Академический Документы

Профессиональный Документы

Культура Документы

Chap1 - Introduction

Загружено:

ghgh140Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Chap1 - Introduction

Загружено:

ghgh140Авторское право:

Доступные форматы

Lectures notes in Natural Gas Process Engineering

CHAPTER 1

INTRODUCTION To

Natural Gas Engineering

1. General Introduction

Natural Gas is a vital component of the world's supply of energy. It is one of the cleanest,

safest, and most useful of all energy sources. Despite its importance, however, there are

many misconceptions about natural gas. For instance, the word 'gas' itself has a variety of

different uses, and meanings. When we fuel our car, we put 'gas' in it. However, the

gasoline that goes into your vehicle, while a fossil fuel itself, is very different from

natural gas. The 'gas' in the common barbecue is actually propane, which, while closely

associated and commonly found in natural gas, is not really natural gas itself. While

commonly grouped in with other fossil fuels and sources of energy, there are many

characteristics of natural gas that make it unique. Below is a bit of background

information about natural gas, what exactly it is, how it is formed, and how it is found in

nature.

2. What is Natural Gas ?

Natural gas, in itself, might be considered a very uninteresting gas - it is colorless,

shapeless, and odorless in its pure form. Quite uninteresting - except that natural gas is

combustible, and when burned it gives off a great deal of energy. Unlike other fossil

fuels, however, natural gas is clean burning and emits lower levels of potentially harmful

byproducts into the air. We require energy constantly, to heat our homes, cook our food,

NGP 321 – chapter 1 1

Lectures notes in Natural Gas Process Engineering

and generate our electricity. It is this need for energy that has elevated natural gas to such

a level of importance in our society, and in our lives.

Natural gas is a combustible mixture of hydrocarbon gases. While natural gas is formed

primarily of methane, it can also include ethane, propane, butane and pentane. The

composition of natural gas can vary widely, but below is a chart outlining the typical

makeup of natural gas before it is refined.

Typical Composition of Natural Gas

Methane CH4 70-90%

Ethane C2H6

Propane C3H8 0-20%

Butane C4H10

Carbon Dioxide CO2 0-8%

Oxygen O2 0-0.2%

Nitrogen N2 0-5%

Hydrogen sulphide H2S 0-5%

Rare gases A, He, Ne, Xe trace

Natural gas accumulations in geological traps can be classified as reservoir, field, or pool.

A reservoir is a porous and permeable underground formation containing an individual

bank of hydrocarbons confined by impermeable rock or water barriers and is

characterized by a single natural pressure system. A field is an area that consists of one or

more reservoirs all related to the same structural feature. A pool contains one or more

reservoirs in isolated structures. Wells in the same field can be classified as gas wells,

condensate wells, and oil wells. Gas wells are wells with producing gas-oil-ration (GOR)

being greater than 100,000 scf/stb; condensate wells are those with producing GOR being

less than 100,000 scf/stb but greater than 5,000 scf/stb; and wells with producing GOR

being less than 5,000 scf/stb are classified as oil wells.

NGP 321 – chapter 1 2

Lectures notes in Natural Gas Process Engineering

Because natural gas is petroleum in a gaseous state, it is always accompanied by oil that

is liquid petroleum. There are three types of natural gases: nonassociated gas, associated

gas, and gas condensate. Nonassociated gas is from reservoirs with minimal oil.

Associated gas is the gas dissolved in oil under natural conditions in the oil reservoir. Gas

condensate refers to gas with high content of liquid hydrocarbon at reduced pressures and

temperatures.

3. History of Natural Gas

Natural gas is nothing new. In fact, most of the natural gas that is brought out from under

the ground is millions and millions of years old. However, it was not until recently that

methods for obtaining this gas, bringing it to the surface, and putting it to use were

developed.

Before there was an understanding of what natural gas was, it posed somewhat of a

mystery to man. Sometimes, such things as lightning strikes would ignite natural gas that

was escaping from under the earth's crust. This would create a fire coming from the earth,

burning the natural gas as it seeped out from underground. These fires puzzled most early

civilizations, and were the root of much myth and superstition. One of the most famous

of these types of flames was found in ancient Greece, on Mount Parnassus approximately

1,000 B.C. A goat herdsman came across what looked like a 'burning spring', a flame

rising from a fissure in the rock. The Greeks, believing it to be of divine origin, built a

temple on the flame. This temple housed a priestess who was known as the Oracle of

Delphi, giving out prophecies she claimed were inspired by the flame.

