Академический Документы

Профессиональный Документы

Культура Документы

PDS Hempadur Hi-Build 45200 en-GB

Загружено:

vitharvanАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

PDS Hempadur Hi-Build 45200 en-GB

Загружено:

vitharvanАвторское право:

Доступные форматы

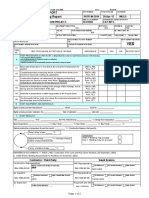

Product Data

HEMPADUR HI-BUILD 45200

45200: BASE 45209: CURING AGENT 95040

Description: HEMPADUR HI-BUILD 45200 is a two-component, high build epoxy paint. It forms a hard and tough

coating resistant to seawater, mineral oils and splashes from petrol and related products. Limited

resistance to animal and vegetable oils and strong solvents such as ketones and esters. Not

recommended for acids, alkalies, or oxidizing solutions. Harmless to grain cargo.

Recommended use: As as intermediate or finishing coat designed for on-line application of containers.

As a sealer for metal-sprayed coatings or zinc silicate primers in epoxy systems.

Service temperature: Maximum, dry exposure only: 140°C/284°F see REMARKS overleaf

Certificates/Approvals: Tested according to section 175.300 of the Code of Federal Regulations Title 21 - Dry Foodstuff.

Consult Hempel for details.

Complies with EU Directive 2004/42/EC: subcategory j.

Availability: Part of Group Assortment. Local availability subject to confirmation.

PHYSICAL CONSTANTS:

Shade nos/Colours: 12170*/ Grey.

Finish: Semi-flat

Volume solids, %: 58 ± 1

Theoretical spreading rate: 7.3 m2/l [292.7 sq.ft./US gallon] - 80 micron/3.2 mils

Flash point: 26 °C [78.8 °F]

Specific gravity: 1.4 kg/litre [12.1 lbs/US gallon]

Surface-dry: 2 approx. hour(s) 20°C/68°F

Dry to touch: 5 - 7 hour(s) 20°C/68°F

Fully cured: 7 day(s) 20°C/68°F

VOC content: 418 g/l [3.5 lbs/US gallon]

Shelf life: 3 years for BASE and 3 years (25°C/77°F) for CURING AGENT from time of production.

- *Wide range of colours available via Hempel's MULTI-TINT system.

- The physical constants stated are nominal data according to the HEMPEL Group's approved formulas.

APPLICATION DETAILS:

Version, mixed product: 45200

Mixing ratio: BASE 45209: CURING AGENT 95040

3:1 by volume

Application method: Airless spray / Brush

Thinner (max.vol.): 08450 (10%) / 08450 (10%)

For on-line container production thinning according to specification

Pot life (Airless spray): 5 hour(s) 20°C/68°F

Pot life (Brush): 8 hour(s) 20°C/68°F

Nozzle orifice: 0.018 - 0.021 "

Nozzle pressure: 250 bar [3625 psi]

(Airless spray data are indicative and subject to adjustment)

Cleaning of tools: HEMPEL'S TOOL CLEANER 99610

Indicated film thickness, dry: 80 micron [3.2 mils] see REMARKS overleaf

Indicated film thickness, wet: 150 micron [6 mils]

Overcoat interval, min: see REMARKS overleaf

Overcoat interval, max: see REMARKS overleaf

-

Safety: Handle with care. Before and during use, observe all safety labels on packaging and paint containers,

consult HEMPEL Safety Data Sheets and follow all local or national safety regulations.

-

-

-

-

-

-

-

-

-

Date of issue: August 2017 Page: 1/2

Product Data

HEMPADUR HI-BUILD 45200

SURFACE PREPARATION: New steel: Remove oil and grease etc. thoroughly with suitable detergent. Remove salts and other

contaminants by high pressure fresh water cleaning. Abrasive blasting to minimum Sa 2½ (ISO 8501-1:

2007) with a surface profile corresponding to Rugotest No. 3, N9a to N10, preferably BN9a to BN10,

Keane-Tator Comparator, 2.0 G/S or ISO Comparator, Medium (G). For temporary protection, if

required, use a suitable shopprimer. All damage of shopprimer and contamination from storage and

fabrication should be thoroughly cleaned prior to final painting. For repair and touch-up use: specified

HEMPADUR paint.

