Академический Документы

Профессиональный Документы

Культура Документы

PDS - Sika Injection-101 RC

Загружено:

joker batmanОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

PDS - Sika Injection-101 RC

Загружено:

joker batmanАвторское право:

Доступные форматы

Product Data Sheet

Edition: 01/10/2012

Identification no: 02 07 05 01 000 0 000001

Version no: GCC

®

Sika Injection-101 RC

Sika® Injection-101 RC

Flexible PUR-Injection Foam for Temporary Water Stopping

®

Product Sika Injection-101 RC is a low viscosity, fast foaming and solvent-free water

reactive polyurethane injection foam resin, which cures to a dense flexible foam

Description with a fine cellular structure.

Suitable for use in hot and tropical climatic conditions.

®

Uses Sika Injection-101 RC is used for the temporary water stopping of high water

intrusions in concrete, brickwork and natural stonework:-

Cracks

Joints

Cavities

® ®

To achieve permanent watertight crack sealing, Sika Injection-201 CE or Sika

Injection-203 should be injected subsequently.

Characteristics / No reaction takes place unless it is in direct contact with water.

®

Advantages Sika Injection-101 RC can be injected as a single component system.

The free foaming expansion in contact with water is up to 40 times.

The reaction speed (foam formation) is influenced by the temperatures of the

mixed material, the structure and the contact water, plus the hydrodynamic

conditions.

®

In cold temperatures (< +10°C) Sika Injection-101 RC can be accelerated

®

using Sika Injection-AC10.

Tests

Standards / Approvals German KTW drinking water certificate

Product Data

Form Part A: Liquid

Part B: Liquid

Appearance/Colours Part A: Colourless

Part B: Brown

Packaging Part A: 10 or 20 kg

Part B: 12,5 or 25 kg

Storage

Storage Conditions Store in dry conditions in original sealed packaging at temperatures between +5°C

and +30°C. Protect from direct heat, sunlight and frost.

Shelf Life 24 months from date of production if stored in unopened, undamaged and original,

sealed packaging.

1 Sika® Injection-101 RC 1/3

Technical Data

Chemical Base Solvent and CFC free, water reactive 2-part polyurethane resin

Density (at 20°C) Part A: ~ 1,0 kg/lt

Part B: ~ 1,25 kg/lt

Viscosity (at 20°C) Part A: ~ 140 mPa·s

Part B: ~ 155 mPa·s

Pot Life (at 20°C) Approx. 2 hours; remove skin from the surface (do not mix in!)

Expansion (at 20°C) Expansion start: Approx. 16 seconds after contact with water

Expansion end: Approx. 70 seconds.

Application Details

Mixing Ratio 1 : 1 parts by volume

Mixing Empty Part’s A and B into a mixing vessel and mix slowly and thoroughly for at

least 2 min (max. 250 rpm) until homogeneous, observing all safety precautions.

The containers are supplied according to the required mixing ratio of 1:1 parts by

volume.

Partial quantities can be measured out in separate vessels. After mixing, pour the

material into the pump’s feed container, stir briefly and apply within the pot life.

®

If the substrate and/or ambient temperatures are < +10°C, Sika Injection-AC 10

®

can be added to Sika Injection-101 RC to accelerate the start of expansion.

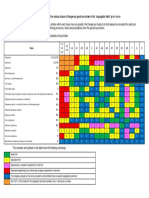

Reaction time table:- Material temperature

®

Sika Injection-101 RC +5°C +10°C +20°C

Expansion start ~ 19 sec ~17 sec ~ 16 sec

Sika Injection-101 RC

Sika Injection-AC10

0%

(compoment A+B)

in % by weight of

Expansion end ~ 97 sec ~ 88 sec ~ 70 sec

Dosage of

Expansion start ~ 12 sec ~ 11 sec ~ 10 sec

5%

Expansion end ~ 57 sec ~ 49 sec ~ 39 sec

®

Expansion start ~ 9 sec ~ 8 sec ~ 7 sec

®

10%

Expansion end ~ 41 sec ~ 37 sec ~ 35 sec

The given data are laboratory parameters and may deviate depending on the object

and conditions on site.

