Академический Документы

Профессиональный Документы

Культура Документы

Piles

Загружено:

Jesús Rodríguez RodríguezАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Piles

Загружено:

Jesús Rodríguez RodríguezАвторское право:

Доступные форматы

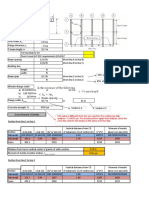

CELL / MODEL NAME DESCRIPTION DATE

F‐HP Steel H piles 2/17/2017

F‐MS Metal shell piles 2/17/2017

F‐PC Precast piles 2/17/2017

Piles Page1 of 1 2/17/2017

bf

t

Typ. along

H-Pile

±10"

t 5 splicer

d

16

A

Typ.

3

1 4

Commercial Bottom of

Concrete encasem ent

"

in

splicer pile cap

.

when specified

STEEL PILE TABLE See Detail B Welded wire fabric 6 x 6-

A A W4.0 x W4.0 weighing

Web and 58#/100 sq. ft. Bend as

Flange Encasement

Depth Flange

Designation width diameter required to fit into wall.

d thickness

bf A

t .

cl

HP 14x117 1414" 1478" 13

16" 30" 3"

11

x102 14" 1434" 16" 30"

H-pile

x89 1378" 1434"

5

8" 30" ELEVATION

1

x73 1358" 1458" 2" 30"

H-Pile

HP 12x84 1214" 1214" 11

16" 24" ELEVATION SECTION A-A

x74 1218" 1214"

5

8" 24"

x63 12" 1218" 1

2" 24" Commercial

splicer INDIVIDUAL PILE

x53 1134" 12" 7

16" 24" Commercial

splicer CONCRETE ENCASEMENT

HP 10x57 10" 1014" 9

16" 24" ** Backup

plate (Forms for encasement may be omitted when

x42 934" 1018" 7

16" 24" 45°

4"

soil conditions permit).

212"

1

HP 8x36 8" 818" 7

16" 18"

t (min.) = 38"

H-pile

Backup H-Pile * Typ. along four

edges of flange ¢

plate * Typ. along four Fw

Ww edges of web ¢

H-pile

Ft

See Detail A Wt

10"

DETAIL "B" ISOMETRIC VIEW

Wt

Ft

Pile shoe

WELDED COMMERCIAL SPLICE See Detail D

W

F

ELEVATION

H-Pile

ELEVATION END VIEW

H-pile

F

Commercial

Typ. shop or

splicer

field weld

***

Designation F Fw W Wt Ww

10"

Ft

60°

m ax.

t

Typ. along

4"

HP 14x117 1212" 1" 7

8" 734" 5

8"

1

2"

Pile shoe splicer 5

1

16 * Typ. along four

edges of flange ¢ x102 1212" 7

8"

3

4" 734" 5

8"

1

2"

Fw

DETAIL A x89 1212" 3

4"

11

16" 734" 5

8"

1

2"

Splice plate

thickness Ft x73 1212" 5

8"

9

16" 734" 5

8"

1

2"

7 11

HP 12x84 10" 8" 16" 612" 5

8"

1

2"

7 11

x74 10" 8" 16" 612" 5

8"

1

2"

SHOE ATTACHMENT

5 1

DETAIL D x63 10" 8" 2" 612" 1

2"

3

8"

ISOMETRIC VIEW x53 10" 5 1

612" 1 3

8" 2" 2" 8"

3 9

HP 10x57 8" 4" 16" 514" 1

2"

3

8"

5 9

x42 8" 8" 16" 514" 1

2"

3

8"

Note:

WELDED COMMERCIAL SPLICE ALTERNATE 5 7

The steel H-piles shall be according to HP 8x36 7" 8" 16" 414" 1

2"

3

8"

AASHTO M270 Grade 50.

Interrupt welds 14" from end of web and/or each flange.

*

WELDED PLATE FIELD SPLICE

** Remove portions of backup plates that extend outside the flanges.

5

F-HP 2-17-2017 *** Weld size per pile shoe manufacturer ( 16" min.).

FILE NAME = USER NAME = DESIGNED REVISED F.A. TOTAL SHEET

- - SECTION COUNTY

HP PILE DETAILS RTE. SHEETS NO.

