Академический Документы

Профессиональный Документы

Культура Документы

Project Eagle: Quality Management Inspection Report

Загружено:

rcpretoriusИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Project Eagle: Quality Management Inspection Report

Загружено:

rcpretoriusАвторское право:

Доступные форматы

Project Eagle

QUALITY MANAGEMENT Date: 22/11/2017

INSPECTION REPORT Revision: 00

FORM PEQC 001-17 IR Pages: 1 of 1

Project No.: CKN17156 Date: Report No.:

Package/Contract: #3 Evaps S/Steel Piping 01/03/2018 006PE2018

Location: Sappi Ngodwana

Vendor: D&M Engineering

Applicable Codes &

ASME B31.3, Sappi Specifications – Piping, Inspection and Testing

Standards:

Equipment Description: Stainless Steel Piping & Tie-In

Equipment No.: 100-STE-G-0030 SHT 1

Visual

☒ Dimensional Inspection ☐ Fit-up Inspection ☐

Inspection

Inspection Activity: Material ID ☐ Surveillance Inspection ☐ Performance Test ☐

Other ☒ Specify other PMI

Findings/Recommendations: Crack on root weld run

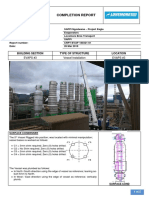

Continuous crack formation was noted by welder while attempting to weld root run on field tie-in. After grinding out the

initial weld pass, the welder notice the same phenomena on other tack welds. The welder then requested the QC Inspector

to visually inspect and witness the welding of the root run. The QC Inspector noticed the crack appearing after less than

10mm of welding being undertaken. The QC Inspector in turn notified the client and the same phenomena was witnessed.

On evaluation, possible causes for this cracking are:

1) New material being welded to old material. Sappi requests a PMI be done by a competent technician in order to

establish baseline metallurgy of the older (in-service) material.

2) Vibration of entire pipe tie-in assembly. The piping is currently connected to equipment that is in service and

is causing vibration to the entire pipe assembly which in turn could be agitating the weld pool to crack during

solidification.

If PMI results are favourable then the contractor must weld this tie-in when the plant is shut down.

Vendor Rep: Client Rep: R. Pretorius

Signature: Signature:

Date: Date: 01/03/2018

Note: This report does not relieve vendor of contractual obligation to supply equipment compliant to relevant codes, standards or

regulations.

1 Project Eagle Phase II

Sappi Ngowana

Quality Control Department

N4 Highway, Ngodwana, 1209

Project Eagle

Figure 1 Noticeable crack in root run

2 Project Eagle Phase II

Sappi Ngowana

Quality Control Department

N4 Highway, Ngodwana, 1209

Вам также может понравиться

- Engineering Science N4 Summary NotesДокумент1 страницаEngineering Science N4 Summary Notesrcpretorius22% (9)

- K-FLEX HVAC Applications Installation ManualДокумент63 страницыK-FLEX HVAC Applications Installation ManualMohammad TaheriОценок пока нет

- Inspection Report 005PE2017 Arminco Rev01Документ1 страницаInspection Report 005PE2017 Arminco Rev01rcpretoriusОценок пока нет

- Material Inspection SheetДокумент3 страницыMaterial Inspection Sheetrahid iqubalОценок пока нет

- Ce Marking: Bureau Veritas ServicesДокумент2 страницыCe Marking: Bureau Veritas ServicesanilОценок пока нет

- 120 PDFДокумент28 страниц120 PDFqczoomenОценок пока нет

- Breakdown Price Piping, Instrument Metering-Subcont Rev-0Документ4 страницыBreakdown Price Piping, Instrument Metering-Subcont Rev-0yuwonoОценок пока нет

- Incoming Raw Material Insp. Report JKДокумент1 страницаIncoming Raw Material Insp. Report JKAmit RaiОценок пока нет

- Pipe & Fittings Water & Sewer: Installation GuideДокумент87 страницPipe & Fittings Water & Sewer: Installation GuideHassan SleemОценок пока нет

- Material Inspection Report 6219-1Документ2 страницыMaterial Inspection Report 6219-1คุณพ่อน้อง บิ๊กบอสОценок пока нет

- Lloyds Steel Industries LTDДокумент20 страницLloyds Steel Industries LTDRohit JohnОценок пока нет

- 2037-PL-PL-0058-FR-T-025 Dated 18.12.19 PDFДокумент14 страниц2037-PL-PL-0058-FR-T-025 Dated 18.12.19 PDFDadaso Baburao JamdarОценок пока нет

- ASMEДокумент38 страницASMEshazanОценок пока нет

- Tech-Trade O&G FabricatorsДокумент7 страницTech-Trade O&G FabricatorsAmirah AzmiОценок пока нет

