Академический Документы

Профессиональный Документы

Культура Документы

Phosphate Dissolves All The Suspended Solids by Making Soluble Complex Compounds Which May Precipitate at PH Higher Than 11

Загружено:

sorinacam_c73110 оценок0% нашли этот документ полезным (0 голосов)

23 просмотров1 страницаPhosphate controls pH in boiler water systems by forming complexes with dissolved solids and buffering against large pH changes. Excess caustic combines with disodium phosphate to form trisodium phosphate, preventing caustic buildup. Different forms of phosphate consume or produce caustic ions as they shift forms to control pH. A new boiler water treatment was developed using only phosphate-derived alkalinity instead of sodium hydroxide, where the sodium to phosphate ratio determines pH and adjusting the ratio of trisodium to monosodium/disodium phosphate achieves the desired pH and phosphate levels without creating free caustic.

Исходное описание:

about anticorrosion

Оригинальное название

Phosphate

Авторское право

© © All Rights Reserved

Доступные форматы

DOCX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документPhosphate controls pH in boiler water systems by forming complexes with dissolved solids and buffering against large pH changes. Excess caustic combines with disodium phosphate to form trisodium phosphate, preventing caustic buildup. Different forms of phosphate consume or produce caustic ions as they shift forms to control pH. A new boiler water treatment was developed using only phosphate-derived alkalinity instead of sodium hydroxide, where the sodium to phosphate ratio determines pH and adjusting the ratio of trisodium to monosodium/disodium phosphate achieves the desired pH and phosphate levels without creating free caustic.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

23 просмотров1 страницаPhosphate Dissolves All The Suspended Solids by Making Soluble Complex Compounds Which May Precipitate at PH Higher Than 11

Загружено:

sorinacam_c7311Phosphate controls pH in boiler water systems by forming complexes with dissolved solids and buffering against large pH changes. Excess caustic combines with disodium phosphate to form trisodium phosphate, preventing caustic buildup. Different forms of phosphate consume or produce caustic ions as they shift forms to control pH. A new boiler water treatment was developed using only phosphate-derived alkalinity instead of sodium hydroxide, where the sodium to phosphate ratio determines pH and adjusting the ratio of trisodium to monosodium/disodium phosphate achieves the desired pH and phosphate levels without creating free caustic.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 1

Phosphate dissolves all the suspended solids by making soluble complex compounds which may

precipitate at pH higher than 11.

Boiler feedwater systems using demineralized or evaporated makeup or pure condensate may be

protected from caustic attack through coordinated phosphate/pH control. Phosphate buffers the boiler

water, reducing the chance of large pH changes due to the development of high caustic concentrations.

Excess caustic combines with disodium phosphate and forms trisodium phosphate. Sufficient disodium

phosphate must be available to combine with all of the free caustic in order to form trisodium

phosphate.

Disodium phosphate neutralizes caustic by the following reaction:

Na2HPO4 + NaOH ® Na3PO4 + H2O

trisodium

disodium phosphate sodium hydroxide water

phosphate

This results in the prevention of caustic buildup beneath deposits or within a crevice where leakage is

occurring. Caustic corrosion (and caustic embrittlement, discussed later) does not occur, because high

caustic concentrations do not develop

Different forms of phosphate consume or add caustic as the phosphate shifts to the proper form. For

example, addition of monosodium phosphate consumes caustic as it reacts with caustic to form

disodium phosphate in the boiler water according to the following reaction:

NaH2PO4 + NaOH ® Na2HPO4 + H2O

monosodium sodium disodium

water

phosphate hydroxide phosphate

Conversely, addition of trisodium phosphate adds caustic, increasing boiler water pH:

Na3PO4 + H2O ® Na2HPO4 + NaOH

sodium

trisodium phosphate water disodium phosphate

hydroxide

Control is achieved through feed of the proper type of phosphate to either raise or lower the pH while

maintaining the proper phosphate level. Increasing blowdown lowers both phosphate and pH.

Therefore, various combinations and feed rates of phosphate, blowdown adjustment, and caustic

addition are used to maintain proper phosphate/pH levels.

