Академический Документы

Профессиональный Документы

Культура Документы

Site Nonconformity Management Procedure

Загружено:

alinor_tnОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Site Nonconformity Management Procedure

Загружено:

alinor_tnАвторское право:

Доступные форматы

CLIENT JOB UNIT

274219 00

PLANT LOCATION MEXICO

EL ENCINO - TOPOLOBAMPO NATURAL GAS SPC. 0000-ZA-E-09403

saimexicana, TRANSPORTATION SYSTEM

PROJECT / UNIT

Rev.

SITE NC MANAGEMENT PROCEDURE Sh. 1 of 11 0

SITE NC MANAGEMENT PROCEDURE

A Issued for Approval

Rev. Description Prepared Checked Approved Date

Data file:000-ZA-E-09403-SITE NC mngmt procedure.doc

This document is the property of Saipem Spa who will safeguard its rights according to the civil and penal provisions of the law.

CLIENT JOB UNIT

274219 00

PLANT LOCATION MEXICO

EL ENCINO - TOPOLOBAMPO NATURAL GAS SPC. 0000-ZA-E-09403

saimexicana, TRANSPORTATION SYSTEM

PROJECT / UNIT

Rev.

SITE NC MANAGEMENT PROCEDURE Sh. 2 of 11 0

TABLE OF CONTENTS

1 INTRODUCTION 3

1.1. Scope of work 3

1.2. Definitions 3

1.3. Abbreviations 3

1.3.1 Project Organization 3

1.3.2 Contractor’s Home Office Departments 4

2 WORK PROCESS AND RESPONSIBILITIES 4

2.1 Objectives and description of the work process 4

2.2 Responsibilities and organisation 5

3 WORKING METHODS 5

3.1 Identification (Costruction, Engineering, Material,

Trasportation) 5

3.2 Segregation 6

3.3 Classification and Solving 6

3.4 Informing 7

4 DOCUMENTATION 8

4.1 Description, verification and administration of the

documents produced 8

ATTACHMENT I: DISTRIBUTION TABLE 9

ATTACHMENT II: NONCONFORMITY REPORT 10

APPENDIX III: NONCONFORMITY REGISTER 11

Data file:000-ZA-E-09403-SITE NC mngmt procedure.doc

This document is the property of Saipem Spa who will safeguard its rights according to the civil and penal provisions of the law.

CLIENT JOB UNIT

274219 00

PLANT LOCATION MEXICO

EL ENCINO - TOPOLOBAMPO NATURAL GAS SPC. 0000-ZA-E-09403

saimexicana, TRANSPORTATION SYSTEM

PROJECT / UNIT

Rev.

SITE NC MANAGEMENT PROCEDURE Sh. 3 of 11 0

1 INTRODUCTION

1.1. Scope of work

This document defines methods and criteria to be followed by the Contractor personnel in

managing any non-conformity found on site regarding materials, equipment, installation or

construction works. Non-conformity refers to a non fulfilment of a specified requirement and in

particular departure or absence of one or more quality features that may requires a corrective

action.

1.2. Definitions

COMPANY: Transportadora de Gas Natural del Noroeste, TGNN

Contractor Saimexicana S.A. da C.V.

Contract Contract between COMPANY and CONTRACTOR with all Annex

and Attachments

Contractor Home Office Saimexicana office (Mexico City)

Subcontractor: means any persons, firm, partnership, corporation or combination

thereof to whom any part of the Works is subcontracted by the

Contractor in accordance with the terms of the Contract, and for

avoidance of doubt includes Vendors

Vendor/Supplier party which supplies equipment, materials and/or services as

specified by Contractor in the scope of supply

1.3. Abbreviations

1.3.1 Project Organization

CM Construction Manager

COM Commissioning Manager

DS Discipline Superintendent

FEM Field Engineering Manager

FCC Field Control Coordinator

FMMS Field Material Management Superintendent

FQM Field Quality Manager

FSE Field Specialist Engineer

PCL Project Construction Leader

PPL Project Process Leader

PSL Project Specialist Leader

PM Project Manager

PQM Project Quality Manager

PROC Project Procurement Manager

QCS Field Quality Control Supervisor

Data file:000-ZA-E-09403-SITE NC mngmt procedure.doc

This document is the property of Saipem Spa who will safeguard its rights according to the civil and penal provisions of the law.

CLIENT JOB UNIT

274219 00

PLANT LOCATION MEXICO

EL ENCINO - TOPOLOBAMPO NATURAL GAS SPC. 0000-ZA-E-09403

saimexicana, TRANSPORTATION SYSTEM

PROJECT / UNIT

Rev.

SITE NC MANAGEMENT PROCEDURE Sh. 4 of 11 0

SM Site Manager

TM Technical Manager

WI Welding Inspector

WS Warehouse Superintendent

1.3.2 Contractor’s Home Office Departments

APR Procurement & Contracting

ACQM Materials Purchasing

ACQS Services Purchasing & Subcontracting

ASF Expediting & Shipping

QCF Purchased Materials Quality Control

HSEQ Health, Safety, Environment & Quality

QUAL Quality

2 WORK PROCESS AND RESPONSIBILITIES

This document defines methods and criteria to be followed by the Contractor personnel in

managing any non-conformity (N.C.) found on site regarding materials, equipment, installation or

construction works.

