Академический Документы

Профессиональный Документы

Культура Документы

Polyethylene Terephthalate Key Properties: Chemical Resistance

Загружено:

rajaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Polyethylene Terephthalate Key Properties: Chemical Resistance

Загружено:

rajaАвторское право:

Доступные форматы

Polyethylene terephthalate Key Properties

Chemical Resistance

Acids - Concentrated Good

Acids - Dilute Good

Alcohols Good

Alkalis Poor

Aromatic Hydrocarbons Fair

Greases and oils Good

Halogens Good

Ketones Good

Electrical Properties

Dielectric Constant @ 1 MHz 3

Dielectric Strength (kV.mm-1) 17

Dissipation Factor @ 1 kHz 0.002

13

Surface Resistivity (Ohm / sq) 10

14

Volume Resistivity (Ohm.cm) > 10

Mechanical Properties

Coefficient of Friction 0.2 - 0.4

Hardess - Rockwell M94-101

Izod Impact Strength (J.m-1) 13 - 35

Poisson's Ratio 0.37 - 0.44 (oriented)

Young's Modulus of Elasticity (109 N.m2) 2 - 2.7

Tensile Modulus (GPa) 2-4

Tensile Strength (MPa) 80, for biax film 190 - 260

Physical Properties

Density (g.cm-3) 1.3 - 1.4

Flammability Self Extinguishing

Limiting Oxygen Index (%) 21

Refractive Index 1.58 - 1.64

Resistance to Ultra-Violet Good

Water Absorption - Equilibrium (%) < 0.7

Water Absorption - over 24 hours (%) 0.1

Thermal Properties

Coefficient of Thermal Expansion (x10-6K-1) 20 - 80

Heat-Deflection Temperature - 0.45MPa (°C) 115

Heat-Deflection Temperature - 1.8MPa (°C) 80

Lower Working Temperature (°C) -40 to -60

Specific Heat (J.K-1.kg-1) 1200 - 1350

Thermal Conductivity (W.m-1.K-1) 0.15 - 0.4 @ 23°C

Upper Working Temperature (°C) 115 - 170

Properties PET Film

Dielectric Strength @ 25 µ m thick KV.mm-1 300

Dissipation Factor @ 1 kHz 0.016

Elongation at Break % 60 - 165

Initial Tear Strength g.µ m-1 18 - 54

-13 3 -2 -1 -1

Permeability to CO2 @ 25°C x10 cm .cm.cm .s .Pa 0.07 - 0.11

-13 3 -2 -1 -1

Permeability to Hydrogen @ 25°C x10 cm .cm.cm .s .Pa 0.45

-13 3 -2 -1 -1

Permeability to Nitrogen @ 25°C x10 cm .cm.cm .s .Pa 0.0034 - 0.0038

-13 3 -2 -1 -1

Permeability to Oxygen @ 25°C x10 cm .cm.cm .s .Pa 0.015 - 0.04

-13 3 -2 -1 -1

Permeability to Water @ 25°C x10 cm .cm.cm .s .Pa 100 - 115

-1 -1

Specific Heat KJ.kg .K 1.3

-1 -1

Thermal Conductivity @ 23°C W.m .K 0.13 - 0.15

Properties PET Fiber

Material Medium High Tenacity

Specific Modulus cN/tex 700 - 800

Specific Tenacity cN/tex 36 70 - 80

Density (g.cm-3) g.cm-3 1.39 1.39

Extension to Break % 36 13 - 16

Modulus GPa 9 - 11

Shrinkage @ 100° C % 4 1.5 - 6

Tenacity GPa 0.5 0.9 - 1.1

Phoenix Technologies International LLC

Phoenix Technologies International LLC provides RPET resins to a variety of customers for specific applications depending upon their needs.

We are not in the business of advising customers and suppliers generally as to usage of our product, including drying and processing procedures,

or to the testing or other methodology which could require modification depending upon the specific applications desired. The above information is

furnished without charge as an accommodation to our customers and suppliers and is of general application only. Phoenix Technologies International

and its affiliates do not warrant or represent the accuracy of such information in each and every application and disclaim any and all responsibility for

the results or consequences of use of such information or the use of any product, method or apparatus referred to above. It is the responsibility of each

customer or user, based on whatever testing criteria it deems appropriate, to determine the suitability of our product or methods for any particular use.

