Академический Документы

Профессиональный Документы

Культура Документы

Mitsubishi Manuals 2319

Загружено:

ElectronicaMecatronics0 оценок0% нашли этот документ полезным (0 голосов)

20 просмотров121 страницаMitsubishi AC SPINDLE FREQROL-SF STANDAR SPICIFICATION

Авторское право

© © All Rights Reserved

Доступные форматы

PDF или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документMitsubishi AC SPINDLE FREQROL-SF STANDAR SPICIFICATION

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

20 просмотров121 страницаMitsubishi Manuals 2319

Загружено:

ElectronicaMecatronicsMitsubishi AC SPINDLE FREQROL-SF STANDAR SPICIFICATION

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

Вы находитесь на странице: 1из 121

MITSUBISHI

AC SPINDLE DRIVE

FREQROL-SF

STANDARD SPECIFICATION

ADVANCED AND EVER ADVANCING

$1.

§3.

$4.

$5.

$s.

87.

$3.

-CONTENTS -

OUTLINE OF AC SPINDLE DRIVE UNIT, SF SERIES

i... Features

1.2 AC spindle drive unit model designation

1.3 Linkage between NC and spindle controller

1.4 Basic functions, auxiliary functions and

optional functions

1.5 Composition

SPECIFICATIONS

2,1 AC spindle motor controller specifications

2.2 Output characterstics

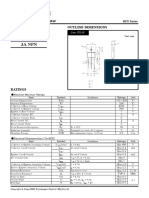

2.5 Outside view and dimensions

FUNCTIONS

3.1 Control input signals

3.2 Control output signals

3.3 Meter output

3.4 Interface electrical specification (for DIO)

WIRING AND SETTING

4.1 External wiring

4.2 Caution for installation of intermediate

panel mount type controller

WIRING

5.1 Power supply connection

5.2 Motor connection

5.3 External wiring

5.4 Cables for main circuit (power) connection

5.5 Control circuit cables

STATUS DISPLAY AND PARAMETER SETTING

6.1 Display by FR-SF readout (LED)

6.2 NC display

ORIENTATED SPINDLE STOP FUNCTION .

MODE AND FUNCTION

7.1 Magnesensor spindle orientaticn (1 div.)

+ OPERATION

DISCRETE COMPONENTS AND DEVICES

8.1 Options

siaae ©

saem 48

eee 54

wees 59

+2108

wee 103

se 107

s+ 107

§1. OUTLINE OF AC SPINDLE DRIVE UNIT, SF SERIES

wa

Features

Enhanced performance and upgraded functin

© Oriented spindle stop function

The newly designed oriented spindle stop functicn assures

smooth, exact and rapid spindle positioning.

© Accurate response to impact load

Flexibility of control system and accurate response char-

acteristic permit powerful cutting.

© Accurate response to low-rigidity load

Because of good flexibility of control system, response

to low-rigidity load, such as belt-driven load, is parti-

eularly good.

© Accurate load meter

Automatic motor rotor temperature compensation and motor

control compensation functions assure exact reading of

load meter.

© High-speed tapping

When the unit is bus-linked to CNC, complete synshroniza-

tion with feed motion can be achieved ... high-speed,

high-performance tapping can be realized.

© Profiling control

When the unit is bus-linked to CNC, C-axis motion’ can be

controlled for profiling.

Easy to use

Flexibility and versatility i:

use

Parameters (maximum motor speed, speed control loop gain,

etc.) can be set by incorporated key switches, as well as

through CRT of NC.

© Diagnosis functions

Diversified diagnosis information such as cause of alarm

is displayed by CRT of NC.

© Reliability

For enhancement of reliability, components are reduced

(about 30% of reduction, as compared with our previous pro-

ducts).

Wide range of models

Models ranging from 3.7kW to 45kW are available in standard

type. Besides standard type, also available are high-speed

type, wide-range constant output type, small-capacity type

and positioning type ....