Repair and maintenance: Remove oil and grease etc. thoroughly with suitable detergent. Remove

salts and other contaminants by high pressure fresh water cleaning. When used as "tiecoat": Remove

all rust and loose material by abrasive blasting or power tool cleaning. Dust off residues. Touch up bare

spots to full film thickness.

Sealer:When used as a sealer on metal-sprayed coatings or zinc silicate primers, the product should

be diluted 10-15% with THINNER 08700, recommended dry film thickness: 40 micron. Application by

"flash coat technique" may be necessary, but a "closed film" is to be obtained and the following coat

should not be applied within the next 8 hours (20°C/68°F).

APPLICATION CONDITIONS: Apply only on a dry and clean surface with a temperature above the dew point to avoid condensation.

Use only where application and curing can proceed at temperatures above: 10°C/50°F, preferably

above 15°C/59°F.The temperature of the surface and that of the paint itself must also be above this

limit.

In confined spaces provide adequate ventilation during application and drying.

PRECEDING COAT: None, or as per specification. Recommended systems are: HEMPADUR PRIMER 15300 or

HEMPADUR ZINC 15360.

SUBSEQUENT COAT: None, or as per specification. Recommended systems are: HEMPATHANE

REMARKS:

VOC - EU Directive 2004/42/EC:

Not available.

Product As supplied 5 vol. % thinning Limit phase II, 2010

4520012170 418 g/l 440 g/l 500 g/l

For VOC of other shades, please refer to Safety Data Sheet.

Colours/Colour stability: Colour stability for some shades may be effected by exposure to harsh chemical atmospheres. This

does not affect the performance of the coating.

For certain colours extra coats may be necessary to obtain full opacity.

Weathering/service temperatures: The natural tendency of epoxy coatings to chalk in outdoor exposure and to become more sensitive to

mechanical damage and chemical exposure at elevated temperatures is also reflected in this product.

Film thicknesses/thinning: May be specified in another film thickness than indicated depending on purpose and area of use. This

will alter spreading rate and may influence drying time and overcoating interval. Normal range dry is:

60-90 micron / 2.4 -3.6 mils for use on containers. For other uses (contact Hempel) normal range is

100-125 micron/4-5 mils which is achieved by none or limited diluting at application.

Overcoating: Overcoating intervals related to later conditions of exposure: If the maximum overcoating interval is

exceeded, roughening of the surface is necessary to ensure intercoat adhesion.

Before overcoating after exposure in contaminated environment, clean the surface thoroughly with high

pressure fresh water hosing and allow drying.

A specification supersedes any guideline overcoat intervals indicated in the table.

Environment Atmospheric, medium

Surface temperature: 10°C (50°F) 20°C (68°F) 30°C (86°F)

Min Max Min Max Min Max

HEMPADUR 30 h Ext. 12 h Ext. 6h Ext.

HEMPATEX 15 h 40 h 6h 16 h 3h 8h

HEMPATHANE 30 h 25 d 12 h 10 d 6h 5d

Environment Immersion

HEMPADUR 40 h 75 d 16 h 30 d 8h 15 d

NR = Not Recommended, Ext. = Extended, m = minute(s), h = hour(s), d = day(s)

Overcoating intervals: According to specification.

Note: HEMPADUR HI-BUILD 45200 For professional use only.

ISSUED BY: HEMPEL A/S 4520012170

X Move PDS Disclaimer to Second page

This Product Data Sheet supersedes those previously issued.

For explanations, definitions and scope, see “Explanatory Notes” available on www.hempel.com. Data, specifications, directions and recommendations given in this data sheet

represent only test results or experience obtained under controlled or specially defined circumstances. Their accuracy, completeness or appropriateness under the actual conditions

of any intended use of the Products herein must be determined exclusively by the Buyer and/or User.

The Products are supplied and all technical assistance is given subject to HEMPEL's GENERAL CONDITIONS OF SALES, DELIVERY AND SERVICE, unless otherwise expressly agreed

in writing. The Manufacturer and Seller disclaim, and Buyer and/or User waive all claims involving, any liability, including but not limited to negligence, except as expressed in said

GENERAL CONDITIONS for all results, injury or direct or consequential losses or damages arising from the use of the Products as recommended above, on the overleaf or otherwise.

