Академический Документы

Профессиональный Документы

Культура Документы

Feasibility Report - UD - B-Aug 02

Загружено:

Manoj BaralОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Feasibility Report - UD - B-Aug 02

Загружено:

Manoj BaralАвторское право:

Доступные форматы

UPPER DARAUNDI–B SMALL HYDROPOWER PROJECT

GORKHA

FEASIBILITY STUDY

VOLUME I – MAIN REPORT

AUGUST 2017

SUBMITTED TO: SUBMITTED BY:

KALIKA CONSTRUCTION PVT LTD. UNITS ENGINEERING

CONSULTANCY

KALIKA TOWER, BALUWATAR

MID-BANESHWOR, KATHMANDU

KATHMANDU

Upper Daraundi–B Small Hydropower Project Feasibility Study

Report

Table of Contents

LIST OF TABLES .......................................................................... VI

LIST OF FIGURES ..................................................................... VIII

SALIENT FEATURES OF THE PROJECT ......................................... X

1 INTRODUCTION .............................................................1–1

1.1 GENERAL.............................................................................................. 1–1

1.2 LOCATION ............................................................................................ 1–2

1.3 ACCESSIBILITY ....................................................................................... 1–2

1.4 DRAINAGE BASIN AND CLIMATE .................................................................. 1–3

1.5 OBJECTIVES .......................................................................................... 1–3

1.6 SCOPE OF WORKS................................................................................... 1–3

1.7 METHODOLOGY ...................................................................................... 1–4

1.8 PROJECT DESCRIPTION ............................................................................. 1–4

2 TOPOGRAPHICAL SURVEY AND MAPPING ....................2–1

2.1 GENERAL.............................................................................................. 2–1

2.2 OBJECTIVES AND SCOPE OF WORKS ............................................................. 2–1

2.3 AVAILABLE INFORMATION AND DATA ............................................................ 2–1

2.4 SURVEY METHODOLOGY ........................................................................... 2–1

2.5 CONTROL TRAVERSING ............................................................................. 2–2

2.6 HORIZONTAL AND VERTICAL CONTROL .......................................................... 2–2

2.7 ACCURACY ............................................................................................ 2–3

2.8 DATA PROCESSING.................................................................................. 2–3

2.9 DETAIL TOPOGRAPHICAL SURVEY ................................................................ 2–3

2.10 MAPPING ........................................................................................... 2–4

2.11 RIVER CROSS-SECTIONS AND PROFILE ....................................................... 2–4

3 HYDROLOGY AND SEDIMENT STUDY ............................3–1

3.1 INTRODUCTION ...................................................................................... 3–1

3.2 PHYSIOGRAPHIC CHARACTERISTICS OF DARAUNDI BASIN ................................... 3–1

3.2.1 The Catchment 3–1

3.2.2 The Climate 3–2

3.2.3 Precipitation Study 3–4

3.3 FIELD HYDROLOGY.................................................................................. 3–5

3.3.1 Stream flow data 3–5

3.3.2 Monthly flow 3–7

3.3.3 Adopted Mean Monthly Flow 3–10

3.4 FLOW DURATION CURVE......................................................................... 3–12

3.5 LOW FLOW ANALYSIS ............................................................................. 3–14

3.6 RIPARIAN RELEASE ............................................................................... 3–14

3.7 FLOOD FLOWS ..................................................................................... 3–14

3.7.1 General 3–14

3.7.2 Flood Frequency Analysis 3–15

3.7.3 Regional Flood Frequency Analysis (Hydro Regional) 3–16

3.7.4 Flood Frequency analysis using WECS-DHM Method. 3–17

Units Engineering Consultancy i

Upper Daraundi–B Small Hydropower Project Feasibility Study

Report

3.7.5 Design Flood 3–17

3.8 DIVERSION FLOOD ................................................................................ 3–18

3.9 RATING CURVES ................................................................................... 3–19

3.10 SEDIMENT STUDY .............................................................................. 3–20

3.10.1 Himalayan Yield Technique 3–20

3.10.2 Sediment Studies by KP Sharma and SR Kansakar 3–20

3.11 CONCLUSION AND RECOMMENDATION ...................................................... 3–20

4 GEOLOGICAL AND GEOTECHNICAL STUDIES ................ 4-1

4.1 INTRODUCTION ....................................................................................... 4-1

4.2 OBJECTIVES ........................................................................................... 4-1

4.3 SCOPE OF THE WORK ................................................................................ 4-1

4.4 STUDY METHODOLOGY .............................................................................. 4-1

4.5 PRESENT INVESTIGATION ........................................................................... 4-2

4.6 REGIONAL GEOLOGY................................................................................. 4-2

4.6.1 Tibetan Tethys Himalaya 4-2

4.6.2 Higher Himalaya 4-2

4.6.3 Lesser Himalaya 4-2

4.6.4 Sub-Himalaya (Siwaliks) 4-3

4.6.5 Gangetic Plain 4-3

4.7 SEISMICITY ............................................................................................ 4-4

4.7.1 Seismicity of Nepal 4-4

4.7.2 Seismic Coefficient 4-4

4.8 GEOLOGY OF THE PROJECT AREA ................................................................. 4-6

4.8.1 Headworks Site 4-7

4.8.2 Headrace Tunnel Alignment 4-9

4.8.3 Surge tank and Penstock Alignment 4-12

4.8.4 Powerhouse and Tailrace 4-13

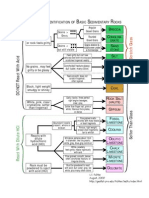

4.9 ROCK SUPPORT DESIGN .......................................................................... 4-13

4.9.1 Q System 4-13

4.9.2 Rock Mass Rating 4-14

4.9.3 Rock Support Estimation 4-15

4.10 CONSTRUCTION MATERIAL SURVEY .......................................................... 4-15

4.11 CONCLUSION AND RECOMMENDATIONS ..................................................... 4-16

5 PROJECT DESCRIPTION AND DESIGN ........................... 5-1

5.1 DESIGN BASIS ........................................................................................ 5-1

5.2 GENERAL ARRANGEMENT OF PROJECT COMPONENTS .......................................... 5-1

5.3 CIVIL WORKS ......................................................................................... 5-1

5.3.1 Diversion during construction 5-1

5.3.2 Headworks 5-2

5.3.3 Weir 5-2

5.3.4 Sluice 5-2

5.3.5 Intake 5-2

5.3.6 Gravel trap 5-3

5.3.7 Steel Pipe Canal 5-3

5.3.8 Settling Basin 5-3

5.3.9 Headrace Canal 5-3

Units Engineering Consultancy ii

Upper Daraundi–B Small Hydropower Project Feasibility Study

Report

5.3.10 Headworks Protection Wall 5-4

5.3.11 Water Conveyance System 5-4

5.3.12 Headrace tunnel 5-4

5.3.13 Steel Penstock Pipe 5-4

5.3.14 Anchor blocks in penstock alignment and saddle 5-5

5.3.15 Saddle supports in penstock alignment 5-6

5.3.16 Surge shaft 5-6

5.3.17 Powerhouse and Tailrace Canal 5-6

5.4 HYDRO-MECHANICAL WORKS ....................................................................... 5-7

5.4.1 Steel Penstock Pipe 5-7

5.4.2 Gates and stoplogs 5-8

5.4.3 Trash Racks 5-9

5.5 ELECTROMECHANICAL EQUIPMENT ................................................................ 5-9

5.5.1 Mechanical equipment 5-9

5.5.2 Turbine 5-10

5.5.3 Unit Capacity 5-12

5.5.4 Description of Turbine 5-13

5.5.5 Turbine Components 5-13

5.6 ELECTRICAL EQUIPMENT .......................................................................... 5-18

5.6.1 General 5-18

5.6.2 Generator 5-19

5.6.3 Generation Voltage Level 5-21

5.6.4 Generator Braking 5-21

5.6.5 Generator Grounding 5-21

5.6.6 Excitation and Automatic Voltage Regulator (AVR) 5-21

5.6.7 Power Transformers 5-23

5.6.8 Switchgears 5-24

5.6.9 Current Transformer (CT) 5-26

5.6.10 Voltage Transformer (PT) 5-26

5.6.11 Lightning Arrestors 5-27

5.6.12 Governor 5-27

5.6.13 Powerhouse Overhead Travelling Crane 5-28

5.6.14 Diesel Generator 5-29

5.6.15 Dc Power Supply 5-29

5.6.16 Grounding / Earthing System 5-29

5.6.17 Black Start/ Island Mode Operation 5-30

5.6.18 Communication System 5-30

5.6.19 Illumination 5-30

5.6.20 Control and SCADA System 5-30

5.7 SWITCHYARD AND TRANSMISSION LINE........................................................ 5-32

5.7.1 132 KV switchyard at Powerhouse 5-32

5.7.2 Interconnection Point 5-33

6 POWER AND ENERGY ..................................................... 6-1

6.1 GENERAL............................................................................................... 6-1

6.2 METHODOLOGY ....................................................................................... 6-1

6.3 INPUT PARAMETERS ................................................................................. 6-1

6.3.1 Hydrology 6-1

Units Engineering Consultancy iii

Upper Daraundi–B Small Hydropower Project Feasibility Study

Report

6.3.2 Headloss 6-1

6.3.3 Efficiency of the machineries 6-2

6.3.4 Energy Loss 6-2

6.3.5 Design Energy and Plant Load Factor 6-2

6.4 ENERGY AND POWER ................................................................................ 6-3

7 THE COST ESTIMATE ...................................................... 7-1

7.1 INTRODUCTION ....................................................................................... 7-1

7.2 CRITERIA, ASSUMPTIONS AND COST COMPONENTS ............................................ 7-1

7.3 ESTIMATING METHODOLOGY ....................................................................... 7-1

7.4 CIVIL WORKS ESTIMATE ............................................................................ 7-2

7.5 RESOURCES COSTS .................................................................................. 7-2

7.5.1 Labor Rates 7-2

7.5.2 Construction Equipment 7-3

7.5.3 Construction Material 7-3

7.6 ELECTRICAL AND MECHANICAL EQUIPMENT ..................................................... 7-3

7.7 SWITCHYARD AND TRANSMISSION LINES ........................................................ 7-3