0 Small-capacity type (REQROL-SFJ)(2.2-7.5kW ... 50% ED rat-

ing)

"90 frame” (motor frame size) is added to complete a series

of 2.2kW - 7.5kW.

Controller is renewed to reduce volume (1/3 of previous

one), floor space (1/2 of previous one) and weight (1/2 of

previous one)..... Refer to Specification BNP-A2821-01.

© Positioning type

Multi-point oriented spindle stop and index with high-speed

= f=

spindle are available, owing to use of motor built in en-

coder, when motor is directly coupled to machine.

Spindle speed and sync. feed signal can be monitored.

Since spindle encoder is not required, spindle head sys~

tem can be simplified.

1.2

AC spindle drive unit model designation

SaaS ea

(Gemi-eloeea)

© CRT fautt atsplay

© CRT speed neter dis-

play

0 CRT load meter dis~

play

‘Sompiese output

stmal

© Torque limit out-|

put signal

© Porque limit con-|

smand. Input

fo Machine ready

input

Alara reset input

Speed reference

Gigital/anaiog,

Select input

Speed overrice

Sepce

Energeny stop

input

Ebergency stop

alare output ON/

OFF select sse~

Geleration time

Constant setting

ik pues A ae ‘Special type Equipped with

3 ane 3500rp0 M: High-speea — -PHEBE control

30-min. rated cute ord zs

put capacity (kW) —— Speninh npent: we

-@-Ger-Co4

fe spindle tne ugg enpecsty

Power supply: ([Symber ‘Name ‘Symbol ‘Name

200" class’ ‘NO SIGN | Stancara ‘NO SIGN | Panel inside mount

Spe

2 esreediate paneT

ope

aye

|e som © Scanaiog 110/T0P | totes)

0 Fettdiog t1orsor | 12,516": option cara

= 3 Wagnesenecr epinaie] ° speed By Bor Pisinct

kare se- crlenvanion o Forward/reverse -

Ge © Enesaer multi-point | ° comand input | R: For connection

i spindle orienta" | o Speed mates out~ | "wath ie coher, than

5 Hon pur Wa00 series he

Z||__ ,. | sietest speed reference] o Encoder mitiepoint | o Lond acter out- | hts incivdes 20

Bilcard ar-| tinct ines spinaie sete | ° pot Hat Sneticn.

Bixee sncatson

Z @ Binary 12-nit 2 ee Sein en | © Zero speed out | D: For connection

5 2s Giles fae med | aaa

Gndez spinele ori Ha00 series ho,

] | Buslink to 1300 series] , gutation | Lg speed’ reference

care sr] © coer tse | Se

a © tighospsed sync. tap | Spinaie speed dis | put stznel sian

Be oBpintie tie | 9, ne

© High-speed sme. tap 13 output signal

(efoeea) wstenocor’ | S27: ford steel | » Spinel facie w29

SHER Rater oten Sortent Sotpe | TMS

© Profiling contro]. © Spindle orientation = R function.

Linkage between NC and spindle controller

CNCs Spinaie

PT Ms 00 SF

ke" aio [ so] ao] S® [imp k | Ta

Scanalog peed reference [O]O|—|olololololo

Digital speed reference “2

(DD | sinary, 12-bi¢/ne0, Oo) = (H) Hepa] || o

SER a asst

Digital TO ofotofolololafolo

cay [Sertan zo (RS422A) |—|—|010 ofofofto

GD [esti 1 (RS485) |—-]Olo]O == =lol=

*1: Without option

*2: With digital speed reference option (planned

to be developed by Ocb. 1987)

“3: For BCD, digits of its code were increased from

2 digits to 3 digits.

