthi kanugulaОценок пока нет

- Prorox WM 960 Sa PDFДокумент1 страницаProrox WM 960 Sa PDFr afriantoОценок пока нет

- Standard Specification FOR Pipeline Internal CoatingДокумент2 страницыStandard Specification FOR Pipeline Internal CoatingRanjan KumarОценок пока нет

- Form Sandblast & Painting ReportДокумент3 страницыForm Sandblast & Painting ReportKMPE Div PPICОценок пока нет

- BlastpaintДокумент12 страницBlastpaintdeje1726Оценок пока нет

- Itp Internal CoatingДокумент4 страницыItp Internal CoatingkamlОценок пока нет

- Abrasive Sand-Blasting Procedure PDFДокумент5 страницAbrasive Sand-Blasting Procedure PDFEko Kurniawan100% (5)

- Daily Painting Report System P 01ndДокумент49 страницDaily Painting Report System P 01ndArung IdОценок пока нет

- Site Paint Repair Procedure IntumescentДокумент4 страницыSite Paint Repair Procedure Intumescentrimshadtp100% (3)

- Surface Preparation StandardsДокумент3 страницыSurface Preparation StandardsReyhand SaveroОценок пока нет

- SA MP LE: Company NameДокумент4 страницыSA MP LE: Company NameAnonymous P8XHEXyIZLОценок пока нет

- UG PIPING COATINGДокумент10 страницUG PIPING COATINGcloud23Оценок пока нет

- Comparison of SSPC PA2 and ISO-19840 - DFT Verification Method and Acceptance CriteriaДокумент5 страницComparison of SSPC PA2 and ISO-19840 - DFT Verification Method and Acceptance Criteriarajali18Оценок пока нет

- Method Statement Installation Os Static Equipment and InternalsДокумент24 страницыMethod Statement Installation Os Static Equipment and InternalsAjin SОценок пока нет

- Objective 2. Reference Documents 3. Procedure 4. Painting System 5. Inspection 6. Repairs 7. Safety AnnexuresДокумент11 страницObjective 2. Reference Documents 3. Procedure 4. Painting System 5. Inspection 6. Repairs 7. Safety AnnexuresChethanОценок пока нет

- 022 Painting Spec (A)Документ8 страниц022 Painting Spec (A)sravan_kits929Оценок пока нет

- Swiss International LLCДокумент4 страницыSwiss International LLCBurning TrainОценок пока нет

- How To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-3) Welding & NDTДокумент5 страницHow To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-3) Welding & NDTVKT TiwariОценок пока нет

- Painting Procedure: Doc. No.: PLP-PAINT-P001Документ9 страницPainting Procedure: Doc. No.: PLP-PAINT-P001คุณพ่อน้อง บิ๊กบอสОценок пока нет

- BLASTING AND PAINTING PROCEDUREДокумент9 страницBLASTING AND PAINTING PROCEDUREAhmad FadlullahОценок пока нет

- Method Statement For Paint Repair Procedure For Piping PDF FreeДокумент16 страницMethod Statement For Paint Repair Procedure For Piping PDF Freeumuhuza salomonОценок пока нет

- Engineer'S Stamp: Contractor'S Stamp:: Al Qunfudhah New City Feeder Water Transmission SystemДокумент45 страницEngineer'S Stamp: Contractor'S Stamp:: Al Qunfudhah New City Feeder Water Transmission SystemUmar ShehzadОценок пока нет

- Welding and Heat Treatment Requirements For Equipment and PipingДокумент34 страницыWelding and Heat Treatment Requirements For Equipment and Pipingonur gunesОценок пока нет

- S 000 13A0 102 Wrapping and CoatingДокумент17 страницS 000 13A0 102 Wrapping and CoatingMidhun K Chandrabose100% (1)

- KNPC tank cleaning and painting proceduresДокумент10 страницKNPC tank cleaning and painting proceduresMohamed RizwanОценок пока нет

- Guide to Protective Coatings: Inspection and MaintenanceДокумент118 страницGuide to Protective Coatings: Inspection and MaintenanceAnilkumar Gurram100% (1)

- Resimlerle Ingilizce Fiilleri Ezberle Ogren PDFДокумент86 страницResimlerle Ingilizce Fiilleri Ezberle Ogren PDFonur gunesОценок пока нет

