Академический Документы

Профессиональный Документы

Культура Документы

Aisi 4130

Загружено:

ravivelamarthyОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Aisi 4130

Загружено:

ravivelamarthyАвторское право:

Доступные форматы

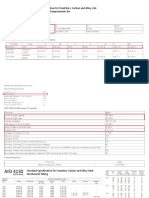

AISI 4130

Category Steel

Class Alloy steel

Type Standard

Common

Chromium-molybdenum steel

Names

Designations AMS 6350, AMS 6350D, AMS 6351A, AMS 6356, AMS 6360, AMS 6360F,

AMS 6361, AMS 6362, AMS 6370, AMS 6370F, AMS 6371, AMS 6371D,

AMS 6373, AMS 6373A, ASTM A322, ASTM A331, ASTM A505, ASTM A513,

ASTM A519, ASTM A646, MIL SPEC MIL-S-16974, SAE J404, SAE J412,

SAE J770, UNS G41300

Composition

Element Weight %

C 0.28-0.33

Mn 0.40-0.60

P 0.035 (max)

S 0.04 (max)

Si 0.15-0.30

Cr 0.80-1.10

Mo 0.15-0.25

Mechanical Properties

Properties

Density (×1000 kg/m3) 7.7-8.03

Poisson's Ratio 0.27-0.30

Elastic Modulus (GPa) 190-210

Tensile Strength (Mpa) 560.5

Yield Strength (Mpa) 360.6

Elongation (%) 28.2

Reduction in Area (%) 55.6

Hardness (HB) 156

Impact Strength (J) (Izod) 61.7

Melting Point (Deg. F) 2610

AISI 4130 is a low alloy steel containing molybdenum and chromium as

Principal

strengthening agents. The carbon content is nominally 0.30% and with this

Design

relatively low carbon content the alloy is excellent from the fusion weldability

Features

standpoint. The alloy can be hardened by heat treatment.

Typical applications for 4130 low alloy steel include. structural use such as

Applications

aircraft engine mounts and welded tubing applications.

This alloy is readily machined by conventional methods. Machinability is best

with the alloy in the normalized and tempered condition. Although the alloy

Machinability

may be machined in the fully heat treated condition, machinability becomes

more difficult with increasing strength (hardness) of the alloy.

Formability is best in the annealed condition for which the ductility is very

Forming

good, Bend radii of 1t on annealed sheet material may be made.

Welding 4130 alloy is noted for its weldability by all of the commercial methods.

Heating at 1600 F followed by an oil quench will harden the 4130 alloy. For

Heat Treatment best results a normalizing pre-hardening heat treatment may be used at

1650 to 1700 F followed by the 1600 F soak and oil quench.

Forging Forge at 2200 F maximum down to 1750 F.

4130 in the annealed condition has excellent ductility. Thus it is usually not

Hot Working necessary to do hot working to form parts. If hot working is needed it can be

done in the range of 2000 F to 1500 F.

Cold Working Cold working by conventional methods is readily accomplished on this alloy.

4130 (and most of the other low alloy steels) may be annealed at 1550 F for

a time long enough to allow thorough heating of the section size. It should

Annealing

then be cooled in the furnace at a rate of less than 50 F per hour down to

900 F, followed by air cooling from 900 F.

Aging Not applicable to this alloy.

Tempering is done to restore some of the ductility that may be lost after the

hardening heat treatment and quench. Alloy 4130 is tempered at between

Tempering

750 F and 1050 F, depending upon the strength level desired. The lower the

tempering temperature the greater the strength.

Hardening is accomplished by heat treatment or by cold working -- see

Hardening

"Heat Treatment".

Other The 4130 alloy is a through hardening alloy and should not be case

Comments hardened.

Вам также может понравиться

- Surface Vehicle Recommended Practice: Rev. JUL95Документ10 страницSurface Vehicle Recommended Practice: Rev. JUL95raulОценок пока нет

- Sky Bees Guide - Sheet1Документ3 страницыSky Bees Guide - Sheet1Max KeltonОценок пока нет

- En10225-2 2019 High Yield Structural Sections For OffshoreДокумент4 страницыEn10225-2 2019 High Yield Structural Sections For OffshoreFYОценок пока нет

- Welding International Volume 25 Heat Tint Colours On Stainless Steel and Welded JointsДокумент5 страницWelding International Volume 25 Heat Tint Colours On Stainless Steel and Welded JointsAPIОценок пока нет

- Temper EmbrittlementДокумент13 страницTemper EmbrittlementAnonymous 5odj1Ic100% (1)

- Astm A800Документ6 страницAstm A800sukrisnoОценок пока нет

- Atomic Structure PacketДокумент11 страницAtomic Structure PacketJaznMonОценок пока нет