Вам также может понравиться

- Insuflex CatalogДокумент15 страницInsuflex Catalogmarceilinus devaluanto100% (1)

- Rotary EvaporatorДокумент4 страницыRotary EvaporatorArif FerdianОценок пока нет

- Periodic Law LabДокумент2 страницыPeriodic Law LabHarrison Lee80% (5)

- Ronnel AC Design Solution 2Документ36 страницRonnel AC Design Solution 2Xype LanderОценок пока нет

- High Density PolypropyleneДокумент2 страницыHigh Density Polypropyleneann 87Оценок пока нет

- ResinTek RTS 075FR-1Документ2 страницыResinTek RTS 075FR-1vishal089Оценок пока нет

- Pe1000 PDFДокумент2 страницыPe1000 PDFrohitdakngОценок пока нет

- 道康宁Dow DOWSIL™ SE 4430白色 导热硅脂 导热胶-附TDS下载Документ3 страницы道康宁Dow DOWSIL™ SE 4430白色 导热硅脂 导热胶-附TDS下载walter karl Nuñez AngoОценок пока нет

- SYLGARD™ 184 Silicone Elastomer: Features & Benefits ApplicationsДокумент4 страницыSYLGARD™ 184 Silicone Elastomer: Features & Benefits ApplicationsZhan FangОценок пока нет

- Spur Gear Spec Some Manufactures Dimension PDFДокумент52 страницыSpur Gear Spec Some Manufactures Dimension PDFagus wahyudiОценок пока нет

- Chemical Composition: ASTM B103Документ1 страницаChemical Composition: ASTM B103MarcoAntonioОценок пока нет

- Tds Px439xs BK Vs Np1025Документ3 страницыTds Px439xs BK Vs Np1025neil minnisОценок пока нет

- SRBP-P3 DatasheetДокумент1 страницаSRBP-P3 DatasheetnaveenupadyaОценок пока нет

- Poli MeroДокумент3 страницыPoli MeroLivio EscuderoОценок пока нет

- AmuДокумент2 страницыAmuavinashchauhan2695Оценок пока нет

- CuZn30 PDFДокумент2 страницыCuZn30 PDFavinashchauhan2695Оценок пока нет

- Rigid PVCДокумент1 страницаRigid PVCRND KencanaОценок пока нет

- Arnitel® EM550, TPC-ET - DSM Engineering Plastics - Plastics FinderДокумент5 страницArnitel® EM550, TPC-ET - DSM Engineering Plastics - Plastics FinderFaiz AnsariОценок пока нет

- Cu-ETP: C11000 Industrial RolledДокумент4 страницыCu-ETP: C11000 Industrial Rolledsrsivaraman81Оценок пока нет

- MetalДокумент3 страницыMetalLivio EscuderoОценок пока нет

- Description: Polystyrene (PS)Документ5 страницDescription: Polystyrene (PS)Murilo SanchesОценок пока нет

- Technical Data Sheet Product 3421: Research, Development & Engineering PreliminaryДокумент3 страницыTechnical Data Sheet Product 3421: Research, Development & Engineering PreliminaryAfzal ImamОценок пока нет

- Description: Polytetrafluoroethylene (Teflon, PTFE)Документ6 страницDescription: Polytetrafluoroethylene (Teflon, PTFE)Yaho HosОценок пока нет

- R433M 433.92MHz 3.0x3.0 6PINДокумент5 страницR433M 433.92MHz 3.0x3.0 6PINAnselmo LimaОценок пока нет

- TDS PC - LEXAN+141R - enДокумент2 страницыTDS PC - LEXAN+141R - enSơn Nguyễn ĐắcОценок пока нет

- Dupont™ Crastin Sk615Sf Nc010 (Preliminary Data) : Thermoplastic Polyester ResinДокумент6 страницDupont™ Crastin Sk615Sf Nc010 (Preliminary Data) : Thermoplastic Polyester ResinomarОценок пока нет

- 694-3 - R10KДокумент5 страниц694-3 - R10KJosé AdelinoОценок пока нет

- CeramicoДокумент3 страницыCeramicoLivio EscuderoОценок пока нет

- Precision Thin Film Chip ResistorsДокумент3 страницыPrecision Thin Film Chip ResistorsJaPan LifeОценок пока нет