1.4 Basic functions, auxiliary functions and optional functions

Function

Detailed |

description] FR-SF-2-[]K-

option

Controller model

Out= | De= Option 5

ol

line | taiis}——]

t

D

Previ-

ous

FR-SE

series

S-analog reference voltage

input, +10V/top speed

o lo

°

°

S-analog reference voltage

input, #10V/top speed

function

Basic

Forward/reverse command

input

Speed meter output

Load meter output signal

Zero speed output signal

Up to speed output signal

Speed detect output signal

Load detect output signal

Spindle fault (alarm) out-

put signal

clolofolofolo

cfolofolololo

clolofofololo

o}ofofolololo

c}olofolololo

Spindle fault (alarm) con-

tent output signal

°

°

°

Torque limit output signal

Torque limit command input

Machine ready input

‘Alarm reset input

|

Auxiliary function

‘Speed reference signal

"digital/analog" selection

input

cfolololo

cfolololo

ofolofolo

ofolololo

cfolololo

Speed override input

Emergency stop input

clo

On-emergency stop alarm

signal ouput "ON/OFF" selec-|

| tion input

Acceleration/deceleration

time constant setting

Spindle orientation command

input

functoin

Optional

Magnesen-

sor used

Magnesensor spin-

dle orientation

Magnesensor high-

speed sync. tap*

Detailed Controller model | preyy—

deseription| FR-SF-2-f}x- He | Sus

Function Out= [De-_| Option symbol ERSSE |

line |taiis/—~ [x | tT [>

1024P/rev.| Encoder (4096 di- - ° ° °

encoder vision) spindle

used orientation

Encoder (4096 di- - ° ° ° °

vision) index

Encoder high- Pe] onp =

speed sync. tap*

Spindle speed =[e}fe |]. °

display/sync.

Zophase

g|contror | £204 signal

&| motor Motor built-in =[e]eo |e °

EJ ousit-an | encoder spindle

Slencoder | orientation

& | Gsea

uae! Motor built-in ~ ° ° ° °

‘a encoder index

5 Motor built-in = = [se |= =

3 encoder high-

& speed sync. tap*

Gontrptier CRT alarm display = = o = =

linked to

CRT speed/load

E00 "CNC. meter display

Coaxis control =a|_= ioe |= =

Digital speed reference

12-bit binary

S-digit BCD selectable wt fom fe = ° °

2oaigit ScD

For use of “high-speed sync. tap" marked with * in this list, con-

troller should be bus-linked to M300 series CNC.

