Академический Документы

Профессиональный Документы

Культура Документы

Sizing Tank Blanketing Regulators

Загружено:

lazunovАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Sizing Tank Blanketing Regulators

Загружено:

lazunovАвторское право:

Доступные форматы

tank blanketing

Republished with permission from Tank Storage magazine.

Republishing not permitted. © Tank Storage Magazine 2015.

Sizing tank blanketing regulators

using the latest API 2000 7th edition guidelines

In March 2014, API Standard 2000 API 2000 – 5th Edition API 2000 – 6th Edition API 2000 – 7th Edition

(Venting Atmospheric and Low-Pressure • Tank volume (Appendix A = API 5th edition) (Appendix A = API

Storage Tanks) was revised. This seventh • Liquid flow (pump-in/-out) • Tank volume 5th edition)

edition is the latest update and this • Temperature change • Liquid flow (pump-in/-out) • Minor calculation

• Pump out changes

article looks at how the latest changes

• Directed at pressure • Temperature change • For volatile liquids, the

affect the sizing of tank blanketing control for hydrocarbons • Average storage outbreathing

regulators, including backpressure ones in low pressure tanks temperature calculation is

used for vapour recovery systems. • Industrial tanks as well • Vapour pressure simply doubled

• Latitude • No need to perform

an evaporation

The fundamentals remain unchanged:

• Additional focus rate calculation

Liquid flow and thermal change on alcohols

• Higher vapour pressures

The first thing to understand is what • Can double the

has not changed. Namely, the inflow (big change in

thermal vacuum)

fundamentals that impact tank pressure

A comparison of recent standard updates

remain intact. This means that liquid

flow (or pump-in and pump-out) and as a basis for the pressure control of average storage temperature, vapour

changes to temperature still form the hydrocarbons, and considered industrial pressure, and latitude were added in the

fundamentals to the sizing calculations. tanks as well. It is this 5th edition that 6th edition, as an additional focus was

is probably in widest use today. placed on alcohols which have higher

API Standard 2000 5th, 6th, and 7th Editions In 2009, this was updated to the API vapour pressures and can significantly

Standard 2000 6th edition. Note that increase the inflow requirements.

The API Standard 2000 5th edition takes the 5th edition remained in the form This year, minor changes were

into account tank volume, liquid flow, of Appendix A, so it was not made implemented and the latest guideline

and temperature change. It was written obsolete per se. The additional factors of is now the 7th edition. One of the

Basic Sizing Considera0ons

Basic sizing considerations

changes has to do with a simplified

calculation for volatile liquids.

• Regulators must be sized to take into account tank pressure changes

New Variables: C-Factor & Y-Factor

• These changes include (1) liquid flow and (2) temperature change

Both the API Standard 2000 6th and

7th editions include new variables in

the calculations which depend on

latitude. The key latitude categories are

Vapor Space heats and expands Vapor Space cools and contracts ‘Below 42 Degrees’, ‘Between 42 and

58 Degrees’ and ‘Above 58 Degrees’.

These latitude lines are where weather

patterns will shift enough to cause

meaningful differences in tank pressure.

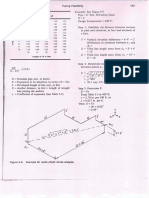

As shown in the tables, the C-Factor

Pump-In Pump-Out

depends not only on latitude, but

also on vapour pressure and average

storage temperature. This C-Factor is

Liquid flow and thermal change used when making in-breathing flow

TANK STORAGE • January/February 2015 D352286X012 81

Between 42 & 58 Deg 0.25

4 6.5 6.5 6.5

Above 58 Deg 0.20

rees 3 5 5 5

tank blanketing

2.5 4 4 4

= [8.02 x 100] + [3.08 x (6.5) x

(50,000 x 5.618)0.7 x 1]

= 131,254 SCFH

Note that the insulation factor is 1 because

there is no insulation. Also, the 5.618

constant converts barrels to cubic feet so

that a result in SCFH can be obtained.