CHECKED - REVISED - STATE OF ILLINOIS

STRUCTURE NO.

PLOT SCALE = DRAWN - REVISED - DEPARTMENT OF TRANSPORTATION CONTRACT NO.

PLOT DATE = CHECKED - REVISED - ILLINOIS FED. AID PROJECT

r

te

e

m

ia

D

t

See Detail A, typ.

5

16

Cut square for tight fit

(within 0.01") before

2'-6"

±10"

welding

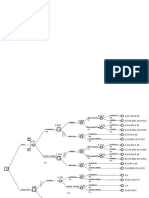

METAL SHELL PILE TABLE

714"

Weight min.

Designation Wall Inside

per Welded wire fabric 6 x 6-

and outside thickness volume Bottom of

foot W4.0 x W4.0 weighing

diameter t (yd.³/ft.) Metal shell piles pile cap

(Lbs./ft.) 58#/100 sq. ft.

Fill bar 18" x

PP12 0.250" 31.37 0.0267

1

2" min.

1

encasem ent

PP14 0.250" 36.71 0.0368 4"

Concrete

min.

PP14 0.312" 45.61 0.0361 A A

3"

.

cl

m in.

16"

PP16 0.312" 52.32 0.0478

5

PP16 0.375" 62.64 0.0470

Metal shell pile

See Detail A

3

16"

Metal shell pile SECTION A-A

Approx.

DETAIL A

Metal shell t WELDED COMMERCIAL SPLICE ELEVATION

pile

Notes:

3

4" End plate The 18" x 12" min. fill bar may be constructed of INDIVIDUAL PILE CONCRETE

60°

2 bars with a 18" max. gap between them.

ENCASEMENT AT PIERS

Shop or Pile segments shall be driven to solid contact with

s field weld splicer before welding.

1

s = t - 16"

END PLATE ATTACHMENT 6" Horizontal bend, typ.

Metal shell

pile

Shop or

60° field weld

t

Field fabricated PP12: 8-#7 bars

t

or commercial PP14: 11-#7 bars

Bottom of

backing ring PP16: 13-#7 bars

abutment

'

(7'-6" long, typ.)

-0'

4"

60°

10'

1

B B

3" Pitch

m in.

#4 bar

2"

Spiral

typ.

60° 1 "

12

l.

* Shop or c

field weld Metal Shell

Metal shell s

pile

pile

1

s = t - 16"

SECTION B-B

PILE SHOE ATTACHMENT

(When called for on the plans, the Contractor

shall furnish metal shell pile shoes consisting

of a single piece conical pile point as shown.

COMPLETE PENETRATION WELD SPLICE ELEVATION

The pile shoes shall be cast in one piece steel

* Field fabricated backing ring may be made from pile shell

according to either ASTM A 148 Grade 90-60 or

by removing segment to allow reducing circumference and

AASHTO M 103 Grade 65-35 and shall provide

vertically rejoin with partial joint penetration weld. REINFORCEMENT AT ABUTMENTS

full bearing over the full circumference of the

metal shell pile. The pile shoe shall have tapered

leads to assure proper alignment and fitting and

shall be secured to the pile with a circumferential

weld). Note:

The metal shell piles shall be according to

Article 1006.05 of the Standard Specifications.

F-MS 2-17-2017

FILE NAME = USER NAME = DESIGNED REVISED F.A. TOTAL SHEET

- - SECTION COUNTY

METAL SHELL PILE DETAILS RTE. SHEETS NO.

CHECKED - REVISED - STATE OF ILLINOIS

STRUCTURE NO.

PLOT SCALE = DRAWN - REVISED - DEPARTMENT OF TRANSPORTATION CONTRACT NO.

PLOT DATE = CHECKED - REVISED - ILLINOIS FED. AID PROJECT

#6 Gauge

112" Chamfer

spiral

4-#8 bars

14"

See End Plan and See End Plan and

End Elevation for End Elevation for

end reinforcement, end reinforcement,

typ. typ.

