Академический Документы

Профессиональный Документы

Культура Документы

Gma 503 - Transmission System Troubleshoot - 24spt13

Загружено:

janurtpatОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Gma 503 - Transmission System Troubleshoot - 24spt13

Загружено:

janurtpatАвторское право:

Доступные форматы

December Edition 2013

MINISTRY OF EDUCATION, MALAYSIA

VOCATIONAL COLLEGE STANDARD CURRICULLUM

COURSE INFORMATION

COURSE NAME : TRANSMISSION SYSTEM TROUBLESHOOT

CODE NAME : GMA 503

LEVEL : 3 SEMESTER 5

CREDIT UNIT : 3.0

CONTACT HOUR :

FACE TO FACE : 5.0 HOURS/WEEK (1T+4P)

NON FACE TO FACE :

COURSE TYPE : VOCATIONAL

PRE-REQUISITE : -

-

CORE REQUISITE :

Last Edited 24 – 26 Sept 2013

Module Page 1/16 Document Page 1

December Edition 2013

COURSE OUTCOMES

At the end of the course, the students should be able to:-

Troubleshoot transmission system problems

Troubleshoot steering system problems

Troubleshoot brake system problem

Troubleshoot hydraulic system problems

COURSE DESCRIPTION

This unit identifies the competence required to troubleshoot transmission system problems using customer complaint form, transmission

testing equipment, hand tools set, new spare parts and checklist so that customer complaint form obtained, troubleshooting works

executed and service checklist recorded in accordance with standard operating procedure

This unit identifies the competence required to troubleshoot steering system problems using customer complaint form, diagnose tools

and equipment, hand tools set, new spare parts and checklist so that steering system service manual obtained, steering system

problems inspected, steering system problems rectified, rectified steering system problems tested and troubleshooting checklist

recorded in accordance with standard operating procedure.

This unit identifies the competence required to Troubleshoot brake system problems using customer complaint form, diagnose tools and

equipment, hand tools set, new spare parts and checklist so that customer complaint form interpreted, brake system problems

checked, brake system service manual identified, troubleshooting works executed and service checklist recorded in accordance with

standard operating procedure.

This unit identifies the competence required to Troubleshoot hydraulic system problems using customer complaint form, diagnose tools

and equipment, hand tools set, new spare parts and checklist so that hydraulic system service manual obtained, hydraulic system

problems checked, hydraulic system problems rectified, rectified hydraulic system problems tested and troubleshooting checklist

recorded in accordance with standard operating procedure.

