Академический Документы

Профессиональный Документы

Культура Документы

Cepu Fract. Project

Загружено:

sari susantiАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Cepu Fract. Project

Загружено:

sari susantiАвторское право:

Доступные форматы

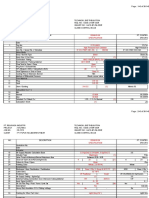

PT PERTAMINA EP ASSET 4 CEPU FIELD

RIG PROGRAM STIMULATION WELL ( FRACTURING )

BNP P1

OBJECTIVE : POOH FRACT STRING, RIH PRODUCTION STRING w/ 2-7/8" TUBING DATE : 00/11/2016

LOCATION : WONOCOLO

HISTORY : Last service..-...-2016 // Last Production Test .../.../...% at 00-Nov.-2016

TIME (HRS)

NO. PROCEDURE RIG 250 HP COST (USD) SNUBBING RIG COST (USD)

1 Moving rig equipment, R/U 100 %, Fuction test all rig System to ensure safe

condition for working, Pre-Job Safety meeting as well program, Hauled fresh 48 48

water 2 times hole volume to Rig tank and mixing sg ..... kill fluid

2 Ensure TP / CP, Observe preventer equipment, casing valve and master valve

working properly 2 2

3 S/I well (close poor boy), R/D temporary production line, R/U circulation line to

poor boy and casing valve, Fill full circulation line with kill fluid. P/T line until 2

times working pressure of well job,must good ( record and Report P/T result to 4 4

office)

4 Ensure clean area for R/U CTU position 3 3

5 R/U line from Rig pump to CT tank , P/T line if neccessary 2 2

6 R/D circulation line at Poor boy, R/U lubricator & M/U Connection Flow tee CT

to Rig tank through MGS, R/U CT BOP, P/T CT BOP until 2 times working

pressure of well job, must good ( record and Report P/T result to office), R/U 3 3

CT Injector

8 M/U & RIH drift test as 2.4" OD x 3 ft length + x/o with CT to 434 mMD, POOH

same string to surface ( observe load sensors CT while RIH and POOH)

note : - Drifted to ensure clearance between Inflatable Packer to ID Fract string

- Open casing valve and flow tee during RIH CT

- Observe and treatment kill fluid in mud tank during job 3.66 3.66

9 M/U & RIH Inflatable Packer +running tool + x/o with CT to 1212 mMD EOS

( observe load sensors CT while running), set inflatable packer, release

running tool @ inflatable packer, POOH CT f/ 1212 m MD to 1205 mMD,

straight Circulate until clean, P/T Casing ....psig/15 min must good , POOH CT 11.31 11.31

to surface, R/D Injector + BOP CT+ Lubricator + Flow tee

10 POOH & L/D fract string as 40- 3-1/2" DP+ 6-4-3/4 DC + 7" Packer f/ 434,41

mKB EOS to surface 6.67 13.67

11 M/U 1-2-7/8" tubing as tail pipe + 7" packer RIH w/ 96-2-7/8" tubing to 900

mKB 4.2 11.67

12 Set paker w/ 10 klbs compress or tension @ 890 mKB , EOS @ 900 mKB, P/T

annulus w/ 500 psig/10' must good 1 1

13 N/D BOP stack, N/U X-mastree and production line

6 6

14 M/U & RIH running tool + x/o with CT to 1212 mMD, latch inflatable packer @

1212 mMD, POOH running tool to surface ( observe load sensors CT while

POOH), 9.31 9.31

note :if possible : - re-set & leave inflatable packer @ 1240 mMD

- unload kill fluid if needed w/ N2 while POOH CT.