14"

112"

112"

112"

112"

2"

2"

2" cl. to

4"

4"

main steel

14"

8 Spa.

8 Spa.

at 1"

at 1"

#6 Gauge #6 Gauge 6-12" Ø Prestressing SECTION C-C C C

spiral spiral strands

8-#8 bars 112" Chamfer 112" Chamfer #6 Gauge 8-#8 bars

spiral

A A B B C C Drill and epoxy

112" Chamfer

2" cl. to 2" cl. to grout 4-#8 bars

14"

14"

main steel main steel

3" Pitch

14"

m ax.

14" 14"

3" Pitch

m ax.

SECTION A-A 2" cl. to

SECTION B-B main steel

14"

SECTION D-D

(Precast)

Pile head before

3" Pitch

3" Pitch

chipping

m in.

6-12" Ø Prestressing

m ax.

m ax.

** 2 2"

#6 Gauge Pile head before

1

strands

spiral chipping

36" m in.

112" Chamfer

*18" to

m in.

* 2 2"

Drill and epoxy

14"

grout 4-#8 bars

m in.

12"

D D

Prestressing strands

8 Spa.

8 Spa.

Precast or precast

or #8 bars

at 1"

at 1"

2" cl. to prestressed concrete

36 bar Ø min. lap

Precast or precast main steel pile

prestressed concrete 14"

pile

112"

112"

SECTION D-D

4"

4"

(Precast prestressed)

To construct pile extension , chip top

*

STANDARD PILE EXTENSION of pile back 36 bar Ø min. to expose

PRECAST CONCRETE PILE PRECAST PRESTRESSED CONCRETE PILE ALTERNATE PILE EXTENSION

vertical bars and lap vertical buildup

bars. Remove spiral to 212" min.

above chipping and provide full

9" strength lap weld exterior face (4"

min. length).

2"

4" 4" 4"

To construct pile extension, chip top

DESIGN STRESSES

4"

**

of pile back 212" to expose wire

14"

f'c = 5,000 p.s.i.(prestressed)

spiral and provide full strength lap

f'c = 4,500 p.s.i. (precast)

weld exterior face (4" min. length).

BAR u NOTES f'ci = 4,000 p.s.i.

Prestressing steel shall be uncoated high strength, low-relaxation f's = 270,000 p.s.i. (41,300 lbs.-12" Ø)

7-wire strand. The nominal diameter shall be 12" with a cross- fsi = 189,000 p.s.i. (28,900 lbs.-12" Ø)

4 pairs #4 u bar

sectional area of 0.153 in�.

as shown in End Plan

For Pile lengths up to 65', use two slings placed at a distance

of 0.21 L* from each end. For Piles longer than 65', use three

END PLAN

slings placed at a distance of 0.12 L* from each end and at midpoint

(End reinforcement only)

END ELEVATION of pile. *L= Overall length of pile to be handled.

(End reinforcement only) For handling pile lengths up to 45', use two slings placed at a

distance of 0.21 L from each end. For handling piles longer than

45', use three slings placed at a distance of 0.12 L from each end

and at midpoint of pile.

F-PC 2-17-2017

FILE NAME = USER NAME = DESIGNED REVISED F.A. TOTAL SHEET

- - SECTION COUNTY

PRECAST PILE DETAILS RTE. SHEETS NO.

CHECKED - REVISED - STATE OF ILLINOIS

STRUCTURE NO.

PLOT SCALE = DRAWN - REVISED - DEPARTMENT OF TRANSPORTATION CONTRACT NO.

PLOT DATE = CHECKED - REVISED - ILLINOIS FED. AID PROJECT

Вам также может понравиться

- Pile Capacity jgj94Документ8 страницPile Capacity jgj94Jesús Rodríguez RodríguezОценок пока нет

- Crack WidthДокумент2 страницыCrack Widthnagaraju-rachamadugu-275185% (13)

- ZBB28441SA Combi Bottom: Easy Freezer MaintenanceДокумент2 страницыZBB28441SA Combi Bottom: Easy Freezer MaintenanceJesús Rodríguez RodríguezОценок пока нет

- Concrete Construction Article PDF - Mechanical vs. Lap SplicingДокумент4 страницыConcrete Construction Article PDF - Mechanical vs. Lap SplicingGilven MedinaОценок пока нет

- Future of LNG - Arup - April17 PDFДокумент21 страницаFuture of LNG - Arup - April17 PDF123habib123fikriОценок пока нет