Product data are subject to change without notice and become void five years from the date of issue.

Date of issue: August 2017 Page: 2/2

Вам также может понравиться

- Jotun Resist 86Документ5 страницJotun Resist 86Ansar AliОценок пока нет

- Company Profile - Rizhao Steel YingkouДокумент41 страницаCompany Profile - Rizhao Steel Yingkourashid isaarОценок пока нет

- Astm 890Документ3 страницыAstm 890bsnegi111Оценок пока нет

- Ai Hempadur 87540 EnglishДокумент2 страницыAi Hempadur 87540 EnglishAmilcar BolagОценок пока нет

- TK®-236 Physical Properties: 1. HardnessДокумент2 страницыTK®-236 Physical Properties: 1. HardnessSaradhi MedapureddyОценок пока нет

- F 941 - 99 - RJK0MQ - PDFДокумент3 страницыF 941 - 99 - RJK0MQ - PDFRománBarciaVazquezОценок пока нет

- PID ResponsibilityДокумент2 страницыPID Responsibilityimurugan06Оценок пока нет

- Inspection & Testing Requirements Scope:: Test and Inspection PerДокумент2 страницыInspection & Testing Requirements Scope:: Test and Inspection PerAbu Anas M.SalaheldinОценок пока нет

- Procedure For Handling, Storage & Transportations of Bare & Coated PipesДокумент6 страницProcedure For Handling, Storage & Transportations of Bare & Coated Pipeskbpatel123Оценок пока нет

- Pentadur 5540 (F6A)Документ3 страницыPentadur 5540 (F6A)SiDdu Kalashetti0% (1)

- 1 Imran Piping QC CVДокумент4 страницы1 Imran Piping QC CVkazim MirzaОценок пока нет

- Saudi Aramco Inspection ChecklistДокумент8 страницSaudi Aramco Inspection ChecklistAnantha PadmanabhanОценок пока нет

- Saudi Aramco Test Report Temperature Tie-In Welding ReportДокумент2 страницыSaudi Aramco Test Report Temperature Tie-In Welding ReportManoj Kumar100% (2)

- Hempel Curing Agent 98021 MsdsДокумент10 страницHempel Curing Agent 98021 MsdsM.FAIZAN ARSHADОценок пока нет

- Hempel'S Galvosil 15780: DescriptionДокумент2 страницыHempel'S Galvosil 15780: DescriptionEngTamer100% (1)

- 658 - Eng - Sigma Phenguard 935 BaseДокумент1 страница658 - Eng - Sigma Phenguard 935 BasetariqueОценок пока нет

- Wps & Pqr-013 (Ss Gtaw-Smaw TGS)Документ17 страницWps & Pqr-013 (Ss Gtaw-Smaw TGS)Atuk SafizОценок пока нет

- Method Statement For Blasting and PaintingДокумент11 страницMethod Statement For Blasting and PaintingAbdullah Abdullah100% (2)

- 0901b80380959cc7 PDFДокумент2 страницы0901b80380959cc7 PDFikan100% (1)

- Apcs 117Документ12 страницApcs 117Ilyas AhmedОценок пока нет

- Method Statement For HDPE Pipe InstallationДокумент19 страницMethod Statement For HDPE Pipe Installationqwertykey3991Оценок пока нет

- Inspection Handbook PDFДокумент20 страницInspection Handbook PDFSamuel JohnОценок пока нет

- SAEP-316 Latest RevisionДокумент25 страницSAEP-316 Latest RevisionHabib RehmanОценок пока нет

- Argon Pure GasДокумент2 страницыArgon Pure GasRaghu Pathy100% (1)

- TDS PDF Intertherm - 751CSAДокумент4 страницыTDS PDF Intertherm - 751CSAwilliam sukyonoОценок пока нет

- Welder Repair Assessment and Tracer Weld Report-Weekly SATR-W-2018 22-Jan-18 WeldДокумент2 страницыWelder Repair Assessment and Tracer Weld Report-Weekly SATR-W-2018 22-Jan-18 Weldkarthi51289Оценок пока нет

- Weld Matrix Format 1Документ7 страницWeld Matrix Format 1Arslan WaheedОценок пока нет