A non-conformity could be caused by errors in construction, deficiency of materials, transport

damages, poor materials preservation, wrong installation, partial or total deficiency of testing and

inspection documents or their non-traceability and by other causes as workmanship, services

provided, etc.

Where this procedure is concerned, the deficiency that appears during the erection and that could

be repaired on site during erection shall not be considered as a non conformity. The relevant

remedial work shall be carried out in accordance with the normal practice and the approval

procedures (such as welding discontinuity). These discontinuities shall be recorded using the

check and inspection records.

This procedure does not deal with cases of material quantity received at site in “over or short”

quantity against the one indicated on the packing list or order, regarding which a different

procedure is issued.

This procedure applies to all executive projects involving construction and/or supervision activities

on site for which the Contractor is responsible.

Contractor shall inform the Company for any deficiency or planned repairs and Company will

approve or reject the proposed repairs solutions based on repair procedures approved by

Company before commencing the work and in accordance with the Contract and applicable

Company and International standards and specification.

2.1 Objectives and description of the work process

The objectives of work process are:

a) to avoid non-conforming materials and/or equipment being unintentionally used or accepted;

b) to ensure that non-conforming materials are managed following established procedures and

by authorised personnel;

Data file:000-ZA-E-09403-SITE NC mngmt procedure.doc

This document is the property of Saipem Spa who will safeguard its rights according to the civil and penal provisions of the law.

CLIENT JOB UNIT

274219 00

PLANT LOCATION MEXICO

EL ENCINO - TOPOLOBAMPO NATURAL GAS SPC. 0000-ZA-E-09403

saimexicana, TRANSPORTATION SYSTEM

PROJECT / UNIT

Rev.

SITE NC MANAGEMENT PROCEDURE Sh. 5 of 11 0

c) to ensure that the documentation necessary for documenting and solving non-conformity

problems is issued;

d) to ensure that the information is distributed to the departments concerned in order to eliminate

the causes of non-conformity and prevent their future recurrence.

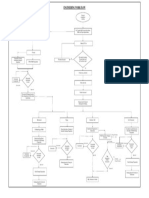

The activities carried out to handle non-conformity are: identification, evaluation, segregation and

solution of non-conformity and administration of related documentation as described in following

sections.

2.2 Responsibilities and organisation

The FQM manages the administration of non-conformity using the “Site non-conformity Register”.

Working with the assistance of the FSE’s, action is taken to solve non-conformity on site by the

WS for non-conformity identified in the warehouse, by the DS for non-conformity identified during

erection and by the COM for non-conformity identified during the plant start-up activities.

They shall request the support and approval of the home office PSL’s/PPL’s and ACQM’s for the

cases specified in the following sections.

The resolutions of non-conformity shall be approved by the FEM and SM and by the PM if non-

conformities may have consequences on schedules and costs which cannot be recovered.

However, the Subcontractor shall perform tasks to close NCR’s so he is responsible for, under the

guidance of the DS or FQM.

3 WORKING METHODS

3.1 Identification (Construction, Engineering, Material, Transportation)

Personnel in the warehouse or in the field shall inform the DS or the FQM of suspected cases of

non-conformity and the material shall be suitably marked to prevent its use while awaiting

evaluation.

The relevant DS or FQM is responsible for establishing whether there is really a non-conformity on

the basis of the codes, drawings and applicable specifications, or of good working practice, with

the help of the relevant FSEs.

Once the finding of a non-conformity has been confirmed, the DS concerned shall ask to the FQM

the progressive NC number and than will fill in the related report (Attachment II) which will identify

precisely the item and the non-conformity filling all the information requested on form, leaving the

part for its solution blank for the time being. As a rule the report should contain the following

information:

- the name of the item

- the drawing number

- the procedure number

- the order number

- the supplier

- the type of material

- the phase in which the non-conformity was detected

- the date when the non-conformity was detected

Data file:000-ZA-E-09403-SITE NC mngmt procedure.doc

This document is the property of Saipem Spa who will safeguard its rights according to the civil and penal provisions of the law.

CLIENT JOB UNIT

274219 00

PLANT LOCATION MEXICO

EL ENCINO - TOPOLOBAMPO NATURAL GAS SPC. 0000-ZA-E-09403

saimexicana, TRANSPORTATION SYSTEM

PROJECT / UNIT

Rev.

SITE NC MANAGEMENT PROCEDURE Sh. 6 of 11 0

- a description of the non-conformity

- the number of pieces affected by the non-conformity

- the number of pieces of the same order and type investigated

- corrective actions

The FQM shall register the non-conformity report on the NC Register and distribute by E.mail to

the involved people accordingly to the distribution table..