Last Edited 24 – 26 Sept 2013

Module Page 2/16 Document Page 2

December Edition 2013

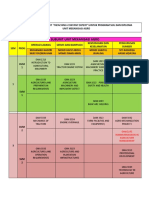

CONTENT AND LEARNING STANDARDS

PROGRAM : AGRICULTURAL MECHANIZATION

COURSE NAME : TRANSMISSION SYSTEM TROUBLESHOOT

CODE NAME : GMA 503

COMPETENCY : 1

CONTENT

LEARNING STANDARD PERFORMANCE CRITERIA

STANDARD Hrs

performance , condition performance,condition, standard

performance

1. Troubleshoot 1.1. Obtain Customer Complaint Form 1.1.1 Explain source of customer complaint form in accordance

Transmission with to standard requirement

System Problems 1.1.2 Explain procedure of acquiring customer complaint form

according to standard requirement

1.1.3 Fill in customer complaint form in accordance with standard

requirement

1.1.4 Determine source of customer complaint form standard

requirement

1.1.5 Acquire customer complaint form according to standard

requirement

1.1.6 Interpret customer complaint form base on standard

requirement

1.2. Execute Troubleshooting Works 1.2.1. Identify procedure of guessing possible rout cause according

to manufacturer specification

1.2.2. Identify rout cause of transmission system fault according to

manufacturer specification

1.2.3. Identify transmission testing equipment according to

manufacturer specification

1.2.4. State possible rout cause according to manufacturer

specification

Last Edited 24 – 26 Sept 2013

Module Page 3/16 Document Page 3

December Edition 2013

CONTENT

LEARNING STANDARD PERFORMANCE CRITERIA

STANDARD Hrs

performance , condition performance,condition, standard

performance

1.2.5. Determine rout cause of fault according to manufacturer

specification

1.2.6. Use transmission testing equipment according to

manufacturer specification

1.2.7. Change transmission system defect parts according to

manufacturer specification

1.2.8. Apply procedure of testing transmission system performance

according to manufacturer specification

1.2.9. Practise safety precaution in compliance with work safety and

health procedure in accordance to standard operational and

safety procedures

1.3. Record Service Checklist 1.3.1. List types of service checklist accordance to standard form

1.3.2. Explain methods of fill in service checklist accordance to

standard form

1.3.3. List techniques of fill in service checklist accordance to

standard form

1.3.4. Determine types of service checklist accordance to standard

form

1.3.5. Fill in service checklist according to standard system.

1.3.6. Apply technique of fill in service checklist according to

standard form.

1.3.7. File service checklist form accordance to standard standard

filing system

1.4. Rectify Steering System Problems 4.1.1 Describe types of steering system problem according to

manufacturer specification.

4.1.2 Explain techniques of steering rectification according to

manufacturer specification.

4.1.3 Explain engine rectification procedures according to

manufacturer specification.

4.1.4 Indentfy techniques special tool handling according to

Last Edited 24 – 26 Sept 2013

Module Page 4/16 Document Page 4

December Edition 2013

CONTENT

LEARNING STANDARD PERFORMANCE CRITERIA

STANDARD Hrs

performance , condition performance,condition, standard

performance

manufacturer specification.

4.1.5 Determine type of steering system problem according to

manufacturer specification.

4.1.6 Perform technique of steering rectification according to

manufacturer specification.

4.1.7 Perform engine rectification procedure according to

manufacturer specification.

4.1.8 Apply technique of handling special tool according to

manufacturer specification.

4.1.9 Follow procedure in inspecting steering according to

manufacturer specification.

4.1.10 Proper usage of service manual compliance with

manufacturer specification.

4.1.11 Practise safety precaution in compliance with healty

work safety requirement in accordance to OSHA

regulation

1.5. Test Steering System Problems 1.5.1 Identify engine testing requirements in according to

manufacturer specification.

1.5.2 Describe methods of steering testing according to

manufacturer specification.

1.5.3 Explain Procedures of steering testing according to

manufacturer specification.

1.5.4 Explain technique of handling testing tool according to

manufacturer specification.

1.5.5 Identify steering testing requirements according to

manufacturer specification.

1.5.6 Perform method of steering testing according to

manufacturer specification.

1.5.7 Follow procedure of steering testing according to

manufacturer specification.

Last Edited 24 – 26 Sept 2013

Module Page 5/16 Document Page 5

December Edition 2013

CONTENT

LEARNING STANDARD PERFORMANCE CRITERIA

STANDARD Hrs

performance , condition performance,condition, standard

performance

1.5.8 Apply technique of handling testing tool according to

manufacturer specification.

1.5.9 Practise safety precaution in compliance with healty

work safety requirement in accordance to OSHA

regulation

1.6. Record Troubleshooting Checklist 1.6.1 List types of troubleshooting service checklist standard form

1.6.2 Explain procedures of troubleshooting record checklist

compliance with standard requirement form.

1.6.3 Fill in of troubleshooting checklist according to standard

form

1.6.4 Determine types of troubleshooting service checklist

according to standard form system.

1.6.5 Apply technique of troubleshooting checklist according to

standard form system.

1.6.6 File troubleshooting checklist record according to standard

filing system.

1.6.7 Perform accuracy of recording record according to standard

filing system.

CONTENT AND LEARNING STANDARDS

PROGRAM : AGRICULTURAL MECHANIZATION

COURSE NAME : TRANSMISSION SYSTEM TROUBLESHOOT

CODE NAME : GMA 503

COMPETENCY : 2

Last Edited 24 – 26 Sept 2013

Module Page 6/16 Document Page 6

December Edition 2013

CONTENT

LEARNING STANDARD PERFORMANCE CRITERIA

STANDARD Hrs

performance , condition performance,condition, standard

performance

2. Troubleshoot 2.1. Obtain brake system service 2.1.1. List sources of brake system service manual according to

brake system manual manufacture

problems 2.1.2. Explain procedures of acquiring brake system service

manual according to manufacture

2.1.3. Explain brake system service manual according to

manufacture

2.1.4. Determine source of brake system service manual according

to manufacture

2.1.5. Acquire brake system service manual according to

manufacture

2.1.6. Interpret brake system service manual according to

manufacture

2.1.7. Justify carefully read and observe precaution warnings given

by manual according to manufacture

2.2. Check brake system problems 2.2.1. List of brake system problem according to maintenance

manual.