- Stud Welding Products, Inc.: 5 5?@AB#BA" " ! D$ G # HДокумент1 страницаStud Welding Products, Inc.: 5 5?@AB#BA" " ! D$ G # HJesús Rodríguez RodríguezОценок пока нет

- 5.3 Dynamic Earth Pressure Methods: Mononobe-Okabe MethodДокумент2 страницы5.3 Dynamic Earth Pressure Methods: Mononobe-Okabe MethodJesús Rodríguez RodríguezОценок пока нет

- Catalogo Aisladores PDFДокумент75 страницCatalogo Aisladores PDFCamilo AguilarОценок пока нет

- Why Is The Pollutant A Problem?: Toxicity, Poisoning and CarcinogenicityДокумент1 страницаWhy Is The Pollutant A Problem?: Toxicity, Poisoning and CarcinogenicityJesús Rodríguez RodríguezОценок пока нет

- CDM 2015Документ90 страницCDM 2015Tariq Akhtar67% (3)

- SectionpropertiesДокумент1 страницаSectionpropertiesJesús Rodríguez RodríguezОценок пока нет

- Programme ExamplesДокумент1 страницаProgramme ExamplesJesús Rodríguez RodríguezОценок пока нет

- Engm033: Durability of Bridges and Structures - Coursework 2Документ1 страницаEngm033: Durability of Bridges and Structures - Coursework 2Jesús Rodríguez RodríguezОценок пока нет

- Strong Motion Simulation For The Philippines Based On Seismic Hazard AssessmentДокумент17 страницStrong Motion Simulation For The Philippines Based On Seismic Hazard AssessmentmpvfolloscoОценок пока нет

- Confirmation of Entry and Timetable: Certificate of Proficiency in English (Thursday) - June (P0) 2011Документ1 страницаConfirmation of Entry and Timetable: Certificate of Proficiency in English (Thursday) - June (P0) 2011Jesús Rodríguez RodríguezОценок пока нет

- Cables PretensadoДокумент12 страницCables PretensadoFelipe CantillanoОценок пока нет

- 275 287Документ13 страниц275 287Jeff GajeОценок пока нет

- Flexural DesignДокумент38 страницFlexural DesignJesús Rodríguez RodríguezОценок пока нет

- T-Beam AnalysisДокумент38 страницT-Beam AnalysisJesús Rodríguez RodríguezОценок пока нет

- 8 WaterSupplyДокумент1 страница8 WaterSupplyJesús Rodríguez RodríguezОценок пока нет

- Masonry WallsДокумент50 страницMasonry WallsJesús Rodríguez RodríguezОценок пока нет

- Flexural DesignДокумент38 страницFlexural DesignJesús Rodríguez RodríguezОценок пока нет

- Design of Box Culvert BridgeДокумент26 страницDesign of Box Culvert BridgeJesús Rodríguez RodríguezОценок пока нет

- Soil PileInteractioninthePileVerticalVibrationBasedonFictitiousSoil PileModel PDFДокумент13 страницSoil PileInteractioninthePileVerticalVibrationBasedonFictitiousSoil PileModel PDFAhmad WaalОценок пока нет

- Bouc-Wen Model of Hysteretic Damping: Procedia Engineering December 2017Документ8 страницBouc-Wen Model of Hysteretic Damping: Procedia Engineering December 2017Jesús Rodríguez RodríguezОценок пока нет

- Decision TreeДокумент2 страницыDecision TreeJesús Rodríguez RodríguezОценок пока нет

- 6 UnitHydrographДокумент1 страница6 UnitHydrographJesús Rodríguez RodríguezОценок пока нет

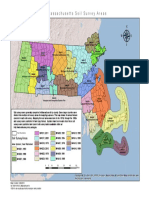

- S D C M: OIL Rainage Atenas of AssachusettsДокумент3 страницыS D C M: OIL Rainage Atenas of AssachusettsJesús Rodríguez RodríguezОценок пока нет

- MAsoilsurveyareas2 MKPДокумент1 страницаMAsoilsurveyareas2 MKPJesús Rodríguez RodríguezОценок пока нет