®

Application Methods/ Use injection pumps suitable for single part products, such as Sika Injection Pump

Tools EL-1, EL-2, Hand-1 or Hand-2.

Substrate Temperature +5°C min. / +35°C max.

Ambient Temperature +5°C min. / +35°C max.

®

Cleaning Clean all tools and application equipment with Sika Colma Cleaner to remove any

polyurethane residue immediately after use.

®

Do not leave Sika Colma Cleaner in the injection pump.

Hardened / cured material can only be removed mechanically.

Application Notes / The waterproofing process is divided into three phases:

Limitations Injection:

The time during which the injection material flows under pressure from the pump to

the desired moisture/water containing areas.

Induction:

The time from initial mixing until the reaction starts.

Reaction:

The period during which the mix viscosity increases and foam expansion takes

place.

®

Sika Injection-101 RC is generally used for the temporary stopping of high water

infiltration. To achieve permanent watertight crack sealing, the subsequent injection

® ®

of Sika Injection-201 CE / Sika Injection-203 is recommended.

2 Sika® Injection-101 RC 2/3

All technical data stated in this Product Data Sheet are based on laboratory tests.

Value Base Actual measured data may vary due to circumstances beyond our control

Please note that as a result of specific local regulations the performance of this

Local Restrictions product may vary from country to country. Please consult the local Product Data

Sheet for the exact description of the product uses.

Health and Safety For information and advice on the safe handling, storage and disposal of chemical

products, users shall refer to the most recent Material Safety Data Sheet containing

Information physical, ecological, toxicological and other safety-related data.

The information, and, in particular, the recommendations relating to the application

Legal Notes and end-use of Sika products, are given in good faith based on Sika's current

knowledge and experience of the products when properly stored, handled and

applied under normal conditions in accordance with Sika’s recommendations. In

practice, the differences in materials, substrates and actual site conditions are such

that no warranty in respect of merchantability or of fitness for a particular purpose,

nor any liability arising out of any legal relationship whatsoever, can be inferred

either from this information, or from any written recommendations, or from any other

advice offered. The user of the product must test the product’s suitability for the

intended application and purpose. Sika reserves the right to change the properties

of its products. The proprietary rights of third parties must be observed. All orders

are accepted subject to our current terms of sale and delivery. Users must always

refer to the most recent issue of the local Product Data Sheet for the product

concerned, copies of which will be supplied on request.

All products are manufactured under a management system certified to conform to the requirements of the

quality, environmental and occupational health & safety standards ISO 9001, ISO 14001 and OHSAS 18001.

Sika UAE L.L.C Sika Gulf B.S.C (c) Sika Saudi Arabia Co. Ltd

P.O. Box 126212 P.O. Box 15776 P.O. Box 112356,

Dubai, Adliya, Jeddah 21371,

United Arab Emirates Kingdom of Bahrain Saudi Arabia

Phone: +971 4 4398200 Phone: +973 17738 188 Phone: +966 2 692 7079

info@ae.sika.com sika.gulf@bh.sika.com jeddah@sa.sika.com

http://gcc.sika.com http://gcc.sika.com http://gcc.sika.com

3 Sika® Injection-101 RC 3/3

Вам также может понравиться

- Sika Injection-101-RC: Flexible PUR-Injection Foam For Temporary WaterstoppingДокумент3 страницыSika Injection-101-RC: Flexible PUR-Injection Foam For Temporary Waterstoppingyunita nitaОценок пока нет

- PDS - Sika Injection-201 CE PDFДокумент3 страницыPDS - Sika Injection-201 CE PDFdodi_182wibowoОценок пока нет

- Sika Injection-101rcДокумент3 страницыSika Injection-101rchazelОценок пока нет

- Sika Injection-201 CEДокумент3 страницыSika Injection-201 CEMuamer Jasna ĐulovićОценок пока нет

- Sika Injection 201 Ce Pds PDFДокумент3 страницыSika Injection 201 Ce Pds PDFGino Francis A. ElmaОценок пока нет

- Sika-Injection-101-Rc PDFДокумент3 страницыSika-Injection-101-Rc PDFAvan Setyo PratamaОценок пока нет

