Академический Документы

Профессиональный Документы

Культура Документы

Relene - Pe 46GP003

Загружено:

Ronald LeonОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Relene - Pe 46GP003

Загружено:

Ronald LeonАвторское право:

Доступные форматы

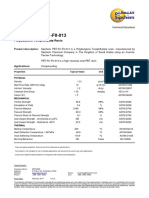

46GP003 POLYETHYLENE RESIN

FOR PIPE EXTRUSION

Relene 46GP003 (PE-100) is a natural colored grade for pipe extrusion. It possesses bimodal molecular weight distribution, which

improves processability. This grade meets the MFI, Density & Hydrostatic strength requirements of material grade PE-100 as per

IS: 4984. When incorporated with adequate quantity of carbon black as specified in clause 5.2.3 of IS: 4984, pipes will meet

PE:100 requirements.

Pipes made from Relene 46GP003 grade passes the Internal Pressure Creep Rupture Test when tested with 5.5 MPa induced stress at

80oC for 165 hrs and with 5.7 MPa induced stress at 80oC for 48 hrs as per clause 8.1 of IS 4984, thereby meeting the requirements of

PE100 grade.

The grade conforms to ISO 4427 specification shown and has been certified for MRS> 10MPa as per ISO 9080.

Property Test Method Unit Remarks

Hydrostatic Pressure Test ISO 1167 Hrs

12.4 MPa @ 20°C – >100

5.4 MPa @ 80°C – >165

5.0 MPa @ 80°C – >1000

MRS ISO 9080 MPa >10.0

SCG ISO 13479 Hrs >500

Typical Characteristics*

Property Test Method Unit Typical Value**

o

Melt Flow Index (190 C / 5.0 Kg ) ASTM D1238 gm/10 min 0.30

Density ( 23oC ) ASTM D1505 gm/cm3 0.945

Thermal stability (O.I.T) 2000C ASTM D3895 Min >30

Tensile Strength at Yield ASTM D638 MPa 28

Elongation at break ASTM D638 % >600

Flexural Modulus ASTM D790 MPa 850

Notched izod impact strength ASTM D256 J/m No Break

ESCR, F50 ASTM D1693 Hours >1000

*Typical values not to be taken as specification

**Mechanical Properties are on Compression moulding

Application

PE-100 pressure pipes.

Regulatory Information

• Meets the requirement stipulated in standard IS: 10146-1982 on “Specification for Polyethylene for safe use in contact with

foodstuffs, pharmaceuticals, and drinking water”. It also conforms to the positive list of constituents as prescribed in IS: 10141-1982.

The grade and the additives incorporated in it also comply with the FDA: CFR Title 21, 177.1520, Olefin Polymers. The level of

antioxidant in 46GP003 is not more than 0.3% by mass of the resin.

Storage Recommendations

• Bags should be stored in dry/closed conditions at temperatures below 50°C and protected from UV / direct sunlight.

Reliance Industries Limited, Product and Application & Technology Group, (P&AT)

Swastik Mill Compound, V. N. Purav Marg, Chembur, Mumbai-400 071. Tel.: +91-22-6767 7000. E-mail: polymer_patsupport@ril.com Website: www.ril.com

• The information and data presented herein is true and accurate to the best of our knowledge. No warranty or guarantee expressed or implied, is made regarding performance or other wise. This

information and data may not be considered as a suggestion to use our products without taking into account existing patents, or legal provisions or regulations, whether national or international. • The user of

any information and/or data is advised to obtain the latest details from any of the offices of the company or its authorised agents, as the information and/or data is subject to change based on the research and

development work undertaken by the company.

Updated as of August, 2009

Вам также может понравиться

- Introduction To PetrochemicalsДокумент49 страницIntroduction To PetrochemicalsezzataОценок пока нет

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsОт EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsРейтинг: 5 из 5 звезд5/5 (1)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionОт EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionРейтинг: 4.5 из 5 звезд4.5/5 (3)

- KCH Surface LiningДокумент12 страницKCH Surface LiningicingrockОценок пока нет

- Chapter 8 How To Henna Your HairДокумент48 страницChapter 8 How To Henna Your Hairjas_wadОценок пока нет

- Foodmax Grease CAS S 2 HS - TDS - 263701201 - ENДокумент2 страницыFoodmax Grease CAS S 2 HS - TDS - 263701201 - ENDeath HeartОценок пока нет