These types of springs became prominent in the religions of India, Greece, and Persia.

Unable to explain where these fires came from, they were often regarded as divine, or

supernatural. It wasn't until about 500 B.C. that the Chinese discovered the potential to

use these fires to their advantage. Finding places where gas was seeping to the surface,

NGP 321 – chapter 1 3

Lectures notes in Natural Gas Process Engineering

the Chinese formed crude pipelines out of bamboo shoots to transport the gas, where it

was used to boil sea water, separating the salt and making it drinkable.

Britain was the first country to commercialize the use of natural gas. Around 1785,

natural gas produced from coal was used to light houses, as well as streetlights.

During most of the 19th century, natural gas was used almost exclusively as a source of

light. Without a pipeline infrastructure, it was difficult to transport the gas very far, or

into homes to be used for heating or cooking. Most of the natural gas produced in this era

was manufactured from coal, as opposed to transported from a well. Near the end of the

19th century, with the rise of electricity, natural gas lights were converted to electric

lights. This led producers of natural gas to look for new uses for their product.

One of the first lengthy pipelines was constructed in 1891. This pipeline was 120 miles

long, and carried natural gas from wells in central Indiana to the city of Chicago.

However, this early pipeline was very rudimentary, and did not transport natural gas

efficiently. It wasn't until the 1920's that any significant effort was put into building a

pipeline infrastructure. After World War II welding techniques, pipe rolling, and

metallurgical advances allowed for the construction of reliable pipelines. This led to a

post-war pipeline construction boom lasting well into the 60's, creating thousands of

miles of pipeline in America.

Once the transportation of natural gas was possible, new uses for natural gas were

discovered. These included using natural gas to heat homes and operate appliances such

as water heaters and oven ranges. Industry began to use natural gas in manufacturing and

processing plants. Also, natural gas was used to heat boilers used to generate electricity.

The transportation infrastructure made natural gas easier to obtain, and as a result

expanded its uses.

NGP 321 – chapter 1 4

Lectures notes in Natural Gas Process Engineering

4. Natural Gas Resources

The current status of primary energy sources is summarized in Figure 1.1. Basically dry

natural gas (natural gas with natural gas liquids [NGLs] removed) is on a par with coal in

importance.

Six countries possess two thirds of the world’s gas reserves (Figure 1.2), with almost half

of the reserves located in Iran and Russia. The total reported natural gas reserves (~6,040

Tcf [171 TSm3] at the beginning of 2005 [Energy Information Administration, 2005c])

do not include discovered reserves that are not economically feasible to bring to market.

This “stranded gas” resides in remote regions, where the reserve size does not justify the

cost of the infrastructure required to bring it to market. Note that proven reserve estimates

are truly

Fig. 1.1 Primary sources of energy in the world in 2003. Total energy used was 405

quadrillion Btu (Energy Information Administration, 2005).

NGP 321 – chapter 1 5

Lectures notes in Natural Gas Process Engineering

Fig. 1.2 Major proven natural gas reserves by country. Total proven reserves estimated

to be 6,040 Tcf (Energy Information Administration, 2005)

As in the Oil and Gas Journal and World Oil publications, estimates world proved natural

gas reserves to be around 5,210.8 Tcf. As can be seen from the graph, most of these

reserves are located in the Middle East with 1,836.2 Tcf, or 34 percent of the world total,

and Europe and the Former U.S.S.R. with 2158.7, or 42 percent of total world reserves.

The United States, by this calculation, possesses 3 percent of the world total natural gas

reserves (Fig. 1.3).

NGP 321 – chapter 1 6

Lectures notes in Natural Gas Process Engineering

Fig. 1.3 World Natural Gas Reserves by Region Dec. 2006, (Oil and Gas journal 2006).