- Sika® Injection-201 IN: Product Data SheetДокумент2 страницыSika® Injection-201 IN: Product Data SheetDeep GandhiОценок пока нет

- Sika Monotop - 160migratingДокумент3 страницыSika Monotop - 160migratingpaulaОценок пока нет

- Sika - Injection-107 - SuitableДокумент3 страницыSika - Injection-107 - SuitableAmulyaRajbharОценок пока нет

- Sika Injection 201 CeДокумент3 страницыSika Injection 201 CeAvan Setyo PratamaОценок пока нет

- Sika TopSeal-107 - 231111 - 161028Документ3 страницыSika TopSeal-107 - 231111 - 161028Evello MercanoОценок пока нет

- Sika® ViscoCrete®-8100Документ2 страницыSika® ViscoCrete®-8100longОценок пока нет

- Sika Seal® - 105Документ4 страницыSika Seal® - 105Mohamed Osama AshmawyОценок пока нет

- Sika MonoSeal 101 H EngДокумент3 страницыSika MonoSeal 101 H Engjpantazis1975Оценок пока нет

- SikaFix®-121 Ground BondДокумент2 страницыSikaFix®-121 Ground BondSisuangly SimamoraОценок пока нет

- Sikacem®-711 Elastic: Provisional Product Data SheetДокумент4 страницыSikacem®-711 Elastic: Provisional Product Data SheetDavid V. BaltazarОценок пока нет

- Sikafix - 101: Single Component, Solvent-Free, Low Viscosity Polyurethane Resin For Flexible Crack SealingДокумент3 страницыSikafix - 101: Single Component, Solvent-Free, Low Viscosity Polyurethane Resin For Flexible Crack SealingAlonso Aguilar SalasОценок пока нет

- Sikalastic®-8440: Product Data SheetДокумент3 страницыSikalastic®-8440: Product Data SheetGeorge EnescuОценок пока нет

- Sika Viscocrete SC 305 Id Pds enДокумент2 страницыSika Viscocrete SC 305 Id Pds enAnonymous e2wolbeFsОценок пока нет

- Sika Monotop®-610: Product Data SheetДокумент3 страницыSika Monotop®-610: Product Data SheetVirah Sammy ChandraОценок пока нет

- Sikagrout - 114Документ3 страницыSikagrout - 114YASHICA VAITTIANATHANОценок пока нет

- Sika Rep: Multi-Purpose Patching and Repair MortarДокумент3 страницыSika Rep: Multi-Purpose Patching and Repair MortarAndreas KamwankaОценок пока нет

- Sika® Injectocem-190: Product Data SheetДокумент3 страницыSika® Injectocem-190: Product Data SheetKhin Sandi KoОценок пока нет

- Sika Monotop®-160 Migrating: Product Data SheetДокумент3 страницыSika Monotop®-160 Migrating: Product Data Sheetslavisa05Оценок пока нет

- Sikacryl® 620 Fire - PDSДокумент3 страницыSikacryl® 620 Fire - PDSMuhammad YasirОценок пока нет

- Sikagrout - 105Документ3 страницыSikagrout - 105YASHICA VAITTIANATHANОценок пока нет

- Sika Monotop r-40 PDFДокумент3 страницыSika Monotop r-40 PDFGabriel LimОценок пока нет

- Sikatop 122 F: Fibre Reinforced, Polymer Modified Repair MortarДокумент3 страницыSikatop 122 F: Fibre Reinforced, Polymer Modified Repair MortarTiger CageОценок пока нет

- Alccofine 1106 TDS V2Документ3 страницыAlccofine 1106 TDS V2Siddhesh Kamat MhamaiОценок пока нет

- Sika Monotop RДокумент3 страницыSika Monotop Rtengok69Оценок пока нет

- Sikatop Seal-107inДокумент4 страницыSikatop Seal-107inSK Emran AliОценок пока нет

- Sika® Viscocrete®-8900: Product Data SheetДокумент3 страницыSika® Viscocrete®-8900: Product Data SheetlongОценок пока нет

- Sika ViscoCrete® - 3425Документ2 страницыSika ViscoCrete® - 3425Ola MayhoubОценок пока нет