2.2.2. Explain methods of handling inspection tools according to

manufacturer specification

2.2.3. Explain procedures of inspecting brake problems according

to precaution in maintenance manual.

2.2.4. Determine brake system problem according to precaution in

maintenance manual.

2.2.5. Apply method of handling inspection tools according to

manufacturer specification

2.2.6. Follow procedure of inspecting brake problems according to

precaution in maintenance manual.

2.2.7. Practise safety precaution compliance and health in work

accordance to osha regulation

Last Edited 24 – 26 Sept 2013

Module Page 7/16 Document Page 7

December Edition 2013

CONTENT

LEARNING STANDARD PERFORMANCE CRITERIA

STANDARD Hrs

performance , condition performance,condition, standard

performance

2.3. Rectify brake system problems 2.3.1 Explain types of brake system problem problem according to

maintenance manual.

2.3.2 Identify techniques of brake rectification according to

maintenance manual.

2.3.3 Identify procedure of engine rectification according to

maintenance manual.

2.3.4 Explain techniques special tool handling according to

manufacturer specification

2.3.5 Determine type of brake sys tem problem according to

maintenance manual.

2.3.6 Apply technique of brake rectification according to

maintenance manual.

2.3.7 Apply procedure of engine rectification according to

maintenance manual.

2.3.8 Apply technique of handling special tool according to

manufacturer specification

2.3.9 Practice safety precaution compliance and health in work

accordance to osha regulation

2.4 Test rectified brake system problems 2.4.1 Prepare requirements of engine testing according to

maintenance manual.

2.4.2 Specify methods of brake testing according to maintenance

manual.

2.4.3 Explain procedures of brake testing according to

maintenance manual.

2.4.4 Explain technique of handling testing tool according to

manufacturer specification

2.4.5 Determine brake testing requirements according to

maintenance manual.

2.4.6 Apply method of brake testing according to maintenance

manual.

2.4.7 Follow procedure of brake testing according to maintenance

manual.

Last Edited 24 – 26 Sept 2013

Module Page 8/16 Document Page 8

December Edition 2013

CONTENT

LEARNING STANDARD PERFORMANCE CRITERIA

STANDARD Hrs

performance , condition performance,condition, standard

performance

2.4.8 Apply technique of handling testing tool according to

manufacturer specification

2.4.9 Practise safety precaution compliance and health in work

accordance to osha regulation

2.5 Record troubleshooting checklist 2.5.1 Identify types of troubleshooting service checklist according

to standard form.

2.5.2 Explain procedures of recording troubleshooting checklist

according to standard form.

2.5.3 Determine types of troubleshooting service checklist

according to standard form.

2.5.4 Record of troubleshooting service checklist according to

standard form.