The Nonconformity Report shall be signed by four hands:

The person who originated the non conformity;

Vendor(s) (if applicable);

The Contractor; (SM)

The Company.

The Company shall be informed for all Site Non-conformities and the Non-conformity reports shall

be distributed and signed by Company.

3.2 Segregation

Once the existence of a non-conformity has been confirmed, the DS concerned shall ensure that:

- the bulk material is marked as such, and is kept separate from other material, so

as to avoid its use as conforming material;

- itemised material is kept under control by means of the non conforming register

and its location by means of layout drawings.

- The Construction item under NC is clearly fiscally identified on construction site

3.3 Classification and Solving

There are four different possible lines of action. (CLASS: a, b, c, d mentioned below)

a) Repair using an approved procedure which obtains full compliance with the established

codes and specifications;

b) Repair which obtains full compliance using a new procedure or one which has not

previously been applied or that requires the approval of the DS concerned (the WI should

be involved when welding is required). In this case, the DS may also involve the relevant

Home Office PSL/PPL, ACQM and supplier. When necessary tests specified in the

applicable codes shall be carried out and documented.

Before the repair acceptance, the DS (or WI) shall confirm its satisfactory result and full

compliance to the established requirements;

c) Acceptance of certain deviations from the established specifications or codes: in this case

the course of action described in Corporate Snamprogetti procedure OPR.GC.XE.5005

regarding modifications to project documents is applied. The DS of the concerned

discipline shall explain the reason for accepting the "Non-conformity report" and he shall

obtain the approval of the PSL, PPL or ACQM before proceeding; in this case Concession

request will be raised to Company approval.

d) Scrapping, in this case the DS involved shall consider all the possible consequences on

the schedules and costs, informing the SM and, when necessary, the project positions

concerned, to evaluate and minimize the consequences.

In all site NC activities (solving, repairs, acceptance, scrapping, etc.) the Company or his

representative shall be involved for review and approve/reject decisions.

Data file:000-ZA-E-09403-SITE NC mngmt procedure.doc

This document is the property of Saipem Spa who will safeguard its rights according to the civil and penal provisions of the law.

CLIENT JOB UNIT

274219 00

PLANT LOCATION MEXICO

EL ENCINO - TOPOLOBAMPO NATURAL GAS SPC. 0000-ZA-E-09403

saimexicana, TRANSPORTATION SYSTEM

PROJECT / UNIT

Rev.

SITE NC MANAGEMENT PROCEDURE Sh. 7 of 11 0

in all Site NC activities (classes a, b, c, and d included) the Company or his representative shall be

involved for his participation for review/approval of site NC

Where situations are as described in sections c) and d), the solution adopted shall be approved by

the SM without impacting schedule and cost.

In cases of non-conformity that have consequences for scheduling and costs that cannot be

absorbed by the system, the PM shall be involved immediately.

Where necessary, the Subcontractor shall be asked to take corrective actions to eliminate the

causes of non-conformity and prevent their recurrence.

The Site NC issued by the Company will require the Contractor response/action and Corrective

action

The Contractor has the final responsibility to eliminate the NC, request the corrective actions and

to prevent the Site NC.

All the Corrective actions will be evaluated and carried out in accordance with the Contract and

applicable Company and International standards and specification.

3.4 Informing

Subcontractors or suppliers and the Company, are to be informed of the type of solution adopted

and of any corrective actions required, so that they can be carried out.

The DS (or WI) involved subsequently shall verify the suitability of the solution, ensuring that the

item in question is subjected to tests, checks and inspections that are no less severe than those

initially required.

The reference is the Corporate Saipem procedure OPR.GC.XE.5008 regarding any back-

charges to be requested from suppliers or claims against transport insurance.

The FQM checks, monitors and expedites implementation, completion and adequacy of non-

conformity disposition and shall initiate preliminary research into the causes of significant cases of

non-conformity in order to prevent their recurrences, subsequently sending the non-conformity

report and his evaluations to the home office QUAL, and ACQM departments.

The corrective actions on quality system, if necessary, will be evaluated and carried out in

accordance with Corporate Saipem procedure OPR.QL.XE.5005 “Corrective and preventive

actions of the quality system”.

Data file:000-ZA-E-09403-SITE NC mngmt procedure.doc

This document is the property of Saipem Spa who will safeguard its rights according to the civil and penal provisions of the law.

CLIENT JOB UNIT

274219 00

PLANT LOCATION MEXICO

EL ENCINO - TOPOLOBAMPO NATURAL GAS SPC. 0000-ZA-E-09403

saimexicana, TRANSPORTATION SYSTEM

PROJECT / UNIT

Rev.

SITE NC MANAGEMENT PROCEDURE Sh. 8 of 11 0

4 DOCUMENTATION

4.1 Description, verification and administration of the documents produced

When solving method of the non-conformity is clear, the DS (or WI) involved shall ensure that the

non-conformity report referred to in previous section is completed with all the information on the

solution and the corrective actions requested.