- Sika Rep Fine®Документ2 страницыSika Rep Fine®Aftab QaisraniОценок пока нет

- Sikafix® Pu: Flexible Polyurethane GroutДокумент2 страницыSikafix® Pu: Flexible Polyurethane GroutPrakashОценок пока нет

- Sikadur - 52 inДокумент3 страницыSikadur - 52 inRavi Kumar KadivetiОценок пока нет

- Sigunit - P1 AF: Accelerating Shotcrete Admixture PowderДокумент3 страницыSigunit - P1 AF: Accelerating Shotcrete Admixture PowderBudhi KurniawanОценок пока нет

- Sika Injection 304 PDS PDFДокумент4 страницыSika Injection 304 PDS PDFslantsyhimОценок пока нет

- Sika Boom FRДокумент3 страницыSika Boom FRAlfian Nur LuthfiОценок пока нет

- SikaTop Seal 107 PDS (CE) PDFДокумент4 страницыSikaTop Seal 107 PDS (CE) PDFSed BeelzeОценок пока нет

- NG NP Sika Viscocrete Tempo 10 PlusДокумент2 страницыNG NP Sika Viscocrete Tempo 10 Plusgaohao01071992Оценок пока нет

- Sika Boom FR Gun Foam PdsДокумент3 страницыSika Boom FR Gun Foam PdsReno MaulanaОценок пока нет

- SikaMonoTop 910N en MY (08 2021) 1 1Документ3 страницыSikaMonoTop 910N en MY (08 2021) 1 1chanqiming51Оценок пока нет

- SikaTop Seal-107 Standard PB ENGДокумент4 страницыSikaTop Seal-107 Standard PB ENGJoshua WijayaОценок пока нет

- Sika Injection-215 RF 2014-02-1Документ3 страницыSika Injection-215 RF 2014-02-1Nyu123456Оценок пока нет

- Sigunit - L20: Liquid Shotcrete Accelerating Admixture For The Wet Spray ProcessДокумент3 страницыSigunit - L20: Liquid Shotcrete Accelerating Admixture For The Wet Spray ProcessYasin AykanatОценок пока нет

- Sikalastic 836 DWДокумент3 страницыSikalastic 836 DWHaniОценок пока нет

- Sikafloor - 161 G PDFДокумент4 страницыSikafloor - 161 G PDFShaik FazilОценок пока нет

- Sika Boom® FR: Product Data SheetДокумент3 страницыSika Boom® FR: Product Data SheetBagasОценок пока нет

- Sika Seal 105Документ3 страницыSika Seal 105John Christopher NewОценок пока нет

- Sikagard 720 Epocem IDДокумент2 страницыSikagard 720 Epocem IDRialno TambunanОценок пока нет

- Technical Data Sheet: Zwaluw Aqua-SiliconeДокумент2 страницыTechnical Data Sheet: Zwaluw Aqua-SiliconeNatalia DumitriuОценок пока нет

- Sika PDS E SikaFix - 101Документ2 страницыSika PDS E SikaFix - 101lwin_oo2435Оценок пока нет

- Sikasil PoolДокумент3 страницыSikasil PoolA GlaumОценок пока нет

- Sikaswell s-2Документ4 страницыSikaswell s-2Eko PriambudiОценок пока нет

- SikaMonoTop-620 en - PDS - TR - (11-2018)Документ3 страницыSikaMonoTop-620 en - PDS - TR - (11-2018)Subhasis BeraОценок пока нет

- Sika Anchorfix SДокумент5 страницSika Anchorfix SRobin Denkins PaulОценок пока нет

- Sika ViscoCrete - 3168Документ3 страницыSika ViscoCrete - 3168Phạm Thanh PhươngОценок пока нет

- Sika Seal - 109Документ2 страницыSika Seal - 109Mohamed Osama AshmawyОценок пока нет

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsОт EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsРейтинг: 5 из 5 звезд5/5 (1)

- Toyota Echo ForewordДокумент263 страницыToyota Echo Forewordjoker batmanОценок пока нет