- Resimlerle Ingilizce Fiilleri Ezberle Ogren PDFДокумент86 страницResimlerle Ingilizce Fiilleri Ezberle Ogren PDFonur gunesОценок пока нет

- Fire Protection and Safety Facilities SpecificationДокумент41 страницаFire Protection and Safety Facilities Specificationonur gunesОценок пока нет

- Fire Protection and Safety Facilities SpecificationДокумент41 страницаFire Protection and Safety Facilities Specificationonur gunesОценок пока нет

- Steel Structures - GeneralДокумент16 страницSteel Structures - Generalonur gunesОценок пока нет

- 3 Specification Stgps n2 Revision 4 FireproofingДокумент24 страницы3 Specification Stgps n2 Revision 4 Fireproofingonur gunesОценок пока нет

- Outside Coating and Wrapping For Ug PipesДокумент7 страницOutside Coating and Wrapping For Ug Pipesonur gunesОценок пока нет

- Basis of Design Flow Level and Weight Measurements For..Документ26 страницBasis of Design Flow Level and Weight Measurements For..onur gunesОценок пока нет

- Basis of Design Cooling WaterДокумент26 страницBasis of Design Cooling Wateronur gunes100% (1)

- Steel Structures - GeneralДокумент16 страницSteel Structures - Generalonur gunesОценок пока нет

- Welding and Heat Treatment Requirements For Equipment and PipingДокумент34 страницыWelding and Heat Treatment Requirements For Equipment and Pipingonur gunesОценок пока нет

- Norsok Material Data Sheet (M-630r2)Документ77 страницNorsok Material Data Sheet (M-630r2)karuna346Оценок пока нет

- Coating Inspection Practices: Wilko Paint, IncДокумент41 страницаCoating Inspection Practices: Wilko Paint, Incdarko kojoОценок пока нет

- Fire Protection and Safety Facilities SpecificationДокумент41 страницаFire Protection and Safety Facilities Specificationonur gunesОценок пока нет

- 000 A EE 0230005 514 Rev0 PDFДокумент18 страниц000 A EE 0230005 514 Rev0 PDFonur gunesОценок пока нет

- 000 A Ee 0020004Документ43 страницы000 A Ee 0020004onur gunesОценок пока нет

- 000 N EE 0020003 Rev1 Acoustic Insulation SpecificationДокумент18 страниц000 N EE 0020003 Rev1 Acoustic Insulation Specificationonur gunesОценок пока нет

- Static Equipment Installation SpecificationДокумент17 страницStatic Equipment Installation Specificationonur gunes100% (2)

- 000 A Ee 0020004Документ43 страницы000 A Ee 0020004onur gunesОценок пока нет

- Electrical InstallationДокумент60 страницElectrical Installationonur gunes100% (1)

- 000 A EE 0230005 514 Rev0 PDFДокумент18 страниц000 A EE 0230005 514 Rev0 PDFonur gunesОценок пока нет

- Job Specification 126158-82A3 Insulation of Coke DrumДокумент104 страницыJob Specification 126158-82A3 Insulation of Coke Drumonur gunes50% (2)

- 000-A-Ee-0020009 r.3 - Hot Insulation SpecificationДокумент75 страниц000-A-Ee-0020009 r.3 - Hot Insulation Specificationonur gunes100% (1)

- Industrial Wire Cutting Machine: A Senior Capstone Design ProjectДокумент17 страницIndustrial Wire Cutting Machine: A Senior Capstone Design ProjectTruta IonutОценок пока нет

- Planning GPS Data Collection: Software Is Provided On The TEC7133 CD-ROM. You Can Also Download ThisДокумент5 страницPlanning GPS Data Collection: Software Is Provided On The TEC7133 CD-ROM. You Can Also Download ThisDoniansyah Mai PutraОценок пока нет

- Ichiban Ushiro No Daimaou Act 7Документ161 страницаIchiban Ushiro No Daimaou Act 7Haif Al HajrafОценок пока нет

- Karnaugh MapsДокумент7 страницKarnaugh Mapsdigitales100% (1)

- Organizational Structure and ProfilesДокумент178 страницOrganizational Structure and ProfilesImran Khan NiaziОценок пока нет

- BMED148 Assessment 1Документ5 страницBMED148 Assessment 1ROMEL ALJUN TARROBALОценок пока нет