- NaturalДокумент2 страницыNaturalLivio EscuderoОценок пока нет

- 1 TDS - KIMMCO-ISOVER Glass Mineral Wool Batt-Blanket - KBR - 24kg - 25mm - FSK - Formal-1Документ3 страницы1 TDS - KIMMCO-ISOVER Glass Mineral Wool Batt-Blanket - KBR - 24kg - 25mm - FSK - Formal-1Kareem HelalОценок пока нет

- High Power Chip ResistorsДокумент3 страницыHigh Power Chip ResistorstadilakshmikiranОценок пока нет

- Cu ZN 10Документ1 страницаCu ZN 10Sara RiddleОценок пока нет

- FR 4Документ1 страницаFR 401fe19bme028Оценок пока нет

- Technical Data Sheet CPVC: (Chlorinated Polyvinyl Chloride)Документ1 страницаTechnical Data Sheet CPVC: (Chlorinated Polyvinyl Chloride)Nam NguyenОценок пока нет

- Axial Leaded - 5 KW 5KP SeriesДокумент6 страницAxial Leaded - 5 KW 5KP SeriesSadegh ShebaniОценок пока нет

- Proton PF-15Документ1 страницаProton PF-15HirenОценок пока нет

- Typical Engineering Properties of High Density Polyethylene: General Properties English Units SI UnitsДокумент2 страницыTypical Engineering Properties of High Density Polyethylene: General Properties English Units SI UnitsAnil AmrawanshiОценок пока нет

- Miniature Aluminum Electrolytic Capacitors For AudioДокумент1 страницаMiniature Aluminum Electrolytic Capacitors For AudioCornel PislaruОценок пока нет

- PEPolyethylene20 30GlassFilledДокумент3 страницыPEPolyethylene20 30GlassFilledshizu monОценок пока нет

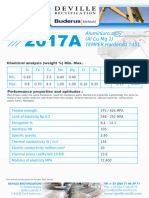

- (Al Cu MG 1) 2017a - RemovedДокумент1 страница(Al Cu MG 1) 2017a - RemovedZo StevanovicОценок пока нет

- Acetal Natural Data SheetДокумент1 страницаAcetal Natural Data SheetvijayОценок пока нет

- Properties of Common Optical Polymers: F D C DДокумент1 страницаProperties of Common Optical Polymers: F D C DHugo MakОценок пока нет

- MediaДокумент6 страницMediaNur Awwaluddin ZОценок пока нет

- MembraneSpecSheet 60umДокумент1 страницаMembraneSpecSheet 60umKenz ZhouОценок пока нет

- Thunderclad 1+ - DatasheetДокумент2 страницыThunderclad 1+ - Datasheethuan nguyenОценок пока нет

- Cu-HCP: C10300 Industrial RolledДокумент7 страницCu-HCP: C10300 Industrial RolledpierocarnelociОценок пока нет

- PORON 4790-92-25041 P Extra SoftSlow ReboundSupportedДокумент2 страницыPORON 4790-92-25041 P Extra SoftSlow ReboundSupportedkarpagsОценок пока нет

- Luran S 797se: Acrylonitrile Styrene Acrylate (ASA)Документ3 страницыLuran S 797se: Acrylonitrile Styrene Acrylate (ASA)bobОценок пока нет

- SELIT Depron 6 MM KartaДокумент2 страницыSELIT Depron 6 MM Kartajanuszkunce57Оценок пока нет

- CRT0603 PX 2321elfДокумент4 страницыCRT0603 PX 2321elfFernando MarquezОценок пока нет

- Stainless Steel Exercice Au ChoixДокумент6 страницStainless Steel Exercice Au ChoixFabrice Haoulassa HamanОценок пока нет

- Conathane En-1556 2e12Документ3 страницыConathane En-1556 2e12scorpionbadshahОценок пока нет

- UHMW-PE Tivar 1000Документ2 страницыUHMW-PE Tivar 1000centurion2988Оценок пока нет

- Raffmetal: UNI EN 1676 and 1706Документ2 страницыRaffmetal: UNI EN 1676 and 1706Raj RajeshОценок пока нет

- Bourns CRM2512 DatasheetДокумент5 страницBourns CRM2512 DatasheetbarisОценок пока нет

- (Jay Shoemaker) Moldflow Design Guide 'A ResourcДокумент3 страницы(Jay Shoemaker) Moldflow Design Guide 'A ResourcFahri ibişoğluОценок пока нет

- Gaas/Ge Single Junction Solar Cells: FeaturesДокумент2 страницыGaas/Ge Single Junction Solar Cells: FeaturesGilberto FigueiredoОценок пока нет