- Nebosh Diploma UnitAДокумент14 страницNebosh Diploma UnitASeleniОценок пока нет

- Hazard AnalysisДокумент82 страницыHazard AnalysisrickymmaОценок пока нет

- 7 Respiratory Protection July2014Документ1 страница7 Respiratory Protection July2014joker batmanОценок пока нет

- Kestrel Heat Index Reference Guide Celsius: !! WARNING!!Документ2 страницыKestrel Heat Index Reference Guide Celsius: !! WARNING!!joker batmanОценок пока нет

- Types of Waterproofing Methods in Construction PDFДокумент5 страницTypes of Waterproofing Methods in Construction PDFjoker batmanОценок пока нет

- Do Not Use Tag PDFДокумент1 страницаDo Not Use Tag PDFjoker batmanОценок пока нет

- Husqvarna K6500 RingДокумент29 страницHusqvarna K6500 Ringjoker batmanОценок пока нет

- Oly Om 1Документ74 страницыOly Om 1Matthew BrooksОценок пока нет

- OHSAS 18001 Lead Auditor Training (IRCA) - 4Документ2 страницыOHSAS 18001 Lead Auditor Training (IRCA) - 4joker batmanОценок пока нет

- Roof Waterproofing Using Bituminous Waterproofing MembraneДокумент3 страницыRoof Waterproofing Using Bituminous Waterproofing Membranejoker batmanОценок пока нет

- Lifting Cable Position: Theory vs RealityДокумент1 страницаLifting Cable Position: Theory vs Realityjoker batmanОценок пока нет

- Msds-016 Conbextra GP - Sds11813 - enДокумент5 страницMsds-016 Conbextra GP - Sds11813 - enjoker batmanОценок пока нет

- HSG Safety Con Strut IonДокумент141 страницаHSG Safety Con Strut IonbelcaОценок пока нет

- Sikadur® 52 Part A: Safety Data SheetДокумент11 страницSikadur® 52 Part A: Safety Data Sheetjoker batmanОценок пока нет

- Msds-014 Preco Hydrotard - Sds11287 - En1Документ5 страницMsds-014 Preco Hydrotard - Sds11287 - En1joker batmanОценок пока нет

- Untitled 1Документ1 страницаUntitled 1joker batmanОценок пока нет

- MSDS-002 Sureflow 100Документ45 страницMSDS-002 Sureflow 100joker batmanОценок пока нет

- Rebar Job Hazard AnalysisДокумент1 страницаRebar Job Hazard Analysisjoker batmanОценок пока нет

- Do Not Use Tag PDFДокумент1 страницаDo Not Use Tag PDFjoker batmanОценок пока нет

- Factsheet ConsultationsДокумент2 страницыFactsheet Consultationsjoker batmanОценок пока нет

- West Nile VirusДокумент2 страницыWest Nile Virusjoker batmanОценок пока нет

- Types of Waterproofing Methods in ConstructionДокумент5 страницTypes of Waterproofing Methods in Constructionjoker batmanОценок пока нет

- Chipper Machine 2 PDFДокумент2 страницыChipper Machine 2 PDFjoker batmanОценок пока нет

- Playground Maintenance For PlayspacesДокумент83 страницыPlayground Maintenance For PlayspacesTess MichaelsОценок пока нет

- OHS in Planning and Preparing For Configuration of Computer Systems and NetworkДокумент23 страницыOHS in Planning and Preparing For Configuration of Computer Systems and NetworkVanna Faye DeJesusОценок пока нет

- L550 Anglais (001-025)Документ25 страницL550 Anglais (001-025)Jonathan WENDTОценок пока нет

- Managing Musculoskeletal Disorders in Checkout Work: A Brief GuideДокумент8 страницManaging Musculoskeletal Disorders in Checkout Work: A Brief GuideandreОценок пока нет

- 6.3 Ergonomics For General Industry & OshaДокумент33 страницы6.3 Ergonomics For General Industry & Osharazlan ghazaliОценок пока нет

- Unit 1 - Introduction To Occupational Health and SafetyДокумент30 страницUnit 1 - Introduction To Occupational Health and Safetyvidya chakitwarОценок пока нет