- Wellhead Systems Rod AccessoriesДокумент18 страницWellhead Systems Rod Accessoriesbuat unduhОценок пока нет

- 002DP48 PDFДокумент2 страницы002DP48 PDFDiadam SharmaОценок пока нет

- TDS Pe 202 SP4808Документ2 страницыTDS Pe 202 SP4808Desri AkbarОценок пока нет

- CALIBRE™ MEGARAD™ 2081-15: Polycarbonate ResinДокумент3 страницыCALIBRE™ MEGARAD™ 2081-15: Polycarbonate ResinmikeybhabaОценок пока нет

- R03RRДокумент1 страницаR03RRPiyush A JoshiОценок пока нет

- Shear Flat SlabДокумент1 страницаShear Flat Slabadnan-651358Оценок пока нет

- Driscopipe 8100 PE4710-PE100 / (PE3408) : Pipe Data SheetДокумент2 страницыDriscopipe 8100 PE4710-PE100 / (PE3408) : Pipe Data SheetmariannyОценок пока нет

- PDS HEX4460p PE80 1Документ3 страницыPDS HEX4460p PE80 1art72 talОценок пока нет

- Sipchem PBT-R1-F0-013: Polybutylene Terephthalate ResinДокумент1 страницаSipchem PBT-R1-F0-013: Polybutylene Terephthalate ResinTahir IqbalОценок пока нет

- TDS Nycogrease GN3058 1E10Документ1 страницаTDS Nycogrease GN3058 1E10Sameen Khan100% (1)

- Y25GRДокумент1 страницаY25GRPiyush A JoshiОценок пока нет

- TDS B0155DДокумент1 страницаTDS B0155DtechnopackishvarlalОценок пока нет

- PP GF30 - Hostacom PC072-3 Naturale-2Документ2 страницыPP GF30 - Hostacom PC072-3 Naturale-2armando0% (1)

- Optigear 1100 RangeДокумент3 страницыOptigear 1100 RangeResistenciaDisidenteОценок пока нет

- Sipchem PBT-R1-G0-011: Polybutylene Terephthalate ResinДокумент1 страницаSipchem PBT-R1-G0-011: Polybutylene Terephthalate ResinTahir IqbalОценок пока нет

- Mitsubishi Chemical Advanced Materials Nylatron ® GSM Nylon, Cast Mos2 Filled Type 6 (Astm Product Data Sheet)Документ2 страницыMitsubishi Chemical Advanced Materials Nylatron ® GSM Nylon, Cast Mos2 Filled Type 6 (Astm Product Data Sheet)Irwan SaputraОценок пока нет

- F03RRДокумент1 страницаF03RRPiyush A JoshiОценок пока нет

- ALTECH ABS A 2020/100 GF20: Technical Data SheetДокумент1 страницаALTECH ABS A 2020/100 GF20: Technical Data SheetarmandoОценок пока нет

- Ra - AER003N PPRДокумент1 страницаRa - AER003N PPRShyam Sundar SahooОценок пока нет

- M12RR PDFДокумент1 страницаM12RR PDFJordan Rock100% (1)

- Impact Copolymer: For Injection Moulded ProductsДокумент1 страницаImpact Copolymer: For Injection Moulded ProductsSanjay SharmaОценок пока нет

- ABS Sabic Cycolac MG94 Cust.cДокумент5 страницABS Sabic Cycolac MG94 Cust.cMurillo AraujoОценок пока нет

- HDPE Pipe Ineos TUB121GNДокумент2 страницыHDPE Pipe Ineos TUB121GNluisalbertolvОценок пока нет

- Castrol Alphasyn HTX RangeДокумент2 страницыCastrol Alphasyn HTX RangeVusal HasanovОценок пока нет

- InnoPlus HD8100MДокумент1 страницаInnoPlus HD8100MLe Minh TuanОценок пока нет

- PC Calibre Technical DataДокумент4 страницыPC Calibre Technical DataMitja GorseОценок пока нет

- Linear Low Density Polyethylene Injection MoldingДокумент2 страницыLinear Low Density Polyethylene Injection MoldingakshayОценок пока нет

- Technical Data SheetДокумент2 страницыTechnical Data SheetIVANCHUОценок пока нет