- George B Dantzig PDFДокумент19 страницGeorge B Dantzig PDFKeith BoltonОценок пока нет

- Mains Junior Assistant GSMA - 232021Документ81 страницаMains Junior Assistant GSMA - 232021RaghuОценок пока нет

- 3.dummy VariablesДокумент25 страниц3.dummy VariablesUnushka ShresthaОценок пока нет

- Chapter 3Документ12 страницChapter 3Raymond LeoОценок пока нет

- Elliptical Head Design ToolДокумент1 страницаElliptical Head Design ToolssierroОценок пока нет

- Laboratory Activity No. 01 - Properties of LiquidДокумент2 страницыLaboratory Activity No. 01 - Properties of LiquidCzarina Relleve0% (1)

- Big Data Analytics and Artificial Intelligence inДокумент10 страницBig Data Analytics and Artificial Intelligence inMbaye Babacar MBODJОценок пока нет

- Even Sem - Odd Sem - MD MS - MA, MSC, MCom - Previous - Final Main Exam Result 2021 - Mahatma Jyotiba Phule Rohilkhand UniversityДокумент2 страницыEven Sem - Odd Sem - MD MS - MA, MSC, MCom - Previous - Final Main Exam Result 2021 - Mahatma Jyotiba Phule Rohilkhand UniversityprashantОценок пока нет

- Systems Analyst Interview Questions GuideДокумент3 страницыSystems Analyst Interview Questions GuidehassanshoaibОценок пока нет

- ISO/TC 46/SC 9/working Group 1Документ4 страницыISO/TC 46/SC 9/working Group 1João Paulo CésarОценок пока нет

- 268US03 Oiltech Technical & Product Catalogue Letter WДокумент48 страниц268US03 Oiltech Technical & Product Catalogue Letter WMauricio CarestiaОценок пока нет

- Reliance - Formulas & Calculations PDFДокумент5 страницReliance - Formulas & Calculations PDFkrishbistОценок пока нет

- Discrete Math Assignment on Recurrence Relations, Graph Theory and Boolean AlgebraДокумент6 страницDiscrete Math Assignment on Recurrence Relations, Graph Theory and Boolean AlgebralakkajaoОценок пока нет

- Mahusay Module 4 Acc3110Документ2 страницыMahusay Module 4 Acc3110Jeth MahusayОценок пока нет

- C ProgДокумент29 страницC ProgaishwaryaОценок пока нет

- Katsina Polytechnic Lecture Notes on History and Philosophy of Science, Technology and MathematicsДокумент33 страницыKatsina Polytechnic Lecture Notes on History and Philosophy of Science, Technology and MathematicsHamisu TafashiyaОценок пока нет

- Four Ball EPДокумент5 страницFour Ball EPu4sachinОценок пока нет

- Independent University, Bangladesh: Term Paper (Group Assignment)Документ16 страницIndependent University, Bangladesh: Term Paper (Group Assignment)Johan Tausifur RahmanОценок пока нет

- Activities For Responding To Reading in Year 2Документ59 страницActivities For Responding To Reading in Year 2lancashireliteracy100% (1)

- ECOSYS FS-2100D Ecosys Fs-2100Dn Ecosys Fs-4100Dn Ecosys Fs-4200Dn Ecosys Fs-4300Dn Ecosys Ls-2100Dn Ecosys Ls-4200Dn Ecosys Ls-4300DnДокумент33 страницыECOSYS FS-2100D Ecosys Fs-2100Dn Ecosys Fs-4100Dn Ecosys Fs-4200Dn Ecosys Fs-4300Dn Ecosys Ls-2100Dn Ecosys Ls-4200Dn Ecosys Ls-4300DnJosé Bonifácio Marques de AmorimОценок пока нет

- Maintenance Procedure For Switchyard Equipment Volume-II (EHДокумент39 страницMaintenance Procedure For Switchyard Equipment Volume-II (EHbisas_rishiОценок пока нет

- SPMPДокумент39 страницSPMPAnkitv PatelОценок пока нет

- A2 Slot CAT2 QPДокумент1 страницаA2 Slot CAT2 QPSeverus SnapeОценок пока нет

- Off-Highway 6600 Series Transmission SpecsДокумент2 страницыOff-Highway 6600 Series Transmission SpecsIng Dimatiguz0% (1)