1.5 Composition

1.5.1 Basic composition (standard) ..... FR-SF-2

Ae spindie controiier AC spindle motor

FR-SF

smarne~an v2

w/ouz23Hz

a ol 3 1%

x

Converter inverter |

cont

Fan otor

Contre section pe

HUST Hewrt nese | eustz | eye's | aunow opreur rowed ~e-as-ua waa seqa0g, -176 2.2 Output characteristics atpat PIPPI [ett Datpat FIFI SI -a50 EFEEIN Simar a sy-ua | Sy (tara are | | a —— on | ae wn Pi a output Fi Bl r acy speed Speed ‘Datpot Fi7PT Fis Gatpae PIPE Si-BAP[si-ma | Si-ma [Sime ives | sinns | si-ae ais cm [eins | ao a | We em [sam | mma | ws a | ao ew ei cy | sr ey | PP Se aa output Pi output 7 | oonts eating | | | | oe 7 | Speed Sptee_ Gn pat Fi7PE Fis) “set pire] LE) ore ie | sae | ia (ea Cee vesam_[ rs (sian Tasos (2am ry] rw (Cansan [sar as Coase my A outst [emi anne output! | a P Speed OO Ea = Datpat rizr atat FIFE iS5=E swe Trae | sum | aise oma Fens ur sen [wh Ta a rw) [ar oP) | as output "| Py =a Speea__@™D Fist] [ourpuerizpszesces |e U) Gace river Gatpat F172] Siasaz —]_337907 Space | se Sinee | SiH H [Beare vi sm reas feat on ses ao Tes | a | a ea mn Caw iar an i a1 as a S] cutpue MI SS [am mam) | parm TS a Te rl A al fone rete | owe pune FY | =e od oa ao ao oe Spec GIN 0 i - 18 Appendix 1 Alerm/warning list alarm To nar"|Abbr.| Name Description we) 10 | ww | vourace sown | this alarm occurs if input supply A volage goes down below the specifi- ed level, or if instantaneous power failure lasting for over 10msec oc- curs. 12 [wer | memory ERROR | this alarm occurs if read from, or A (FAULT) 1 | write to internal memory for con- troller system control does not go normally (memory is checked when the controller is turned on). 15 |me2 | memory exaor| this alarm occurs if 2-port memory A (FAULT) 2 | tor data communication (when FR-SF is bus-linked with M300 series chc) does not function properly. 17 | Be | Po BoaRD | this alarm occurs if any part of A es control card is not in good condi- tion. 20 |nsi | No stcNat 1 | This alarm occurs if signal zrom a (eu) motor built-in encoder is not at normal level. a1 [nse [no stenaL | this alarm occurs if signal from a (Spind ENC.) encoder for oriented spindle stop is not input, or not at normal level 22 |nss | rc mac This alarm occurs if 1¢ "Mac 012) of| A 012 FAULT control card does not function pro- perly. 23 |osz | SPEED CONTROL| This alarm occurs if difference bet-| A ERROR EXCESS | yeen true motor speed and referenced speed is excessiv 24 |par | srEaKeR TRIP | This alarm occurs if current exceed-| A ing the specified limit flows in the main (power) circuit. « ie Alarm (Nete)| To [Abbr.| Name Description meee) 25 |coc | converter | this alarm occurs if current exceed-| A OVERCURRENT | ing the specified limit flows in converter. 26 PL | POWER PHASE | This alarm occurs if any one of A EALLURS: three phases of input power supply fails. 27 [cruz] cpu aut | this alarm occurs if error in arith-|_ A metic opeartion, due to improper Parameter setting, occurs. sa | os | oversreep | this alarm occurs if motor speed A exceeds 115% of the maximum motor speed. 32 oc | OVERVOLTAGE,| This alarm occurs if current exceed- A TAVERTSE ip ing the specified limit flows in controller. 33 | ov | overvontacs.| this alarm occurs if voltage charged| A CONVEREER, in main circuit capacitor goes up, /| due to. regenerative brake energy, over the specified limit. 24 | pp | pata pantry | this alarm occurs if parity check A CHECK ERROR | error occurs in data transmission between M300 series CNC and FR-SF (when FR-SF is bus-linked with ONC). as | ve | pata ERROR | This alarm occurs if movement com- A mand specified by CNC exceeds the specified limit (when FR-SF is bus- linked with CNC). 36 TE | DATA TRANS- | This alarm occurs if data transfer A FER ERROR does not go satisfactorily (when FR-SF is bus-linked with CNC). 37 PE | PARAMETER This alarm occurs if set parameter A anes} value is out of the permissible range (this check is made when the ea =: laLarm| Thote) her" Aber.| Name Description wee controller is turned on). 43 |oaF | conrRouuer | This alarm occurs if ambient temp- | OVERHEAT erature is excessively high, or main (power) circuit semiconductor overheats due to overload or stop of cooling fan. 46 | om | motor over- | this alarm occurs if motor overheats| A HEAT due to overload or stop of motor cooling fan. s2 [op | ERROR This alarm occurs if difference a FADES (error) between referenced position and true position is excessive in position loop control. ss [em | Emercency | this alarm occurs if emergency stop | 6B Srp signal is given by extemal signal source. se [oa | omen axts | this alarm occurs if trouble occurs | A FAULT with other servo control axis (when FR-SF is bus-linked with cNc). zo | ter | instantane- | this warning occurs if input power | c OUS POWER ous row supply is interrupted or its voltage goes down momentarily. e1 | wor | oveRLoap ‘This warning occurs if controller A and/or motor is under overload con- dition for over the specified time. £4 | we | PARAMETER | If illegal parameter is set, this c SETTING aa warning occurs. 27 | nce | NC EMERGENCY| This warning occurs if emergency = anor stop signal is input from CNC (when FR-SF is bus-linked with CNC). This warning occurs if emergency stop signal is input from external signal source (when external emer- 21 - [ALarm No. ] a Abbr.| Name Description nee gency signal is acceptable ... para meter set). Note: If protective function listed above is activated, Alarm No. is displayed by 7-segment readout and the following occurs. Motion A . + Controller base current is shut off, main (power) circuit contactor opens and the motor stops after coasting. Fault signal contact FA-FC opens. Motor is decelerated by regenerative brake and stops. After motor stops, base current is interrupted. In this case, whether fault signal contact FA-FC opens or not depends on parameter set- ting. Only warning is displayed (operation can be continued) . = 22 -