- Sigmacover™ 620: Product Data SheetДокумент5 страницSigmacover™ 620: Product Data SheetMahmoud TahaОценок пока нет

- Sample ReportДокумент8 страницSample ReportRonel John CustodioОценок пока нет

- ASME P-Numbers PDFДокумент1 страницаASME P-Numbers PDFFahri Risfa ZulfiОценок пока нет

- Satr Nde 2011Документ2 страницыSatr Nde 2011JaseelKanhirathinkalОценок пока нет

- SATIP-T-492-01 Ver 08Документ1 страницаSATIP-T-492-01 Ver 08thezaidОценок пока нет

- Iso 14692 4 2017Документ15 страницIso 14692 4 2017Mayara AlvesОценок пока нет

- SATIP-L-450-03 Mechanical Ne: Saudi Aramco Typical Inspection Plan Cross Country Above Ground PipeliДокумент13 страницSATIP-L-450-03 Mechanical Ne: Saudi Aramco Typical Inspection Plan Cross Country Above Ground Pipelikarthi51289Оценок пока нет

- Painting Procedure GlobalДокумент15 страницPainting Procedure GlobalUbed KudachiОценок пока нет

- Health Hazards: CHB 4220 CHB 4220Документ1 страницаHealth Hazards: CHB 4220 CHB 4220MARKОценок пока нет

- Sigmacover 410Документ4 страницыSigmacover 410gstketutОценок пока нет

- Inspection Check List PWHT-Post Weld Heat-Treatment: Inspection Process Yes No N/A CommentsДокумент1 страницаInspection Check List PWHT-Post Weld Heat-Treatment: Inspection Process Yes No N/A CommentsmukeshayoorОценок пока нет

- Audit Checklist Blasting PaintingДокумент4 страницыAudit Checklist Blasting PaintingEyoh EffiongОценок пока нет

- Pipeline WorkДокумент22 страницыPipeline Workchandu666creatorОценок пока нет

- Tds of Eterset 2844Документ2 страницыTds of Eterset 2844Nandkumar PawarОценок пока нет

- Astm A516 1990Документ5 страницAstm A516 1990Indra Gugun GunawanОценок пока нет

- Materials System SpecificationДокумент10 страницMaterials System SpecificationAjeetKumar100% (1)

- PSV DatasheetДокумент40 страницPSV DatasheetJonson Cao100% (1)

- Awais Inspector-PaintingДокумент6 страницAwais Inspector-PaintingMohammed GaniОценок пока нет

- Apcs 1a 15570Документ2 страницыApcs 1a 15570jojo_323Оценок пока нет

- APCS-22A HempelДокумент3 страницыAPCS-22A Hempelarjunmohanan50% (2)

- Material Safety Data Sheet: Poly Cell AdhesiveДокумент8 страницMaterial Safety Data Sheet: Poly Cell AdhesiveMinh BảoОценок пока нет

- Saudi Aramco Inspection Checklist: Gravity Sewer Piping Installation Inspection SAIC-L-2138 25-May-05 PlumbДокумент3 страницыSaudi Aramco Inspection Checklist: Gravity Sewer Piping Installation Inspection SAIC-L-2138 25-May-05 PlumbHesham HelalОценок пока нет

- Nava Cast Iron PN16 Gate Valve 631Документ1 страницаNava Cast Iron PN16 Gate Valve 631Avk Sanjeevan100% (1)

- Revision Questions PA 10 Specific Page 23-12Документ2 страницыRevision Questions PA 10 Specific Page 23-12Bayu Falen100% (2)

- G8s-5034-02-Bubble Leak TestДокумент4 страницыG8s-5034-02-Bubble Leak TestmaheshОценок пока нет

- Hydrosatic PresentationДокумент78 страницHydrosatic PresentationZain Ali KidwaiОценок пока нет

- Installation ManualДокумент20 страницInstallation ManualHasan GüleryüzОценок пока нет

- SAEP-379 Quality Issues NotificationДокумент4 страницыSAEP-379 Quality Issues NotificationMusic And FunОценок пока нет