- Solution Manual Brady Chemistry 6TH Edition PDFДокумент584 страницыSolution Manual Brady Chemistry 6TH Edition PDFJeremy Gavriel50% (12)

- AISI 4130: Standard Specification For Steel Bars, Carbon and Alloy, Hot-Wrought, General Requirements ForДокумент3 страницыAISI 4130: Standard Specification For Steel Bars, Carbon and Alloy, Hot-Wrought, General Requirements ForAndy SaputroОценок пока нет

- Bohler Welding Guide PDFДокумент515 страницBohler Welding Guide PDFParveen (Atam Valves)100% (1)

- Equivalent TableДокумент12 страницEquivalent TableArie HendriyanaОценок пока нет

- 42 Crmo 4Документ2 страницы42 Crmo 4Shiva Kumar MОценок пока нет

- Surface Vehicle Standard: Chemical Compositions of SAE Alloy SteelsДокумент6 страницSurface Vehicle Standard: Chemical Compositions of SAE Alloy SteelsDhandapani MetallionОценок пока нет

- Welding AISI 4130 PDFДокумент5 страницWelding AISI 4130 PDFDarioОценок пока нет

- Astm Volume 02 02Документ4 страницыAstm Volume 02 02RonОценок пока нет

- S For Quenching D Tentpering-: SteelДокумент28 страницS For Quenching D Tentpering-: SteelDidier LZОценок пока нет

- Lunch & Learn: Structural Steel SelectionДокумент17 страницLunch & Learn: Structural Steel Selectionanuj SinghОценок пока нет

- Aisi SteelДокумент11 страницAisi SteelIlham SetiadiОценок пока нет

- Specification For Nickel-Copper Alloy Rod, Bar, and WireДокумент12 страницSpecification For Nickel-Copper Alloy Rod, Bar, and WireAnilОценок пока нет

- AISI 1035 cs46Документ2 страницыAISI 1035 cs46Russell ShacklefordОценок пока нет

- Usability Designators FCAWДокумент5 страницUsability Designators FCAWAnonymous dh6DITОценок пока нет

- Steel Heat Treatment Handbook Chapter 12Документ46 страницSteel Heat Treatment Handbook Chapter 12Syed Shoaib Raza100% (1)

- Astm B209 B209M (2001)Документ26 страницAstm B209 B209M (2001)Asif ChougleОценок пока нет

- Kobe Welding Handbook 2004Документ183 страницыKobe Welding Handbook 2004Nasywafi AlyaОценок пока нет

- Type 347-347H Stainless SteelДокумент2 страницыType 347-347H Stainless SteelPravin PawarОценок пока нет

- SAE AMS2658 Hardness and Conductivity InspectionДокумент8 страницSAE AMS2658 Hardness and Conductivity InspectionAimanAlimin94100% (1)

- Steel SpecДокумент82 страницыSteel Specmglp54Оценок пока нет

- A-23 WB36 Rev 03 15NiCuMoNb5 MicrostructureДокумент4 страницыA-23 WB36 Rev 03 15NiCuMoNb5 Microstructuremavis16Оценок пока нет

- Zinc Coating Life Predictor: Derived From TheДокумент2 страницыZinc Coating Life Predictor: Derived From ThelakshanОценок пока нет

- Inconel 625Документ3 страницыInconel 625alokbdasОценок пока нет

- Duplex Stainless Steel 3rd EditionДокумент68 страницDuplex Stainless Steel 3rd EditionPhani Sridhar Ch100% (3)

- Guidelines For Welding: ZERON 100 Super Duplex Stainless SteelДокумент16 страницGuidelines For Welding: ZERON 100 Super Duplex Stainless SteelHrishikesanОценок пока нет

- Control Atmospheric Brazing Technology For Heat Exchangers ManufacturingДокумент23 страницыControl Atmospheric Brazing Technology For Heat Exchangers ManufacturingInternational Journal of Innovative Science and Research Technology100% (1)

- Galvanized Steel Vs Zinc Rich PaintДокумент2 страницыGalvanized Steel Vs Zinc Rich PaintImam SitumeangОценок пока нет

- Iso 8503 4Документ11 страницIso 8503 4AfetОценок пока нет

- Grade 316 316LДокумент9 страницGrade 316 316LvsajuОценок пока нет

- En Aw 6082 Rev 2 Final PDFДокумент3 страницыEn Aw 6082 Rev 2 Final PDFtechspawОценок пока нет

- Duplex Stainless SteelsДокумент19 страницDuplex Stainless SteelsdinaksОценок пока нет

- Geomet 321Документ2 страницыGeomet 321Satnam Rachna FastenersОценок пока нет

- American Galvanizing Association PDFДокумент81 страницаAmerican Galvanizing Association PDFআসিফহাসানখানОценок пока нет