7.8 UNIT RATES ........................................................................................... 7-3

7.9 CONTINGENCIES ...................................................................................... 7-4

7.10 ENVIRONMENTAL PROGRAMS .................................................................... 7-4

7.11 ENGINEERING AND MANAGEMENT .............................................................. 7-4

7.12 TOTAL ESTIMATED COST......................................................................... 7-4

8 PROJECT EVALUATION................................................... 8-1

8.1 DECISION MAKING TOOLS .......................................................................... 8-1

8.2 DEBT-EQUITY RATIO AND INTEREST ............................................................. 8-1

8.3 OPERATION & MAINTENANCE (O&M), INSURANCE AND OTHER COSTS ................... 8-1

8.4 ELECTRO-MECHANICAL REPLACEMENT COST .................................................... 8-1

8.5 ROYALTIES AND TAXES .............................................................................. 8-2

8.6 ANNUAL GENERATION AND OUTAGE .............................................................. 8-2

8.7 FINANCIAL ANALYSIS RESULTS .................................................................... 8-2

8.8 SENSITIVITY ANALYSIS .............................................................................. 8-4

8.8.1 Interest rate 8-4

8.8.2 Project cost variation 8-4

8.8.3 Variation in energy generation 8-4

8.8.4 Results 8-4

9 CONSTRUCTION PLANNING AND SCHEDULE ................ 9-1

9.1 BROAD PROGRAM .................................................................................... 9-1

9.2 MAJOR COMPONENTS ............................................................................... 9-1

9.3 ACCESS TO SITE ...................................................................................... 9-1

9.3.1 Access in India 9-1

9.3.2 Access in Nepal 9-2

9.4 CONSTRUCTION MATERIALS ........................................................................ 9-2

9.4.1 General 9-2

9.4.2 Stone for Masonry Work 9-2

9.4.3 Reinforcement steel and cement 9-2

9.4.4 Structural Steel for Penstock and other Hydro-mechanical Works 9-2

Units Engineering Consultancy iv

Upper Daraundi–B Small Hydropower Project Feasibility Study

Report

9.4.5 Other Materials 9-2

9.5 CONSTRUCTION CONTRACTS ....................................................................... 9-3

9.6 LAND ACQUISITION .................................................................................. 9-3

9.7 MOBILIZATION ........................................................................................ 9-3

9.8 CONSTRUCTION POWER............................................................................. 9-3

9.9 CAMP ESTABLISHMENT .............................................................................. 9-4

9.10 CONSTRUCTION PLANNING ...................................................................... 9-4

9.10.1 Construction facilities 9-4

9.11 CONSTRUCTION OF CIVIL COMPONENTS ...................................................... 9-5

9.11.1 Headworks 9-5

9.11.2 Headrace Tunnel 9-6

9.11.3 Surge Shaft 9-6

9.11.4 Powerhouse, tailrace and switch yard 9-6

9.11.5 Hydro-mechanical Works 9-7

9.11.6 Electro-mechanical Works 9-7

9.11.7 Transmission Line Works 9-7

9.12 IMPLEMENTATION SCHEDULE BAR CHART ..................................................... 9-7

10 CONCLUSION AND RECOMMENDATION ...................... 10-1

10.1 CONCLUSION ..................................................................................... 10-1

10.2 RECOMMENDATION .............................................................................. 10-2

Units Engineering Consultancy v

Upper Daraundi–B Small Hydropower Project Feasibility Study

Report

List of Tables

Table 2-1: Co-ordinate and Elevation of Basic Control Points ........................................... 2–2

Table 3-1: Information of Precipitation Stations around Project Basin .............................. 3–2

Table 3-2: Climate Data at Station 809 Gorkha ............................................................... 3–3

Table 3-3: Mean Monthly Precipitation (at Index No 809, Gorkha) ................................... 3–4

Table 3-4: Discharge Measurements at gauge location.................................................... 3–5

Table 3-5: Mean Monthly Discharge of Chepe River at Garambeshi .................................. 3–6

Table 3-6: Mean Monthly Discharge at Intake Site .......................................................... 3–8

Table 3-7: Mean Monthly Discharge (m3/s) by MIP Method ............................................. 3–9

Table 3-8: Long-Term Mean Monthly Flow by MHSP Method ......................................... 3–10

Table 3-9: Long-Term Mean Monthly Flow by WECS/DHM Method ................................. 3–10

Table 3-10: Mean monthly discharges from various methods ........................................ 3–11

Table 3-11: Adopted Mean Monthly Flow (m3/s) at Intake Site ...................................... 3–11

Table 3-12: Numerical value of flow duration curve by different methods....................... 3–12

Table 3-13: Time Exceedance of Flows at Intake site .................................................... 3–13

Table 3-14: Low Flow Frequency Analysis (Log Normal Distribution) .............................. 3–14

Table 3-15: Flood frequency analysis using regression method at intake ........................ 3–16

Table 3-16: Results of Regional Analysis for intake ....................................................... 3–17

Table 3-17: Flood from HYDEST (WECS-DHM) Method for intake .................................. 3–17

Table 3-18: Summary of flood (m3/s) analysis by different methods for intake ............... 3–17

Table 3-19: Summary of flood (m3/s) analysis by different methods for powerhouse ...... 3–18

Table 3-20: Estimated Floods for River Diversion .......................................................... 3–18

Table 4-1: Rock quality estimation of rock based on surface mapping ............................. 4-9

Table 4-2: Orientation and characteristics of discontinuity of rock at inlet portal of headrace

tunnel .......................................................................................................................... 4-9

Table 4-3: Orientation and characteristics of discontinuity of rock at headrace tunnel from

chainage 0+000 to 1+500m .........................................................................................4-10

Table 4-4: Orientation and characteristics of discontinuity of rock at headrace tunnel from

chainage 1+500 to 2+440m .........................................................................................4-10

Table 4-5: Rock mass class and its tentative representation along the HRT ....................4-11

Table 4-6: Orientation and characteristics of discontinuity of rock at surge tank area......4-12

Table 4-7: Headrace tunnel rock support class and respective rock support ...................4-15

Table 5-1: Penstock Pipe details .................................................................................... 5-7

Table 5-2: Details of gates ............................................................................................ 5-8

Units Engineering Consultancy vi

Upper Daraundi–B Small Hydropower Project Feasibility Study

Report

Table 5-3: Details of stoplogs ........................................................................................ 5-9

Table 5-4: Details of Trash racks ................................................................................... 5-9

Table 5-5: Turbine Data ...............................................................................................5-17

Table 5-6: Generator Data ...........................................................................................5-20

Table 5-7: Data for Power Transformer .........................................................................5-23

Table 5-8: Details of station transformer .......................................................................5-24

Table 5-9: Data for Generator Circuit Breaker................................................................5-25

Table 5-10: Data for Transformer incomer Circuit Breaker..............................................5-25

Table 5-11: Details of 6.6kV Potential Transformer ........................................................5-26

Table 5-12 Details of 6.6kV Lightning Arrestor ...............................................................5-27

Table 5-13: Capacity of EOT crane ...............................................................................5-28

Table 5-14: Data for 132 KV Circuit Breaker ..................................................................5-32

Table 5-15: Details of 132kV Potential Transformer .......................................................5-32

Table 5-16: Details of 132kV Current Transformer .........................................................5-33

Table 5-17: Details of 132kV Lighting Arrestor...............................................................5-33

Table 6-1: Monthly flow used for energy estimation ........................................................ 6-1

Table 6-2: Summary of Monthly Headloss ...................................................................... 6-2

Table 6-3: Power and Energy Computation .................................................................... 6-3

Table 7-1: Summary of project cost ............................................................................... 7-5

Table 8-1: Input Parameters ......................................................................................... 8-3

Table 8-2: Results of financial analysis ........................................................................... 8-3

Table 8-3: Sensitivity analysis results ............................................................................. 8-4

Table 9-1: Contract Packaging....................................................................................... 9-3

Units Engineering Consultancy vii

Upper Daraundi–B Small Hydropower Project Feasibility Study

Report

List of Figures

Figure 1-1: Location Map .............................................................................................. 1–2

Figure 3-1: Catchment area of UDBSHP intake site ......................................................... 3–2

Figure 3-2: Mean Monthly Flow at intake site ............................................................... 3–11

