Академический Документы

Профессиональный Документы

Культура Документы

P250024S1020 - HPS Post Insulator PDF

Загружено:

Yanuar WidyarsaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

P250024S1020 - HPS Post Insulator PDF

Загружено:

Yanuar WidyarsaАвторское право:

Доступные форматы

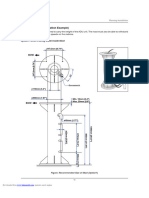

Vertical Line Post Insulators

2.5” (63.5 mm) Rod Diameter

Maximum Design Tension = 2,500 lbs. (11.1 kN)

0.6875’’ Dia. (17 mm ) 5” Dia. Bolt Circle

(127 mm)

11’’

(279 mm)

0.8125’’ Dia.

(21 mm)

Section Length

8’’

(203 mm)

0.9375’’ Dia.

(24 mm)

4’’

(102 mm)

4.125’’ 4.125’’

(105 mm) (105 mm) 0.8125’’ Dia.

(21 mm)

8’’

(203 mm)

1.125’’

(29 mm)

0.8125’’ x 1” Slot 3.875’’ 3.875’’

(21 mm x 25 mm) (98 mm) (98 mm)

Cat. No. 75115

Rated 134,400 lb.-in.

Vertical Line Post Insulators

2.5” (63.5 mm) Rod Diameter

ANSI Values IEC Values

Selection Guide: Nominal Section Strike Leakage (2)

60-Hz (2)Impulse (2)Impulse

(2) (2) (2) (2)

Typical Line Catalog Polymer Length Distance Distance 60-Hz 60-Hz Critical Critical SCL lbs.

1-minute Positive Negative

Voltage, kV(1) Numbers(3) Length inches inches inches Dry Wet Impulse Impulse (kN)

Wet Withstand Withstand

inches (mm) (mm) (mm) Flashover Flashover Positive Negative

Withstand (kV) (kV)

(kV) (kV) (kV) (kV)

69 110 132 161 (kV)

P250024S2050 024 35.0 (889) 25.0 (635) 63 (1600) 255 235 385 505 195 365 475 5000 (22.3)

P250026S2050 026 37.4 (950) 27.4 (696) 69 (1753) 280 255 425 540 215 400 510 5000 (22.3)

P250031S2050 031 42.3 (1074) 32.2 (818) 82 (2083) 330 300 510 615 255 480 580 4200 (18.7)

P250036S2050 036 47.1 (1196) 37.1 (942) 95 (2413) 380 345 580 690 290 550 655 3720 (16.6)

P250043S2050 043 54.4 (1382) 44.3 (1125) 113 (2870) 455 405 700 800 340 665 760 3180 (14.2)

P250048S2050 048 59.2 (1504) 49.2 (1250) 126 (3200) 515 450 770 880 380 730 835 2900 (12.9)

P250053S2050 053 64.1 (1628) 54.0 (1372) 139 (3531) 565 495 855 950 420 810 900 2660 (11.8)

P250058S2050 058 68.9 (1750) 58.8 (1494) 151 (3835) 600 525 920 1025 445 870 970 2460 (10.9)

P250060S2050 060 71.3 (1811) 61.3 (1557) 158 (4013) 625 540 955 1065 455 905 1010 2370 (10.5)

Notes:

1) For voltages above 161 kV, other section lengths, or end fitting combinations, please contact your HPS representative.

2) Electrical values are without corona ring. For voltages equal to or greater than 220 kV, refer to page 20 for corona rings and associated

physical/electrical changes to the above data. Dimensions are within allowable tolerances as specified by IEC 61952 and ANSI C29.17.

3) The catalog number shown on the table is for a 2.5” (63.5mm) rod diameter line post with a vertical clamptop on the line end and a 5’’ Bolt

Circle with tapped holes on the ground end. For other end fitting combinations, please refer to the Catalog Number Key on page 8.

page 22 January 2011

CATALOG NUMBER KEY

The Quadri*Sil ® Insulators Numbering Scheme is organized according to a smart numbering system. Each group of digits defines a

characteristic of the product you are ordering. To fill out this form, start on “a: Insulator Type.” Then, fill in your selection in the box

corresponding to the letter “a.” Apply the same rule for all the other sections.

a Insulator Type P — Post or S — Suspension d Weathershed Profile

Suspension

a) Insulator Type. Defines your insulator type: Post or Suspension.