15 R/D CTU completed 3 3

16 Rig released, R/D RIG Mast and Equipment completed, MOSR 48 48

Estimate Sub-Total Time & Cost 104.15 0.00 169.62 0.00

Fuel (USD 1.00 / L) 1952.83 1952.83 3180.33 3,180.33

Well site Supervision (USD 5.00 / HRS) 104.15 520.76 169.62 848.09

Estimate Total Cost (USD) 2473.59 4,028.42

Well & Job Hazard :

* Prepare well control plan if sign of kick happened. (Well intermittent flow when POOH & RIH tubular string

please monitor SITP & SICP, pump filtered completion fluid to fill up well)

* High formation pressure .... Psia ( est.)

Prepared By Reviewed By Reviewed By Approved By

Ario Adimir Fibarata

Ast Man Tek Prod PE Ast Man WOWS Ast Man Cepu Field Manager

CC : * RAM Ast Man Cepu Field

* HSSE Ast Man Cepu Field

* L&R Ast Man Cepu Field

* Prod Ops Ast Man Cepu Field

* SCM Ast Man Cepu Field

Вам также может понравиться

- Karcher Pressure Washer Parts and Basic Repair Service Manual Pump 785 HD2500G HD2500MTD HD2600DK HD2700DH HD2701DRДокумент17 страницKarcher Pressure Washer Parts and Basic Repair Service Manual Pump 785 HD2500G HD2500MTD HD2600DK HD2700DH HD2701DRt_zonne855750% (2)

- 01 - Drill 16'' Hole Section & POOHДокумент3 страницы01 - Drill 16'' Hole Section & POOHDrilling Engineering ChannelОценок пока нет

- Havila Clipper SpecificationДокумент4 страницыHavila Clipper SpecificationPriyanshu JoshiОценок пока нет

- Dokumen - Tips Coal Handling Plant 589be8a41d9eaДокумент29 страницDokumen - Tips Coal Handling Plant 589be8a41d9eaWasim MalkaniОценок пока нет

- A320 Ame Self ExaminationДокумент6 страницA320 Ame Self ExaminationKarwane MuntazireenОценок пока нет

- 793F Main SchematicДокумент13 страниц793F Main SchematicBrian CareelОценок пока нет

- FakinasolДокумент17 страницFakinasolmasgontarОценок пока нет

- Plano Sistema Vibracion CS78BДокумент2 страницыPlano Sistema Vibracion CS78BricsnikОценок пока нет

- Sulzer Centrifugal Pumps - Basic OperationДокумент26 страницSulzer Centrifugal Pumps - Basic OperationMarcelo PerettiОценок пока нет

- 13 38 in TP-194 (HAS-2) Cement Program V1Документ21 страница13 38 in TP-194 (HAS-2) Cement Program V1hakoubОценок пока нет

- BHEL Turbine ManualДокумент58 страницBHEL Turbine Manualnivasssv75% (4)

- Overview STG-BB Untuk KPДокумент56 страницOverview STG-BB Untuk KPJibraltar Amin SyamОценок пока нет

- Data Sheet CV-Sapphire PDFДокумент1 страницаData Sheet CV-Sapphire PDFthehoang12310Оценок пока нет

- Grundfos Pump Installation BookДокумент84 страницыGrundfos Pump Installation BookSujalsathwaraОценок пока нет

- Factsheet TurritellaДокумент2 страницыFactsheet TurritellaJeganeswaranОценок пока нет

- KARAM-10 Perforation ProgramДокумент7 страницKARAM-10 Perforation ProgramAhmed AliОценок пока нет

- LPBFP - Sizing Calculation LP HRSG Feed Pump - Doc PG DC 292 100 d603 - R 1Документ8 страницLPBFP - Sizing Calculation LP HRSG Feed Pump - Doc PG DC 292 100 d603 - R 1anbesivam87_49857255Оценок пока нет

- Precheck Before Light-Up: Drum Metal Temp. DiffДокумент12 страницPrecheck Before Light-Up: Drum Metal Temp. DiffAhemadОценок пока нет

- Turbine Main Engines: The Commonwealth and International Library: Marine Engineering DivisionОт EverandTurbine Main Engines: The Commonwealth and International Library: Marine Engineering DivisionРейтинг: 5 из 5 звезд5/5 (4)