Figure 3-3: Flow Duration Curve at Intake Site ................................................... 3–14

Figure 3-4: Rating curve at the intake location ............................................................. 3–19

Figure 3-5: Rating curve at the powerhouse location .................................................... 3–19

Figure 4-1: Regional Geological Map of Nepal................................................................. 4-3

Figure 4-2: Seismic Risk Map of Nepal ........................................................................... 4-5

Figure 4-3: Seismic Hazard Map of Nepal ....................................................................... 4-6

Figure 4-4: Geological Map of Project Area (DMG) .......................................................... 4-7

Figure 4-5: Contour density diagram at Headwork area at right bank............................... 4-8

Figure 4-6: Stereographic Projection of main joints ......................................................... 4-9

Figure 4-7: Rosette diagram showing tunnel alignment through bed rock .......................4-11

Figure 4-8: Stereographic Projection of discontinuities (Headrace Tunnel).......................4-12

Figure 4-9: NGI Q-System from Barton and Grimstad 1993 ............................................4-14

Figure 5-1: Penstock pipe optimization results .......................................................... 5-5

Figure 5-2: Turbine Selection Chart ..............................................................................5-12

Figure 5-3: Pelton Runner ............................................................................................5-14

Figure 5-4: Graphical view of turbine parts....................................................................5-16

Figure 5-5: Turbine Generator Arrangement ..................................................................5-17

Figure 5-6: Technical Data Sheet ..................................................................................5-18

Figure 5-7: Excitation System .......................................................................................5-22

Figure 5-8: Governing System Architect ........................................................................5-28

Figure 7-1: Distribution of the project cost ..................................................................... 7-6

Units Engineering Consultancy viii

Upper Daraundi–B Small Hydropower Project Feasibility Study

Report

List of Abbreviations

% Percentage

‘ Minutes

‘’ Seconds

amsl Above mean Sea Level

cm/s Centimetre per second

DHM Department of Hydrology and Meteorology

DoS Department of Survey

f Angle of repose for the soil

GWh Giga watt hour

km Kilometre

KN Kilo Newton

kV Kilovolt

kW Kilowatt

kWh Kilowatt hour

m Metre

m2 Square metre

M3/s Cubic metre per second

MIP Medium Irrigation Project

mm2 Square millimeter

MW Megawatt

N Newton

NEA Nepal Electricity Authority

º Degree

ºC Temperature in degree centigrade

US$ United States Dollars

VDC Village Development Committee

WL Water Level

yr Year

Units Engineering Consultancy ix

Upper Daraundi–B Small Hydropower Project Feasibility Study

Report

Salient Features of the Project

General

Project Name Upper Daraundi-B Small Hydropower Project

Name of River Daraundi

Nearest Village Barpak

Location

District / Development Region: Gorkha, Western Development Region

Type of power plant: Run-of-River

Project Co-ordinate

Easting 84⁰ 43' 45" E to 84⁰ 44 '30" E

Northing 28⁰ 13' 24" N to 28⁰ 15' 00" N

Hydrology

Catchment area at intake site 101 km2

Long term annual average flow 8.03 m3/s

Design Discharge (Q40) 4.7 m3/s

Design flood at intake (1 in 100) 360 m3/s

Design Flood at Powerhouse (1 in 100) 428 m3/s

Diversion weir

Type Permanent concrete weir

Shape Trapezoidal

Crest level 1378.5 amsl

Length 8m

Height 2.9 m from the Bed level

Crest Width 1.75 m

Base Width 8.00 m

Sluice

Number 1

Width 1.50 m

Height 2.00 m

Slope 1 in 10

Intake

Type Side Intake orifice type

No. of Opening 2

Size opening 1.2 m x 1.0 m clear opening

Units Engineering Consultancy x

Upper Daraundi–B Small Hydropower Project Feasibility Study

Report

Gravel Trap

Length 5.5 m excluding transition length

Width 3m

Headrace pipe

Length 67.0 m

Diameter 1.4 m

Thickness 8 mm

Settling basin

No of bays 1.00 nos.

Nominal size of trapped particle 0.20 mm, 90.00% trap efficiency

Uniform Length 26.00 m

Invert slope 1:50

Width 3.6m

Depth 4.3m average

Waterways

Headrace tunnel

Length 2466 m up to surge shaft

Diameter 2.5m finished

Height 2.5m finished

Penstock

Penstock Pipe length 406.5 m up to bifurcation

Diameter 1.20m/1.1m

Maximum shell thickness 8.00 mm to 16.00 mm

Powerhouse

Length and width 38.5m x 15.0m x 19m

Tail water level 1146.76 amsl

Tailrace

Length of Tailrace canal 75.00 m

Turbine

Type Pelton (Horizontal Axis)

No of units 2.00

Turbine center elevation 1150.0 amsl

Rated output 4400 KW

Rated Speed 428.6 rpm

Rated Efficiency 90%

Units Engineering Consultancy xi

Upper Daraundi–B Small Hydropower Project Feasibility Study

Report

Generator

No of Units 2

Type Synchronous with brushless excitation

Rated Capacity 5000 KVA

Rated Efficiency 96%

Power factor 0.85

Speed 428.6 rpm

Frequency 50HZ

Generation voltage 6.6kV

Transformer

No of Units 1

Type Three phase

Rated Capacity 12.5 MVA

Frequency 50 Hz

Transmission Line

Capacity 132 kV

Length 30 km (Powerhouse site to Marki Chowk

Substation)

Switch Yard 20.00 m long by 20.00 wide

Access

Project is accessible from Abukhaireni on the road to Barpak, Gorkha

Power and Energy

Gross Head 223.1 m

Net Head 212.07 m

Installed Capacity 8.3 MW

Dry season Energy 14.234GWh (Considering Outage)

Wet season Energy 33.047GWh (Considering Outage)

Total Energy 47.282GWh

Environmental Study

Downstream release 0.15 m3/s

Construction Period 3 Years

Project evaluation

Project cost without IDC NRs. 1505.47 million

Project cost with IDC NRs. 1655.77 million

Internal rate of return (IRR) 14.42%

BC ratio 1.41

Units Engineering Consultancy xii

Upper Daraundi–B Small Hydropower Project Feasibility Study

Report

Return on Equity 19.68%

Net Present Value NRs. 547.706 million

Units Engineering Consultancy xiii

Upper Daraundi–B Small Hydropower Project Feasibility Study

Report

1 INTRODUCTION

1.1 General

Nepal is blessed with abundant water resources combined with large geographical variations

from High Himalayas to the plain of the Terai within a short distance. About six thousand

rivers and rivulets in Nepal carry about 225 billion cubic meter of water every year and flow

down to Indian Ocean via India. The ample water sources and the geographical variations

are extending immense hydropower potential in the country.

Of the estimated 83,000 MW hydropower potential of the country, it has been assessed that

42,000 MW can be exploited economically. However, Nepal has developed only 894 MW

(including isolated micro and small hydropower plants) of hydropower to date, which is

slightly more than 1% of total hydropower potential of the country. The underutilization of

these vast resources has been due to various reasons including lack of consistent policy

mechanism and project selection criteria, lack of basic infrastructure facilities, lack of

technical and financial strengths of the country etc. Still traditional source of energy such as

fuel wood, agriculture residue and animal waste is playing major role (86%) of the total

energy consumption of the country. Commercial energy sources like fossil fuel and electricity

share the remaining portion of the energy consumption, of which, electricity contributes

about 1.5% of the total energy needs.

The Hydropower can be utilized to boost up the economic growth of the country. However,

scarce resource available in the country and ever decreasing foreign assistance has made

pace of Hydropower development less than desirable. In order to expedite the pace of

development, it was felt necessary to involve private sector. The unstable politics and lack of

basic infrastructures like access road and national grid to the potential project sites are the

shortfall of private sector involvement.

In order to meet increasing demand of power, necessary steps are taken to consolidate and

strengthen existing generating facilities with a view to increase efficiency in production and

distribution of energy. The Government of Nepal (GoN) has adopted an open and free

market policy in order to attract domestic and foreign hydropower developers for expediting

hydropower development. The GoN has promulgated Water Resources Act 1992, Water

Resources Act 1992 and Water Resources Regulation 1993. In addition to this, GoN has

adopted the new Hydropower Policy 2001. These acts, regulations and policies are focusing

on easing and simplifying procedures of licenses, royalties, income taxes, customs and

excise duties, foreign currency and selling of electricity. As a result, the private entrepreneur

has developed Khimti (60 MW), BhoteKoshi (36 MW), Indrawati (7.5 MW), Sange (183 KW),

Chaku Khola (1.5 MW), Sunkoshi (2.5 MW) and Piluwa (3 MW) etc. Similarly, many other

hydropower projects are either in under construction or in pre-construction phase by private

sector like Khudi (3.45 MW), Mailun Khola (5 MW), Mardi (3.1 MW), Upper Modi (14 MW)

etc. Many hydropower projects are in different stages of studies, licensing, and development.

Upper Daraundi-B Small Hydropower Project (UDBSHP) is a run-of-river type project with

installed capacity of 8300kW that will generates 47.282 GWh energy annually. The project is

located in Gorkha District in the Western Development Region of Nepal.