Select “P” or “S” for Post or Suspension, respectively, and fill in your S — Standard Leakage Distance (2.5)

selection in the box designated for “a.” In this example, we selected a H — High Leakage Distance (2.9 or 3.3)

suspension insulator.

Post

S S — Standard Leakage Distance

d) Weathershed Profile. Defines the leakage distance design. For a suspension

insulator with standard leakage distance, use “S.” For a suspension insulator

with high leakage distance, use “H.” For a line post, only the standard leakage

b Mechanical Strength

distance design is available. Fill in your selection in the box designated for “d.”

For example, if you want an insulator with high leakage distance, you would

Suspension (SML), Rod Diameter

place an “H” in the box designated “d.”

025 — 25 kip, 5/8” (16 mm)

030 — 30 kip, 5/8” (16 mm)

050 — 50 kip, 7/8” (22 mm) S 0 2 5 0 4 9 H

120 — 120 kN, 5/8” (16 mm)

160 — 160 kN, 7/8” (22 mm)

210 — 210 kN, 7/8” (22 mm)

Post

e Top Fitting

250 — Series 250, standard strength 2.5”,

(63.5 mm)

Suspension Insulators

Suspension Insulators LineLine

PostPost Insulators

Insulators

0 — Chain Eye 0 — Tear Drop Blade

b) Strength. Defines the mechanical strength of your insulator. Fill in your

selection in the boxes designated for “b.”

1 — ANSI Ball 1 — Horizontal Clamptop

Note: kip = Kilopound, kN = Kilonewton

2 — Y-Clevis 2 — Vertical Clamptop

For example, if you want a Suspension insulator with 25 kip, this is what

your form would look like so far:

3 — ANSI Socket 3 — 5” (127 mm) Bolt Circle

5/8” (16 mm) Tapped Hole

4 — ANSI Straight Clevis

S 0 2 5 5 — 5” (127 mm) Bolt Circle

7 — IEC Ball Fitting 5/8” (16 mm) Through Hole

16 mm for 120 kN

20 mm for 160 kN and 210 kN 9 — Long Tear Drop Blade

c Polymer Length 8 — IEC Straight Clevis

3 digits for distance between metal A — IEC Socket

parts, in inches 16 mm for 120 kN

20 mm for 160 kN and 210 kN

c) Polymer Length. Defines the polymer length of the insulator (please use

catalog tables for possible polymer lengths). Fill in your selection in the boxes

designated for section “c.” For example, if you want a 49-inch polymer length,

enter:

e) Top Fitting. Defines the top end fitting of your insulator. Fill in your

S 0 2 5 0 4 9 selection in the box designated for “e.” For example, if you want a

suspension insulator with a Y-clevis top end fitting, you would place a

“2” in the box designated for “e.”

S 0 2 5 0 4 9 H 2

page 8 January 2011

Вам также может понравиться

- Q4622443 - HydacДокумент4 страницыQ4622443 - HydacSofanuddin vyanОценок пока нет

- 4X Leveling Pad Pin Dimension: Electrical Connection Air Connection 1 2Документ3 страницы4X Leveling Pad Pin Dimension: Electrical Connection Air Connection 1 2Edwin RodríguezОценок пока нет

- 6X Leveling Pad Pin Dimension: Electrical Connection Air Connection 1 2Документ3 страницы6X Leveling Pad Pin Dimension: Electrical Connection Air Connection 1 2Pablo PillajoОценок пока нет

- Xa 310850BДокумент1 страницаXa 310850BBenny YacilaОценок пока нет

- RD 5700 SpecificationsДокумент6 страницRD 5700 SpecificationsGomathi sankarОценок пока нет

- Datasheet of DS 1276ZJ SUS Black 20190108Документ1 страницаDatasheet of DS 1276ZJ SUS Black 20190108Klayton PiresОценок пока нет

- Dimension Guide W10356098 D WHДокумент2 страницыDimension Guide W10356098 D WHjvargas.satelОценок пока нет

- Reach Truck Rr5700 Profile SheetДокумент5 страницReach Truck Rr5700 Profile SheetMA TotalforkliftОценок пока нет

- RR 5700 Profile SheetДокумент8 страницRR 5700 Profile SheetTRMОценок пока нет

- Dimension Guide W10445545B D MTДокумент2 страницыDimension Guide W10445545B D MTyukadooОценок пока нет

- M Profile SheetДокумент4 страницыM Profile SheetPrasanna RamanathanОценок пока нет

- RR 5700s SpecificationsДокумент8 страницRR 5700s SpecificationsRaymundo MartinezОценок пока нет