In Egypt (source : EGas), the total natural gas production has reached 52.2 BCM in

2005/2006 (including gas for export), out of which 34BCM were for local consumption

representing 61% of local natural gas consumption to the electricity sector which is the

largest gas consuming sector and has reached to 20.8BCM. Cumulative gas production

till 12/2006 is 1.9 TCF. Proven gas reserves is 68.2 TCF by 2005/2006

5. Natural Gas Uses

There are so many different applications for natural gas as fuel that it is hard to provide

an exhaustive list of everything it is used for. And no doubt, new uses are being

discovered all the time. Natural gas has many applications, commercially, in your home,

in industry, and even in the transportation sector! While the uses described here are not

exhaustive, they may help to show just how many things natural gas can do. Natural gas

is used across all sectors, in varying amounts. The graph below gives an idea of the

proportion of natural gas use per sector. The industrial sector accounts for the greatest

proportion of natural gas use in Egypt. Figures 1.4 and 1.5 present the use of the natural

gas as an energy source in different sectors in Egypt.

NGP 321 – chapter 1 7

Lectures notes in Natural Gas Process Engineering

Fig. 1.4 Egyptian natural Gas consumption by sector. (source : egas)

Fig. 1.5 Egyptian growth of local natural gas consumption

NGP 321 – chapter 1 8

Lectures notes in Natural Gas Process Engineering

The different applications of the natural gas uses and utilization can be listed as follows:

(1) Industrial Use

Natural gas has a multitude of industrial uses, including providing the base ingredients

for such varied products as plastic, fertilizer, anti-freeze, and fabrics. In fact, industry is

the largest consumer of natural gas, accounting for 43 percent of natural gas use across all

sectors. Natural gas is the second most used energy source in industry, trailing only

electricity. Lighting is the main use of energy in the industrial sector, which accounts for

the tremendous electricity requirements of this sector. The graphs below show some of

the industrial applications

Direct Contact Water Heaters

Direct contact water heating is an application that works by having the energy from the

combustion of natural gas transferred directly from the flame into the water. These

systems are incredibly efficient at heating water. Normal industrial water heaters operate

in the 60 - 70 percent energy efficiency range. However, direct contact water heaters can

achieve efficiencies up to 99.7 percent! Obviously, this leads to tremendous cost savings

in industries where hot water is essential.

Fig. 1.6 Natural gas water heater.

NGP 321 – chapter 1 9

Lectures notes in Natural Gas Process Engineering

Industrial Combined Heat and Power

Industrial consumers reap great benefits from operating natural gas Combined Heat and

Power (CHP) and Combined Cooling, Heat, and Power (CCHP) systems, similar to those

used commercial settings. For instance, natural gas may be used to generate electricity

needed in a particular industrial setting. The excess heat and steam produced from this

process can be harnessed to fulfill other industrial applications, including space heating,

water heating, and powering industrial boilers. Since industry is such a heavy user of

energy, and particularly electricity, providing increased efficiency can save a great deal

of money. The industrial sector is also subject to regulations regarding harmful

emissions, and the burning attributes of natural gas help industry to reduce its emissions.

Click to learn more about the environmental advantages of using natural gas in industrial

processes.

Industrial Co-firing

Natural gas co-firing technologies are also helping to increase industrial energy

efficiency, and reduce harmful atmospheric emissions. Co-firing is the process in which

natural gas is used as a supplemental fuel in the combustion of other fuels, such as coal,

wood, and biomass energy. For example, a traditional industrial wood boiler would

simply burn wood to generate energy. However, in this type of boiler, a significant

amount of energy is lost, and harmful emissions are very high. Adding natural gas to the

combustion mix can have a two-fold effect. Natural gas emits fewer harmful substances

into the air than a fuel such as wood. Since the energy needed to power the natural gas

boiler remains constant, adding natural gas to the combustion mix can reduce harmful

emissions.

NGP 321 – chapter 1 10

Lectures notes in Natural Gas Process Engineering

Fig. 1.7 Industrial Co firing.

(2) Electric generation using natural gas

Natural gas, because of its clean burning nature, has become a very popular fuel for the

generation of electricity. In the 1970's and 80's, the choices for most electric utility

generators were large coal or nuclear powered plants; but, due to economic,

environmental, and technological changes, natural gas has become the fuel of choice for

new power plants. In fact, in 2000, 23,453 MW (megawatts) of new electric capacity was

added in the U.S. Of this, almost 95 percent, or 22,238 MW were natural gas fired

additions. The graph below shows how, according to the Energy Information

Administration (EIA), natural gas fired electricity generation is expected to increase

dramatically over the next 20 years, as all of the new capacity that is currently being

constructed comes online.