The headworks and powerhouse of the project lie on the right bank of the Daraundi Khola at

Ghyachowk VDC. The surface powerhouse is located about 3 Km downstream of the

Units Engineering Consultancy 1–1

Upper Daraundi–B Small Hydropower Project Feasibility Study

Report

proposed weir site. Headrace tunnel is a major waterway component. The generated power

will be evacuated through 30km long 132 kV transmission line from switchyard to

Markichowk substation at Tanahun. The cost of the transmission line is proposed to be

shared with other projects in the vicinity.

1.2 Location

The project area is located between 1380m and 1150m above mean sea level in the upper

reach of Daraundi Khola of Gorkha District, Gandaki Zone of the Western Development

Region of Nepal. Geographically the project area is located between longitudes 84°43'45" to

84°44'30" and latitudes 28°13'24" to 28°15'00". The project area lies in Ghyachowk and

Barpak VDCs. The project area location map is shown in Figure 1-1.

Upper Daraudi-B

Hydropower Project

Figure 1-1: Location Map

1.3 Accessibility

Highway from Kathmandu to 11 Kilo (Gorkha) is about 135km long black top road and

further about 40 km from 11 Kilo to Mandre is fair weatherd earthen road which is the main

access road from Kathmandu to the project site. Around 3 km access road is to be upgraded

to access near Tumsika Village.The project site is not accessible by vehicle at present. The

headworks and powerhouse are accessed by foot trail from Tumsika village at the moment.

New roads will need to be built from this point up to the powerhouse as well as the

headworks site. About 1.5 km access road needs to construct to link the powerhouse site.

Similarly, about 3 km long access road needs to be constructed to link the powerhouse and

headworks site.

Units Engineering Consultancy 1–2

Upper Daraundi–B Small Hydropower Project Feasibility Study

Report

1.4 Drainage Basin and Climate

Physiographically, the project area belongs to the Middle Mountains, and lies in between

1380m to 1150m above mean sea level. The mountains are characterized by steep to

medium sloped landscape, which varies with elevation. Fairly dense mixed forests are found

between elevation 1200m to 1500m and landscape changes to subtropical forest below

2000m. Excessive cultivation can be found up to the altitude of 1600m. The project area is

under the influence of southwest monsoon. The climate of the basin is also influenced by the

physiography of the region. The Upper Daraudi-B Small Hydropower Project has its

catchment area of 101 km2 at the proposed headwork site and 120 km2 at powerhouse site.

1.5 Objectives

The main objective of the present study is to carry out the feasibility study for the technical

and economic viability of the Project, which will be interconnected with the Integrated Nepal

Power System (INPS). The feasibility study report can be used as a basis for PPA, for

obtaining the license of generation from the government and for funding arrangement of the

construction. Following are the general objectives of this feasibility study:

To identify the headwork site and select the best option, water conveyance system

area and Powerhouse site area of the Upper Daraudi-B Small Hydropower Project.

To carryout site survey and investigation.

To obtain basic information / data through field surveys, investigation and laboratory

tests.

To prepare necessary maps and sections/ profiles as per the project requirement.

To finalize the project layout.

To conduct the hydrological and meteorological study.

To conduct the geological study to determine the overburden condition at the sites of

major hydraulic structures and to assess rock conditions.

To conduct a detailed feasibility study level design and prepare necessary drawings.

To prepare Bill of Quantity (BOQ) and make cost estimates.

To prepare construction plan and project implementation schedule.

To conduct financial evaluation.

1.6 Scope of Works

In order to achieve above-mentioned objectives, the primary task of the Consultant is to

conduct Feasibility Study of the project.

The feasibility study was carried out in accordance with the requirements of the Client and

the standard practice. In line to this, the study was performed in accordance with the

requirements mentioned in the Standards for Study of Hydropower Projects published by

GoN/ DoED. The study covered all aspects of the project including:

Review of previous studies

Hydrological, meteorological and sediment studies

Topographical survey and mapping

Units Engineering Consultancy 1–3

Upper Daraundi–B Small Hydropower Project Feasibility Study

Report

Geological and geo-technical studies

Project layout

Optimal design of project components

Construction methods and planning

Cost estimate and

Financial analyses of the project.

1.7 Methodology

Review of literature related to hydropower generation is done in the project office. Previous

studies on the Project have been reviewed. A team of experts comprising of Senior

Hydropower Engineer, Hydrologist, Geologist and Surveyor visited the site. Leveling was

carried out for the alternative locations of intake and powerhouse sites to create a basis for

selection of most promising alternative among the identified alternatives.

Based on site-specific information gathered during this initial site visit, a field investigation

program for detailed survey, geological investigation and hydrological measurement as well

as gauge height recording was prepared.

The topographical survey and geological investigations carried out and preparation of

necessary scale topographical maps using CAD were completed.

The hydraulic design of structures, drawings and quantity calculation was done where the

rate analysis of the items of work was carried out on the basis of district rates and standard

norm. Financial evaluation of the project was carried out and the reports were prepared.

1.8 Project description

Upper Daraundi – B Small Hydropower Project is a run-of-river type project with weir crest

level at 1378 amsl and powerhouse level at about 1150 amsl respectively. The project is a

cascade project to Upper Daraundi C Hydropower Project and hence, the major discharge is

received from the upper project. The additional water to meet the design discharge is

diverted to the water conveyance system through intake, gravel trap, headrace pipe, settling

basin, headrace tunnel and penstock. And then water is feed into powerhouse to hit the

turbine and generate electricity which is evacuated to national grid through about 30km long

132 KV transmission line.

The diversion weir of 2.9 m high concrete weir is proposed to divert the required water. The

project utilizes design discharge and gross head of 4.7m3/s and 223.1 m (measured from

tailwater level of the upper project) respectively. Out of 4.7m3/s, the upper project

contributes 3.2m3/s flow.

The topography of the area is characterized by gentle and steep slope. Abundance

vegetation can be observed in the project area. There are not any major landslides in the

area.

The total length of waterways will be about 2873m before bifurcation. Besides, the major

components of the project can be visualized as the combination of the following hydraulic

structures:

Units Engineering Consultancy 1–4

Upper Daraundi–B Small Hydropower Project Feasibility Study

Report

Diversion weir, Orifice type side intake for additional flow

Gravel trap with bed load flushing arrangement

Headrace pipe

Settling basin with flushing arrangement

Headrace Tunnel

Surge tank

Penstock

Powerhouse

Switching substation

Tailrace canal

Access road

132 kV transmission line

The design aspects of the above components are described in Chapter 5 of this report.

General Layout, Plan & Profile and design drawings of the project are presented in Volume

II.

Units Engineering Consultancy 1–5

Upper Daraundi–B Small Hydropower Project Feasibility Study

Report

2 TOPOGRAPHICAL SURVEY AND MAPPING

2.1 General

The methodology adopted for topographical survey works of Upper Daraudi-B Small

Hydropower Project is described in this section.

2.2 Objectives and Scope of Works

The main objective of the survey works was to prepare detail topographic maps of the

project area for locating major components of the project like headwork, settling basin,

tunnel alignment, surge tank, powerhouse and tailrace in appropriate scale, which can be

used for detail design purpose.

Scope of work for the field survey includes the following:

Undertaking the survey works using coordinates and elevation of a point fixed by

DGPS within project area of Upper Daraundi B.

Establishment of ground control points by close traverse surveys.

Establishment of major ground control points by making concrete pillars or marking

on permanent boulders.

Establishment of benchmarks at various locations.

Carry out the longitudinal profile of Daraudi-B from headwork site to tailrace site.

Carry out the river cross-sections at various locations of headwork and powerhouse

sites.

Preparation of topographical sheets of intake, settling basin, tunnel, penstock line

and powerhouse sites at appropriate scales.

2.3 Available Information and Data

The information available for carrying out the surveying work of the project is as follows:

Topographical map sheet No 2884 15B (1:25000 Scale) prepared by the Department

of Survey.

Project layout plan and general layout plan produced during desk study.

Digital data of the above topographical sheet.

2.4 Survey Methodology

Prior to field survey, a desk study was carried out by using the most recent topographic map

of the project area. Detail information about the project area for the survey work was noted.

Finally all the available information and location maps prepared during identification study

were collected.

After finalization the desk study, a survey team was mobilized for the field survey. In order

to carry out the detail survey, a brief reconnaissance survey was carried out with flagging at

necessary points around the entire area to be mapped.

The survey teams established sufficient survey stations in and around the project

components. Major control points were made at boulder and rocks by enamel painting. Some

Units Engineering Consultancy 2–1

Upper Daraundi–B Small Hydropower Project Feasibility Study

Report

of the major control points were marked either by iron pin in the rock or fixed by cross

marks chiseled on the boulders. Chiseled marks were made conspicuous by enamel paint.

2.5 Control Traversing

Basic ground control survey was carried out from the points established by the DGPS.

Several other required ground control stations were established by conventional traverse

survey covering the entire area to be mapped from the headwork’s site to powerhouse site.

Altogether seven control points were established at the project area, from Headworks to

Powerhouse area. The coordinates and the elevations of the established ground control

stations are given in Table 2-1.