In those cases described in sections 3.3 a) and b), the report shall be signed by the DS (or WI)

concerned, while in the cases described in sections 3.3 c) and d) it shall be signed by the SM.

The FQM maintains the original of this report and, particularly where the course of action 3.3 c)

has been adopted, shall verify that all the positions concerned have been involved and the

necessary approval ,(including Concession request wherever required), has been obtained.

Copies of the report shall be sent to the positions shown in attachment I.

The FQM shall number and record the situation of non-conformity in the relevant register for

monitoring the implementation of the resolutions (attachment III). Documentation shall be

maintained as a record until provisional acceptance.

The NC report shall be reviewed and signed by the Company in all stages of NC (identification,

classification, corrective action, closing and acceptance).

5 DOCUMENTATION

ATTACHMENT I : DISTRIBUTION TABLE

ATTACHMENT II : NON CONFORMITY REPORT

ATTACHMENT III : NON CONFORMITY REGISTER

Data file:000-ZA-E-09403-SITE NC mngmt procedure.doc

This document is the property of Saipem Spa who will safeguard its rights according to the civil and penal provisions of the law.

CLIENT JOB UNIT

274219 00

PLANT LOCATION MEXICO

EL ENCINO - TOPOLOBAMPO NATURAL GAS SPC. 0000-ZA-E-09403

saimexicana, TRANSPORTATION SYSTEM

PROJECT / UNIT

Rev.

SITE NC MANAGEMENT PROCEDURE Sh. 9 of 11 0

ATTACHMENT I: DISTRIBUTION TABLE

SM CM COM FQM FEM DS FMMS PSL PQM ACQM PM PPL

1. Non-conformity A C V A C E (3) Z (2) (4) (3)

report for Z Z Z Z

Transportation and

materials

2. Non-conformity A C V A E (3) Z (4) (3)

report during Z Z Z

Construction works

3. Non-conformity A C E V A (3) Z (4) (3)

report during pre- Z Z Z

commissioning

4.Non-conformity Z Z Z E Z Z Z Z Z

register

A = APPROVAL

V = REVIEW

E = EXECUTION

C = COMMENTS

Z = TO BE INFORMED

* = IN AREAS OF RESPONSIBILITY

(2) IN CASES WHERE THERE ARE NON-CONFORMITY PROBLEMS WITH SUPPLIES, CONFIRMATION MUST BE

OBTAINED FROM ACQM VIA FAX OR TELEX BEFORE ISSUING A BACK-CHARGE REQUEST TO THE SUPPLIER. SEE

CORPORATE SNAMPROGETTI OPR.GC.XE.5008, BACK-CHARGE PROCEDURE FOR NON-CONFORMING ITEMS ON

SITE.

(3) IN NON-CONFORMITY CASES 3.3.b AND 3.3.c "ACCEPTANCE OF CERTAIN DEVIATIONS", APPROVAL OF PSL, PPL

OR ACQM MUST BE OBTAINED BEFORE PROCEEDING.

(4) IN CASES OF NON-CONFORMITY WHICH HAVE CONSEQUENCES ON COSTS AND SCHEDULES WHICH CANNOT BE

ABSORBED, THE PM MUST BE INVOLVED IMMEDIATELY.

Data file:000-ZA-E-09403-SITE NC mngmt procedure.doc

This document is the property of Saipem Spa who will safeguard its rights according to the civil and penal provisions of the law.

CLIENT JOB UNIT

274219 00

PLANT LOCATION MEXICO

EL ENCINO - TOPOLOBAMPO NATURAL GAS SPC. 0000-ZA-E-09403

saimexicana, TRANSPORTATION SYSTEM

PROJECT / UNIT

Rev.

SITE NC MANAGEMENT PROCEDURE Sh. 10 of 11 0

ATTACHMENT II: NONCONFORMITY REPORT

NON CONFORMITY REPORT

Originator REFERENCES

Order/Contract No.: Order Position:

Name:

…………………………………………….

Position: Attachment (if any):

…………………………………………….

Open date: Supplier: Subcontractor:

…………………………………………….

NC Identification

Costruction □ Engineering □ □ Material Trasportation □ Class: a □ b□ c□ d□

Discipline: ELE □ SMAUT □ □ □CIV PIPING MECHANICAL □ PACKAGE □ □ PIPELINE

NON CONFORMITY CODE

NON CONFORMITY DESCRIPTION (by originator)

CORRECTIVE ACTION:

Approval of Corrective action

Supplier or Subcontractor Signature/date Contractor Signature/ Date: Company Signature/ Date:

CORRECTIVE ACTION(S) CONTROL AND REINSPECTION RECORD REFERENCE

NC positive closing Record reference if any:

NC closing acceptance

Supplier or Subcontractor Signature/date Contractor Signature/ Date: Company Signature/ Date:

COST/CONSTRUCTION MANHOURS

See report attached if any :

Home Office Review Signature& Date:

Data file:000-ZA-E-09403-SITE NC mngmt procedure.doc

This document is the property of Saipem Spa who will safeguard its rights according to the civil and penal provisions of the law.