- Tes-W-109.01-R0-General Welding CriteriaДокумент23 страницыTes-W-109.01-R0-General Welding CriteriaUtkucan KILIÇОценок пока нет

- Elcometer 128 Pictorial Surface Standards Data SheetДокумент2 страницыElcometer 128 Pictorial Surface Standards Data SheetBalaji GuruОценок пока нет

- Standard GB - T1804-m & ISO 2768-1 - 2 - Advanced CeramicsДокумент5 страницStandard GB - T1804-m & ISO 2768-1 - 2 - Advanced CeramicsMohd DanishОценок пока нет

- Astm A 668 A668m 2013 PDFДокумент10 страницAstm A 668 A668m 2013 PDFCarlos GuerraОценок пока нет

- En 10025 - 2004Документ11 страницEn 10025 - 2004Abhishek GoelОценок пока нет

- UNS R30006 Steel GradesДокумент3 страницыUNS R30006 Steel GradesRatnakar PatilОценок пока нет

- Standard EN10029Документ4 страницыStandard EN10029Florin JipaОценок пока нет

- List of Oil & Gas Industry Standards of InterestДокумент7 страницList of Oil & Gas Industry Standards of InterestrajikhannaОценок пока нет

- 7 1-2008Документ8 страниц7 1-2008SAI Global - APACОценок пока нет

- Aisi 4130Документ2 страницыAisi 4130Marcos CarreroОценок пока нет

- Astmo E1558 ElectropulidoДокумент13 страницAstmo E1558 Electropulidoanamariamg15Оценок пока нет

- Shallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceОт EverandShallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceОценок пока нет

- Aisi 4130Документ2 страницыAisi 4130Ravi Chaitanya VelamarthyОценок пока нет

- Aisi 4130 Alloy Steel (Uns g41300)Документ3 страницыAisi 4130 Alloy Steel (Uns g41300)murphygtОценок пока нет

- Ferrous Alloys: Printed: 1988 WДокумент34 страницыFerrous Alloys: Printed: 1988 WsunsirОценок пока нет

- Aalco Metals LTD Stainless Steel 155 PH 310Документ3 страницыAalco Metals LTD Stainless Steel 155 PH 310Ria MustikaОценок пока нет

- Aalco Metals LTD Stainless Steel 14021 Bar 311Документ2 страницыAalco Metals LTD Stainless Steel 14021 Bar 311joseocsilvaОценок пока нет

- A Report On AISI 4130:-: Chemistry DataДокумент4 страницыA Report On AISI 4130:-: Chemistry Datavaibhavporwal1Оценок пока нет

- 420 Martensitic Stainless Steel BarДокумент4 страницы420 Martensitic Stainless Steel BarAHMED FATHIОценок пока нет

- 410 Grade SteelДокумент4 страницы410 Grade SteelShashank Saxena0% (1)

- AISI 4130 Alloy SteelДокумент2 страницыAISI 4130 Alloy SteelSantosh IngaleОценок пока нет

- AISI 4130 Alloy SteelДокумент2 страницыAISI 4130 Alloy SteelKandeepanОценок пока нет

- Amie Material Science Notes PDFДокумент276 страницAmie Material Science Notes PDFAlok KulkarniОценок пока нет

- Charpy Test - Determination of Impact Energy Using The Charpy TestДокумент3 страницыCharpy Test - Determination of Impact Energy Using The Charpy TestravivelamarthyОценок пока нет

- Jetlube Grease PDFДокумент20 страницJetlube Grease PDFravivelamarthyОценок пока нет

- ReviewofWearandGallingCharacteristicsofStainlessSteel 9006Документ0 страницReviewofWearandGallingCharacteristicsofStainlessSteel 9006fahreezОценок пока нет

- How Offshore Capping Stacks WorkДокумент3 страницыHow Offshore Capping Stacks WorkLaloMendietaОценок пока нет

- Fastenal Product Standard: FNL - PP.SOCKET - FS.LC.P: Pipe Plug, Socket, Merchant Steel, Flush Seal 7/8" Taper, PlainДокумент1 страницаFastenal Product Standard: FNL - PP.SOCKET - FS.LC.P: Pipe Plug, Socket, Merchant Steel, Flush Seal 7/8" Taper, PlainravivelamarthyОценок пока нет

- .75 Taper Dry Seal PDFДокумент1 страница.75 Taper Dry Seal PDFravivelamarthyОценок пока нет

- Plugs B16.11Документ1 страницаPlugs B16.11ravivelamarthyОценок пока нет

- A Glossary of Forging TermsДокумент22 страницыA Glossary of Forging TermsSiva Subramaniam M BОценок пока нет

