Академический Документы

Профессиональный Документы

Культура Документы

Anexo 1-1 - Embreak 2W906

Загружено:

cpcarmОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Anexo 1-1 - Embreak 2W906

Загружено:

cpcarmАвторское право:

Доступные форматы

Fact Sheet

Embreak* 2W906

Emulsion Breaker

Embreak* 2W906 is designed to: Due to the 32°F (0°C) freeze point of this product,

• Resolve emulsions in the water phase of crude freeze protection is required.

oil desalters For consistent effectiveness, Embreak 2W906 is

• Reduce the buildup of emulsions and solids at strongly advised to have a Hastelloy or Inconel /quill

the desalter interface injection system for ambient and elevated temp

• Enhance performance of primary desalter applications. It is usually fed to the suction side of

emulsion breaker to improve desalter perform- the desalter wash water or mud wash pump.

ance

DO NOT MIX with other process chemicals unless

• Reduce emulsion growth in desalters during

compatibility has been checked with product man-

crude tank switches and crude slate changes

agement.

Description and Use Evaluation & Storage

Embreak 2W906 is a water-soluble emulsion

For best treatment performance, the Embreak

breaker specifically formulated to resolve water

2W906 program must be conscientiously evaluated

continuous (reverse) emulsions in crude oil desal-

by periodically recording critical unit parameters

ters. This product coalesces oil in the water phase

such as; crude source and quality, wash water

of the desalter so that it rises back into the oil

source and quality, and desalter operation (mix

phase. As a result, Embreak 2W906 improves desal-

valve dP, interface level, electrical grid operation).

ter performance by deoiling the brine effluent.

Embreak 2W906 can also be used in other refinery Embreak 2W906 is approved for storage in polyeth-

applications where water effluent needs deoiling ylene or lined steel tanks only. All piping and pump

internals which come in contact with neat, undi-

Typical Application luted chemical should be at least Alloy 20 for ambi-

ent temperature applications. At temperatures

Embreak 2W906 is effective in resolving reverse

above 100°F (38°C), Inconel or Hastelloy are re-

emulsions produced by many crude slates during

quired. Teflon, HDCLPE, Viton and Kalrez are ac-

the desalting process. It has been particularly effec-

ceptable seal materials. Avoid neoprene and Tygon

tive in desalters processing Latin American, African,

materials.

Canadian, Arabian, and many domestic crudes.

(Inconel is a trademark of Burns Stainless, LLC. Hastelloy is a

Treatment and Feeding Requirements trademark of Haynes International. Teflon, Viton and Kalrez are

trademarks of Dupont Corporation. Tygon is a trademark of

Proper treatment levels for Embreak 2W906 depend Piedmont Plastics, Inc.)

on many factors such as crude composition and the

severity of the desalter operation. Safety Precautions

This product is to be used in accordance with con- A Material Safety Data Sheet (MSDS) containing

trol procedures GE establishes for each specific ap- physical properties data and detailed safety infor-

plication. mation for this product is available by contacting

your GE representative.

Find a contact near you by visiting www.ge.com/water and clicking on “Contact Us” .

* Trademark of General Electric Company; may be registered in one or more countries.

©2011, General Electric Company. All rights reserved.

AM-FShpEmbreak2W906_EN.doc Feb-11

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Instructions For Repairing AlternatorДокумент3 страницыInstructions For Repairing AlternatordamoccaОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Vehicle Suspension DesignДокумент63 страницыVehicle Suspension DesignVenkatesh ChegireddyОценок пока нет

- Ohlins Tool Manual 2017Документ46 страницOhlins Tool Manual 2017Pier o.f.r.Оценок пока нет

- 30 StabilizersДокумент29 страниц30 StabilizersnjileoОценок пока нет

- AC 43.13-1B Section 5 Penetrant InspectionДокумент8 страницAC 43.13-1B Section 5 Penetrant Inspection320338100% (1)