- More Production: in Less TimeДокумент2 страницыMore Production: in Less TimeDaniel GarciaОценок пока нет

- Opal - Hdpe - 4Документ2 страницыOpal - Hdpe - 4Piyush A JoshiОценок пока нет

- Mdpe 3305MQДокумент2 страницыMdpe 3305MQHữu LộcОценок пока нет

- Exceed™ XP 8318MJ: Performance PolymerДокумент2 страницыExceed™ XP 8318MJ: Performance PolymerMaram YasserОценок пока нет

- Fluteck P7500 CA v01.19Документ2 страницыFluteck P7500 CA v01.19fprovitaliОценок пока нет

- PEADM5372Документ2 страницыPEADM5372nicolas yoris marcoglieseОценок пока нет

- HDPE Blow Ineos-G50-100Документ2 страницыHDPE Blow Ineos-G50-100luisalbertolvОценок пока нет

- Y35GRДокумент1 страницаY35GRPiyush A JoshiОценок пока нет

- Elite NG 5401BДокумент3 страницыElite NG 5401BAbdo WalidОценок пока нет

- Datenblatt Rohstoff Torlon 4301Документ4 страницыDatenblatt Rohstoff Torlon 4301DarkedgeОценок пока нет

- Ryton R-4-200NA: Polyphenylene SulfideДокумент3 страницыRyton R-4-200NA: Polyphenylene SulfideMatteo BaldiniОценок пока нет

- Castrol Magna 150 Ep - TDSДокумент2 страницыCastrol Magna 150 Ep - TDSHector Martin BarajasОценок пока нет

- PP11280 SpecificationДокумент2 страницыPP11280 Specificationudummy552Оценок пока нет

- SABIC Cycolac MG47FДокумент3 страницыSABIC Cycolac MG47FChu ChuОценок пока нет

- Natpet Teldene H03TFДокумент2 страницыNatpet Teldene H03TFTychОценок пока нет

- Marlex K307Документ1 страницаMarlex K307Santiago Jorge Toledo ToledoОценок пока нет

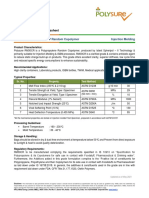

- Polysure PP RM30CRДокумент1 страницаPolysure PP RM30CRyansyafОценок пока нет

- Styrolution PS 165N/L: General Purpose Polystyrene (GPPS)Документ3 страницыStyrolution PS 165N/L: General Purpose Polystyrene (GPPS)Inês MorgadoОценок пока нет

- Driscoplex 5300 Series Pe3608 / (Pe3408) : Geothermal Systems Data SheetДокумент2 страницыDriscoplex 5300 Series Pe3608 / (Pe3408) : Geothermal Systems Data SheetmariannyОценок пока нет

- TDS LC670 Eng 220216Документ1 страницаTDS LC670 Eng 220216AthonioMourinhoОценок пока нет

- TIVAR® 1000 Natural Virgin UHMW-PE: Physical Properties Metric English CommentsДокумент2 страницыTIVAR® 1000 Natural Virgin UHMW-PE: Physical Properties Metric English CommentsVictor AguirreОценок пока нет

- Um180821 TDS Tpu 95a RB V11Документ3 страницыUm180821 TDS Tpu 95a RB V11Steven DonosoОценок пока нет

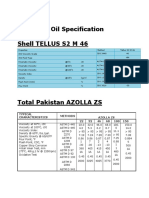

- Specifications For Hydraulic OilДокумент3 страницыSpecifications For Hydraulic OilAliya NaseemОценок пока нет

- SABIC® HDPE - M200056 - Global - Technical - Data - SheetДокумент2 страницыSABIC® HDPE - M200056 - Global - Technical - Data - SheetAhmed Elgazar100% (1)

- Technical Data Sheet Polyfoam Normal: Extruded Polystyrene Insulation (Non Fire R Etardant)Документ1 страницаTechnical Data Sheet Polyfoam Normal: Extruded Polystyrene Insulation (Non Fire R Etardant)Raha Trading and ContactingОценок пока нет

- SABIC® FORTIFY™ - C3080 - Global - Technical - Data - Sheet PDFДокумент2 страницыSABIC® FORTIFY™ - C3080 - Global - Technical - Data - Sheet PDFvishal mehtaОценок пока нет