- Machine Layout Drawing - UMC-750/SS/P: Operating DimensionsДокумент5 страницMachine Layout Drawing - UMC-750/SS/P: Operating DimensionsBolek ŻmigrodzkiОценок пока нет

- Datasheet of DS 1276ZJ SUS - 20171201Документ1 страницаDatasheet of DS 1276ZJ SUS - 20171201Ngọc Lan Lê ThịОценок пока нет

- Monitor Stryker 26 PLGДокумент28 страницMonitor Stryker 26 PLGBrandon MendozaОценок пока нет

- DS-1275ZJ-SUS Bracket PoleДокумент1 страницаDS-1275ZJ-SUS Bracket PoleDILMER JAVIERОценок пока нет

- 0.375" (9.5 MM) 5.000" (127.0 MM)Документ1 страница0.375" (9.5 MM) 5.000" (127.0 MM)Angel Sebastian Paz RocaОценок пока нет

- KB100-st - TD CAMBIADORДокумент3 страницыKB100-st - TD CAMBIADORarquiashОценок пока нет

- Sav9D DC CCTV Power Supply: (0.55 Amp Per Device, 2.5 Amp Max.)Документ2 страницыSav9D DC CCTV Power Supply: (0.55 Amp Per Device, 2.5 Amp Max.)Tas DtОценок пока нет

- 6.1. Single Panel Enclosure - JT-ENC1PДокумент1 страница6.1. Single Panel Enclosure - JT-ENC1PThái Dương Trà100% (1)

- VF-7-50 Rev EДокумент1 страницаVF-7-50 Rev EmarhiОценок пока нет

- AL300PD4220 Multi-Output Power Supply/ChargerДокумент2 страницыAL300PD4220 Multi-Output Power Supply/Chargeralberto quispe aliagaОценок пока нет

- FB0258SolarBrochure 070715Документ6 страницFB0258SolarBrochure 070715charithaОценок пока нет

- Power Supply AltronixДокумент2 страницыPower Supply AltronixTas DtОценок пока нет

- 400B Product Guide ImperialДокумент20 страниц400B Product Guide ImperialChiheb BEN ABDALLAHОценок пока нет

- Architectural/Mechanical Product Specifications: 2500 State Road 44 - Oshkosh, Wi 54904 920.231.8222 - Fax 920.231.4666Документ2 страницыArchitectural/Mechanical Product Specifications: 2500 State Road 44 - Oshkosh, Wi 54904 920.231.8222 - Fax 920.231.4666Jose MartinОценок пока нет

- EC-1600ZT Machine Layout Drawing: For Machines Built After December 2019Документ3 страницыEC-1600ZT Machine Layout Drawing: For Machines Built After December 2019FelipeCamachoIbarraОценок пока нет

- RM 6000 RMD 6000: SeriesДокумент7 страницRM 6000 RMD 6000: SeriesNicolas ChauttaОценок пока нет

- Echorange SpecificationsДокумент4 страницыEchorange Specificationslich_tran01Оценок пока нет

- SHR 5500 SpecificationsДокумент6 страницSHR 5500 SpecificationsDM NaeemОценок пока нет

- AL600ULPD4 Multi-Output Power Supply/ChargerДокумент2 страницыAL600ULPD4 Multi-Output Power Supply/Chargeralberto quispe aliagaОценок пока нет

- EC-1600ZT Machine Layout Drawing: Haas Technical PublicationsДокумент3 страницыEC-1600ZT Machine Layout Drawing: Haas Technical PublicationsCraig WaxОценок пока нет

- 8X Leveling Pad Pin Dimension: Electrical Connection Air Connection 1 2Документ2 страницы8X Leveling Pad Pin Dimension: Electrical Connection Air Connection 1 2FelipeCamachoIbarraОценок пока нет

- Spec Sheet 7695000Документ1 страницаSpec Sheet 7695000ibnrafeeqОценок пока нет

- Crown Pc4500-Spec-SheetДокумент6 страницCrown Pc4500-Spec-SheetJONHHY NGUYEN DANGОценок пока нет

- Series 20 Weld HeadДокумент4 страницыSeries 20 Weld HeadKhyle Laurenz DuroОценок пока нет

- Neo-Flex Dual Display Lift Stand: Dimensional & Range of Motion IllustrationsДокумент1 страницаNeo-Flex Dual Display Lift Stand: Dimensional & Range of Motion IllustrationsErin FezellОценок пока нет