- Superior Packer Setting ProceduereДокумент10 страницSuperior Packer Setting ProcedueretarangtusharОценок пока нет

- Procedure For Condenser Vacuum PullingДокумент4 страницыProcedure For Condenser Vacuum PullingPulkit AgarwalОценок пока нет

- Schlumberger Production Logging Tool ProgramДокумент3 страницыSchlumberger Production Logging Tool ProgramdoombuggyОценок пока нет

- Fast Reference: CompressorДокумент8 страницFast Reference: CompressorJUNFERNОценок пока нет

- Petronas Carigali Sdn. BHD.: Objective Programme (Routine Wireline)Документ2 страницыPetronas Carigali Sdn. BHD.: Objective Programme (Routine Wireline)Rick Raynold ClaudiusОценок пока нет

- Programa Completo Completacion InicialДокумент23 страницыPrograma Completo Completacion InicialAlejandro JaramilloОценок пока нет

- Job OrderДокумент9 страницJob OrderMayada AliОценок пока нет

- SLB COSL 223 Morning Report 11-Jul-2020) REV.01Документ2 страницыSLB COSL 223 Morning Report 11-Jul-2020) REV.01Jusman Van Sitohang100% (1)

- CE441 Class Lecture 06Документ23 страницыCE441 Class Lecture 06ASHJAEE MANSIB CHOWDHURYОценок пока нет

- GAME PLAN RTTS RBP Wellhead WorkДокумент1 страницаGAME PLAN RTTS RBP Wellhead WorkMohamed AbozeimaОценок пока нет

- Mom 509Документ7 страницMom 509Julinus PrioОценок пока нет

- 03-LEK-1050 Drill 12.25 Inch SectionДокумент4 страницы03-LEK-1050 Drill 12.25 Inch SectionDrilling Engineering ChannelОценок пока нет

- Casing Data Bit Data Mud Data: Hours RemarksДокумент8 страницCasing Data Bit Data Mud Data: Hours RemarksdiegoОценок пока нет

- DSQ PD HistoryДокумент22 страницыDSQ PD Historyeng20072007Оценок пока нет

- ZK082-03D - 16in Pre Section Meeting SheetДокумент16 страницZK082-03D - 16in Pre Section Meeting Sheetallammalke3Оценок пока нет

- Electrical Safety Pre-Survey QuestionnaireДокумент2 страницыElectrical Safety Pre-Survey QuestionnaireAbdul WahabОценок пока нет

- BIANCO Presentation PDFДокумент33 страницыBIANCO Presentation PDFnothing1aОценок пока нет

- Ds-Me-0018 - Mechanical Data Sheet For Overfill Prevention Valve (Rev.0)Документ2 страницыDs-Me-0018 - Mechanical Data Sheet For Overfill Prevention Valve (Rev.0)Panisa BanimaОценок пока нет

- Dwor#14 - Cosl-225 - Titi A-16 - 11 Jan 2024Документ1 страницаDwor#14 - Cosl-225 - Titi A-16 - 11 Jan 2024Surya FandanaОценок пока нет

- Job Order #21-13.375'' CSG Running JobДокумент2 страницыJob Order #21-13.375'' CSG Running JobAli RazaОценок пока нет

- AnnexureДокумент391 страницаAnnexureTommy ArjanggiОценок пока нет

- SLB COSL 223 Morning Report 12-Jul-2020) REV.01Документ2 страницыSLB COSL 223 Morning Report 12-Jul-2020) REV.01Jusman Van SitohangОценок пока нет

- Karam-12 Unsecuring ProgramДокумент2 страницыKaram-12 Unsecuring ProgramAhmed AliОценок пока нет

- Sailing Instruction (ps1 - Hhlo, HHHG, Hhok, Hhta, Hhny, HHCF) Tiw AddДокумент10 страницSailing Instruction (ps1 - Hhlo, HHHG, Hhok, Hhta, Hhny, HHCF) Tiw AddPaing Myint Zaw OoОценок пока нет