- RTCC Manual WPS Approval WE-WPS-001Документ7 страницRTCC Manual WPS Approval WE-WPS-001Akansha SharmaОценок пока нет

- PART 92 Cu-Ni Welding - Part 1 Cu-Ni Material PropertiesДокумент16 страницPART 92 Cu-Ni Welding - Part 1 Cu-Ni Material Propertiesravindra_jivaniОценок пока нет

- L&T Construction: Sno Desription Frequency of Updation Date of UpdationДокумент4 страницыL&T Construction: Sno Desription Frequency of Updation Date of UpdationANILОценок пока нет

- Doing Business in Vietnam 2023: An Introduction ToДокумент65 страницDoing Business in Vietnam 2023: An Introduction ToVy TranОценок пока нет

- PRES TIG Hot Wire Narrow Gap Welding enДокумент25 страницPRES TIG Hot Wire Narrow Gap Welding enRavishankarОценок пока нет

- Prds & Piping QapДокумент2 страницыPrds & Piping QapPavul RajОценок пока нет

- Installation Guide - Pipes and Fittings2Документ84 страницыInstallation Guide - Pipes and Fittings2EstebanОценок пока нет

- PreheatДокумент2 страницыPreheatScott TrainorОценок пока нет

- Product Inspection Report: Results OverviewДокумент8 страницProduct Inspection Report: Results Overviewblackberry7130gОценок пока нет

- Pipe Fabrication Brochure CompressedДокумент2 страницыPipe Fabrication Brochure CompressedLeDzungОценок пока нет

- Duqm Refinery Project EPC Package 2 - Utilities and OffsitesДокумент2 страницыDuqm Refinery Project EPC Package 2 - Utilities and OffsitesDadaso Baburao JamdarОценок пока нет

- L&T Construction: Sno Desription Frequency of Updation Date of UpdationДокумент2 страницыL&T Construction: Sno Desription Frequency of Updation Date of UpdationANILОценок пока нет

- Weld Repairs:: 1) Production Repairs 2) In-Service RepairsДокумент4 страницыWeld Repairs:: 1) Production Repairs 2) In-Service RepairsEhsan KhanОценок пока нет

- WOWLibrary Preheating of Materials ConsumablesДокумент4 страницыWOWLibrary Preheating of Materials ConsumableshreerОценок пока нет

- L&T Construction: R ReportДокумент2 страницыL&T Construction: R ReportANILОценок пока нет

- Inspection Flash Report: RFI NO & Date: 1.0 Type of VisitДокумент3 страницыInspection Flash Report: RFI NO & Date: 1.0 Type of VisitFahad AhmadОценок пока нет

- Field Joint Coating Installation ProcedureДокумент2 страницыField Joint Coating Installation Procedureunix manОценок пока нет

- Complete Short Circuit CycleДокумент8 страницComplete Short Circuit CycleWilly UioОценок пока нет

- Standard Welding Procedures: by Walter J. SperkoДокумент4 страницыStandard Welding Procedures: by Walter J. SperkoK ArunsiddharthОценок пока нет

- Book - Vol.1&2 - BasicsAndQuality - 22junДокумент82 страницыBook - Vol.1&2 - BasicsAndQuality - 22junlth770310Оценок пока нет

- Welding Electrode ProjectДокумент36 страницWelding Electrode ProjectjswldeepОценок пока нет

- PDF Iso 3834 Checklist 1 CompressДокумент12 страницPDF Iso 3834 Checklist 1 CompressViệt VũОценок пока нет

- PQR - WPQ Witness ReportДокумент1 страницаPQR - WPQ Witness Reportsdkeskar40Оценок пока нет

- Drawing With Spec Dimensions: General Inspection Report For All Materials & ProductsДокумент1 страницаDrawing With Spec Dimensions: General Inspection Report For All Materials & ProductsAbhishek AnandОценок пока нет

- GTAW Welding of CP Titanium and Ti6Al4VДокумент1 страницаGTAW Welding of CP Titanium and Ti6Al4VDeepak KumarОценок пока нет

- Dimensional Inspection Report PDFДокумент1 страницаDimensional Inspection Report PDFThe Welding Inspections CommunityОценок пока нет

- Tata Steel Corporate PresentationДокумент49 страницTata Steel Corporate Presentationjyoti mahajanОценок пока нет

- WIC-WPS-01 Rev. 00 - FCAW - 1.2Документ2 страницыWIC-WPS-01 Rev. 00 - FCAW - 1.2murshid badshahОценок пока нет

- HP Lok: 2010 EditionДокумент38 страницHP Lok: 2010 Editiondeema saleemОценок пока нет