Implications of the new

guideline: in-breathing

The latest API Standard 2000 7th edition

(and 6th edition for that matter) result

in greater in-breathing requirements,

and they may be much greater

depending on the C-Factor which

takes into account vapour pressure,

The latitude variable

average storage pressure, and latitude.

C-Factor

Latitude Vapour pressure similar to Hexane Vapour pressure higher than Hexane or unknown

Average storage temperature

<77°F >77°F <77°F >77°F

Below 42 Deg 4 6.5 6.5 6.5

Between 42 and 58 Deg 3 5 5 5

Above 58 Deg 2.5 4 4 4

(Note that the constants 8.02 and 3.08 are to This is illustrated in the graph below

Latitude Y-Factor

convert the result from metric to English units.) which shows in-breathing requirements

Below 42 Deg 0.32

versus tank size. The curve at the bottom

Between 42 & 58 Deg 0.25 To illustrate how this calculation, of the graph depicts results using API

Above 58 Deg 0.20 consider the following example: Standard 2000 5th edition, also known as

Latitude → Below 42 Degrees Appendix A. Note that this curve ends at

C-Factor and Y-Factor

Vapour pressure → Unknown 180,000 barrels. This is because the scope

calculations, which are required to size a Average storage temp → 80°F of this edition was limited to this tank size.

tank blanketing regulator. The Y-Factor, Tank volume → 50,000 barrels All of the other curves depict the 7th

on the other hand, is only dependent on Insulation → None edition, under different C-Factors. It can

latitude and is used when making out- Max pump in/out → 100 gallons/ be seen that the relationship between in-

breathing calculations, which are required min → Volatile breathing and tank size is not a linear one.

to size a vapour recovery regulator. The reason is that for smaller tanks, the

Tank blanketing regulator flow = maximum tank surface to volume ratio is greater –

Sizing calculation for a tank pump out rate + temperature drop and for larger tanks, the surface to volume

blanketing regulator = [8.02 x maximum pump out ratio is smaller. This is why the curves start

rate] + [3.08 x C-Factor x (Tank out linear and then tend to flatten out.

Let’s now turn to the sizing calculations Volume) 0.7 x insulation factor]

themselves, starting with in-breathing,

which will determine the flow

requirement for a tank blanketing

regulator. The general steps are:

(1) determine the volumetric flow

rate required to replace the

liquid being pumped out;

(2) determine the volumetric flow rate

required due to temperature drop;

(3) add the results of (1) and (2) together.

Tank blanketing regulator flow = maximum

pump out rate + temperature drop

= [8.02 x maximum pump out

rate] + [3.08 x C-Factor x (Tank

Volume)0.7 x insulation factor] API Standard 2000 5th versus 6th/7th editions – in-breathing

82 January/February 2015 • TANK STORAGE

tank blanketing

Sizing calculation for a vapour

recovery regulator

Let’s now turn to the sizing calculations

for out-breathing, which will

determine the flow requirement for

a vapour recovery regulator. The

general steps in this case are:

(1) determine the volumetric flow

rate required to compensate for

the liquid being pumped in;

(2) determine the volumetric flow rate

required due to temperature rise;

(3) add the results of (1) and (2) together.

In the case of the out-breathing

calculations, there are two sets of API Standard 2000 5th vs. 6th/7th editions – out-breathing

equations, one for non-volatile,

and another for volatile liquids. edition. However, it is important to

= [16.04 x maximum pump in rate] recognise that the changes set forth by

Non-volatile liquids + [1.51 x Y-Factor x (tank volume API Standard 2000 6th edition remain

x 5.618)0.9 x Insulation factor] intact. Although the 5th edition continues

Vapour recovery regulator flow = to be widely used for sizing blanketing and

maximum pump in rate + temperature rise = [16.04 x 100] + [1.51 x 0.32 x vapour recovery regulators, it is expected

(50,000 x 5.618)0.9 x 1] that the newer editions will gain more

= [8.02 x maximum pump in rate] acceptance and use in the years ahead.