Table 2-1: Co-ordinate and Elevation of Basic Control Points

SN Easting Northing Elevation Remarks

1 572147.348 3123166.710 1147.394 DGPS BM-1

2 572147.213 3123270.193 1150.718 DGPS BM-2

3 572145.725 3123377.200 1157.810 DGPS BM-3

4 572768.142 3124348.113 1479.826 DGPS BM-4

5 572780.061 3124260.706 1468.867 DGPS BM-5

6 572440.905 3125618.124 1509.555 DGPS BM-6

7 572386.441 3125623.132 1474.880 DGPS BM-7

2.6 Horizontal and Vertical Control

The control points were established by the traverse method. The traverse was conducted

along the Daraundi Khola left Bank and was then closed to the same station covering the

necessary area of the Headwork to powerhouse sites topographical survey

Topcon Total Station with a least count of 5" was used for measuring horizontal and vertical

angles. One complete set of horizontal and vertical angles were observed during the control

traversing.

For horizontal control it includes the following:

Mean angle and distance computation was checked precisely.

Angular closure checked for closed loops.

Angular misclosure was adjusted.

In traverse survey the horizontal angles were observed in one complete round within a mean

of 15". Distances were measured in fore and back sight directions and the mean distance

was adopted. The closing errors were distributed according to common survey standards.

Units Engineering Consultancy 2–2

Upper Daraundi–B Small Hydropower Project Feasibility Study

Report

Altogether 8 Permanent & (approximately 75 station Survey control points) were established

in the Project area of main-traverse line. From headworks to powerhouse site. Different

offset points were established wherever necessary around the project area.

Computation for Σ Back sight, Σ Foresight, Σ Difference of height was checked

precisely.

Computation of Δh for each loops were checked, and

All the loops were adjusted by Dell method so as to provide consistent heights for

use in spot surveying.

While surveying a traverse line, all angles and distances were measured by either instrument

employing the force centering method. Both back sighting and fore sighting direct distance

were measured. Reasonable closing error was achieved.

2.7 Accuracy

The closing errors are in permissible limits and distributed according to common survey

standards.

2.8 Data Processing

All the survey data were computed in the field as well as in the office. Similarly, some field

data were evaluated and horizontal distance and elevation were calculated reciprocally. All

the coordinates and elevations of each station and survey point were then computed with

respect to given UTM.

2.9 Detail Topographical Survey

Proper survey and leveling works are necessary to design the components, to prepare

drawings and to calculate the quantities of the project components. The survey data greatly

affects the quality of design. Therefore, all the survey works were carried out precisely and

correctly.

All the required areas from the weir site to powerhouse site were identified by permanently

marked control points, which were made conspicuous in the field with yellow paints.

The terrain features were surveyed by means of spot surveying. Spot positions were taken

by tachometric method from different traverse points. Inaccessible points like rock faces, top

of cliff, landslide edge etc. were sighted from at least two known points reading both the

horizontal and vertical angles.

Features such as riverbanks, high flood level, landslides, cliff, house, cultivated lands, roads,

canal, embankment, boulders etc were recorded.

At the headwork area, the detailed survey covered about 150 m upstream and about 150 m

downstream of the proposed diversion structure. The survey was also conducted about 20 m

above the existing river bed level on both sides of Daraundi Khola to mark regular and

previous flood level and also to include the areas for camping site and road to intake.

Units Engineering Consultancy 2–3

Upper Daraundi–B Small Hydropower Project Feasibility Study

Report

2.10 Mapping

Detailed topographical mapping of Headwork’s site of rivers, settling basin, tunnel, surge

shaft, powerhouse and tailrace area were carried out in required scale.

Finally, Land development tool was used to process the survey data and to produce

topographical map in a digital format. All the important structures were produced in the

following scale.

Headwork : Scale 1:1000 and 1 m contour interval

Waterway : Scale 1:5000 and 1 m contour interval

Powerhouse : Scale 1:1000 and 1 m contour interval

Besides this, river profiles and cross sections were produced for both headworks and

powerhouse areas as per the needed.

2.11 River Cross-sections and Profile

Several cross-sections of the Daraundi were taken to provide river cross-sections for

computing rating curves for headwork and powerhouse sites. The sections were taken at

interval of 50 m.

Units Engineering Consultancy 2–4

Upper Daraundi–B Small Hydropower Project Feasibility Study

Report

3 HYDROLOGY AND SEDIMENT STUDY

3.1 Introduction

The proposed Upper Daraundi-B Small Hydropower Project will utilize the flow available in

Daraundi Khola, one of the major tributaries of Marshyangdi River which originates from the

Buddha Himal. The proposed project is located at Gorkha district.

The hydrological inputs play a very vital role in planning, execution and operation of any

water resource development project. The hydrological studies are carried out with a view to

assess the quantity of available water and its time variation, estimation of design flood

usually required for the hydraulic design as well as for safety of the structure and

sedimentation studies.

This chapter describes the hydrological studies carried out for UDBSHP with a view to:

Assess the availability of water for power generation

Assess design floods.

Assess sediment exclusion provisions.

3.2 Physiographic Characteristics of Daraundi Basin

3.2.1 The Catchment

The Daraundi Khola is a tributary of the Marsyangdi River, which is a major tributary of the

Kali Gandaki River Basin. The length of Daraundi Khola is 67.37 kilometres. The total

drainage area at headworks location is about 101km2.The catchment area of Daraundi basin

below 3000 m elevation is about 36.75km2.Whole catchment area lies in Gorkha District.

The proposed intake of Upper Daraundi-B Small Hydropower Project lies at Latitude

28°14'54" N and Longitude 84°44'00" E, at about Elevation 1380 amsl. The drainage area at

the proposed dam site is about 101km2.

The proposed powerhouse site of Upper Daraundi-B Hydropower Project lies at Latitude

28°13'27" N and Longitude 84°43'56.76" E, at about Elevation 1150 amsl and located at

about 3 km downstream of the proposed intake. The total catchment area at proposed

powerhouse site is 120km2.

Based on the topographical maps, there are no lakes within the Daraundi basin. All of the

above mentioned drainage areas have been estimated based on the latest topographical

maps compiled from 1:50000 scale aerial photography of 1996 by the Survey Dept. and also

with GIS application.

Units Engineering Consultancy 3–1

Upper Daraundi–B Small Hydropower Project Feasibility Study

Report

Figure 3-1: Catchment area of UDBSHP intake site

3.2.2 The Climate

Monthly precipitation records published by Department of Hydrology and Meteorology (DHM)

are available for different stations which are pertinent for the project study. Information of

the pertinent precipitation stations are given in Table 3-1 below.

Table 3-1: Information of Precipitation Stations around Project Basin

Index Station Location Altitude Record Precipitation

No. Name (m) Length

Annual(mm)

808 Bandipur 27°56'/84°25' 1956-2000 965 1863.3

809 Gorkha 28°00'/84°/37' 1956-2000 1097 1745.3

The absolute extreme temperature and relative humidity for this station are reproduced in

the Table 3-2.

Units Engineering Consultancy 3–2

Upper Daraundi–B Small Hydropower Project Feasibility Study

Report

Table 3-2: Climate Data at Station 809 Gorkha

Temperature Relative Humidity

24 hrs.

Year (Centigrade) (%)

Max Ppt (mm)

Max Min Max Min

1971 30.9 3.2 94 41 78

1972 34.1 3 94 38 105

1973 34.7 4.3 94 38 83

1974 33.2 0.9 94 46 95

1975 34.6 6.2 91 41 103

1976 30.3 6.3 92 33 153

1977 32.5 4.5 92 43 86

1978 30.3 4.6 93 49 86

1979 35.4 6.2 91 42 124

1980 33.7 6.6 92 53 118

1981 33 5.5 92 61 116

1982 34.2 5.1 93 43 94

1983 34 3.2 93 45 140

1984 32.5 5.4 91 46 119

1985 33 5.5 94 45 89

1986 33 5.2 92 51 95

1987 33.4 6 90 51 134

1988 33.2 6.8 92 59 100

1989 33.2 5.5 91 58 76

1990 32 6.2 94 65 105

1991 32.8 5.2 91 55 90

1992 33.9 4.3 86 54 86

1993 31.8 7.3 89 62 78

1994 31.3 5.3 92 67 117

1995 35.3 5.3 92 58 133

1996 35.5 6.5 92 56 97

The basin experiences warm and humid climate during the month June to October and most

dry and cold temperature occur during the month December to February. Since the Index

No. 809 is near on the Daraundi Khola basin, this can be used as the representative

climatological station. The maximum extreme temperature of the project site varies between

30.3°C to 35°C and that of minimum extreme temperature varies between 0.9°C to

7.3°C.The relative humidity in percent is 92, maximum in July-August and minimum 42 in

March -April at the proposed intake site.

Units Engineering Consultancy 3–3

Upper Daraundi–B Small Hydropower Project Feasibility Study

Report

3.2.3 Precipitation Study

The long term annual precipitation to the selected rain gauge stations are given in Table 3-3.

The reference precipitation station for Daraundi Khola considered is Index No. 0809, Gorkha

to estimate the basin precipitation. The average annual precipitation of this station is 1741

mm.