Many of the new natural gas fired power plants are what are known as 'combined-cycle'

units. In these types of generating facilities, there is both a gas turbine and a steam unit,

all in one. The gas turbine operates in much the same way as a normal gas turbine, using

the hot gases released from burning natural gas to turn a turbine and generate electricity.

In combined-cycle plants, the waste heat from the gas-turbine process is directed towards

NGP 321 – chapter 1 11

Lectures notes in Natural Gas Process Engineering

generating steam, which is then used to generate electricity much like a steam unit.

Because of this efficient use of the heat energy released from the natural gas, combined-

cycle plants are much more efficient than steam units or gas turbines alone. In fact,

combined-plants can achieve thermal efficiencies of up to 50 to 60 percent.

Fig. 1.8 Natural Gas Combined cycle in New York.

(3) Natural Gas in Transportation systems

Natural gas has long been considered an alternative fuel for the transportation sector. In

fact, the first internal combustion engine vehicle to run on natural gas was created by

Etienne Lenoir in 1860. According to the Natural Gas Vehicle Coalition, there are

currently 150,000 Natural Gas Vehicles (NGVs) on the road in the United States today,

and more than 5 million NGVs worldwide. In fact, the transportation sector accounts for

3 percent of all natural gas used in the United States. In recent years, technology has

improved to allow for a proliferation of natural gas vehicles, particularly for fuel

intensive vehicle fleets, such as taxicabs and public buses. However, virtually all types of

natural gas vehicles are either in production today for sale to the public or in

NGP 321 – chapter 1 12

Lectures notes in Natural Gas Process Engineering

development, from passenger cars, trucks, buses, vans, and even heavy-duty utility

vehicles.

(4) Commercial Use

Commercial uses of natural gas are very similar to residential uses. The commercial

sector includes public and private enterprises, like office buildings, schools, churches,

hotels, restaurants, and government buildings. The main uses of natural gas in this sector

include space heating, water heating, and cooling. For restaurants and other

establishments that require cooking facilities, natural gas is a popular choice to fulfill

these needs

Fig. 1.9 Commercial energy use in USA, 2005 DOE.

(5) Residential (or domestic) Use

Natural gas is one of the cheapest forms of energy available to the residential consumer.

In fact, natural gas has historically been much cheaper than electricity as a source of

energy. The Department of Energy (DOE) estimates that in 2002, natural gas is the

lowest cost conventional energy source available for residential use. According to the

DOE natural gas costs less than 30 percent of the cost of electricity. Figure 1.10 shows a

comparison between the price of the BTU for each available energy type as USA

standard.

NGP 321 – chapter 1 13

Lectures notes in Natural Gas Process Engineering

Fig. 1.10 Residential Energy Costs pert BTU (source : US department of energy DOE,

2005)

Not only is natural gas cheap for the residential consumer, it also has a number of varied

uses. The best known uses for natural gas around the home are natural gas heating and

cooking. Cooking with a natural gas range or oven can provide many benefits, including

easy temperature control, self ignition and self cleaning, as well as being approximately

one-half the cost of cooking with an electric range. Many of the top chefs prefer natural

gas ranges for their quick heating ability and temperature control. Gone are the days of

temperamental natural gas ranges, the newer generations of natural gas ranges allow for

some of the most efficient, economical, and versatile cooking appliances ever

For local Use in Egypt, the next figure shows the different sectors and applications that

apply and produce the natural gas technologies.

NGP 321 – chapter 1 14

Lectures notes in Natural Gas Process Engineering

Fig. 1.11 Natural Gas sectors and applications in Egypt.

NGP 321 – chapter 1 15

Вам также может понравиться

- IMM MicroreactorsДокумент90 страницIMM MicroreactorsGoutam GottumukkalaОценок пока нет

- Oil and Gas Journal - February, 02 2009 PDFДокумент84 страницыOil and Gas Journal - February, 02 2009 PDFAnonymous KWScd5Es7Оценок пока нет

- LNG FuelДокумент10 страницLNG FuelengnaderrОценок пока нет

- Gas Transportation & Storage Flow EquationsДокумент52 страницыGas Transportation & Storage Flow EquationsJohny ImitazОценок пока нет

- 113.ammonium ChlorideДокумент19 страниц113.ammonium ChloridetadiyosОценок пока нет

- Hydrotreating & Hydrocracking Process Technology Training Course - PetroKnowledgeДокумент3 страницыHydrotreating & Hydrocracking Process Technology Training Course - PetroKnowledgenishilgeorgeОценок пока нет