+ [1.51 x Y-Factor x (Tank Volume = 40,314 SCFH These newer editions often result in

x 5.618)0.9 x Insulation Factor] greater flow requirements, especially for

in-breathing. So it is important to recognise

(Note that the constants 8.02

and 1.51 are to convert the result

The additional factors that the selection of the appropriate

regulator may be impacted. Once

from metric to English units.) of average storage the required flow is determined, other

Volatile liquids

temperature, vapour factors to consider would be the type

of application, pipe size requirements,

pressure and latitude pressure, the desired set point, and the

Vapour recovery regulator flow =

maximum pump in rate + temperature rise

were added in 6th chemical compatibility of materials.

= [16.04 x maximum pump in rate] edition

+ [1.51 x Y-Factor x (Tank Volume For more information:

This article was written by Steve S. Attri,

x 5.618)0.9 x Insulation Factor]

Global Product Manager, Emerson Process

Implications of the new Management, www2.emersonprocess.com

The only difference between the guideline: out-breathing

equations for non-volatile and volatile

liquids is that the 8.02 constant changes The graph above shows a comparison of *Neither Emerson, Emerson Process

Management, nor any of their affiliated

to 16.04 for volatile liquids. This is a key out-breathing requirements versus tank entities assumes responsibility for the selection,

simplification mentioned earlier, that has size. The two curves indicated as Appendix use or maintenance of any product.

Responsibility for proper selection, use,

been implemented with the 7th edition A represent the API Standard 2000 5th

and maintenance of any product remains

of API Standard 2000. Volatile liquids will edition. There are two curves shown to solely with the purchaser and end user.

result in twice the out-breathing flow illustrate both non-volatile and volatile The contents of this publication are presented

for informational purposes only, and while every

requirements as non-volatile ones. liquids. The remaining curves depict effort has been made to ensure their accuracy,

To illustrate how this calculation works, results obtained using the 7th edition, they are not to be construed as warranties or

guarantees, express or implied, regarding the

consider the same example once again: under different Y-Factor figures. The use of products or services described herein or their

the latest guideline can result in greater use or applicability. All sales are governed by

our terms and conditions, which are available

Latitude → Below 42 Degrees out-breathing requirements, but not

upon request. We reserve the right to modify

Vapour pressure → Unknown always. In general, when increased flow or improve the designs or specifications of

Average storage temp → 80°F requirements result, they do not represent such products at any time without notice.

Tank volume → 50,000 barrels as much of a difference as do the in-

Insulation → None breathing requirements explained earlier.

Max pump in/out → 100 Gallons/min

Liquid type → Volatile Conclusions

Vapour recovery regulator flow = The latest API Standard 2000 7th edition

maximum pump in rate + temperature rise represents minor changes to the previous

TANK STORAGE • January/February 2015 83

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- Chaps 1-2 Control Mass Analysis On Work, Heat and 1 LawДокумент2 страницыChaps 1-2 Control Mass Analysis On Work, Heat and 1 LawYerko Navarro FloresОценок пока нет

- Sleeper DesignДокумент4 страницыSleeper DesignriccecriОценок пока нет

- Types of Evaporators: Adarsha Govinda KДокумент35 страницTypes of Evaporators: Adarsha Govinda KAdarsha Govinda KОценок пока нет

- J & K All PapersДокумент104 страницыJ & K All PapersCgpscAspirantОценок пока нет

- Chapter 2 Design For ServiceabilityДокумент29 страницChapter 2 Design For ServiceabilityJoena Linda100% (1)

- Axitop Diffuser For Axial Fans: Industries Greentech Company Career Press Info-Center ContactДокумент2 страницыAxitop Diffuser For Axial Fans: Industries Greentech Company Career Press Info-Center ContactJOMARTINEZMОценок пока нет