Table 3-3: Mean Monthly Precipitation (at Index No 809, Gorkha)

Year Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Total

1956 N.A. N.A. N.A. N.A. N.A. 505 420 403 123 92 8.6 12.6 N.A.

1957 117 0 12 2 67 227 465 634 123 53 0.8 30.4 1701

1958 8.7 0.3 41.6 60 140 190 385 395 260 93 0 11.9 1574

1959 54.8 0 0 92 195 400 410 212 224 132 0 0 1720

1960 0 1.1 54.2 31 222 N.A. N.A. N.A. N.A. N.A. 0 0 N.A.

1963 N.A. N.A. 69.5 59 131 280 460 581 202 24 22 N.A. N.A.

1964 4.2 0.9 4.2 56 179 209 422 452 240 39 0 1.1 1605

1965 1.4 6.3 20.8 90 88 431 703 321 106 78 126 0 1973

1966 37.9 22.4 0 36 78 222 427 511 107 50 0.2 3.6 1491

1967 0 4.7 42.6 111 92 358 448 361 79 11 19.5 11.8 1526

1968 56.9 2.5 112.2 19 128 403 335 244 180 115 0 0 1595

1969 11 1.6 50.8 54 77 201 426 217 313 11 0.4 0 1362

1970 20.7 31.5 16.8 90 89 301 401 389 116 12 0 0 1467

1971 2 4.9 20.6 217 133 604 277 362 205 121 23.4 0 1970

1972 2.3 59.9 37.3 36 251 478 464 220 286 92 14.5 0 1941

1973 50.7 27.6 18.1 39 192 333 279 335 292 227 N.A. N.A. N.A.

1974 28 12.8 42.4 72 151 234 629 368 325 72 0 5.8 1933

1975 24.1 29.7 14.7 63 176 248 555 313 347 23 0 0 1794

1976 25.2 1.7 0 21 299 812 451 422 264 17 0.2 0 2312

1977 12.5 10.5 20.2 139 231 296 391 495 77 16 46.6 45.7 1734

1978 2 16 89.6 77 359 377 431 518 360 56 4.5 9.3 2289

1979 5.2 32.1 5.7 60 109 355 450 397 147 133 20.4 113 1714

1980 0 32 55.4 2 113 332 498 265 172 51 0 2.2 1521

1981 39.7 4.2 49.8 188 109 297 478 295 237 2 21.5 0 1721

1982 26.4 40.4 97.4 53 80 220 557 435 172 16 22 1.5 1719

1983 19 5.3 17.3 82 222 197 663 352 333 163 0 16.6 2053

1984 23.1 7.4 22.1 85 241 301 417 382 320 25 0 3.9 1823

1985 2.9 0 25.9 95 158 303 488 310 346 212 9.6 52.2 1951

1986 0 17.6 60.1 68 196 361 531 287 227 44 0 78.1 1792

1987 3.9 8.4 72.4 73 96 253 564 381 150 16 2 63.7 1620

1988 0 0 36.2 65 230 43 226 251 192 44 7.7 44.8 1095

1989 161 0 96.1 43 223 272 450 404 252 65 1 8.5 1968

Units Engineering Consultancy 3–4

Upper Daraundi–B Small Hydropower Project Feasibility Study

Report

1990 6 62.1 116.8 129 130 331 544 270 158 41 0.2 9.4 1789

1991 21 17.2 100.2 36 101 389 344 207 132 0 0 20.1 1347

1992 2.8 0 0 0 98 309 147 397 32 21 N.A. 0 N.A.

1993 8.5 13.1 51.6 50 349 249 243 242 240 1 0 0 1448

1994 38.2 12.1 94.5 3 217 265 628 746 185 0 0 0 2190

1995 8 42 20 N.A. N.A. 886 591 212 251 66 58 6 N.A.

1996 61 40 19 41 95 336 408 718 138 80 0 0 1936

1997 24.7 14.4 32.8 315 N.A. 353 384 127 50 10 12.7 37.8 N.A.

1998 8.1 12.2 21.3 9 73 181 326 61 19 2 0 14.8 728.1

1999 0.2 N.A. N.A. 13 359 187 705 467 162 50 0 0 N.A.

2000 14.4 14 N.A. N.A. 251 432 282 474 154 0 0 0 N.A.

Mean 23 15.2 41.56 69 168 332 445 367 198 57 10.3 14.7 1741

The locations of the meteorological stations and the mean annual isohyetal map of the

project and adjacent basins are shown in the annex. The estimated mean annual basin

precipitation for the Daraundi Project at the weir site is about 1800mm.

3.3 Field Hydrology

The river is not gauged by the Department of Hydrology and Meteorology (DHM). The

Consultant carried out spot discharge measurement around the project intake site within the

Daraundi Khola. The measured data at that location are analyzed in this study. The

catchment area at the gauging point is about 105km2.

The discharge data have been presented in Table 3-4.

Table 3-4: Discharge Measurements at gauge location

Date of measurement Flow (m3/sec) Remarks

01 Dec 2016 3.42 Current meter

06 Feb 2017 2.02 Current meter

03 April 2017 4.27 Current Meter

3.3.1 Stream flow data

The stream gauge stations in the vicinity which provide reliable monthly data for the stream-

flow analysis is:

Chepe river at Garambeshi, Station no.440

Because of the non-availability of long-term discharge data at the project site, the reference

hydrology for the Upper Daraundi- B Hydropower project has been derived from the gauging

station at Garambeshi of Chepe khola.

Looking at the physiographic conditions and proximity of the gauging stations, it would be

more appropriate to use the discharge data from Garambeshi station for deriving the stream

flow at the intake site. The drainage area of Chepe at Garambeshi is 308km2. Mean monthly

discharge data are available from DHM. The period of data available for Garambeshi station

Units Engineering Consultancy 3–5

Upper Daraundi–B Small Hydropower Project Feasibility Study

Report

440 is 1964-2006.The historic mean monthly discharge data of Chepe at Garambeshi are

given below in Table 3.5.

Table 3-5: Mean Monthly Discharge of Chepe River at Garambeshi

Year Jan. Feb. Mar. Apr. May Jun. Jul. Aug. Sep. Oct. Nov. Dec.