- Procedures for Atmospheric TestingДокумент2 страницыProcedures for Atmospheric Testingivan20175029bОценок пока нет

- 7.2.4 Segregation Table: Class 1.1 1.2 1.5 1.3 1.6 1.4 2.1 2.2 2.3 3 4.1 4.2 4.3 5.1 5.2 6.1 6.2 7 8 9Документ1 страница7.2.4 Segregation Table: Class 1.1 1.2 1.5 1.3 1.6 1.4 2.1 2.2 2.3 3 4.1 4.2 4.3 5.1 5.2 6.1 6.2 7 8 9ejrango74Оценок пока нет

- Occupational Disease Surveillance and PreventionДокумент21 страницаOccupational Disease Surveillance and PreventionWidya AnggrainiОценок пока нет

- MIB Risk Assessment FormДокумент2 страницыMIB Risk Assessment Formnurul nabilah bt khairul anuarОценок пока нет

- External Alert 15-14 IADC Improper CSE Results in Multiple FatalitiesДокумент1 страницаExternal Alert 15-14 IADC Improper CSE Results in Multiple FatalitiesaswinОценок пока нет

- Primer 116970Документ6 страницPrimer 116970willis kristianОценок пока нет

- Delo Gold Ultra SAE 15W-40 Safety Data SheetДокумент6 страницDelo Gold Ultra SAE 15W-40 Safety Data SheetNasta Ina RobayasaОценок пока нет

- K-12 TLE Caregiving Course GuideДокумент16 страницK-12 TLE Caregiving Course GuideJoseph Lee100% (3)

- Drawing and Interprating Basic SketchДокумент64 страницыDrawing and Interprating Basic SketchJocy ShiferaОценок пока нет

- Contractor Safety QuestionnaireДокумент3 страницыContractor Safety QuestionnaireMart oro alОценок пока нет

- Super Stainless Polish SDSДокумент6 страницSuper Stainless Polish SDSjummakhan jummakhanОценок пока нет

- Confined Space Rescue PlanДокумент27 страницConfined Space Rescue Planarunjith r100% (1)

- HIRA in Construction Sector PDFДокумент44 страницыHIRA in Construction Sector PDFE. Ricardo Ponce EspejoОценок пока нет

- Chapter 33 Hazardous Materials Response Priorities and ActionsДокумент2 страницыChapter 33 Hazardous Materials Response Priorities and ActionsAndrea ZambranoОценок пока нет

- Clariant SDS GENAPOL LA 030 USA EnglishДокумент13 страницClariant SDS GENAPOL LA 030 USA EnglishShailendra SinghОценок пока нет

- Jollibee Foods Corporation Safety ManagementДокумент25 страницJollibee Foods Corporation Safety ManagementClint Therens Bacasmas83% (6)

- Real Estate Sector Report on Oberoi, Brigade & NBCCДокумент56 страницReal Estate Sector Report on Oberoi, Brigade & NBCCMital GohilОценок пока нет

- National Detergents Oman NewДокумент14 страницNational Detergents Oman NewRizwan Hameed0% (1)

- SS JSP - 063 Testing and Pre-Commissioning WorksДокумент9 страницSS JSP - 063 Testing and Pre-Commissioning WorksBarkat UllahОценок пока нет

- MSDS Insuget 2021Документ8 страницMSDS Insuget 2021cheryl abaroОценок пока нет

- Safe Hospitality: Safety, Health & Welfare in Hotels, Restaurants, Catering & BarsДокумент61 страницаSafe Hospitality: Safety, Health & Welfare in Hotels, Restaurants, Catering & BarsTiago RodriguesОценок пока нет

- Risk Assessment - Water TankДокумент4 страницыRisk Assessment - Water Tankfairoos aliОценок пока нет

- 5.0 Environmental Management Plan: Proposed Domaine de Grand Baie Residential Development - EIA ReportДокумент9 страниц5.0 Environmental Management Plan: Proposed Domaine de Grand Baie Residential Development - EIA ReportProperty TwelveОценок пока нет

- Ammonia Standards and Regulations SummaryДокумент31 страницаAmmonia Standards and Regulations SummarybtoroОценок пока нет