- Luxathane 5000 Polyurethane High Gloss Finish: Technical DataДокумент3 страницыLuxathane 5000 Polyurethane High Gloss Finish: Technical DataPV AnandОценок пока нет

- PDS en-GB 45751Документ2 страницыPDS en-GB 45751Anuar SalehОценок пока нет

- PDS Hempadur Multi-Strength 45753 en-GBДокумент2 страницыPDS Hempadur Multi-Strength 45753 en-GBJosip LasanОценок пока нет

- Hempathane Hs 55610 55610 En-GbДокумент2 страницыHempathane Hs 55610 55610 En-GbfaizalОценок пока нет

- PDS-QD ThinnerДокумент1 страницаPDS-QD ThinnervitharvanОценок пока нет

- Pds Hempel's Thinner 08450 En-GbДокумент1 страницаPds Hempel's Thinner 08450 En-GbIlham NugrohoОценок пока нет

- Pds-Solvalux 5-30 ClearДокумент1 страницаPds-Solvalux 5-30 ClearvitharvanОценок пока нет

- En Iso 9606 1 AДокумент2 страницыEn Iso 9606 1 AvitharvanОценок пока нет

- PDS Hempel's Thinner 08700 en-GBДокумент1 страницаPDS Hempel's Thinner 08700 en-GBvitharvanОценок пока нет

- PDS Hempel's Thinner 08700 en-GBДокумент1 страницаPDS Hempel's Thinner 08700 en-GBvitharvanОценок пока нет

- 50 Timeless ScientistsДокумент194 страницы50 Timeless ScientistsShyamranjan Singha100% (1)

- PDS Hempel's Silicone Aluminium 56910 en-GBДокумент2 страницыPDS Hempel's Silicone Aluminium 56910 en-GBdanishОценок пока нет

- PDS Hempadur 85671 en-GBДокумент3 страницыPDS Hempadur 85671 en-GBvitharvanОценок пока нет

- Pds Hempadur Mastic 45881 En-GbДокумент3 страницыPds Hempadur Mastic 45881 En-Gbshujad77Оценок пока нет

- AI Hempel's Galvosil 15700 EnglishДокумент7 страницAI Hempel's Galvosil 15700 EnglishvitharvanОценок пока нет

- PDS HEMPATHANE TOPCOAT 55210 en-GB PDFДокумент2 страницыPDS HEMPATHANE TOPCOAT 55210 en-GB PDFQA QCОценок пока нет

- Hempel Galvosil 1570019840Документ2 страницыHempel Galvosil 1570019840Jj OredinaОценок пока нет

- Hempadur Primer 15300Документ3 страницыHempadur Primer 15300vitharvanОценок пока нет

- Penguard Midcoat MIO: Technical Data SheetДокумент4 страницыPenguard Midcoat MIO: Technical Data SheetajuhaseenОценок пока нет

- TDS - Thinner No. 17 Issued.11.26.2010Документ2 страницыTDS - Thinner No. 17 Issued.11.26.2010MuthuKumarОценок пока нет

- TDS - Penguard HB - Issued.26.11.2010Документ4 страницыTDS - Penguard HB - Issued.26.11.2010vitharvanОценок пока нет

- Semstone 8084 PDS 7-10Документ1 страницаSemstone 8084 PDS 7-10vitharvanОценок пока нет

- Hempadur 85531 PDFДокумент2 страницыHempadur 85531 PDFvitharvan0% (1)

- TDS - Durathane English Issued.09.05.2011Документ4 страницыTDS - Durathane English Issued.09.05.2011vitharvanОценок пока нет

- TDS - Penguard Primer - Issued.26.11.2010Документ4 страницыTDS - Penguard Primer - Issued.26.11.2010vitharvanОценок пока нет

- TDS - Penguard Midcoat - Issu.26.11.2010 PDFДокумент4 страницыTDS - Penguard Midcoat - Issu.26.11.2010 PDFvitharvanОценок пока нет

- TDS - Resist 78 - English (Uk)Документ4 страницыTDS - Resist 78 - English (Uk)Chaerul AnwarОценок пока нет

- TDS - Hardtop XP - English (Uk) - Azad Jotun Ras TanuraДокумент4 страницыTDS - Hardtop XP - English (Uk) - Azad Jotun Ras TanuraAzadAhmadОценок пока нет