- .75 Taper Dry Seal PDFДокумент1 страница.75 Taper Dry Seal PDFravivelamarthyОценок пока нет

- Fastenal Product Standard: FNL - PP.SOCKET - FS.LC.P: Pipe Plug, Socket, Merchant Steel, Flush Seal 7/8" Taper, PlainДокумент1 страницаFastenal Product Standard: FNL - PP.SOCKET - FS.LC.P: Pipe Plug, Socket, Merchant Steel, Flush Seal 7/8" Taper, PlainravivelamarthyОценок пока нет

- .75 Taper Dry SealДокумент1 страница.75 Taper Dry SealravivelamarthyОценок пока нет

- Hydril Pressu ReДокумент5 страницHydril Pressu ReravivelamarthyОценок пока нет

- Standard Size and Connections of Drill PipesДокумент2 страницыStandard Size and Connections of Drill PipesravivelamarthyОценок пока нет

- Sae J451Документ5 страницSae J451Douglas RodriguesОценок пока нет

- Section A: HKCEE Paper I Running Answer Text 2000 ChemistryДокумент11 страницSection A: HKCEE Paper I Running Answer Text 2000 ChemistryKathy WongОценок пока нет

- High Speed SteelДокумент6 страницHigh Speed SteelLvl100% (1)

- Request For Quotation - RFQ - PDFДокумент5 страницRequest For Quotation - RFQ - PDFavmr0% (1)

- Industrial Training ReportДокумент19 страницIndustrial Training ReportRam PandeyОценок пока нет

- Periodic Table of The ElementsДокумент4 страницыPeriodic Table of The Elementsalpatil2Оценок пока нет

- Impact Firecrackers - John Donner PDFДокумент33 страницыImpact Firecrackers - John Donner PDFwarrior_2008Оценок пока нет

- N-W.F.P. University of Engineering and Technology Peshawar: Design of Steel Structures CE-409Документ37 страницN-W.F.P. University of Engineering and Technology Peshawar: Design of Steel Structures CE-409abryant633777Оценок пока нет

- ASTM F593: MaterialsДокумент1 страницаASTM F593: MaterialsBilly DОценок пока нет

- Soal Atom Dan MolekulДокумент5 страницSoal Atom Dan MolekulIka Marta NovaniОценок пока нет

- Liquid Penetrant System Chemistry and Effluent Waste: HapterДокумент0 страницLiquid Penetrant System Chemistry and Effluent Waste: HapterSihem BenОценок пока нет

- 11th Sci Solved Short Questions With SolutionsДокумент14 страниц11th Sci Solved Short Questions With SolutionsTOXOREEDОценок пока нет

- PD 464 - Real Property Tax CodeДокумент36 страницPD 464 - Real Property Tax CodeCrislene CruzОценок пока нет

- Iffi' RR R: Equipment Data Equipment TypelconfigurationДокумент2 страницыIffi' RR R: Equipment Data Equipment TypelconfigurationJanakiraman Malliga0% (1)

- Review Paper On Hard Facing Processes and MaterialsДокумент4 страницыReview Paper On Hard Facing Processes and MaterialsJaveed A. KhanОценок пока нет

- RSI Introduction LetterДокумент1 страницаRSI Introduction LetterBharat TailorОценок пока нет

- Final Year Project - (Mechanical) IEEE 2016-17 Project ListДокумент10 страницFinal Year Project - (Mechanical) IEEE 2016-17 Project ListSPECTRUM SOLUTIONSОценок пока нет

- Tarnish and Corrosion / Orthodontic Courses by Indian Dental AcademyДокумент20 страницTarnish and Corrosion / Orthodontic Courses by Indian Dental Academyindian dental academy100% (1)

- Samson Eco HopperДокумент8 страницSamson Eco HopperMauricio MpintoОценок пока нет

- Henk Alodine 1201 TdsДокумент4 страницыHenk Alodine 1201 TdstassawarОценок пока нет

- Exercises 1Документ4 страницыExercises 1Nurliana RoslanОценок пока нет

- Buried Steel PenstocksДокумент96 страницBuried Steel PenstocksSantiago Parillo OhaОценок пока нет

- Powder MetallurgyДокумент44 страницыPowder MetallurgyjrvinodОценок пока нет

- Conservation Between Art and ScienceДокумент18 страницConservation Between Art and ScienceMichael Nabil100% (1)

- Effect of Welding Current On The Mechanical and StructuralДокумент8 страницEffect of Welding Current On The Mechanical and StructuralBhramandhikaNalendraGhuptaОценок пока нет

- Cambridge International General Certificate of Secondary EducationДокумент16 страницCambridge International General Certificate of Secondary Educationzainab tamerОценок пока нет

- List of Employers in AustraliaДокумент45 страницList of Employers in AustraliaOmid TajikОценок пока нет