- Seminar Report On Hydrogen As The Future FuelДокумент63 страницыSeminar Report On Hydrogen As The Future FuelMOHIT MGMОценок пока нет

- Mass Transfer Operations: 4/8/2020 - By: Rohit N Chaudhari (J18IMT640)Документ6 страницMass Transfer Operations: 4/8/2020 - By: Rohit N Chaudhari (J18IMT640)RohitОценок пока нет

- Overview of Instrumentation in Oil and Gas IndustryДокумент16 страницOverview of Instrumentation in Oil and Gas IndustryChibuzo NnonyeluОценок пока нет

- 11) Economic Justification of HPA Technology - r14 - EMSДокумент54 страницы11) Economic Justification of HPA Technology - r14 - EMSrio panji wicaksonoОценок пока нет

- Lessons and Learnings From Vizag Gas Leak-Disaster: Efficaz Consulting & Solutions Nov 2020Документ11 страницLessons and Learnings From Vizag Gas Leak-Disaster: Efficaz Consulting & Solutions Nov 2020Pushpa SinghОценок пока нет

- Natural Gas Engineering Hand Book (2005) Ch.4Документ14 страницNatural Gas Engineering Hand Book (2005) Ch.4Abdelrahman Saeed0% (1)

- MASS TRANSFER LAB MANUALДокумент24 страницыMASS TRANSFER LAB MANUALDhande SanketОценок пока нет

- Lawal KA 2011 PHD Thesis PDFДокумент327 страницLawal KA 2011 PHD Thesis PDFpedro aguilarОценок пока нет

- Economics and Geopolitics of Oil and GasДокумент12 страницEconomics and Geopolitics of Oil and Gasm_arrive89Оценок пока нет

- Plug Flow ReactorДокумент6 страницPlug Flow Reactormattgrisewood0% (1)

- Bottle Wall Construction Seminar Report 2014Документ18 страницBottle Wall Construction Seminar Report 2014Safalsha BabuОценок пока нет

- Module 2 Notes 18ME81Документ28 страницModule 2 Notes 18ME81Gaviroy PrasadОценок пока нет

- Petrochemical Engineering exam questions on refinery processesДокумент9 страницPetrochemical Engineering exam questions on refinery processesollie4hortonОценок пока нет

- A Project Report Submitted in Partial Fulfillment of The Requirements For Bachelor of Engineering (Mechanical)Документ48 страницA Project Report Submitted in Partial Fulfillment of The Requirements For Bachelor of Engineering (Mechanical)Kamod Ranjan100% (1)

- Volume and Flow MeasurementДокумент63 страницыVolume and Flow MeasurementshikhaОценок пока нет

- Gas Flaring in Nigeria: Opportunity For Household Cooking UtilizationДокумент6 страницGas Flaring in Nigeria: Opportunity For Household Cooking Utilizationra_abediОценок пока нет

- CSTR Startup TimeДокумент16 страницCSTR Startup TimeAnanda CahyaОценок пока нет

- Seminar Report (L&T)Документ27 страницSeminar Report (L&T)Pushpendu SinghОценок пока нет

- Crude Oil Refinery-Short VersionДокумент14 страницCrude Oil Refinery-Short Versionligia hancuОценок пока нет

- Small Scale NGLДокумент45 страницSmall Scale NGLNoirchevalОценок пока нет

- Hydrogen Fuel CellsДокумент7 страницHydrogen Fuel Cellsapi-291790740Оценок пока нет

- Role of Tourism Industry in India's Economic DevelopmentДокумент4 страницыRole of Tourism Industry in India's Economic DevelopmentIJAR JOURNALОценок пока нет

- Reactor Bach Vs Reactor PFRДокумент2 страницыReactor Bach Vs Reactor PFRPolloEcheverriaОценок пока нет

- Customer Perception and Distribution Chanel of HulДокумент76 страницCustomer Perception and Distribution Chanel of HulShariq KhanОценок пока нет

- Project TatipakaДокумент22 страницыProject Tatipakakhajachem80% (5)

- Sceintific Review of HHO KitДокумент3 страницыSceintific Review of HHO KitAsim RiazОценок пока нет