- PP ARPP200-1 Black 14 Melt HomoДокумент1 страницаPP ARPP200-1 Black 14 Melt HomocountzeroaslОценок пока нет

- Ensinger Tecapeek® CF30 Polyetheretherketone, 30% Carbon Reinforced (PEEK)Документ2 страницыEnsinger Tecapeek® CF30 Polyetheretherketone, 30% Carbon Reinforced (PEEK)Arthur EmidioОценок пока нет

- Chang Chun Plastics CO., LTDДокумент2 страницыChang Chun Plastics CO., LTDChunYenHuangОценок пока нет

- How to prepare Welding Procedures for Oil & Gas PipelinesОт EverandHow to prepare Welding Procedures for Oil & Gas PipelinesРейтинг: 5 из 5 звезд5/5 (1)

- Admixtures: Hollow Blocks ManufacturingДокумент14 страницAdmixtures: Hollow Blocks ManufacturingGerald De OcampoОценок пока нет

- SGL Technical Info SIGRATHERM Chemical Resistance ENДокумент13 страницSGL Technical Info SIGRATHERM Chemical Resistance ENTushar LateОценок пока нет

- Nail Care TOOLS and Equipment: By: Ms - PurplebloodДокумент47 страницNail Care TOOLS and Equipment: By: Ms - PurplebloodrobertОценок пока нет

- Adhesive Bandage: Jump To Navigation Jump To SearchДокумент6 страницAdhesive Bandage: Jump To Navigation Jump To SearchtokagheruОценок пока нет

- Soil Stablisation Using Coconut Coir Fibre & EggДокумент12 страницSoil Stablisation Using Coconut Coir Fibre & EggDeepansh YadavОценок пока нет

- Diels Alder LabДокумент8 страницDiels Alder Labfatevilcow0% (1)

- Chem202 Carboxylic Acids NitrilesДокумент8 страницChem202 Carboxylic Acids NitrilesPrue SuwantoОценок пока нет

- Pharmaceutical Dosage Forms Answer Key BLUE and PINK PACOPДокумент115 страницPharmaceutical Dosage Forms Answer Key BLUE and PINK PACOPAlexios Deimos (alxios)Оценок пока нет

- Clariant Aristoflex GuideДокумент6 страницClariant Aristoflex GuidekhoachiОценок пока нет

- Analisis Morfin Dan Opiat GC-MSДокумент3 страницыAnalisis Morfin Dan Opiat GC-MSintan kusumaningtyasОценок пока нет

- Aerolite 111Документ2 страницыAerolite 111amzsoftОценок пока нет

- Fragrance Technologies and Applications (2012-04-04)Документ78 страницFragrance Technologies and Applications (2012-04-04)FtjjhfdОценок пока нет

- AggregatesДокумент2 страницыAggregatesWinArthurОценок пока нет

- Actual Lesson PlanДокумент3 страницыActual Lesson PlanShaik Magbul BashaОценок пока нет

- FBE Merged - MidsemДокумент276 страницFBE Merged - MidsemAnusha DesaiОценок пока нет

- Nitoproof 600 PDFДокумент4 страницыNitoproof 600 PDFmilanbrasinaОценок пока нет

- Ergot TryptophanДокумент7 страницErgot Tryptophanwonsun1682Оценок пока нет

- Ripex ApplicationsДокумент3 страницыRipex ApplicationsAle VázquezОценок пока нет

- Topic 13 Natural Materials-Rubber: SynopsisДокумент7 страницTopic 13 Natural Materials-Rubber: SynopsisKaynine KikoОценок пока нет

- An Introduction To FRP Composites For Construction: ISIS Educational Module 2Документ27 страницAn Introduction To FRP Composites For Construction: ISIS Educational Module 2Shital ChaudhariОценок пока нет

- PVC HistoryДокумент2 страницыPVC HistoryPUSHPSHEELОценок пока нет

- 340-Article Text-1115-1-10-20121115 PDFДокумент7 страниц340-Article Text-1115-1-10-20121115 PDFNguyễn HiềnОценок пока нет

- Module 7Документ25 страницModule 7ajmalОценок пока нет

- Current+Organic+Chemistry +2008, 12,+1116-1183Документ96 страницCurrent+Organic+Chemistry +2008, 12,+1116-1183Murali Venkat NagОценок пока нет

- CmaiДокумент17 страницCmaiAdrenal AbrahamОценок пока нет