1964 5.66 3.91 3.07 3.24 3.85 11.6 47.5 78.8 159 52.7 12.2 6.58

1965 4.21 3.37 3.35 4.36 2.94 33.7 94.8 129 79.4 42.2 17.2 7.69

1966 5.79 4.85 4.35 3.74 2.92 8.35 134 90.4 83.6 50.1 29.6 16.3

1967 6.02 4.18 4.06 5.09 6.48 10.3 69.5 64.6 41 16.7 9.47 7.75

1968 5.96 4.67 4.67 4.85 4.88 21.1 54.3 53.7 40.4 33 12.2 7.57

1969 5.75 4.47 4.49 3.89 4.71 9.21 41.3 64.6 53.1 22.5 9.88 6.44

1970 4.86 4.44 3.72 3.43 3.49 17.7 65.1 75.8 44.5 26 10.9 6.68

1971 4.96 3.99 3.76 6.23 9.13 56.1 70.3 73.8 53.3 34.8 16.2 8.04

1972 5.45 4.83 3.85 3.71 4.69 14.4 64.4 59.1 50.7 21.2 11.8 6.7

1973 6.12 5.19 5.12 4.45 6.94 41.7 47.1 71.8 58.7 46.3 16.8 8.53

1974 6.11 4.55 3.7 4.29 4.87 15.6 77.1 79.9 49 22.2 11.8 8.26

1975 6.48 5.96 4.97 4.61 5.14 23.2 68 52.3 73.1 25.3 10.6 5.98

1976 4.23 3.6 2.64 2.82 5.34 35.7 50.8 76.3 47 17 8.85 5.75

1977 4.56 3.72 3.37 5.16 10.4 11.9 51 84.1 42.6 19.8 12.3 7.86

1978 6.08 5.1 5.34 5.54 8.53 19.9 61.3 71.9 44.6 22.3 10.8 7.06

1979 4.9 4.42 3.3 3.61 5.32 9.03 51.2 73.3 44 22.2 12.6 8.91

1980 6.64 5.61 6.14 5.15 5.67 15.2 57.9 64 47.2 20.1 10.4 7.87

1981 6.47 5.46 4.27 5.78 6.74 11.5 45 59 35.6 16.1 9.26 5.64

1982 4.2 4.28 5.42 5.54 5.63 11.7 56.2 55.5 46.5 18.7 9.68 7.15

1983 5.85 4.95 4.55 4.64 8.16 8.16 31.9 55.3 58 28.2 12.4 7.38

1984 5.43 4.08 3.24 3.11 4.93 17.4 70.6 54.5 64.6 20.9 12 7.76

1985 5.71 4.66 3.88 3.95 5.11 11.3 58.6 48.9 46.2 28.8 13.4 8.95

1986 6.21 4.51 4.35 5.06 5.33 17.1 53.2 65.9 69.7 30.7 14.4 9.71

1987 7.24 5.86 6.07 6.79 7.53 17.6 103 ... ... 18.8 11.5 7.66

1988 6.77 5.43 5.29 4.89 6.65 19.1 70.6 107 50 16.2 9.71 7.5

1989 7.34 5.75 5.11 4.76 10.2 26.5 65.6 91.3 53 23 12.1 8.32

1990 6.27 5.71 6.18 6.79 10.2 25.6 61.6 63.1 53.8 22.1 11.5 7.43

1991 6.11 4.73 4.53 4.87 5.82 15.3 36.5 66.6 59.7 18.1 9.55 6.53

1992 5.16 4.57 3.5 2.75 4.25 10.5 25 67.8 46.2 21.4 11.2 7.41

1993 5.56 4.52 4.19 4.27 5.56 10.7 41.9 92.3 58.9 25.5 12.4 7.13

1994 ... ... ... 5.78 6.24 22.8 49.1 73.8 53.8 ... ... 7.13

1995 5.66 4.68 4.56 4.12 10.3 62.4 93.2 ... ... 22.8 13.5 7.99

Units Engineering Consultancy 3–6

Upper Daraundi–B Small Hydropower Project Feasibility Study

Report

1996 6.79 5.96 5.45 4.76 5.23 19.3 76.3 102 71.8 31.2 12.5 7.08

1997 5.4 4.14 4.48 5.51 5.14 12.4 46.8 54.6 38.8 19.6 11.2 8.82

1998 6.23 5.04 5.93 5.96 8.38 19.1 89.1 127 65.5 28.4 12.6 7.81

1999 4.73 5.62 4.44 3.98 6.43 27.8 63.7 62.4 45.9 22.7 8.72 4.39

2000 5.84 5.51 4.87 5.05 10.1 54 90.5 101 78.8 23.5 12.2 7.68

2001 5.82 4.66 3.29 3.64 13.5 35.1 70.3 96.2 73.7 28.2 13.4 7.41

2002 6.23 4.13 3.89 4.24 9.27 29.9 128 102 52.1 28.9 16 10.7

2003 8.35 7.09 7.86 7.75 7.77 18.2 214 95.3 76.7 36.6 13.6 7.42

2004 8.8 7.03 4.41 6.12 14 31.9 86 79.3 66.6 37.9 17.8 10.8

2005 8.55 6.5 5.18 4.38 5.79 7.17 50.5 65.6 40.1 19.3 12 6.74

2006 4.81 4.07 3.04 4.09 7.62 21.1 53.1 62.7 53.1 20 12.2 6.83

AVG: 5.94 4.9 4.473 4.72 6.772 21.36 68.277 75.915 57.812 26.2 12.58 7.752

Min 4.2 3.37 2.64 2.75 2.92 7.17 25 48.9 35.6 16.1 8.72 4.39

Max 8.8 7.09 7.86 7.75 14 62.4 214 129 159 52.7 29.6 16.3

The reference hydrology for the project has been analyzed from four methods. They are

a) Correlation method

b) MIP (medium irrigation project ) method

c) Regional hydrology method

d) WECS-DHM method

3.3.2 Monthly flow

3.3.2.1 Catchment correlation method

There is a gauging station at Chepe River at Garambeshi close to the project site. Daraundi

is one of the major tributaries of Marshyangdi River having similar hydro-meteorological

characteristic. Therefore, the discharge available at Chepe at Garambeshi site can be used

for water availability study of Upper Daraundi-B Small HP intake site after transposing the

data on catchment area proportion basis. The transposing ratio computed in this study is

0.32.

Q1 P1

P2 A1

A2 Q2

Where,

P = Average Annual Precipitation (mm)

A = Basin Area (km2)

Q = River Discharge (m3/s)

Units Engineering Consultancy 3–7

Upper Daraundi–B Small Hydropower Project Feasibility Study

Report

The mean monthly discharge at head works are shown in the Table 3-6. As seen from the

table the lowest monthly flow occurs in the month of March. The long term mean monthly

flow at the intake site has been estimated as 8.03m3/s.

Table 3-6: Mean Monthly Discharge at Intake Site

Year Jan. Feb. Mar. Apr. May Jun. Jul. Aug. Sep. Oct. Nov. Dec.

1964 1.84 1.27 1 1.05 1.25 3.77 15.42 25.58 51.62 17.11 3.96 2.14

1965 1.37 1.09 1.09 1.42 0.95 10.94 30.78 41.88 25.78 13.7 5.58 2.5

1966 1.88 1.57 1.41 1.21 0.95 2.71 43.51 29.35 27.14 16.27 9.61 5.29

1967 1.95 1.36 1.32 1.65 2.1 3.34 22.56 20.97 13.31 5.42 3.07 2.52

1968 1.94 1.52 1.52 1.57 1.58 6.85 17.63 17.44 13.12 10.71 3.96 2.46

1969 1.87 1.45 1.46 1.26 1.53 2.99 13.41 20.97 17.24 7.31 3.21 2.09

1970 1.58 1.44 1.21 1.11 1.13 5.75 21.14 24.61 14.45 8.44 3.54 2.17

1971 1.61 1.3 1.22 2.02 2.96 18.21 22.82 23.96 17.31 11.3 5.26 2.61

1972 1.77 1.57 1.25 1.2 1.52 4.68 20.91 19.19 16.46 6.88 3.83 2.18

1973 1.99 1.69 1.66 1.44 2.25 13.54 15.29 23.31 19.06 15.03 5.45 2.77

1974 1.98 1.48 1.2 1.39 1.58 5.06 25.03 25.94 15.91 7.21 3.83 2.68

1975 2.1 1.94 1.61 1.5 1.67 7.53 22.08 16.98 23.73 8.21 3.44 1.94

1976 1.37 1.17 0.86 0.92 1.73 11.59 16.49 24.77 15.26 5.52 2.87 1.87

1977 1.48 1.21 1.09 1.68 3.38 3.86 16.56 27.31 13.83 6.43 3.99 2.55

1978 1.97 1.66 1.73 1.8 2.77 6.46 19.9 23.34 14.48 7.24 3.51 2.29

1979 1.59 1.44 1.07 1.17 1.73 2.93 16.62 23.8 14.29 7.21 4.09 2.89

1980 2.16 1.82 1.99 1.67 1.84 4.94 18.8 20.78 15.32 6.53 3.38 2.56

1981 2.1 1.77 1.39 1.88 2.19 3.73 14.61 19.16 11.56 5.23 3.01 1.83

1982 1.36 1.39 1.76 1.8 1.83 3.8 18.25 18.02 15.1 6.07 3.14 2.32

1983 1.9 1.61 1.48 1.51 2.65 2.65 10.36 17.95 18.83 9.16 4.03 2.4

1984 1.76 1.32 1.05 1.01 1.6 5.65 22.92 17.69 20.97 6.79 3.9 2.52

1985 1.85 1.51 1.26 1.28 1.66 3.67 19.03 15.88 15 9.35 4.35 2.91

1986 2.02 1.46 1.41 1.64 1.73 5.55 17.27 21.4 22.63 9.97 4.68 3.15

1987 2.35 1.9 1.97 2.2 2.44 5.71 33.44 6.1 3.73 2.49

1988 2.2 1.76 1.72 1.59 2.16 6.2 22.92 34.74 16.23 5.26 3.15 2.44

1989 2.38 1.87 1.66 1.55 3.31 8.6 21.3 29.64 17.21 7.47 3.93 2.7

1990 ... ... 2.01 2.2 ... ... ... 20.49 17.47 7.18 3.73 2.41

1991 1.98 1.54 1.47 1.58 1.89 4.97 11.85 21.62 19.38 5.88 3.1 2.12

1992 1.68 1.48 1.14 0.89 1.38 3.41 8.12 22.01 15 6.95 3.64 2.41

1993 1.81 1.47 1.36 1.39 1.81 3.47 13.6 29.97 19.12 8.28 4.03 2.31

1994 1.88 2.03 7.4 15.94 23.96 17.47 2.31

Units Engineering Consultancy 3–8

Upper Daraundi–B Small Hydropower Project Feasibility Study

Report

1995 1.84 1.52 1.48 1.34 3.34 20.26 30.26 7.4 4.38 2.59

1996 2.2 1.94 1.77 1.55 1.7 6.27 24.77 33.12 23.31 ... ... 2.3

1997 1.75 1.34 1.45 1.79 1.67 4.03 15.19 17.73 12.6 6.36 3.64 2.86

1998 2.02 1.64 1.93 1.94 2.72 6.2 28.93 41.23 21.27 9.22 4.09 2.54

1999 1.54 1.82 1.44 1.29 2.09 9.03 20.68 20.26 14.9 7.37 2.83 1.43

2000 1.9 1.79 1.58 1.64 3.28 17.53 29.38 32.79 25.58 7.63 3.96 2.49

2001 1.89 1.51 1.07 1.18 4.38 11.4 22.82 31.23 23.93 9.16 4.35 2.41

2002 2.02 1.34 1.26 1.38 3.01 9.71 41.56 33.12 16.92 9.38 5.19 3.47

2003 2.71 2.3 2.55 2.52 2.52 5.91 69.48 30.94 24.9 11.88 4.42 2.41

2004 2.86 2.28 1.43 1.99 4.55 10.36 27.92 25.75 21.62 12.31 5.78 3.51

2005 2.78 2.11 1.68 1.42 1.88 2.33 16.4 21.3 13.02 6.27 3.9 2.19

2006 1.56 1.32 0.99 1.33 2.47 6.85 17.24 20.36 17.24 6.49 3.96 2.22

AVG: 1.93 1.59 1.45 1.53 2.2 6.93 22.17 24.65 18.77 8.52 4.08 2.52

3.3.2.2 Mean Monthly Flow by MIP Method

The field discharge measurements taken on various dates at the Daraundi Khola were used

in the MIP method for generating long-term mean monthly flow data. The Daraundi lies in

Region 1 according to the MIP Manual. The long term average flow at the intake site has

been estimated as 6.57m3/s. The mean monthly discharge at head works are shown in the

Table 3.7.