2.5.5 Apply technique of filling troubleshooting checklist according

to standard filing system

2.5.6 Compile file troubleshooting checklist record according to

standard filing system

Last Edited 24 – 26 Sept 2013

Module Page 9/16 Document Page 9

December Edition 2013

CONTENT AND LEARNING STANDARDS

PROGRAM : AGRICULTURAL MECHANIZATION

COURSE NAME : TRANSMISSION SYSTEM TROUBLESHOOT

CODE NAME : GMA 503

COMPETENCY : 3

CONTENT

LEARNING STANDARD PERFORMANCE CRITERIA

STANDARD Hrs

performance , condition performance,condition, standard

performance

3 Troubleshoot 3.1 Obtain steering system service 3.1.1 Determine sources of steering system service manual

steering system manual compliance with manufacture

problems 3.1.2 Identify procedures of acquiring steering system service

manual compliance with manufacture

3.1.3 Acquire steering system service manual compliance with

manufacture

3.1.4 Interpret steering system service manual compliance with

manufacture

3.2 Check steering system problems 3.2.1 Identify steering system problem accordance to

manufacture’s service manual

3.2.2 Identify methods of handling inspection tools according to

manufacturer specification

3.2.3 Explain procedure of inspecting steering problems

accordance to manufacture’s service manual

3.2.4 Apply method of handling inspection tools according to

manufacturer specification

3.2.5 Apply procedure of inspecting steering problems accordance

to manufacture’s service manual

3.2.6 Practice safety precaution compliance and health in work

accordance to osha regulation

Last Edited 24 – 26 Sept 2013

Module Page 10/16 Document Page 10

December Edition 2013

CONTENT

LEARNING STANDARD PERFORMANCE CRITERIA

STANDARD Hrs

performance , condition performance,condition, standard

performance

3.3 Rectify steering System Problems 3.3.1 Inspect types of steering system problem problems

accordance to manufacture’s service manual

3.3.2 Identify techniques of steering rectification problems

accordance to manufacture’s service manual

3.3.3 Define steering rectification procedures problems accordance

to manufacture’s service manual

3.3.4 Identify techniques special tool handling according to

manufacturer specification

3.3.5 Apply steering rectification procedure accordance to

manufacture’s service manual

3.3.6 Apply technique of handling special tool according to

manufacturer specification

3.3.7 Practise safety precaution compliance and health in work

accordance to OSHA regulation

3.4 Test rectification steering system 3.4.1 Define steering testing requirements according to

problems manufacturer specification

3.4.2 Identify methods of steering testing according to

manufacturer specification

3.4.3 Identify procedures of steering testing accordance to

manufacture’s service manual

3.4.4 Identify technique of handling testing tool according to

manufacturer specification

3.4.5 Apply method of steering testing accordance to

manufacture’s service manual

3.4.6 Apply procedure of steering testing accordance to

manufacture’s service manual

3.4.7 Apply technique of handling testing tool according to

manufacturer specification

3.4.8 Practice safety precaution compliance and health in work

accordance to OSHA regulation

Last Edited 24 – 26 Sept 2013

Module Page 11/16 Document Page 11

December Edition 2013

CONTENT

LEARNING STANDARD PERFORMANCE CRITERIA

STANDARD Hrs

performance , condition performance,condition, standard

performance

3.5 Record troubleshooting checklist 3.5.1 Identify types of troubleshooting service checklist according

to standard form.

3.5.2 Explain procedures of recording troubleshooting checklist

according to standard form.

3.5.3 Determine types of troubleshooting service checklist

according to standard form.

3.5.4 Record of troubleshooting service checklist according to

standard form.