- Blue Seas Ammeter DiagramДокумент1 страницаBlue Seas Ammeter DiagramKyle EversОценок пока нет

- XA-310990 Colector Grua ViajeraДокумент1 страницаXA-310990 Colector Grua Viajeraduque_sadeОценок пока нет

- Rc45iii Cone Crusher SpecificationДокумент2 страницыRc45iii Cone Crusher SpecificationNet FlofiОценок пока нет

- ST-20Y Machine Views 2Документ1 страницаST-20Y Machine Views 2Abhishek VelagaОценок пока нет

- Dim Lxdualstacktall OrigДокумент3 страницыDim Lxdualstacktall OrigDavid NavaОценок пока нет

- Manual de Instruções JBL JS-120 (2 Páginas)Документ2 страницыManual de Instruções JBL JS-120 (2 Páginas)Sennin SennaОценок пока нет

- Combiner Combiner USB Gateway Data ConverterДокумент2 страницыCombiner Combiner USB Gateway Data Convertertoumassis_pОценок пока нет

- GCD15 Product GuideДокумент28 страницGCD15 Product Guideing.juantincoОценок пока нет

- v85nx Antenna InstallДокумент3 страницыv85nx Antenna Installsouthpoint.dooОценок пока нет

- ST-40 Machine ViewsДокумент1 страницаST-40 Machine ViewsAbhishek VelagaОценок пока нет

- Trbajo 040 LunesДокумент1 страницаTrbajo 040 LunesLAURA LYNCOLN ARUCUTIPA LLAVEОценок пока нет

- PEGSON - 'M' Series JAW Crusher (Curvas de Produccion) (+++)Документ8 страницPEGSON - 'M' Series JAW Crusher (Curvas de Produccion) (+++)Juan CarlosОценок пока нет

- Product Options Advantages: 5131 Cash Road Dallas, TX 75247 P 214.631.8070 F 214.631.3673 800.847.0380Документ2 страницыProduct Options Advantages: 5131 Cash Road Dallas, TX 75247 P 214.631.8070 F 214.631.3673 800.847.0380FREDDY YAJAMINОценок пока нет

- TMS 500 eДокумент18 страницTMS 500 ef22sdqk6bvОценок пока нет

- Kb110 Ssre TDДокумент3 страницыKb110 Ssre TDPradeepОценок пока нет

- C-6100-AC Cramer Hysteresis 11 09-2Документ2 страницыC-6100-AC Cramer Hysteresis 11 09-2Eng KapoОценок пока нет

- RM3U1913VBK: Section TT-TT UUДокумент1 страницаRM3U1913VBK: Section TT-TT UU123abcdefsdsdsdОценок пока нет

- Ah Ahcl1530pДокумент1 страницаAh Ahcl1530pJaime MartinОценок пока нет

- MegaStrip 9650 DS EN A4 V1Документ2 страницыMegaStrip 9650 DS EN A4 V1san nguyễn vănОценок пока нет

- 10-20 Belt Scale MT9101 8017.0113Документ4 страницы10-20 Belt Scale MT9101 8017.0113RickОценок пока нет

- Type Tower NO Tower: Waktu PelaksanaanДокумент34 страницыType Tower NO Tower: Waktu PelaksanaanYanuar WidyarsaОценок пока нет

- Initial Analysis, Planning and Calculation of Vertical Delivery in High-Rise Building ConstructionДокумент6 страницInitial Analysis, Planning and Calculation of Vertical Delivery in High-Rise Building ConstructionYanuar WidyarsaОценок пока нет

- Pt. Tehate Putratunggal List Material Tower Type AA+0Документ49 страницPt. Tehate Putratunggal List Material Tower Type AA+0Yanuar WidyarsaОценок пока нет

- GERGRGGRGДокумент3 страницыGERGRGGRGYanuar WidyarsaОценок пока нет

- VDVDFVДокумент3 страницыVDVDFVYanuar WidyarsaОценок пока нет

- Penting PDFДокумент1 страницаPenting PDFYanuar WidyarsaОценок пока нет

- Penting PDFДокумент1 страницаPenting PDFYanuar WidyarsaОценок пока нет

- Quadri PDFДокумент44 страницыQuadri PDFYanuar WidyarsaОценок пока нет

- KEMA ReportДокумент53 страницыKEMA ReportYanuar WidyarsaОценок пока нет

- EEEEEEEEEEEEEEEДокумент1 страницаEEEEEEEEEEEEEEEYanuar WidyarsaОценок пока нет

- P250024S1020 - HPS Post InsulatorДокумент2 страницыP250024S1020 - HPS Post InsulatorYanuar WidyarsaОценок пока нет