Table 3-7: Mean Monthly Discharge (m3/s) by MIP Method

Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec

2.19 1.65 1.19 0.91 2.38 3.51 13.26 22.86 15.09 7.32 3.75 2.83

3.3.2.3 Regional Hydrological Method

In the regional analysis, a number of gauging stations have been used to develop the

regional analysis and the data used are from the year 1964 to 1993. The stations considered

are the reliable stations in the country. For the regional analysis, the long-term average

monthly flows were related to basin characteristics.

The regression for long term average monthly flows showed that total drainage area “A” and

the monsoon wetness index “MWI” produced the statistically most significant regression

coefficients. The list below gives the formulae to be applied to ungauged basins for the

estimation of the long-term average monthly flows.

January: Q = 0.03117 * A0.8644

February: Q = 0.02417 * A0.8752

March: Q = 0.02053 * A0.8902

April: Q = 0.01783 * A0.9258

May: Q = 0.01930 * A0.9657

Units Engineering Consultancy 3–9

Upper Daraundi–B Small Hydropower Project Feasibility Study

Report

June: Q = 0.01135 * A0.9466 * MWI0.2402

July: Q = 0.01641 * A0.9216 * MWI0.3534

August: Q = 0.02592 * A0.9095 * MWI0.3242

September: Q = 0.02206 * A0.8963 * MWI0.3217

October: Q = 0.01504 * A0.8772 * MWI0.2848

November: Q = 0.00792 * A0.8804 * MWI0.2707

December: Q = 0.00538 * A0.8890 * MWI0.2580

From the average monthly flows obtained by regression, the average annual flow was

developed for each of the ungauged sites. The monthly flow data from above equations are

shown in Table 3.8.The long term average flow at the intake site has been estimated as

6.375m3/s.

Table 3-8: Long-Term Mean Monthly Flow by MHSP Method

Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec

1.67 1.36 1.24 1.45 1.65 5.37 16.17 19.41 15.26 7.22 3.47 2.23

3.3.2.4 Mean Monthly Flow by WECS/DHM Method

A study on 'Methodologies for Estimating Hydrologic Characteristics of Ungauged Locations

in Nepal' (July 1990) was carried out by WECS and DHM. This study uses the approach of

multiple regression equations relating the physiographic and/or climatologic characteristics of

the selected basins to the average monthly flow values. Altogether, 12 individual monthly

regression equations were developed.

The results of this study are used as an alternate approach for estimation of mean monthly

discharges at the Intake site. The Table 3-9 shows the results from WECS/DHM method. The

long term average flow at the intake site has been estimated as 5.48m3/s.

Table 3-9: Long-Term Mean Monthly Flow by WECS/DHM Method

Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec

1.25 1.07 0.95 0.96 1.24 4.84 14.28 17.36 13.43 5.87 2.75 1.79

3.3.3 Adopted Mean Monthly Flow

The values calculated by different methods were compared carefully (Table 3-10). There are

insufficient discharge measurements in Daraundi to rely fully on them, but they are useful

for comparison with the other methods. The MHSP and WECS/DHM method seems to give

rather low average flows in dry seasons than others. Regarding the MIP method single

discharge measurement input give twelve month discharge. Also spot discharge measured at

sites are not comparable to flow derived from these methods .Hence it is unreliable to

predict long term average flow of Daraundi Khola by these methods. Catchment correlation

with Chepe River having similar nature to Daraundi of same region is considered more

Units Engineering Consultancy 3–10

Upper Daraundi–B Small Hydropower Project Feasibility Study

Report

reliable. Therefore, we have adopted monthly flows from CAR method for feasibility study.

The adopted mean monthly flow and hydrograph are presented in Table 3-11.

Table 3-10: Mean monthly discharges from various methods

CAR with MIP

Month MHSP WECS/DHM

Chepe Method

January 1.67 1.25 1.93 2.19

February 1.36 1.07 1.59 1.65

March 1.24 0.95 1.45 1.19

April 1.45 0.95 1.53 0.91

May 1.65 1.24 2.20 2.38

June 5.37 4.84 6.93 5.49

July 16.17 14.28 22.17 13.26

August 19.41 17.36 24.65 22.86

September 15.26 13.43 18.77 15.09

October 7.22 5.87 8.52 7.32

November 3.47 2.75 4.08 3.75

December 2.23 1.79 2.52 2.83

Average 6.375 5.481 8.028 6.576

Table 3-11: Adopted Mean Monthly Flow (m3/s) at Intake Site

Month Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec

Adopted

Monthly

1.93 1.59 1.45 1.53 2.20 6.93 22.17 24.65 18.77 8.52 4.08 2.52

Flow

(m3/s)

Figure 3-2: Mean Monthly Flow at intake site

Units Engineering Consultancy 3–11

Upper Daraundi–B Small Hydropower Project Feasibility Study

Report

3.4 Flow Duration Curve

The flow duration curve (FDC) is a probability discharge curve that shows the percentage of

time a particular flow is equaled or exceeded. As discussed above, the long term flow series

at Upper Daraundi B HPP intake has been generated from catchment correlation with Chepe

River at Garambeshi station (St no 440). The flow duration curve has been derived based on

the monthly average discharge computed using catchment area ratio method. For the

purpose of comparative study, flow duration curve was also estimated by empirical methods;

WECS/DHM, MHSP and MIP. Numerical value of flow duration curve by different methods are

presented in Table 3-12.

Table 3-12: Numerical value of flow duration curve by different methods

CAR

Probability of

(m3/sec) MHSP WECS/DHM MIP

exceedance (%)

Monthly

18.59

5 25.75 17.63 15.67

14.91

10 21.62 16.08 14.19

13.90

15 18.33 15.58 13.73

12.07

20 16.3 13.65 11.92

8.80

25 13.17 9.23 7.76

6.77

30 8.33 6.67 5.56

5.76

35 6.27 5.65 4.99

4.79

40 4.68 4.61 4.00

3.84

45 3.75 3.57 2.85

3.29

50 3.04 2.85 2.27

2.81

55 2.55 2.20 1.76

2.56

60 2.3 1.89 1.47

2.35

65 2.02 1.67 1.25

2.25

70 1.88 1.65 1.24

2.06

75 1.76 1.60 1.19

1.76

80 1.61 1.49 1.10

1.49

85 1.5 1.42 1.02

1.23

90 1.39 1.37 0.96

1.07

95 1.21 1.31 0.95

0.91

100 0.86 1.24 0.95

The value from correlation with Chepe has been adopted further analysis and these values

are presented in Table 3-13 and the flow duration curve is presented in Figure 3-3. Based on

the flow duration curve, it is observed that the flow corresponding to 40 % exceedance is

about 4.68m3/s.

Units Engineering Consultancy 3–12

Upper Daraundi–B Small Hydropower Project Feasibility Study

Report

Table 3-13: Time Exceedance of Flows at Intake site

Probability of CAR (m3/sec) Monthly

Exceedance No. of days

(%) (Adopted Flow)

5 25.75 19

10 21.62 37

15 18.33 55

20 16.3 73

25 13.17 92

30 8.33 110

35 6.27 128

40 4.68 146

45 3.75 165

50 3.04 183

55 2.55 201

60 2.3 219

65 2.02 238

70 1.88 256

75 1.76 274

80 1.61 292

85 1.5 311

90 1.39 329

95 1.21 347

100 0.86 365

Units Engineering Consultancy 3–13

Upper Daraundi–B Small Hydropower Project Feasibility Study

Report

Fig

ure 3-3: Flow Duration Curve at Intake Site

3.5 Low flow analysis

The low flow information is generally used to assess the reliability and the economics of the

proposed project. If the occurrence of inadequate flow is too much frequent, a particular

project might prove to be uneconomic and unreliable. Knowledge of minimum stream flow is

therefore essential in the planning of any hydropower project.

For such type of ungauged rivers, HYDEST method was used for low flow computation. For

the purpose, different durations viz: 1-day, 7-day, 30 days and monthly were adopted to

compute the low flow for different return periods. The estimated low flows from the

HYDEST method are presented in Table 3.14.

Table 3-14: Low Flow Frequency Analysis (Log Normal Distribution)

Return Period Low flows, Q m3/s

2 1

10 0.9

20 0.7

3.6 Riparian Release

The long term mean monthly flow for the driest month, March, at the intake site is

1.45m3/sec. As a general practice, a flow equivalent to 10% of this month, i.e. 0.145m3/sec

will be released downstream as the riparian release for downstream riverine habitat.

3.7 Flood Flows

3.7.1 General

Design flood assessment involves the computation of a set of values of various return

periods of say 10, 20, 50 and 100 years, through frequency analysis of flood series or

Units Engineering Consultancy 3–14

Upper Daraundi–B Small Hydropower Project Feasibility Study

Report

through hydro-meteorological approach with the help of inputs of rainfall storm parameters

provided by the Meteorologist and flood data provided by the river gauging units. These

peak flood values are required to design headworks and powerhouse complex.