- Mylonakis Et Al Kinematic Moments Geotechnique 2001Документ17 страницMylonakis Et Al Kinematic Moments Geotechnique 2001Jesús Rodríguez RodríguezОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Project Report Modify PDFДокумент24 страницыProject Report Modify PDFTasmay EnterprisesОценок пока нет

- Concrete Hollow BlocksДокумент1 страницаConcrete Hollow BlocksChristian PorlucasОценок пока нет

- Soil NailingДокумент1 страницаSoil NailingPartha Pratim Sasmal0% (1)

- 3SS NW00 00007 PDFДокумент10 страниц3SS NW00 00007 PDFKarthikОценок пока нет

- Operation PhilosophyДокумент29 страницOperation PhilosophyMashiur RahmanОценок пока нет

- Eternia Brochure PDFДокумент16 страницEternia Brochure PDFmathew1965Оценок пока нет

- Magnetic Level Gauges & Level Transmitters: FeaturesДокумент3 страницыMagnetic Level Gauges & Level Transmitters: Featuressunshine dreamОценок пока нет

- CHB Wall & Slab EstimateДокумент13 страницCHB Wall & Slab EstimateNuel LacionОценок пока нет

- Grain Growth Behavior, Tensile Impact Weldability of Cerium - Doped Iridium AlloysДокумент62 страницыGrain Growth Behavior, Tensile Impact Weldability of Cerium - Doped Iridium AlloysKamal ThummarОценок пока нет

- CK 60 PDFДокумент3 страницыCK 60 PDFtaban89Оценок пока нет

- 8 SemДокумент22 страницы8 SemHarsh ShahОценок пока нет

- Sheet Metal DesignДокумент13 страницSheet Metal Designsivakumar subramanianОценок пока нет

- Conducting Corrosion Coupon Tests in Field Applications: Standard Guide ForДокумент10 страницConducting Corrosion Coupon Tests in Field Applications: Standard Guide ForCris GauchoОценок пока нет

- Ethylene Vinyl Acetate WikipediaДокумент4 страницыEthylene Vinyl Acetate WikipediaxiaoboshiОценок пока нет

- Welding TechnologyДокумент218 страницWelding Technologywbl_200789% (9)

- 1Документ14 страниц1bk100% (2)

- Section 02820 Ornamental Metal Fences and GatesДокумент14 страницSection 02820 Ornamental Metal Fences and GatesMØhãmmed ØwięsОценок пока нет

- Die CastingДокумент13 страницDie CastingDENNY JACOBОценок пока нет

- AOK Spec Only 2016-02Документ17 страницAOK Spec Only 2016-02Iulian MihaiОценок пока нет

- Cavity Wall-Method StatementДокумент4 страницыCavity Wall-Method StatementTAHER AMMAR100% (1)

- Bohler Colour ChartДокумент1 страницаBohler Colour Chartscooba84Оценок пока нет

- TC 302010-3 602 BW SCH 80-11121B1,10440B1,19M3792B2 (440 To 476) (JC 6303)Документ2 страницыTC 302010-3 602 BW SCH 80-11121B1,10440B1,19M3792B2 (440 To 476) (JC 6303)SAMANOОценок пока нет

- Astm A394Документ6 страницAstm A394MaxОценок пока нет

- WEICON CatalogueДокумент284 страницыWEICON CataloguefranekzapaОценок пока нет

- Underground Utilities Way Design Based On AASHTO-17th & 2018 IBCДокумент1 страницаUnderground Utilities Way Design Based On AASHTO-17th & 2018 IBCafvilavilanoriegaОценок пока нет

- Munro c301Документ8 страницMunro c301m4x4rtОценок пока нет

- MCT SEM 4 Engineer WoodДокумент16 страницMCT SEM 4 Engineer WoodKhushi ChauhanОценок пока нет

- PVC-PP-PVDF Swing Check Valve SpecificationsДокумент4 страницыPVC-PP-PVDF Swing Check Valve SpecificationsthangОценок пока нет

- Design of Superpassage (Ch. 75.377)Документ6 страницDesign of Superpassage (Ch. 75.377)Sumit Kumar100% (1)

- Blanking and PiercingДокумент5 страницBlanking and Piercingm9966822Оценок пока нет