Вам также может понравиться

- Driver Azul PDFДокумент24 страницыDriver Azul PDFElectronicaMecatronicsОценок пока нет

- GFZ 62564E 102l PDFДокумент487 страницGFZ 62564E 102l PDFd_feltrinoОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- PARAMETERSДокумент19 страницPARAMETERSElectronicaMecatronicsОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Driver Azul PDFДокумент24 страницыDriver Azul PDFElectronicaMecatronicsОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- D5SB10 D5SB100Документ2 страницыD5SB10 D5SB100ElectronicaMecatronicsОценок пока нет

- FANUC Open CNC FROM/SRAM Management Utility Command Line SpecificationДокумент9 страницFANUC Open CNC FROM/SRAM Management Utility Command Line SpecificationElectronicaMecatronics100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- 2 SC 4583Документ10 страниц2 SC 4583ElectronicaMecatronicsОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- CNC4640 V2.0 ProgrammingДокумент90 страницCNC4640 V2.0 ProgrammingElectronicaMecatronicsОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- ADTECH 4 Series Controller-MДокумент194 страницыADTECH 4 Series Controller-MBala SingamОценок пока нет

- ALARM 975 (Bus Error) : Causes and ActionsДокумент1 страницаALARM 975 (Bus Error) : Causes and ActionsElectronicaMecatronics100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- 74LS163Документ11 страниц74LS163real375100% (1)

- Miniature Solenoid Directional Valves GuideДокумент5 страницMiniature Solenoid Directional Valves GuideElectronicaMecatronicsОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Toshiba Mos Memory Product: TC5561 P-55 TC5561 P-70Документ6 страницToshiba Mos Memory Product: TC5561 P-55 TC5561 P-70ElectronicaMecatronicsОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Special Funcion Manual-Osp500y5020 PDFДокумент267 страницSpecial Funcion Manual-Osp500y5020 PDFElectronicaMecatronicsОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- AN7900T/AN7900F Series: 3-Pin Negative Output Voltage Regulators (1A Type)Документ8 страницAN7900T/AN7900F Series: 3-Pin Negative Output Voltage Regulators (1A Type)Krisno MujahidОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Miniature Solenoid Directional Valves GuideДокумент5 страницMiniature Solenoid Directional Valves GuideElectronicaMecatronicsОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- PowerMILL 2016 - Macro Programming EN PDFДокумент133 страницыPowerMILL 2016 - Macro Programming EN PDFElectronicaMecatronicsОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- NEC FD1165 MaintenanceДокумент104 страницыNEC FD1165 MaintenanceElectronicaMecatronicsОценок пока нет

- Readme en PDFДокумент11 страницReadme en PDFElectronicaMecatronicsОценок пока нет

- PostProcessor Reference Help enДокумент270 страницPostProcessor Reference Help enHisham Hanafy100% (2)

- M500 Reinitialization & Format ProcedureДокумент5 страницM500 Reinitialization & Format ProcedureElectronicaMecatronics100% (2)

- STV9302BДокумент15 страницSTV9302BcocolisoteОценок пока нет

- 6th Central Pay Commission Salary CalculatorДокумент15 страниц6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)