Elevated temperatures at the boiler tube wall or deposits can result in some precipitation of phosphate.

This effect, termed "phosphate hideout," usually occurs when loads increase. When the load is

reduced, phosphate reappears.

Clean boiler water surfaces reduce potential concentration sites for caustic. Deposit control treatment

programs, such as those based on chelants and synthetic polymers, can help provide clean surfaces.

Where steam blanketing is occurring, corrosion can take place even without the presence of caustic,

due to the steam/magnetite reaction and the dissolution of magnetite. In such cases, operational

changes or design modifications may be necessary to eliminate the cause of the problem.

New boiler water treatment was developed using the alkalinity derived from phosphate alone,

eliminating sodium hydroxide – The sodium to phosphate ratio determines the pH of the water (3:1) –

Ratio of trisodium to monosodium or disodium phosphate is adjusted to desired pH and phosphate

levels can be attained without creating free caustic (3:1) – As trisodium phosphate hydrolyzes in the

water it produces a hydroxyl ion (OH) which controls the pH level – Monosodium or disodium phosphate

do not produce OH – Use of two different phosphates prevented complete program control at times.

Вам также может понравиться

- Boiler Water TreatmentДокумент7 страницBoiler Water TreatmentJAY PARIKH100% (1)

- Using of Congruent Phosphate As Equilibrium PhosphДокумент12 страницUsing of Congruent Phosphate As Equilibrium Phosphhendra desfiantoroОценок пока нет

- Using of Congruent Phosphate As EquilibrДокумент10 страницUsing of Congruent Phosphate As Equilibregyptian_scientistОценок пока нет

- Boiler Phosphate HideoutДокумент3 страницыBoiler Phosphate Hideoutzeeshan100% (1)

- Formula: H-O4-P.2Na: Sodium PhosphateДокумент3 страницыFormula: H-O4-P.2Na: Sodium PhosphateKeiffer Ann LopezОценок пока нет

- The Main Purposes of Chemical Applications:: CausticДокумент11 страницThe Main Purposes of Chemical Applications:: CausticMahmoud AbdelaalОценок пока нет

- United States: Patent OfficeДокумент3 страницыUnited States: Patent OfficefredyОценок пока нет

- Phosphate Hideout PDFДокумент4 страницыPhosphate Hideout PDFUsama JawaidОценок пока нет

- Phosphate Hideout PDFДокумент4 страницыPhosphate Hideout PDFAHMAD DZAKYОценок пока нет

- Orthophosphoric Acid or PhosphoricДокумент4 страницыOrthophosphoric Acid or PhosphoricArish AhmedОценок пока нет

- 2096682530-Ich 305 Phosphorus Based ChemicalsДокумент9 страниц2096682530-Ich 305 Phosphorus Based ChemicalsDennis JosephОценок пока нет

- Uses Applications of Phosphates in Cooling Water TreatmentДокумент3 страницыUses Applications of Phosphates in Cooling Water TreatmentMahmoud AliОценок пока нет

- Co-Ordinated and Congruent Phosphate Treatments: AlkalinityДокумент3 страницыCo-Ordinated and Congruent Phosphate Treatments: AlkalinityMeghanath AdkonkarОценок пока нет

- Phosphate Hideout: Questions and AnswersДокумент4 страницыPhosphate Hideout: Questions and AnswersSivakumar Rajagopal100% (3)

- PO4-Phosphate Buffers-RECIPES - Preparation of PH Buffer Solutions, PH1.0-PH13.0 - Recipes Ex Web-Delloyd's Lab Tech - Hompage (14!02!18pdf)Документ5 страницPO4-Phosphate Buffers-RECIPES - Preparation of PH Buffer Solutions, PH1.0-PH13.0 - Recipes Ex Web-Delloyd's Lab Tech - Hompage (14!02!18pdf)PinoteDiegoОценок пока нет

- Preparation of PH Buffer Solutions (AnalChem Resources, Ex Web10!04!1613!08!07pdf)Документ5 страницPreparation of PH Buffer Solutions (AnalChem Resources, Ex Web10!04!1613!08!07pdf)Diana ChiscaОценок пока нет