- Reactor DesignДокумент9 страницReactor DesignKin Wai CheahОценок пока нет

- ENGG 1100 Introduction To Engineering DesignДокумент43 страницыENGG 1100 Introduction To Engineering DesignDavid EspinoОценок пока нет

- Energy Optimization of Crude Oil Distillation Using Different Designs of Pre-Flash Drums PDFДокумент7 страницEnergy Optimization of Crude Oil Distillation Using Different Designs of Pre-Flash Drums PDFGabriela Urdaneta100% (1)

- Union Carbide India LimitedДокумент4 страницыUnion Carbide India LimitedJohn RayОценок пока нет

- Organic Rankine CycleДокумент4 страницыOrganic Rankine CycleMilos MilosavljevicОценок пока нет

- Plant Design Kojic Acid Beta 1Документ41 страницаPlant Design Kojic Acid Beta 1Milton Dels RosaОценок пока нет

- Godavari Biorefinery Capital Budgeting StudyДокумент63 страницыGodavari Biorefinery Capital Budgeting StudyShivprabhu AntinОценок пока нет

- Nikita Project 01-06-2016Документ38 страницNikita Project 01-06-2016Shobhit GoswamiОценок пока нет

- NaphthaДокумент10 страницNaphthaShagun Bhardwaj0% (1)

- BTP Report Rahul FinalДокумент170 страницBTP Report Rahul FinalGopal VermaОценок пока нет

- 01 Gas GradesДокумент20 страниц01 Gas GradesRadu CerneaОценок пока нет

- Mid Country Refinery: Refinery's Housing ComplexДокумент8 страницMid Country Refinery: Refinery's Housing ComplexNaveed AhmedОценок пока нет

- CHE3044F, 2013: Reactor Design 1: TUTORIAL 8: K 0.1 Mi N K 0.1 Mi NДокумент2 страницыCHE3044F, 2013: Reactor Design 1: TUTORIAL 8: K 0.1 Mi N K 0.1 Mi NnmhatityeОценок пока нет

- Octane PDFДокумент7 страницOctane PDFAli Tatar100% (1)

- HydrogenДокумент10 страницHydrogentony jammerОценок пока нет

- Fuel ConsumptionДокумент11 страницFuel ConsumptionMerick Diamante Jr.Оценок пока нет

- China Construction ContractorsДокумент3 страницыChina Construction ContractorsAbdul WahabОценок пока нет

- Alternating Injection Thermal Heavy Oil RecoveryДокумент327 страницAlternating Injection Thermal Heavy Oil Recoverypedro aguilar100% (1)

- NG Engineering by Engr DR CIC AnyadiegwuДокумент31 страницаNG Engineering by Engr DR CIC Anyadiegwudavidchinedu008Оценок пока нет

- Properties of Natural GasДокумент67 страницProperties of Natural Gasxion_mew2Оценок пока нет

- Review of LiteratureДокумент2 страницыReview of LiteratureGreeshma Savin0% (1)

- CHE3044F Reactor Design TutorialДокумент2 страницыCHE3044F Reactor Design TutorialnmhatityeОценок пока нет

- Clay-Fly Ash Bricks Seminar ReportДокумент29 страницClay-Fly Ash Bricks Seminar ReportadnanОценок пока нет

- Ogjournal20150706 DLДокумент136 страницOgjournal20150706 DLrasyid93Оценок пока нет

- Refining TutorialДокумент38 страницRefining TutorialEmeka ChinakaОценок пока нет

- Chapter 1Документ28 страницChapter 1Diego PardoОценок пока нет

- Global Gas IndustryДокумент37 страницGlobal Gas IndustrySuleiman BaruniОценок пока нет

- Moustafa Mohamed MetwallyДокумент1 страницаMoustafa Mohamed Metwallyghgh140Оценок пока нет

- Mechanical Engineer - Hurghada: See Similar JobsДокумент3 страницыMechanical Engineer - Hurghada: See Similar Jobsghgh140Оценок пока нет

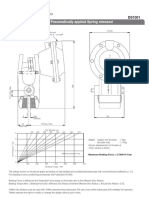

- MUS2 Disc Brake Caliper - Spring Applied Pneumatically ReleasedДокумент2 страницыMUS2 Disc Brake Caliper - Spring Applied Pneumatically Releasedghgh140Оценок пока нет