3.5.5 Apply technique of filling troubleshooting checklist according

to standard filing system

3.5.6 Compile file troubleshooting checklist record according to

standard filing system

Last Edited 24 – 26 Sept 2013

Module Page 12/16 Document Page 12

December Edition 2013

CONTENT AND LEARNING STANDARDS

PROGRAM : AGRICULTURAL MECHANIZATION

COURSE NAME : TRANSMISSION SYSTEM TROUBLESHOOT

CODE NAME : GMA 503

COMPETENCY : 4

CONTENT

LEARNING STANDARD PERFORMANCE CRITERIA

STANDARD Hrs

performance , condition performance,condition, standard

performance

4. Troubleshoot 4.1. Obtain hydraulic system service 4.1.1 Determine sources of hydraulic system service manual

hydraulic system manual compliance with manufacture

problems 4.1.2 Identify procedures of acquiring hydraulic system service

manual compliance with manufacture

4.1.3 Acquire hydraulic system service manual compliance with

manufacture

4.1.4 Interpret hydraulic system service manual compliance with

manufacture

4.2. Check hydraulic system problems 4.2.1 Identify hydraulic system problem accordance to

manufacture’s service manual

4.2.2 Identify methods of handling inspection tools according to

manufacturer specification

4.2.3 Explain procedure of inspecting hydraulic problems

accordance to manufacture’s service manual

4.2.4 Apply method of handling inspection tools according to

manufacturer specification

Last Edited 24 – 26 Sept 2013

Module Page 13/16 Document Page 13

December Edition 2013

CONTENT

LEARNING STANDARD PERFORMANCE CRITERIA

STANDARD Hrs

performance , condition performance,condition, standard

performance

4.2.5 Apply procedure of inspecting hydraulic problems accordance

to manufacture’s service manual

4.2.6 Practice safety precaution compliance and health in work

accordance to OSHA regulation

4.3. Rectify hydraulic system problems 4.3.1 Inspect types of hydraulic system problem problems

accordance to manufacture’s service manual

4.3.2 Identify techniques of hydraulic rectification problems

accordance to manufacture’s service manual

4.3.3 Define hydraulic rectification procedures problems

accordance to manufacture’s service manual

4.3.4 Identify techniques special tool handling according to

manufacturer specification

4.3.5 Apply hydraulic rectification procedure accordance to

manufacture’s service manual

4.3.6 Apply technique of handling special tool according to

manufacturer specification

4.3.7 Practice safety precaution compliance and health in work

accordance to OSHA regulation

4.4. Test rectification hydraulic system 4.4.1 Define hydraulic testing requirements according to

problems manufacturer specification

4.4.2 Identify methods o hydraulic testing according to manufacturer

specification

4.4.3 Identify procedures of hydraulic testing accordance to

manufacture’s service manual

4.4.4 Identify technique of handling testing tool according to

manufacturer specification

4.4.5 Apply method of hydraulic testing accordance to

Last Edited 24 – 26 Sept 2013

Module Page 14/16 Document Page 14

December Edition 2013

CONTENT

LEARNING STANDARD PERFORMANCE CRITERIA

STANDARD Hrs

performance , condition performance,condition, standard

performance

manufacture’s service manual

4.4.6 Apply procedure of hydraulic testing accordance to

manufacture’s service manual

4.4.7 Apply technique of handling testing tool according to

manufacturer specification

4.4.8 Practice safety precaution compliance and health in work

accordance to OSHA regulation

4.5. Record troubleshooting checklist 4.5.1 Identify types of troubleshooting service checklist according

to standard form.

4.5.2 explain procedures of recording troubleshooting checklist

according to standard form.

4.5.3 Determine types of troubleshooting service checklist

according to standard form.

4.5.4 Record of troubleshooting service checklist according to

standard form.

4.5.5 Apply technique of filling troubleshooting checklist according

to standard filing system

4.5.6 Compile file troubleshooting checklist record according to

standard filing system

Last Edited 24 – 26 Sept 2013

Module Page 15/16 Document Page 15

December Edition 2013

CONTENT

LEARNING STANDARD PERFORMANCE CRITERIA

STANDARD Hrs

performance , condition performance,condition, standard

performance

Last Edited 24 – 26 Sept 2013

Module Page 16/16 Document Page 16

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Land PreparationДокумент3 страницыLand PreparationjanurtpatОценок пока нет

- SoftДокумент8 страницSoftjanurtpatОценок пока нет

- ANALISIS DATA Kualitatih KuantitatifДокумент12 страницANALISIS DATA Kualitatih KuantitatifjanurtpatОценок пока нет

- Land Preparation Machineries Used in AgricultureДокумент47 страницLand Preparation Machineries Used in Agriculturejanurtpat0% (1)

- Subunit Unit Mekanisasi AgroДокумент5 страницSubunit Unit Mekanisasi AgrojanurtpatОценок пока нет

- Supervisory Skill: Jabatan Teknologi Mekanikal Dan Pembuatan Teknologi Penyejukan Dan Penyamanan UdaraДокумент5 страницSupervisory Skill: Jabatan Teknologi Mekanikal Dan Pembuatan Teknologi Penyejukan Dan Penyamanan UdarajanurtpatОценок пока нет

- MPP 5013 Course Outline RДокумент5 страницMPP 5013 Course Outline RjanurtpatОценок пока нет

- Gma 6023 - Combine Harvester TroubleshootДокумент12 страницGma 6023 - Combine Harvester Troubleshootjanurtpat100% (1)

- Supervising Skills DevelopmentДокумент5 страницSupervising Skills DevelopmentjanurtpatОценок пока нет

- Last Edited MEI 2016 Module Page 1/11 Document Page 1Документ11 страницLast Edited MEI 2016 Module Page 1/11 Document Page 1janurtpatОценок пока нет

- Gma 5013Документ10 страницGma 5013janurtpatОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Specification Erection Static EquipmentДокумент11 страницSpecification Erection Static Equipmentagaricus67% (3)

- Standard Bidding Document: Procurement of Goods Sealed QuotationДокумент48 страницStandard Bidding Document: Procurement of Goods Sealed QuotationMMTS NepalОценок пока нет