- Phosphate HideoutДокумент3 страницыPhosphate HideoutGreater Potential Tutoring100% (1)

- Fosfato Simple 2Документ4 страницыFosfato Simple 2Jose CortezОценок пока нет

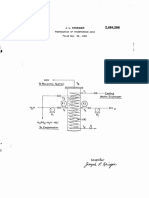

- July 20, 1954 J. L. Krieger 2,684,286: InventorДокумент4 страницыJuly 20, 1954 J. L. Krieger 2,684,286: InventorNurhafizah Abd JabarОценок пока нет

- Preparation of PH Buffer SolutionsДокумент5 страницPreparation of PH Buffer Solutionsnikhilesh2011Оценок пока нет

- Phosphoric AcidДокумент3 страницыPhosphoric AcidAsnan BYОценок пока нет

- Uses Applications of Phosphates in Cooling Water TreatmentДокумент3 страницыUses Applications of Phosphates in Cooling Water Treatmenthassan aliОценок пока нет

- United States Patent Office: 2 Claims. (CI. 71-29)Документ2 страницыUnited States Patent Office: 2 Claims. (CI. 71-29)Fernando Nieto OchoaОценок пока нет

- United States Patent Office: Patented Jan. I9, 1954Документ2 страницыUnited States Patent Office: Patented Jan. I9, 1954JavierОценок пока нет

- Lecture 35 PDFДокумент8 страницLecture 35 PDFabderrahimn100% (1)

- PH Control in Water Treatment Plant by The Addition of CO2Документ10 страницPH Control in Water Treatment Plant by The Addition of CO2George DobreОценок пока нет

- Final Hydrogen-Peroxide ReportДокумент9 страницFinal Hydrogen-Peroxide ReportAshley PeridaОценок пока нет

- Why Is TSPДокумент4 страницыWhy Is TSPAbhi SharmaОценок пока нет

- PhosphateДокумент18 страницPhosphatejaykotak12345100% (8)

- Boiler Water Treatment FundamentalsДокумент8 страницBoiler Water Treatment FundamentalssauravsinhaaОценок пока нет

- HydrazineДокумент13 страницHydrazineSubharaj DasОценок пока нет

- Internal Treatment: Slight Residual Hardness and Also Corrosive Tendencies in WaterДокумент8 страницInternal Treatment: Slight Residual Hardness and Also Corrosive Tendencies in WaterRaunit VermaОценок пока нет

- United States Patent Office: Patented Jan. 1, 1957Документ4 страницыUnited States Patent Office: Patented Jan. 1, 1957felipeОценок пока нет

- Bulletin: Sodium Bicarbonate ChemistryДокумент2 страницыBulletin: Sodium Bicarbonate ChemistryKhurshid AliОценок пока нет

- G.D.Goenka Public School, Sector-22, Rohini CLASS - 10 Chemistry Chapter-2 Acids, Bases and Salts (Notes)Документ3 страницыG.D.Goenka Public School, Sector-22, Rohini CLASS - 10 Chemistry Chapter-2 Acids, Bases and Salts (Notes)vikas aggarwalОценок пока нет

- US3416887Документ6 страницUS3416887khairulОценок пока нет

- Matrix Acidizing of Sandstone4Документ5 страницMatrix Acidizing of Sandstone4HelyaОценок пока нет

- Acid Base Lab ReportДокумент6 страницAcid Base Lab ReportYEEHSHIN JILL GAYOОценок пока нет

- Phosphoric AcidДокумент4 страницыPhosphoric Acidsuleman205Оценок пока нет

- Chemistry Lab Report 1 Titration 2012Документ9 страницChemistry Lab Report 1 Titration 2012VeiliLookОценок пока нет

- Research PaperДокумент10 страницResearch PaperCatherine chaimaОценок пока нет

- PhosphorousДокумент8 страницPhosphorousUJJWAL JHAОценок пока нет

- Sodium Tripolyphosphate D ChinaДокумент11 страницSodium Tripolyphosphate D ChinaKarem Jeanette Saenz BernalОценок пока нет