CLIENT JOB UNIT

274219 00

PLANT LOCATION MEXICO

EL ENCINO - TOPOLOBAMPO NATURAL GAS SPC. 0000-ZA-E-09403

saimexicana, TRANSPORTATION SYSTEM

PROJECT / UNIT

Rev.

SITE NC MANAGEMENT PROCEDURE Sh. 11 of 11 0

APPENDIX III: NONCONFORMITY REGISTER

NON CONFORMITY REGISTER

NC Issue Date SITE/UNIT Discipline Class Identification Brief Detail of Non Conformity Brief Detail of Company Close Out cost Remarks

Report ELE- (a,b,c,d) (Construction, Corrective Action Approval Date impact

N° SMAUT Engineering, Required

CIV- Material, (Yes-No)

PIPING-

Transportation

MECHANICAL

PIPELINE

PACKAGE

Data file:000-ZA-E-09403-SITE NC mngmt procedure.doc

This document is the property of Saipem Spa who will safeguard its rights according to the civil and penal provisions of the law.

Вам также может понравиться

- MSCAT - One Page FormatДокумент1 страницаMSCAT - One Page FormatGeorge Espejo100% (1)

- Omniscan Techniques For Crack SizingДокумент31 страницаOmniscan Techniques For Crack Sizingalinor_tnОценок пока нет

- Flushing and Cleaning Procedure: Gta Hub / Terminal - FacilitiesДокумент27 страницFlushing and Cleaning Procedure: Gta Hub / Terminal - FacilitiesSuci Nur HidayahОценок пока нет

- WPS MS 01C Rev. 0Документ1 страницаWPS MS 01C Rev. 0alinor_tnОценок пока нет

- Welders MatrixДокумент1 страницаWelders Matrixalinor_tn100% (1)

- Revision of Vibracast Refractory Lining Standard SpecificationДокумент38 страницRevision of Vibracast Refractory Lining Standard SpecificationPierre Ramirez100% (1)

- PIP RFEG1000 Guidelines For Use of Refractory PracticesДокумент5 страницPIP RFEG1000 Guidelines For Use of Refractory PracticesNicolasMontoreRosОценок пока нет

- DRP001-OUF-GAL-PRO-Q-000-067 Rev-S1Документ61 страницаDRP001-OUF-GAL-PRO-Q-000-067 Rev-S1Rafat KhanОценок пока нет

- Vendor Front Sheet: Sao Vang and Dai Nguyet Development ProjectДокумент4 страницыVendor Front Sheet: Sao Vang and Dai Nguyet Development ProjectjfdlksaОценок пока нет

- VD V013 ZPM Pro 1507Документ105 страницVD V013 ZPM Pro 1507abdulОценок пока нет

- P6012MAB.000.10.03.771 - O3 - With JV Comments PDFДокумент27 страницP6012MAB.000.10.03.771 - O3 - With JV Comments PDFMukesh MuraleedharanОценок пока нет

- RAPID-FE1-TPX-CMM-SPN-0001-0903, Rev 1Документ6 страницRAPID-FE1-TPX-CMM-SPN-0001-0903, Rev 1Đình NamОценок пока нет

- 140706dpga14328 Exde01 05Документ5 страниц140706dpga14328 Exde01 05Oussama Baddadi100% (1)

- Calculation of Steel Piping SupportsДокумент21 страницаCalculation of Steel Piping Supportsalinor_tnОценок пока нет

- DRP001-OUF-GAL-RAM-E-000-191 Rev-S! PDFДокумент10 страницDRP001-OUF-GAL-RAM-E-000-191 Rev-S! PDFMohammad AftabОценок пока нет

- Construction Steel Erection PlansДокумент10 страницConstruction Steel Erection PlansTran KhuynhОценок пока нет

- RevisionДокумент154 страницыRevisionhalyОценок пока нет

- Khadimally RT011215Документ33 страницыKhadimally RT011215jkj_13874Оценок пока нет

- KR Parco Ps6 Ms 0001 M.S For ConcreteДокумент11 страницKR Parco Ps6 Ms 0001 M.S For ConcretebulzaeОценок пока нет

- Manufacturer Record Book Index for Ball Check and Globe ValvesДокумент17 страницManufacturer Record Book Index for Ball Check and Globe Valvesanil pkОценок пока нет

- Jangkrik Complex - Mto Piping Bulk (Bidding)Документ13 страницJangkrik Complex - Mto Piping Bulk (Bidding)shoghi wisesaОценок пока нет

- Upper Zakum 750 Islands Surface Facilities Project - EPC2 PROJECT No. P7512Документ15 страницUpper Zakum 750 Islands Surface Facilities Project - EPC2 PROJECT No. P7512Anonymous xyZH2OaUVОценок пока нет

- A07 Za e 7002586 - Baa - DДокумент17 страницA07 Za e 7002586 - Baa - DRAMIL100% (1)