- Gmaw & Fcaw-MsmeДокумент73 страницыGmaw & Fcaw-MsmemilindОценок пока нет

- GTAW and Power SourcesДокумент18 страницGTAW and Power SourcesRavi Kumar SinghОценок пока нет

- Ds Universal Wps Migmag enДокумент6 страницDs Universal Wps Migmag enMarija IvanovskaОценок пока нет

- TVL-Shielded Metal Arc Welding 12 Third: PanimulaДокумент3 страницыTVL-Shielded Metal Arc Welding 12 Third: PanimulaFlorinda Gagasa100% (1)

- Kou2003 PDFДокумент6 страницKou2003 PDFGe EffgenОценок пока нет

- Welding Recommendation TS890Документ2 страницыWelding Recommendation TS890max_powerОценок пока нет

- URA - Workers DormitoryДокумент2 страницыURA - Workers DormitoryJimmy TanОценок пока нет

- GMAW Facilitator GuideДокумент42 страницыGMAW Facilitator GuideEng trk100% (1)

- Planning Risk Evaluation ChecklistДокумент6 страницPlanning Risk Evaluation ChecklistHussain ElarabiОценок пока нет

- STD PPM 330-3000 Opl v3 ENДокумент33 страницыSTD PPM 330-3000 Opl v3 ENRenata SantosОценок пока нет

- Social Media Dashboard Template: Visits Per WeekДокумент5 страницSocial Media Dashboard Template: Visits Per Weekgj1ch3240okОценок пока нет

- En 15085-2020-What Has ChangedДокумент2 страницыEn 15085-2020-What Has ChangedBoran YelkenciogluОценок пока нет

- Heat Shrink Sleeves Install Manual 2005Документ3 страницыHeat Shrink Sleeves Install Manual 2005Engr Arfan Ali DhamrahoОценок пока нет

- How To MIG Weld AluminumДокумент8 страницHow To MIG Weld AluminumHandri YantoОценок пока нет

- Wel 13 HДокумент8 страницWel 13 HWilly Uio100% (1)

- Inspection Report 008PE2018 EndetoДокумент2 страницыInspection Report 008PE2018 Endetorcpretorius0% (1)

- Inspection Report 008PE2018 HowdenДокумент2 страницыInspection Report 008PE2018 HowdenrcpretoriusОценок пока нет

- 25875-000-V1A-PS02-00004 - Rev.003-With ApprovalДокумент11 страниц25875-000-V1A-PS02-00004 - Rev.003-With ApprovalKarthikОценок пока нет

- Disney Form PDFДокумент2 страницыDisney Form PDFrcpretoriusОценок пока нет

- Mathematics P1 Nov 2016 Memo Afr & EngДокумент20 страницMathematics P1 Nov 2016 Memo Afr & EngrcpretoriusОценок пока нет

- PC SDK: Application ManualДокумент136 страницPC SDK: Application ManualrcpretoriusОценок пока нет

- Project Vuilindlela - Piping Contractors - Quality and Techincal Audit RatingДокумент2 страницыProject Vuilindlela - Piping Contractors - Quality and Techincal Audit RatingrcpretoriusОценок пока нет

- (No Subject) : (Meng) 062 412 1834/031 467 5129Документ1 страница(No Subject) : (Meng) 062 412 1834/031 467 5129rcpretoriusОценок пока нет

- 180920-000-DE10-GAD-0013rev7 PRELIMДокумент1 страница180920-000-DE10-GAD-0013rev7 PRELIMrcpretoriusОценок пока нет

- 2 Oak Repairs (For Information)Документ2 страницы2 Oak Repairs (For Information)rcpretoriusОценок пока нет

- Vessel CRPTДокумент5 страницVessel CRPTrcpretoriusОценок пока нет

- 01 Let GoДокумент2 страницы01 Let GorcpretoriusОценок пока нет

- Miller Welding TitaniumДокумент20 страницMiller Welding TitaniumrcpretoriusОценок пока нет

- RCPretorius AWS Weld Strength CalculationsДокумент1 страницаRCPretorius AWS Weld Strength CalculationsrcpretoriusОценок пока нет

- 1Документ21 страница1rcpretoriusОценок пока нет

- 096-STD-G-0006-0001 - P4 AfcДокумент1 страница096-STD-G-0006-0001 - P4 AfcrcpretoriusОценок пока нет

- Bidvest Luxi Cover - November 2014Документ13 страницBidvest Luxi Cover - November 2014rcpretoriusОценок пока нет

- 2017 Generic Orientation Guide D10057563-E6Документ67 страниц2017 Generic Orientation Guide D10057563-E6rcpretoriusОценок пока нет

- D10056019 E1Документ33 страницыD10056019 E1rcpretoriusОценок пока нет

- Mechanotechnics N5 Exam Pack D10056036: Edition 1Документ65 страницMechanotechnics N5 Exam Pack D10056036: Edition 1rcpretoriusОценок пока нет