- Basic Tanker Training (Oil, Chemical and Liquefied Gas Tanker)Документ487 страницBasic Tanker Training (Oil, Chemical and Liquefied Gas Tanker)Abdul Hafiz67% (3)

- Mainframe AbendsДокумент12 страницMainframe AbendsMadhuriTungal100% (1)

- Lane Departure Warning SystemДокумент7 страницLane Departure Warning SystemRavisingh RajputОценок пока нет

- Syllabus Compendium For PCN Aerospace Sector ExaminationsДокумент27 страницSyllabus Compendium For PCN Aerospace Sector ExaminationstomcanОценок пока нет

- 40 kVA Specification SheetДокумент2 страницы40 kVA Specification SheetAlex MohanОценок пока нет

- Group 14 : Strainers, Traps, Fine-Mesh Filters Filling Device For Methanol Drain DeviceДокумент3 страницыGroup 14 : Strainers, Traps, Fine-Mesh Filters Filling Device For Methanol Drain DeviceLPG Equipment Consulting and ServicesОценок пока нет

- FC Model - 012201Документ4 страницыFC Model - 012201jlvega18Оценок пока нет

- Octagonal Blender PDFДокумент4 страницыOctagonal Blender PDFMohsinShaikhОценок пока нет

- q64DA PDFДокумент1 страницаq64DA PDFSebastián LozadaОценок пока нет

- Guidelines For Ceiling Framing WorksДокумент3 страницыGuidelines For Ceiling Framing WorksRal GLОценок пока нет

- Bioreactor Design: Mata Kuliah: Pengantar Teknologi BioprosesДокумент33 страницыBioreactor Design: Mata Kuliah: Pengantar Teknologi BioprosesyassinharanОценок пока нет

- MESCO News January 2016Документ4 страницыMESCO News January 2016GoriZakirSalimОценок пока нет

- 2016 GME Steel ProductsДокумент16 страниц2016 GME Steel ProductsMarco Dos Santos NevesОценок пока нет

- Axis College of Engineering & Technology, AmbanolyДокумент3 страницыAxis College of Engineering & Technology, AmbanolygatewayglobalОценок пока нет

- Q - Bae146 Inventory - SSS-Jan 2010Документ6 страницQ - Bae146 Inventory - SSS-Jan 2010sssavОценок пока нет

- SEPG and Consulting ProcessДокумент20 страницSEPG and Consulting ProcesszafzОценок пока нет

- Audesk InventorДокумент7 страницAudesk InventorEddy Wilder Zea UmiñaОценок пока нет

- Geopolymer Reinforced With Bamboo For Sustainable Construction MaterialsДокумент7 страницGeopolymer Reinforced With Bamboo For Sustainable Construction MaterialsSamyuktha SridharОценок пока нет

- ITW Rust Inhibitive Primer 7CZ Product Data 1469103Документ2 страницыITW Rust Inhibitive Primer 7CZ Product Data 1469103rihtak123Оценок пока нет

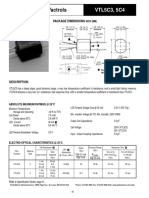

- Low Cost Axial Vactrols: VTL5C3, 5C4Документ2 страницыLow Cost Axial Vactrols: VTL5C3, 5C4sillyОценок пока нет

- Atv71 Controller Inside en v3Документ25 страницAtv71 Controller Inside en v3Juan Rodriguez ArevaloОценок пока нет

- Bowmar MX55 Electronic Calculator ManualДокумент22 страницыBowmar MX55 Electronic Calculator ManualDjango RodОценок пока нет

- Kleene ClosureДокумент6 страницKleene ClosurepbhmmmmОценок пока нет

- Structural Welding Inspection: 2019 CBC: DSA Forms DSA PublicationsДокумент3 страницыStructural Welding Inspection: 2019 CBC: DSA Forms DSA PublicationsfracevОценок пока нет

- Protection For HV Line BayДокумент3 страницыProtection For HV Line BayhasaladОценок пока нет