- Pre-Commissioning, Commissioning and Reliability Run Plan for 10 MW Geothermal PlantДокумент22 страницыPre-Commissioning, Commissioning and Reliability Run Plan for 10 MW Geothermal PlantMaulana HaniefОценок пока нет

- Att#20 - 7077T-000-PP-0000-108 - 00 List of Codes and StandardsДокумент62 страницыAtt#20 - 7077T-000-PP-0000-108 - 00 List of Codes and Standardsabdelmalek boudjemaaОценок пока нет

- Saudi Aramco Inspection ChecklistДокумент6 страницSaudi Aramco Inspection Checklistnisha_khanОценок пока нет

- 0 Letter ITTДокумент2 страницы0 Letter ITTalphadingОценок пока нет

- SPD0006ERN - Excution Procedures (Basic Design)Документ15 страницSPD0006ERN - Excution Procedures (Basic Design)chuntao fengОценок пока нет

- IDS For Fiber Optic CableДокумент5 страницIDS For Fiber Optic Cablealinor_tnОценок пока нет

- TEP-1177734-B01-0017 - 06 - GIS SS Telecom Layout and Cable Route Diagram PDFДокумент12 страницTEP-1177734-B01-0017 - 06 - GIS SS Telecom Layout and Cable Route Diagram PDFYohannes Eko Hadi NugrohoОценок пока нет

- Material Certification and Traceability RequirementsДокумент12 страницMaterial Certification and Traceability RequirementsAliZenati100% (1)

- IONE-AA00-PE-CM-0001 Precommissioning & Commissioning Execution Plan Rev.0Документ48 страницIONE-AA00-PE-CM-0001 Precommissioning & Commissioning Execution Plan Rev.0YusufОценок пока нет

- Lighting System ITP SummaryДокумент12 страницLighting System ITP SummaryNamta GeorgeОценок пока нет

- T-14.427.475 Work Method Statement For Construction of Abutment and Slope Protection Works - 210623Документ77 страницT-14.427.475 Work Method Statement For Construction of Abutment and Slope Protection Works - 210623JosiahОценок пока нет

- Ssec Profile 2010Документ47 страницSsec Profile 2010Syaiful AzliОценок пока нет

- ATEC PMC ProfileДокумент22 страницыATEC PMC ProfileArun Rajan100% (1)

- Ogbotobo Flowstation Power System Revamp ProjectДокумент10 страницOgbotobo Flowstation Power System Revamp ProjectDaniel DamboОценок пока нет

- 9500-WGEL-S003-ISGP-G00000-MP-4306-00017 - 01A - MTO PFF - by LayoutДокумент7 страниц9500-WGEL-S003-ISGP-G00000-MP-4306-00017 - 01A - MTO PFF - by Layoutsuresh100% (1)

- Power GenerationДокумент34 страницыPower GenerationTaufiq AkbarОценок пока нет

- 1 ITB For Scour Protection at SLTS PROJECTДокумент13 страниц1 ITB For Scour Protection at SLTS PROJECTEng Muhammad Afzal AlmaniОценок пока нет

- Idc-000-Mgp-Onp-Pro-005518en-01 Weld NumberingДокумент18 страницIdc-000-Mgp-Onp-Pro-005518en-01 Weld NumberingJovan Poznan100% (1)

- Annexure 2 - Requisition For Pipe 4inch & AboveДокумент11 страницAnnexure 2 - Requisition For Pipe 4inch & Abovefrankz89Оценок пока нет

- PT Synergy Engineering Proposal for Detailed Engineering Support of Kerendan Field DevelopmentДокумент7 страницPT Synergy Engineering Proposal for Detailed Engineering Support of Kerendan Field DevelopmentmatsuruОценок пока нет

- QA&QC-DT-FRMC-020 Foundation Work of Transmission LineДокумент2 страницыQA&QC-DT-FRMC-020 Foundation Work of Transmission LineTariq Ali SialОценок пока нет

- 000 Pe DS 0001Документ5 страниц000 Pe DS 0001Dar FallОценок пока нет

- UNDERGROUND PIPINGДокумент9 страницUNDERGROUND PIPINGMidhun K ChandraboseОценок пока нет

- Piping Fabrication Installation Erection and Testing PDFДокумент33 страницыPiping Fabrication Installation Erection and Testing PDFDeepak0% (1)

- KP-00+++-CQ712-B7358-Rev 0-ITP For DS PDFДокумент3 страницыKP-00+++-CQ712-B7358-Rev 0-ITP For DS PDFUtku Can KılıçОценок пока нет

- SPIE Document Deliverable Register Commisioning (10-Jan-2018)Документ139 страницSPIE Document Deliverable Register Commisioning (10-Jan-2018)BalasubramanianОценок пока нет

- FEED - Front End Engineering & Design in Oil & Gas Projects - CPO INNOVATIONДокумент6 страницFEED - Front End Engineering & Design in Oil & Gas Projects - CPO INNOVATIONdriveamar21Оценок пока нет

- RFQ For Pressure TransmitterДокумент21 страницаRFQ For Pressure Transmittersugeng wahyudiОценок пока нет