- The A. Hoen & Co Lithograph BuildingДокумент1 страницаThe A. Hoen & Co Lithograph BuildingFOX45Оценок пока нет

- Green Architecture A Sustainable Lifestyle in IloiloДокумент13 страницGreen Architecture A Sustainable Lifestyle in IloiloBenjie LatrizОценок пока нет

- HLF 10 Man TGL 12.250Документ2 страницыHLF 10 Man TGL 12.250Forum PompieriiОценок пока нет

- Heat Load For Guest Room (N&E)Документ1 страницаHeat Load For Guest Room (N&E)words4devОценок пока нет

- Copyreading and HWДокумент16 страницCopyreading and HWJenniferОценок пока нет

- BD9215AFVДокумент5 страницBD9215AFVYusuf Agustaf SatrianiОценок пока нет

- Catalytic PyrolysisДокумент7 страницCatalytic Pyrolysiseksilivut100% (1)

- Attachment - 2-Color Coding and Labeling: Identification & SizeДокумент6 страницAttachment - 2-Color Coding and Labeling: Identification & SizeAli RazaОценок пока нет

- Syllabus For Non Conventional Energy Systems: Faculty In-Charge: Category: Total Number of HoursДокумент63 страницыSyllabus For Non Conventional Energy Systems: Faculty In-Charge: Category: Total Number of HoursAdenKlatenОценок пока нет

- Maker Culture - WikipediaДокумент8 страницMaker Culture - Wikipediabarnblan2900Оценок пока нет

- Daewoo Piping Design PracticeДокумент120 страницDaewoo Piping Design Practicesmithwork100% (1)

- SM PC200, PC200LC-7Документ810 страницSM PC200, PC200LC-7caing92% (13)

- VicRoads Standard Drawings For Road SignsДокумент106 страницVicRoads Standard Drawings For Road Signsyyanan1118100% (1)

- Pieux Design Pile Foundation Following Eurocode 7 - R. Franck + Examples PDFДокумент19 страницPieux Design Pile Foundation Following Eurocode 7 - R. Franck + Examples PDFmichalakis483Оценок пока нет

- LCD TypesДокумент6 страницLCD Typesarianaa30Оценок пока нет

- Understanding Low-E CoatingsДокумент78 страницUnderstanding Low-E CoatingsRoland ArimadoОценок пока нет

- Em534mvi3 InstallationandoperatinginstructionsДокумент36 страницEm534mvi3 InstallationandoperatinginstructionscipyyyyОценок пока нет

- Hotronix Clam Hover Press Operators ManualДокумент12 страницHotronix Clam Hover Press Operators ManualJavi BuenoОценок пока нет

- Injection Pump R&RДокумент17 страницInjection Pump R&RMahdi Besbes100% (2)

- Handrail & Baluster DRAFT-1Документ2 страницыHandrail & Baluster DRAFT-1jijinjohnОценок пока нет

- Synthetic Fibers and PlasticsДокумент36 страницSynthetic Fibers and Plasticssanjayagrawal70-1100% (2)

- Book of Abstract - DeMII 2017Документ186 страницBook of Abstract - DeMII 2017GogyОценок пока нет

- Deutz - Block Load BF6M1013Документ2 страницыDeutz - Block Load BF6M1013Jayaprathap NithiyanandanОценок пока нет

- Fire Detection and Alarm Systems BS5839-1 +A2Документ16 страницFire Detection and Alarm Systems BS5839-1 +A2ipliprens100% (2)

- 05-2806a01-L-Mds Inet Series Ref ManДокумент173 страницы05-2806a01-L-Mds Inet Series Ref ManPedro Vives MelendezОценок пока нет

- Duffle Bag Sewing PatternДокумент12 страницDuffle Bag Sewing PatternAnne HuangОценок пока нет

- Tar TangДокумент143 страницыTar TangPradeepta PatraОценок пока нет

- Emerson FP-40R Charger PDFДокумент2 страницыEmerson FP-40R Charger PDFmartins73Оценок пока нет

- Soil Mechanics by Jumikis PDFДокумент825 страницSoil Mechanics by Jumikis PDFroberto86% (7)

- Affiliated Colleges de 2009-10Документ2 страницыAffiliated Colleges de 2009-10hardikjthakkarОценок пока нет