- MSL Disc Brake Caliper - Spring Applied, Hydraulically ReleasedДокумент2 страницыMSL Disc Brake Caliper - Spring Applied, Hydraulically Releasedghgh140Оценок пока нет

- Six Sigma Foundations and Principles QuizДокумент3 страницыSix Sigma Foundations and Principles Quizghgh140Оценок пока нет

- MS Disc Brake CaliperДокумент2 страницыMS Disc Brake Caliperghgh140Оценок пока нет

- Aya Mohamed Metwally Gad Ali: Work ExperienceДокумент1 страницаAya Mohamed Metwally Gad Ali: Work Experienceghgh140Оценок пока нет

- 1 Learning OutcomesДокумент1 страница1 Learning Outcomesghgh140Оценок пока нет

- 6 - Value of Six SigmaДокумент2 страницы6 - Value of Six SigmaBeshoy GergesОценок пока нет

- Optional Threads: Example: S.A.E.-AFC-3M-25 Example: JIC-AFC-3M-25RC Example: BSP-AFC-3M-25Документ1 страницаOptional Threads: Example: S.A.E.-AFC-3M-25 Example: JIC-AFC-3M-25RC Example: BSP-AFC-3M-25ghgh140Оценок пока нет

- MU Disc Brake Caliper: For MUP OnlyДокумент2 страницыMU Disc Brake Caliper: For MUP Onlyghgh140Оценок пока нет

- DS1001-MU3 Disc Brake Caliper SpecsДокумент2 страницыDS1001-MU3 Disc Brake Caliper Specsghgh140Оценок пока нет

- Brd. Klee AS en 057153203401 HEPCO GV3 Bearing LJ 34 CДокумент1 страницаBrd. Klee AS en 057153203401 HEPCO GV3 Bearing LJ 34 Cghgh140Оценок пока нет

- MSK Disc Brake Caliper - Spring Applied, Pneumatically ReleasedДокумент2 страницыMSK Disc Brake Caliper - Spring Applied, Pneumatically Releasedghgh140Оценок пока нет

- Clean Resume Vol 1Документ1 страницаClean Resume Vol 1ghgh140Оценок пока нет

- FfsДокумент1 страницаFfsghgh140Оценок пока нет

- Moustafa Mohamed MetwallyДокумент1 страницаMoustafa Mohamed Metwallyghgh140Оценок пока нет

- Discs, Hubs, Bushings, Custom Parts CatalogДокумент1 страницаDiscs, Hubs, Bushings, Custom Parts Catalogghgh140Оценок пока нет

- Applicant Interview Questions and AnswersДокумент4 страницыApplicant Interview Questions and Answersghgh140Оценок пока нет

- Cover LetterДокумент1 страницаCover Letterghgh140Оценок пока нет

- GE Advance Material and CoatingДокумент30 страницGE Advance Material and Coatingkhunplatt100% (1)

- MaintenanceДокумент75 страницMaintenanceshahzad afzal100% (21)

- Quality Assurance and Quality ControlДокумент17 страницQuality Assurance and Quality Controltraslie0% (1)

- Gas TurbineДокумент27 страницGas Turbineghgh140100% (1)

- Internal Combustion Engine1Документ53 страницыInternal Combustion Engine1ghgh140Оценок пока нет

- Chap3 - Seperators and Seperation TechniquesДокумент37 страницChap3 - Seperators and Seperation Techniquesghgh140Оценок пока нет

- 9 Gas Turbine - Cogeneration PDFДокумент30 страниц9 Gas Turbine - Cogeneration PDFghgh140Оценок пока нет

- Quality Control: Methodology and ApplicationsДокумент12 страницQuality Control: Methodology and Applicationsghgh140Оценок пока нет

- Evaporator 4 PDFДокумент17 страницEvaporator 4 PDFBagas Aryo SasongkoОценок пока нет

- Course Contents: Lecturers Notes in Natural Gas Process EngineeringДокумент1 страницаCourse Contents: Lecturers Notes in Natural Gas Process Engineeringghgh140Оценок пока нет

- Pre-Finals Tasks Performance Concept PaperДокумент8 страницPre-Finals Tasks Performance Concept PaperIris MizalОценок пока нет

- Determining Soil Texture by FeelДокумент4 страницыDetermining Soil Texture by FeelKy TaОценок пока нет

- Chapter - 17 Static ElectricityДокумент54 страницыChapter - 17 Static ElectricityNayeem HakimОценок пока нет