- Paint Specification Package CДокумент32 страницыPaint Specification Package CMohammedОценок пока нет

- Ethane Deep Recovery Facility Project (Edrf) : Tie-In Package For Tip-0122Документ64 страницыEthane Deep Recovery Facility Project (Edrf) : Tie-In Package For Tip-0122sarangpuneОценок пока нет

- 1242352015di400100 D1Документ6 страниц1242352015di400100 D1Cristinel NechiforОценок пока нет

- DESB-NOE-MDR-OO1 Rev A (Master Document Register)Документ2 страницыDESB-NOE-MDR-OO1 Rev A (Master Document Register)Amy100% (1)

- CCTV System Interconnect DiagramДокумент8 страницCCTV System Interconnect DiagramSlobodan MilosavljevicОценок пока нет

- SVDN-CPP-M-0006-M12-0002-Rev.07-PSV CalculationДокумент38 страницSVDN-CPP-M-0006-M12-0002-Rev.07-PSV CalculationVu TranОценок пока нет

- Witness Joint & Sampling MatrixДокумент13 страницWitness Joint & Sampling MatrixPazhamalai RajanОценок пока нет

- Inst Vortex PDFДокумент54 страницыInst Vortex PDFambeshОценок пока нет

- Control of Welding Consumable ProcedureДокумент23 страницыControl of Welding Consumable ProcedureZaidiОценок пока нет

- Suban Compression Project: Document Title: Equipment Protection and Preservation Procedure at SiteДокумент23 страницыSuban Compression Project: Document Title: Equipment Protection and Preservation Procedure at SiteMikiRoniWijayaОценок пока нет

- Koc Design BasisДокумент92 страницыKoc Design BasisgyanwapiОценок пока нет

- Engineering Flow ChartДокумент1 страницаEngineering Flow ChartThamotharanОценок пока нет

- K2S-CWS230907-GEN-BA6070-00007 - A01 - Work Method Statement For The Installation of 8mva TransfomerДокумент16 страницK2S-CWS230907-GEN-BA6070-00007 - A01 - Work Method Statement For The Installation of 8mva TransfomerAzeta Robert100% (1)

- 000-ZA-E-09413 Construction Progress Meas ProcДокумент12 страниц000-ZA-E-09413 Construction Progress Meas Procalinor_tnОценок пока нет

- 000 ZA E 09411 Punch List ProcedureДокумент17 страниц000 ZA E 09411 Punch List Procedurealinor_tn100% (1)

- Walkways Steel Structure and R.C. Foundations DrawingsДокумент3 страницыWalkways Steel Structure and R.C. Foundations Drawingsalinor_tnОценок пока нет

- Pipeline Welding Visual Inspection ReportДокумент8 страницPipeline Welding Visual Inspection Reportalinor_tn0% (1)

- IDS For Fiber Optic CableДокумент5 страницIDS For Fiber Optic Cablealinor_tnОценок пока нет

- Hazop Sil Study Report For 6 Buy Back Gas PipelineДокумент32 страницыHazop Sil Study Report For 6 Buy Back Gas Pipelinealinor_tn100% (1)

- Technical Data Sheet For Control ValveДокумент5 страницTechnical Data Sheet For Control Valvealinor_tnОценок пока нет

- Pipeline Hydrotest ProcedureДокумент78 страницPipeline Hydrotest Procedurealinor_tn100% (1)

- Calculation of Steel Piping SupportsДокумент21 страницаCalculation of Steel Piping Supportsalinor_tnОценок пока нет

- Technical Data Sheet For Temperature TransmitterДокумент38 страницTechnical Data Sheet For Temperature Transmitteralinor_tnОценок пока нет

- Work Method Statement For De-Watering Drying and Purging After HydrotestДокумент12 страницWork Method Statement For De-Watering Drying and Purging After Hydrotestalinor_tnОценок пока нет

- 000-Za-E-09303 - 0 Packing and Marking ProcedureДокумент251 страница000-Za-E-09303 - 0 Packing and Marking Procedurealinor_tnОценок пока нет

- 000-ZA-E-09413 Construction Progress Meas ProcДокумент12 страниц000-ZA-E-09413 Construction Progress Meas Procalinor_tnОценок пока нет

- 000 ZA E 09411 Punch List ProcedureДокумент17 страниц000 ZA E 09411 Punch List Procedurealinor_tn100% (1)

- Sample Test Pack - Piping HydrotestДокумент96 страницSample Test Pack - Piping Hydrotestalinor_tn75% (4)

- Flowlines NDT RequestДокумент4 страницыFlowlines NDT Requestalinor_tnОценок пока нет

- Reports Approval Status - 11.12.2017Документ4 страницыReports Approval Status - 11.12.2017alinor_tnОценок пока нет

- MLE System SubSystem SheduleДокумент29 страницMLE System SubSystem Shedulealinor_tnОценок пока нет

- ESAB - PipelinesДокумент65 страницESAB - PipelinesLigia114100% (2)