- Isometric ExampleДокумент1 страницаIsometric ExamplercpretoriusОценок пока нет

- Copy of 2 Evaps Piping Control RegisterДокумент5 страницCopy of 2 Evaps Piping Control RegisterrcpretoriusОценок пока нет

- Inspection Report 008PE2018 EndetoДокумент2 страницыInspection Report 008PE2018 Endetorcpretorius0% (1)

- Space Structures TosДокумент8 страницSpace Structures TossushmakОценок пока нет

- Engineering and Ethics SyllabusДокумент6 страницEngineering and Ethics SyllabusSarah BurgenОценок пока нет

- Training Catalogue: QRA and CFD Simulation Phast, Safeti and KFXДокумент16 страницTraining Catalogue: QRA and CFD Simulation Phast, Safeti and KFXKrishna KusumaОценок пока нет

- RSBДокумент2 страницыRSBJohn Aries Almelor SarzaОценок пока нет

- Prashant KumarДокумент2 страницыPrashant KumarShree RamОценок пока нет

- UT Dallas Syllabus For Mech2310.001.11s Taught by P L Thamban (Stephan)Документ7 страницUT Dallas Syllabus For Mech2310.001.11s Taught by P L Thamban (Stephan)UT Dallas Provost's Technology GroupОценок пока нет

- IE464 - T2 - Engineering Anthropometry and Workspace DesignДокумент32 страницыIE464 - T2 - Engineering Anthropometry and Workspace DesignIbrahem Abdulrahman100% (2)

- CV For Prof. Charles Manasseh Mokua Ondieki-012016Документ6 страницCV For Prof. Charles Manasseh Mokua Ondieki-012016Charles OndiekiОценок пока нет

- Belliss Morcom Industrial Brochure ENДокумент5 страницBelliss Morcom Industrial Brochure ENAlectroОценок пока нет

- ASHRAE/IESNA Standard 90.1-1999Документ69 страницASHRAE/IESNA Standard 90.1-1999Jônatas SilvaОценок пока нет

- SOP For Calibration of Instruments in Production and Quality Control - Pharmaceutical GuidelinesДокумент2 страницыSOP For Calibration of Instruments in Production and Quality Control - Pharmaceutical Guidelinest836549Оценок пока нет

- Hyper Compressor CatalougeДокумент24 страницыHyper Compressor Catalougetatarey79Оценок пока нет

- Post Tensioning ManualДокумент11 страницPost Tensioning Manualimzee25100% (7)

- Training 132 KV IndriДокумент9 страницTraining 132 KV IndriPreet ChahalОценок пока нет

- Bop RFQ Cog FlareДокумент51 страницаBop RFQ Cog Flarekoushik42000100% (1)

- APAC India Programmer Analyst InternДокумент1 страницаAPAC India Programmer Analyst InternJaswanth SuggulaОценок пока нет

- Man Space RequirementsДокумент150 страницMan Space RequirementsKaten MistryОценок пока нет

- Electric Drives Boldea I and Nasar SA 2006 Book ReДокумент2 страницыElectric Drives Boldea I and Nasar SA 2006 Book ReMahir DžafićОценок пока нет

- Plo Transcript ReportДокумент3 страницыPlo Transcript ReportDayyan Zahid KhanОценок пока нет

- Castwise CookwareДокумент9 страницCastwise CookwarePreet Inder SinghОценок пока нет

- Rozaimi Mohd Noor MFKA2009Документ99 страницRozaimi Mohd Noor MFKA2009chin_kb100% (1)

- MQ SP e 6001Документ41 страницаMQ SP e 6001jaseel kОценок пока нет

- Welcome To Presentation On: Pipe Support Systems & Piping FlexibilityДокумент67 страницWelcome To Presentation On: Pipe Support Systems & Piping Flexibilitysids8292% (24)

- Bridge BearingДокумент162 страницыBridge BearingKabbilawsh Peruvazhuthi100% (6)

- Advance Water Distrubution System Final1Документ60 страницAdvance Water Distrubution System Final1Suraj RaghuwanshiОценок пока нет

- T19101 118Документ18 страницT19101 118Chintan Raval100% (1)

- Final Thesis - With AppendicesДокумент103 страницыFinal Thesis - With AppendicesAzkalzstriker Den100% (1)

- Astm C881Документ13 страницAstm C881Jan LhesterОценок пока нет

- 2021 ORIENTATION PresentationДокумент49 страниц2021 ORIENTATION PresentationGopal KrishanОценок пока нет

- Napier NT1 BrochureДокумент16 страницNapier NT1 Brochureairtupas100% (2)