- Core Bit Run Report SBL-7Документ5 страницCore Bit Run Report SBL-7Miguel Chavez CocaОценок пока нет

- Pertamina Ep Asset 1 Field Ramba: Rig Operation ActivitiesДокумент2 страницыPertamina Ep Asset 1 Field Ramba: Rig Operation ActivitiesBayu Eko AriestaОценок пока нет

- CT Plug Cementing Program Stage 2Документ10 страницCT Plug Cementing Program Stage 2sidikkuntobОценок пока нет

- Oil and Natural Gas Corporation LTD.: Evening Drilling Reports DTD: 06Th November 2021 - 1800 HRS-MGRДокумент3 страницыOil and Natural Gas Corporation LTD.: Evening Drilling Reports DTD: 06Th November 2021 - 1800 HRS-MGRPrabha KaranОценок пока нет

- Halila Foresight SpecificationДокумент5 страницHalila Foresight SpecificationPriyanshu JoshiОценок пока нет

- SOC Alerada H13-6 MSI+MTI Logging Procedure TGT 03.11.2022 Rev2Документ11 страницSOC Alerada H13-6 MSI+MTI Logging Procedure TGT 03.11.2022 Rev2mohanedОценок пока нет

- Piping Pressure Drop and Pump Design Calculation Sheet: PT Ca Ltex Pacific IndonesiaДокумент3 страницыPiping Pressure Drop and Pump Design Calculation Sheet: PT Ca Ltex Pacific IndonesiaElias EliasОценок пока нет

- Activity: AZIM (Deg)Документ1 страницаActivity: AZIM (Deg)Naisee KilLОценок пока нет

- N2 Training ManualДокумент4 страницыN2 Training ManualAbderahmane DahiliОценок пока нет

- Compaq Prover - Rev - ABДокумент1 страницаCompaq Prover - Rev - ABPsa Metering RU II DumaiОценок пока нет

- Shift LogДокумент4 страницыShift LogRohith kumarОценок пока нет

- Quotation - Applied EngineeringДокумент3 страницыQuotation - Applied EngineeringAyie KhairiОценок пока нет

- Juno Lighting Price Book Trac-Master Distributor 6-76Документ4 страницыJuno Lighting Price Book Trac-Master Distributor 6-76Alan MastersОценок пока нет

- SLB STAR ONYX Barge Morning Report 1-Nov-2020) REV.01Документ2 страницыSLB STAR ONYX Barge Morning Report 1-Nov-2020) REV.01Jusman SitohangОценок пока нет

- 12.25 PlanДокумент2 страницы12.25 PlanAhmedОценок пока нет

- 04 GTP-M-PCE Part4Документ67 страниц04 GTP-M-PCE Part4Ramesh-NairОценок пока нет

- Energex Estimation GuideДокумент88 страницEnergex Estimation GuideCarl James GranadaОценок пока нет

- Case Study - Boiler ExplosionДокумент18 страницCase Study - Boiler ExplosionSatish ChavanОценок пока нет

- Basic Instrument Contol PFD P ID HAZOP 0Документ3 страницыBasic Instrument Contol PFD P ID HAZOP 0Ferdian AziziОценок пока нет

- EPC-1A Hot Tappings Post-Site-Visit Master 23nov2020Документ1 страницаEPC-1A Hot Tappings Post-Site-Visit Master 23nov2020Joseley D'souzaОценок пока нет

- Job Pertamina-Petrochina East Java: Wahdanadi, ErikДокумент2 страницыJob Pertamina-Petrochina East Java: Wahdanadi, Erikuli ulinuhaОценок пока нет

- Logbook Ctu 07 (Arif SB 2023) - 1Документ240 страницLogbook Ctu 07 (Arif SB 2023) - 1Arief Setia budiОценок пока нет

- Surface Well Testing - 2020408Документ6 страницSurface Well Testing - 2020408PrashantYadavОценок пока нет