- Tie-In StatusДокумент22 страницыTie-In Statusalinor_tnОценок пока нет

- RT Permit To WorkДокумент1 страницаRT Permit To Workalinor_tnОценок пока нет

- Piezometer Marker Installation GuideДокумент1 страницаPiezometer Marker Installation Guidealinor_tn100% (1)

- Mechanical Test Specimens PlanДокумент3 страницыMechanical Test Specimens Planalinor_tn100% (1)

- Comparison of API 1104 Appendix A and BS 7910 Procedures For The Assessment of Girth Weld FlawsДокумент10 страницComparison of API 1104 Appendix A and BS 7910 Procedures For The Assessment of Girth Weld Flawsalinor_tnОценок пока нет

- ITP-000 Piping Fabrication (Exemple)Документ5 страницITP-000 Piping Fabrication (Exemple)alinor_tn100% (1)

- General Procedure For AUTДокумент19 страницGeneral Procedure For AUTalinor_tn100% (2)

- Recommandation TodfДокумент14 страницRecommandation Todfalinor_tnОценок пока нет

- Ch16 Fss CodeДокумент7 страницCh16 Fss Codeerudite_0206Оценок пока нет

- Astm B 1 - 95Документ5 страницAstm B 1 - 95MarceloОценок пока нет

- Practical Structural Examination of Container Handling Cranes in Ports and TerminalsДокумент17 страницPractical Structural Examination of Container Handling Cranes in Ports and TerminalsStella SofiaОценок пока нет

- Report WritingДокумент6 страницReport WritingPurushotham MPОценок пока нет

- DQ-10657 Initial Inspection Report 05.02.18Документ7 страницDQ-10657 Initial Inspection Report 05.02.18abidhassan1100% (1)

- Hose Handling, Inspection & Testing Guidelines: For Dantec Composite Hoses Installed in ServiceДокумент17 страницHose Handling, Inspection & Testing Guidelines: For Dantec Composite Hoses Installed in ServicecmpuckОценок пока нет

- Monthly ChecklistДокумент34 страницыMonthly ChecklistPavel Viktor100% (1)

- Pressure Vessel DesignДокумент83 страницыPressure Vessel Designsmrajbe100% (3)

- Bus Duct Unloading, Shifting, Installing MS 01Документ25 страницBus Duct Unloading, Shifting, Installing MS 01Sufiyan KhedekarОценок пока нет

- Project PPT - OKДокумент28 страницProject PPT - OKkrushna NikamОценок пока нет

- Flare Stack ITP Inspection PlanДокумент3 страницыFlare Stack ITP Inspection Planlailatul kodriОценок пока нет

- SAMSUNGДокумент13 страницSAMSUNGTicketОценок пока нет

- Risk Based Process Safety 1679636677Документ87 страницRisk Based Process Safety 1679636677nhishamОценок пока нет

- Inspection and Test Plan (Itp)Документ20 страницInspection and Test Plan (Itp)المهندس محمد الزواهرة Eng Mohummed Al-zawhreh100% (2)

- Inspection and Test Plan, Pre-Production & Production Requirements. SD2. (Subsea)Документ18 страницInspection and Test Plan, Pre-Production & Production Requirements. SD2. (Subsea)carydacОценок пока нет

- Astm 403Документ7 страницAstm 403JOSEPH REFUERZOОценок пока нет

- 02-779 Requirements For 90-10 Copper - Nickel - Alloy Part-3 TubingДокумент47 страниц02-779 Requirements For 90-10 Copper - Nickel - Alloy Part-3 TubingHattar MОценок пока нет

- Lifting Slinging SafetyДокумент40 страницLifting Slinging SafetykamalОценок пока нет

- 2 ASME Quality Control SystemДокумент25 страниц2 ASME Quality Control SystemOsu AmpawanonОценок пока нет

- Internal Audit Check Sheet Ok 2016Документ11 страницInternal Audit Check Sheet Ok 2016manttupandeyОценок пока нет

- Icbo Administrative Code-97Документ23 страницыIcbo Administrative Code-97Matthew Taylor100% (1)

- COMAH Site-Prioritisation-MethodologyДокумент11 страницCOMAH Site-Prioritisation-MethodologyDanny BoysieОценок пока нет

- Ips M PM 220Документ16 страницIps M PM 220Ak OraОценок пока нет

- Spec - Shop Inspection RequirementДокумент28 страницSpec - Shop Inspection RequirementarissaОценок пока нет

- Mbs Sop-121 Hse PermitsДокумент12 страницMbs Sop-121 Hse Permitsosei kwadwoОценок пока нет

- NVQ Level 5 Equivalence for Construction TechnologyДокумент46 страницNVQ Level 5 Equivalence for Construction TechnologyJanaka SenanayakaОценок пока нет

- Globalpmc - Doc - Rev 4Документ51 страницаGlobalpmc - Doc - Rev 4Salman HussainОценок пока нет

- FMS Gap AnalysisДокумент10 страницFMS Gap AnalysisRuni ArundantiОценок пока нет