- Nozzles: Narayanan Komerath 1Документ34 страницыNozzles: Narayanan Komerath 1Virendra KumarОценок пока нет

- Archimedes Number: WhereДокумент39 страницArchimedes Number: WhereZain UlabideenОценок пока нет

- CHM 152 - Thermodynamics (Ch. 16) Spontaneity: False eДокумент7 страницCHM 152 - Thermodynamics (Ch. 16) Spontaneity: False eQueenQiОценок пока нет

- Finite Element Analysis of The Direct Shear Box Test - Potts (1987) PDFДокумент13 страницFinite Element Analysis of The Direct Shear Box Test - Potts (1987) PDFAlfredo López HernándezОценок пока нет

- PSCG Design StepsДокумент3 страницыPSCG Design StepsJaycee Bareng PagadorОценок пока нет

- Moody Chart PDFДокумент2 страницыMoody Chart PDFlhphong021191Оценок пока нет

- 22.312 Engineering: Nuclear Reactors Homework #13: Author: Lulu Li Professor: Mujid S. KazimiДокумент4 страницы22.312 Engineering: Nuclear Reactors Homework #13: Author: Lulu Li Professor: Mujid S. KazimiSheikh ShoaibОценок пока нет

- Engineering Structures: Qiang Han, Yulong Zhou, Yuchen Ou, Xiuli DuДокумент12 страницEngineering Structures: Qiang Han, Yulong Zhou, Yuchen Ou, Xiuli Duserkanozen80Оценок пока нет

- Fcu PipingДокумент20 страницFcu PipingRamadan RashadОценок пока нет

- Refrigerant Recovery and Recycling Units: Supersedes: 50.40-OM1 Form 50.40-OM1Документ44 страницыRefrigerant Recovery and Recycling Units: Supersedes: 50.40-OM1 Form 50.40-OM1James MurrayОценок пока нет

- Engineering Mathematics-Iii: Visvesvaraya Technological University, BelagaviДокумент134 страницыEngineering Mathematics-Iii: Visvesvaraya Technological University, BelagavirameshОценок пока нет

- 84 Top Strength of Materials Question and AnswersДокумент11 страниц84 Top Strength of Materials Question and AnswersM Tatualla0% (1)

- LEC#2Документ33 страницыLEC#2Asia mesoОценок пока нет

- In-Breathing, Out-Breathing Tank Vapor Vents OriginalДокумент8 страницIn-Breathing, Out-Breathing Tank Vapor Vents OriginalPatricio G. ArrienОценок пока нет

- Exam 1 Properties of Fluids UploadДокумент2 страницыExam 1 Properties of Fluids UploadJoryОценок пока нет

- FINALДокумент19 страницFINALanesaОценок пока нет

- Thermal Conductivity of Metal Rod: Instruction ManualДокумент8 страницThermal Conductivity of Metal Rod: Instruction ManualAdityaОценок пока нет

- Assignment2 Answer-KeyДокумент11 страницAssignment2 Answer-KeyRed Crazy0% (1)

- Chap 2 PDFДокумент36 страницChap 2 PDFCemre KuzeyОценок пока нет

- State-Of-The-Art in Design Tools For Floating Offshore Wind Tur-BinesДокумент30 страницState-Of-The-Art in Design Tools For Floating Offshore Wind Tur-BinesKiran Raju AlluriОценок пока нет

- Pipe Line Flexibility Manual CalculationДокумент20 страницPipe Line Flexibility Manual CalculationKagira Drawing Soltuion100% (3)

- Chapter 7Документ30 страницChapter 7Marcus NatividadesОценок пока нет

- Introduction To ANSYS CFD ProfessionalДокумент27 страницIntroduction To ANSYS CFD ProfessionalTran Van TienОценок пока нет

- CHM13P Learning Task 3Документ3 страницыCHM13P Learning Task 3Paolo Gochingco0% (1)