- Manufacture: Phosphoric Acid, Also Known As Orthophosphoric Acid or Phosphoric (V) Acid, Is AДокумент3 страницыManufacture: Phosphoric Acid, Also Known As Orthophosphoric Acid or Phosphoric (V) Acid, Is AVinod NairОценок пока нет

- Single Supephosphate: Agricultural UseДокумент4 страницыSingle Supephosphate: Agricultural UseRida akhtarОценок пока нет

- Hydrogen Sulfide Control and RemovalДокумент3 страницыHydrogen Sulfide Control and RemovalsalcedopozasОценок пока нет

- United States Patent 0: Patented Jan. 26, 1965 2Документ5 страницUnited States Patent 0: Patented Jan. 26, 1965 2Waheed ZebОценок пока нет

- Co-Ordinated and Congruent Phosphate Treatment of Boiler WaterДокумент3 страницыCo-Ordinated and Congruent Phosphate Treatment of Boiler WaterRavi Shankar0% (1)

- AIMДокумент5 страницAIMroshanjimaxoutОценок пока нет

- 10eng PDFДокумент18 страниц10eng PDFАхмед АбдуллаОценок пока нет

- Ceramic Test - EdrineДокумент7 страницCeramic Test - EdrineL edrineОценок пока нет

- Refinery PH Control in Sour Water Stripping e April2010Документ2 страницыRefinery PH Control in Sour Water Stripping e April2010sunny_lit6806Оценок пока нет

- Superphosphoric Acid by Absorption - of Phosphorus Pentoxide VaporДокумент6 страницSuperphosphoric Acid by Absorption - of Phosphorus Pentoxide Vaporemerentiana1Оценок пока нет

- LD2668T41956F45Документ49 страницLD2668T41956F45bitisa5368Оценок пока нет

- Boiler Water Chemistry Analysis PB QBook PDFДокумент8 страницBoiler Water Chemistry Analysis PB QBook PDFelgawadhaОценок пока нет

- Bleaching Methods of Cellulosic Textile MaterialДокумент13 страницBleaching Methods of Cellulosic Textile Materialshalini sharaffОценок пока нет

- BUFFERДокумент10 страницBUFFERakinolaboluwatife83Оценок пока нет

- SuperphosphatesДокумент2 страницыSuperphosphatesS.P.Оценок пока нет

- Legal Chemistry: A Guide to the Detection of Poisons, Examination of Tea, Stains, Etc., as Applied to Chemical JurisprudenceОт EverandLegal Chemistry: A Guide to the Detection of Poisons, Examination of Tea, Stains, Etc., as Applied to Chemical JurisprudenceОценок пока нет

- Encyclopedia of NeedleworkДокумент608 страницEncyclopedia of Needleworksorinacam_c7311Оценок пока нет

- Crystal Palace YarnsДокумент29 страницCrystal Palace Yarnssorinacam_c7311Оценок пока нет

- Front Construction Lapels ButtonsДокумент12 страницFront Construction Lapels Buttonssorinacam_c7311Оценок пока нет

- Collar ConstructionДокумент13 страницCollar Constructionsorinacam_c7311Оценок пока нет

- PDF BanneredДокумент6 страницPDF Banneredsorinacam_c7311Оценок пока нет

- Now We Are FreeДокумент2 страницыNow We Are Freesorinacam_c7311Оценок пока нет

- HornДокумент16 страницHornFred LiuОценок пока нет

- 2012 D61ex-15e0Документ1 239 страниц2012 D61ex-15e0Alex San Tana100% (3)

- Bomba FlightДокумент2 страницыBomba FlightGustavo HRОценок пока нет

- Isuzu 4hk1x Sheet HRДокумент4 страницыIsuzu 4hk1x Sheet HRMuhammad Haqi Priyono100% (1)

- Winter Internship Report (23/09/2016 - 31/01/2017)Документ56 страницWinter Internship Report (23/09/2016 - 31/01/2017)AyushОценок пока нет

- MS3XV30 Hardware 1.3Документ229 страницMS3XV30 Hardware 1.3Colton CarmichaelОценок пока нет

- Photosynthesis LabДокумент3 страницыPhotosynthesis Labapi-276121304Оценок пока нет