- Cssbi S15 01 PDFДокумент13 страницCssbi S15 01 PDFTuanQuachОценок пока нет

- A562 PDFДокумент4 страницыA562 PDFSofiaJabadanEspulgarОценок пока нет

- Software RequirementsДокумент10 страницSoftware RequirementsFarah Khan0% (1)

- Sealant PrimerДокумент10 страницSealant PrimerAlex BeldnerОценок пока нет

- Terms & Condition of Saidpur Railway Workshop TenderДокумент11 страницTerms & Condition of Saidpur Railway Workshop TenderAnonymous cakUUIxSОценок пока нет

- STE05501 Fixed Ladders and Cages Design GuideДокумент25 страницSTE05501 Fixed Ladders and Cages Design GuideeGnEsToMcОценок пока нет

- PAES 226 - Micromill - SpecsДокумент8 страницPAES 226 - Micromill - Specsshuvatheduva123123123Оценок пока нет

- ASTM A 47 M Ferritic Malleable Iron Castings PDFДокумент5 страницASTM A 47 M Ferritic Malleable Iron Castings PDFAhmad ZaidОценок пока нет

- Royal Brewery Car Park Tender Docs 120625Документ382 страницыRoyal Brewery Car Park Tender Docs 120625christopher_bir7392100% (1)

- C550 90Документ16 страницC550 90Ahmed Mohamed Rashed100% (4)

- S1000D To S3000L Interchange Specification: Issue 1.0 2011-03-31Документ282 страницыS1000D To S3000L Interchange Specification: Issue 1.0 2011-03-31chandu614Оценок пока нет

- Se Bits Unit Bit 3Документ5 страницSe Bits Unit Bit 3Sai HarshiniОценок пока нет

- System Analysis and Design Midterm Quizzes 100%Документ12 страницSystem Analysis and Design Midterm Quizzes 100%Kaye CariñoОценок пока нет

- Engine Oil, Global Factory-Fill, Spark-Ignited Engine, SAE 5W-30Документ9 страницEngine Oil, Global Factory-Fill, Spark-Ignited Engine, SAE 5W-30Akmal NizametdinovОценок пока нет

- ToR - Electrical EngineerДокумент4 страницыToR - Electrical EngineerBruno SamosОценок пока нет

- MPU-6050 Product Specification PDFДокумент53 страницыMPU-6050 Product Specification PDFAchmad Rozi NurhudaОценок пока нет

- Catalog - Steel DeckДокумент116 страницCatalog - Steel DeckyichihchОценок пока нет

- InterClean Hybrid Transit Bus Wash With RecyclingДокумент21 страницаInterClean Hybrid Transit Bus Wash With Recyclingmelgarcia829100% (1)

- ANPQP 2.3 - Changes PDFДокумент23 страницыANPQP 2.3 - Changes PDFClaudia MataОценок пока нет

- Equipment-Installation-Verification-Testing-Procedures-and-Validation-Protocol-GMP-Checksheets-Getreskilled.comДокумент3 страницыEquipment-Installation-Verification-Testing-Procedures-and-Validation-Protocol-GMP-Checksheets-Getreskilled.comrodcam1100% (2)

- Norma AAR M101 Axle 2007Документ22 страницыNorma AAR M101 Axle 2007CarlosОценок пока нет

- Just The Facts (Comparison of Concrete Pipe and HDPE Pipe)Документ15 страницJust The Facts (Comparison of Concrete Pipe and HDPE Pipe)yyanan1118Оценок пока нет

- Pts Painting 2017Документ67 страницPts Painting 2017Faiz IshakОценок пока нет

- Guide To The Application of The Checking, Testing and Acceptance (CER) Procedure For Bodywork Assembly PlantsДокумент14 страницGuide To The Application of The Checking, Testing and Acceptance (CER) Procedure For Bodywork Assembly PlantsDuvan TamayoОценок пока нет

- PIP Ladder & CagesДокумент9 страницPIP Ladder & CagesCarlos Maldonado SalazarОценок пока нет

- PV System Design NC IIIДокумент68 страницPV System Design NC IIIAngelo MichaelsОценок пока нет

- Specification Pressure VesselДокумент122 страницыSpecification Pressure Vesselbennie buysОценок пока нет

- Cosmetic GMP Implementation Part 6Документ23 страницыCosmetic GMP Implementation Part 6Anonymous yBhOAi5UH100% (1)