- Activity: - Repeat Pass: 1600-1690 MMDДокумент1 страницаActivity: - Repeat Pass: 1600-1690 MMDNaisee KilLОценок пока нет

- Up MofДокумент32 страницыUp MofKrishitva R GowdaОценок пока нет

- DesignДокумент9 страницDesignNaresh NaniОценок пока нет

- CE 8403 Applied Hydraulic Engineering Assignment Question Unit-IvДокумент1 страницаCE 8403 Applied Hydraulic Engineering Assignment Question Unit-Ivmaran2326Оценок пока нет

- Steel Adapters Hydraulic Quick Disconnects Hydraulic Valves & AccessoriesДокумент54 страницыSteel Adapters Hydraulic Quick Disconnects Hydraulic Valves & AccessoriesIvanОценок пока нет

- Pump Unit: Technical SpecificationsДокумент5 страницPump Unit: Technical SpecificationsSir'lehe JohnОценок пока нет

- Observations and Tabulation Table 1 Results of Centrifugal Pump (Rated Speed)Документ6 страницObservations and Tabulation Table 1 Results of Centrifugal Pump (Rated Speed)adityaОценок пока нет

- CP Desoutter Air Motors 2022Документ36 страницCP Desoutter Air Motors 2022roxop51421Оценок пока нет

- Cond Fe Cover Sheet-A98Документ4 страницыCond Fe Cover Sheet-A98Ravi KumarОценок пока нет

- Valves CrossДокумент2 страницыValves CrossAlaa saidОценок пока нет

- Peerless - Process - 116 - 118 CurvasДокумент6 страницPeerless - Process - 116 - 118 CurvasedwinsazzzОценок пока нет

- FORM U-5 MANUFACTURERS DATA REPORT SUPPLEMENTARY SHEET SHELL-AND-TUBE HEAT EXCHANGERS Edit2017Документ2 страницыFORM U-5 MANUFACTURERS DATA REPORT SUPPLEMENTARY SHEET SHELL-AND-TUBE HEAT EXCHANGERS Edit2017Ashish PatelОценок пока нет

- Abribiaturas PipingДокумент15 страницAbribiaturas Pipingmarceloankzy100% (1)

- 0708-Q-CC-004 Pipe Stress Calculation From KO Drum To Flare Rev AДокумент9 страниц0708-Q-CC-004 Pipe Stress Calculation From KO Drum To Flare Rev AElias EliasОценок пока нет

- Yale and Sentry Closures: Closures Catalog-FINAL - QXD 12/8/09 9:40 AM Page 1Документ16 страницYale and Sentry Closures: Closures Catalog-FINAL - QXD 12/8/09 9:40 AM Page 1Daryl DelimanОценок пока нет

- APV (Austrian Pipe Valve)Документ36 страницAPV (Austrian Pipe Valve)iswantmachooОценок пока нет

- Pipelines and Pumping Pipelines and Pumping Station Design Station DesignДокумент78 страницPipelines and Pumping Pipelines and Pumping Station Design Station Designmohamed ahmedОценок пока нет

- Motor PDFДокумент81 страницаMotor PDFmaungОценок пока нет

- Thermal Turbomachinary Unit-III: Prof. Onkar SinghДокумент34 страницыThermal Turbomachinary Unit-III: Prof. Onkar SinghVipin PandeyОценок пока нет

- Rotar BSC R-Evo 10-15-20Документ78 страницRotar BSC R-Evo 10-15-20benjaminОценок пока нет

- The Dow Chemical Company Engineering Specification Process Containment K9S-1000-02 Ol2K 06-JAN-2005 Page 1 of 4Документ4 страницыThe Dow Chemical Company Engineering Specification Process Containment K9S-1000-02 Ol2K 06-JAN-2005 Page 1 of 4maheshОценок пока нет

- Pilots and Accessories: Application: OperationДокумент2 страницыPilots and Accessories: Application: OperationBraulio CollanteОценок пока нет