- Penguard HB 2005 PDFДокумент4 страницыPenguard HB 2005 PDFMuthuKumarОценок пока нет

- Dual Prime Source Datasheet 1Документ1 страницаDual Prime Source Datasheet 1EstebanОценок пока нет

- China Chassis Cj14Документ1 страницаChina Chassis Cj14David Argote BellidoОценок пока нет

- Pli New 22012006Документ119 страницPli New 22012006Sai PraneethОценок пока нет

- India International Centre India International Centre QuarterlyДокумент15 страницIndia International Centre India International Centre QuarterlySruti UОценок пока нет

- Yamaha Acoustic GuitarsДокумент18 страницYamaha Acoustic Guitarsrusf123100% (5)

- Cve 240-Assignment 5 - Chapter 4Документ3 страницыCve 240-Assignment 5 - Chapter 4Ehab Wilson0% (1)

- Quad Exclusive or Gate: PD CC oДокумент7 страницQuad Exclusive or Gate: PD CC oHungChiHoОценок пока нет

- FM 5-102 - CountermobilityДокумент220 страницFM 5-102 - CountermobilitySurvivIt100% (2)

- L11 ImageplacementДокумент2 страницыL11 ImageplacementJayram JavierОценок пока нет

- How To Update SoftwareДокумент4 страницыHow To Update SoftwareNayarit TianguisОценок пока нет

- To Improve Quality and Reduce Rejection Level Through Quality ControlДокумент5 страницTo Improve Quality and Reduce Rejection Level Through Quality ControlEditor IJRITCCОценок пока нет

- Poster BC - Bored PileДокумент1 страницаPoster BC - Bored PileZaim Adli100% (1)

- Ls Pu BackgroundДокумент5 страницLs Pu BackgroundRolando Cruzada Jr.Оценок пока нет

- DjikstraДокумент5 страницDjikstramanoj1390Оценок пока нет

- Business Plan ScrunshineДокумент2 страницыBusiness Plan ScrunshineEnjhelle MarinoОценок пока нет

- Water Jug & MissionariesДокумент52 страницыWater Jug & MissionariesAdmire ChaniwaОценок пока нет

- Performance Measurement. The ENAPS ApproachДокумент33 страницыPerformance Measurement. The ENAPS ApproachPavel Yandyganov100% (1)

- Orbital Rendezvous Using An Augmented Lambert Guidance SchemeДокумент0 страницOrbital Rendezvous Using An Augmented Lambert Guidance Schemegirithik14Оценок пока нет

- のわる式証明写真メーカー|PicrewДокумент1 страницаのわる式証明写真メーカー|PicrewpapafritarancheraОценок пока нет

- Fuzzy LogicДокумент27 страницFuzzy LogicvibhutiОценок пока нет

- Stone MasonaryДокумент23 страницыStone MasonarypurvaОценок пока нет

- Potential of Osmotic Power Generation by Pressure Retarded Osmosis Using Seawater As Feed Solution: Analysis and ExperimentsДокумент8 страницPotential of Osmotic Power Generation by Pressure Retarded Osmosis Using Seawater As Feed Solution: Analysis and ExperimentsAugusto MeloОценок пока нет

- Presentation STAAD ProДокумент47 страницPresentation STAAD ProjosephfelixОценок пока нет

- HabaCHIAN Slat Conveyor ChainsДокумент128 страницHabaCHIAN Slat Conveyor Chainsjunico76Оценок пока нет

- EL3020 Data PDFДокумент24 страницыEL3020 Data PDFichrakОценок пока нет

- MU-MIMO in LTEДокумент13 страницMU-MIMO in LTECM_123Оценок пока нет

- Resume - Abishek AntonyДокумент4 страницыResume - Abishek AntonyabishekantonyОценок пока нет

- Repair Parts Sheet: A Unit of Applied Power IncДокумент2 страницыRepair Parts Sheet: A Unit of Applied Power IncLukas EzequielОценок пока нет

- Machine Guarding PDFДокумент133 страницыMachine Guarding PDFbrsharmaОценок пока нет

- Standing Seam Installation-23-11-21Документ35 страницStanding Seam Installation-23-11-21Gokulnath TgОценок пока нет