- Solar RadiationtransДокумент51 страницаSolar RadiationtransmrizqynugrahaОценок пока нет

- How Is The Philippines Affected by Climate ChangeДокумент2 страницыHow Is The Philippines Affected by Climate ChangeQueenie SantosОценок пока нет

- LTV - Thi Thu Vao 10 Lan 1 - 2019Документ5 страницLTV - Thi Thu Vao 10 Lan 1 - 2019Thùy Linh NguyễnОценок пока нет

- Sustainable Planning & Architecture: Notes Prepared by Ar. Achilles Sophia M.GДокумент33 страницыSustainable Planning & Architecture: Notes Prepared by Ar. Achilles Sophia M.GVijay VОценок пока нет

- Student Exploration: Air Track: Name: Akshat Date:12/15/20Документ9 страницStudent Exploration: Air Track: Name: Akshat Date:12/15/20Akshat Pant100% (8)

- Y9 HT3 Holiday Homeworkbonding No AnswersДокумент8 страницY9 HT3 Holiday Homeworkbonding No Answersaqeelf146Оценок пока нет

- The Routledge Handbook of Energy Security: Edited by Benjamin K. SovacoolДокумент3 страницыThe Routledge Handbook of Energy Security: Edited by Benjamin K. SovacoolNagesh K OjhaОценок пока нет

- 1st Quarter Exams ESCI 1st SemДокумент6 страниц1st Quarter Exams ESCI 1st SemAmar Poñado BagacinaОценок пока нет

- Green Building ReportДокумент18 страницGreen Building Reportchechumenendez100% (1)

- NEET UG Biology Evolution PDFДокумент22 страницыNEET UG Biology Evolution PDFamsaeangovanОценок пока нет

- Study On Solar Power PlantДокумент26 страницStudy On Solar Power PlantPrakash MarathiОценок пока нет

- Heat Transfer From Fin SurfacesДокумент25 страницHeat Transfer From Fin SurfacesAizaz HabibОценок пока нет

- Tropical SoilsДокумент88 страницTropical SoilsBernard Kipng'eno100% (1)

- 1 s2.0 S0001868613001140 Main PDFДокумент11 страниц1 s2.0 S0001868613001140 Main PDFBEN DUNCAN MALAGA ESPICHANОценок пока нет

- How To Determine BasicityДокумент10 страницHow To Determine Basicityccy9489Оценок пока нет

- Causes of Global Warming: National Geographic SocietyДокумент5 страницCauses of Global Warming: National Geographic SocietyNahirОценок пока нет

- The Planets of The Solar System With All Their DescriptionsДокумент1 страницаThe Planets of The Solar System With All Their DescriptionsMiranda SosaОценок пока нет

- r050210801 Fluid Mechanics For Chemical EngineeringДокумент7 страницr050210801 Fluid Mechanics For Chemical EngineeringSrinivasa Rao GОценок пока нет

- Indian Energy ScenarioДокумент19 страницIndian Energy ScenarioVishal RamakrishnanОценок пока нет

- Photosynthesis Lesson at Fisher Valley CollegeДокумент5 страницPhotosynthesis Lesson at Fisher Valley CollegeRomielyn MenguezОценок пока нет

- Chapter 4: Soil Test and SurveyДокумент17 страницChapter 4: Soil Test and SurveyOpaw Kho100% (1)

- An Overview of Turbulent Flows PDFДокумент20 страницAn Overview of Turbulent Flows PDFmervedОценок пока нет

- EMS Brochure by SchneiderДокумент4 страницыEMS Brochure by SchneiderPratik SarkarОценок пока нет

- Environmental Aspects and Impacts Assessment Guide: PTS 60.3202 June 2006Документ34 страницыEnvironmental Aspects and Impacts Assessment Guide: PTS 60.3202 June 2006enviroОценок пока нет

- St. Ignacia High School 1st Preliminary Exam in Science 10Документ12 страницSt. Ignacia High School 1st Preliminary Exam in Science 10Mira VeranoОценок пока нет

- Chemistry TextbookДокумент148 страницChemistry TextbookOtuku DavidОценок пока нет

- 6.26 Transient Analysis Depressurising and Venting (Pipeline)Документ54 страницы6.26 Transient Analysis Depressurising and Venting (Pipeline)shivajireturnsОценок пока нет