- PB Hydro en PDFДокумент86 страницPB Hydro en PDFWahyu Tirta NugrahaОценок пока нет

- 200 Questions AnswersДокумент150 страниц200 Questions AnswersvempadareddyОценок пока нет

- An Analysis of The Ejector-Ram-Rocket EngineДокумент9 страницAn Analysis of The Ejector-Ram-Rocket Enginefundamental_aeroОценок пока нет

- MOTOR Brushless ss2814 Xiii 1000kvДокумент1 страницаMOTOR Brushless ss2814 Xiii 1000kvsalah eddineОценок пока нет

- RTE Online Application Form For Admission Year 2018 19Документ6 страницRTE Online Application Form For Admission Year 2018 19sudheer singhОценок пока нет

- Ilovepdf Merged MergedДокумент209 страницIlovepdf Merged MergedDeepak AgrawalОценок пока нет

- Abstract of ASTM F1470 1998Документ7 страницAbstract of ASTM F1470 1998Jesse ChenОценок пока нет

- Brochure FDP - EG 16.08.2021-1-2-2Документ3 страницыBrochure FDP - EG 16.08.2021-1-2-2sri sivaОценок пока нет

- Fundamentals of Fluid Mechanics (5th Edition) - Munson, OkiishiДокумент818 страницFundamentals of Fluid Mechanics (5th Edition) - Munson, OkiishiMohit Verma85% (20)

- Udyam Registration Certificate UDYAM-MH-26-0097771Документ3 страницыUdyam Registration Certificate UDYAM-MH-26-0097771Suresh D ChemateОценок пока нет

- YcivДокумент68 страницYcivBelhassen Saddadi100% (2)

- RE 2017 EOT Brochure 4AДокумент20 страницRE 2017 EOT Brochure 4AOrangutan SolutionsОценок пока нет

- PeopleSoft Doc UpdateДокумент20 страницPeopleSoft Doc UpdateupenderОценок пока нет

- Universal USB Installer - Easy As 1 2 3 - USB Pen Drive LinuxДокумент4 страницыUniversal USB Installer - Easy As 1 2 3 - USB Pen Drive LinuxAishwarya GuptaОценок пока нет

- Surveying Civil Engineering Pictorial Booklet 15 English MediumДокумент125 страницSurveying Civil Engineering Pictorial Booklet 15 English MediumtnstcnpalanisamyОценок пока нет

- Cane - Sugar - Manufacture - in - India Datos Sobre Producción de AzucarДокумент525 страницCane - Sugar - Manufacture - in - India Datos Sobre Producción de AzucarEnrique Lucero100% (1)

- Alloc 150 DMДокумент301 страницаAlloc 150 DMSheik Mohamed ImranОценок пока нет

- SuperOhm 3754 (3748-11) - Technical Data Sheet - ECC - Rev 2 - 2016-09Документ2 страницыSuperOhm 3754 (3748-11) - Technical Data Sheet - ECC - Rev 2 - 2016-09igor brocaОценок пока нет

- ARMY TM 9-1804 Power Train Body Frame .25ton 4X4 Truck M38 Jul52Документ206 страницARMY TM 9-1804 Power Train Body Frame .25ton 4X4 Truck M38 Jul52RockWagon100% (2)

- Centrala Termica Pe Lemn Si Carbune Rima SF Manual Tehnic LB EnglezaДокумент26 страницCentrala Termica Pe Lemn Si Carbune Rima SF Manual Tehnic LB EnglezaDobrin PaulОценок пока нет

- QBDC - Season 5-RulebookДокумент50 страницQBDC - Season 5-RulebookHggvgОценок пока нет

- Splunk 7 Essentials Third EditionДокумент388 страницSplunk 7 Essentials Third EditionHaripriya100% (1)

- Project Presentation SurveyingДокумент14 страницProject Presentation SurveyingSACHIN MEENAОценок пока нет

- Treatment Processes: Coagulation and Filtration: Draft Guidelines For Drinking-Water QualityДокумент25 страницTreatment Processes: Coagulation and Filtration: Draft Guidelines For Drinking-Water QualityAbsharinaОценок пока нет