- TDS L2057216Документ3 страницыTDS L2057216erolsarОценок пока нет

- Mechanical Properties of TiO2Документ1 страницаMechanical Properties of TiO2Firda AzizaОценок пока нет

- SensorsДокумент69 страницSensorsRiahi Rezeg100% (1)

- PBN DatasheetДокумент1 страницаPBN DatasheetLove MishraОценок пока нет

- Bengkel GPB 2019Документ3 страницыBengkel GPB 2019rajaОценок пока нет

- Bahan Ilakkanam N IlakkiyamДокумент14 страницBahan Ilakkanam N Ilakkiyamநித்தியா இராஜசேகர்Оценок пока нет

- Knock Out CyberbullyingДокумент11 страницKnock Out CyberbullyingrajaОценок пока нет

- PBL Physics MH370Документ7 страницPBL Physics MH370rajaОценок пока нет

- Egn3365 12Документ42 страницыEgn3365 12rajaОценок пока нет

- Physics Notes For DVT - PHY 1A-1Документ94 страницыPhysics Notes For DVT - PHY 1A-1rajaОценок пока нет

- LS-PL-Anchors-CDA 2010Документ14 страницLS-PL-Anchors-CDA 2010EmОценок пока нет

- SFS Solid Front Process Pressure GaugeДокумент2 страницыSFS Solid Front Process Pressure GaugeTlehony HaryОценок пока нет

- CHEM1020 Module1 ViewingДокумент199 страницCHEM1020 Module1 ViewingclearcastingОценок пока нет

- Ficha Tecnica - Lana Mineral ThermafiberДокумент2 страницыFicha Tecnica - Lana Mineral ThermafiberJeshua Diego BarrientosОценок пока нет

- The Physical Chemistry of Water and Aqueous Solutions: 3-1 IntroductionДокумент38 страницThe Physical Chemistry of Water and Aqueous Solutions: 3-1 IntroductionChau MaiОценок пока нет

- 150 5320 6eДокумент9 страниц150 5320 6eomidziaОценок пока нет

- Reference - PIM-SU-3541-D - HydrotestДокумент14 страницReference - PIM-SU-3541-D - Hydrotestaslam.ambОценок пока нет

- Ocused Ion Beam Microscopy and Micromachining: C.A. Volkert and A.M. Minor, Guest EditorsДокумент11 страницOcused Ion Beam Microscopy and Micromachining: C.A. Volkert and A.M. Minor, Guest EditorsrmehfuzОценок пока нет

- Checklist - FFS Inlet HeaderДокумент3 страницыChecklist - FFS Inlet HeaderRamalingam PrabhakaranОценок пока нет

- Metal Joining ProcessДокумент28 страницMetal Joining ProcessVenkatesh Modi100% (2)

- 8 - Inorganic Salt AnalysisДокумент95 страниц8 - Inorganic Salt AnalysisArkaОценок пока нет

- Plastics Carbon FootprintДокумент14 страницPlastics Carbon FootprintBegenkzОценок пока нет

- The Eur o P e An Uni o N: EDI CT OF GovernmentДокумент105 страницThe Eur o P e An Uni o N: EDI CT OF GovernmentBanuta GabrielОценок пока нет

- Thermometer Exp 1Документ11 страницThermometer Exp 1hayder alaliОценок пока нет

- Algerian CondensateДокумент3 страницыAlgerian CondensateibrankОценок пока нет

- ESA MCQДокумент3 страницыESA MCQvamsikrishnamamidiОценок пока нет

- ZPurlinR1 OdsДокумент21 страницаZPurlinR1 OdsRamachandra SahuОценок пока нет

- FT Bitumseal enДокумент1 страницаFT Bitumseal enGerman GonzalezОценок пока нет

- Estado Del Arte de Las Resinas 2011Документ10 страницEstado Del Arte de Las Resinas 2011kelly johanna quintero arevaloОценок пока нет

- Emt RymcoДокумент2 страницыEmt RymcoPablo HernandezОценок пока нет

- Galambos Ravindra 1976Документ103 страницыGalambos Ravindra 1976Eric NolascoОценок пока нет

- Additive Sunset YellowДокумент2 страницыAdditive Sunset YellowMohammad RofikОценок пока нет

- My Separating Mixture Summary Poster 1Документ1 страницаMy Separating Mixture Summary Poster 1MinduliОценок пока нет

- TO Oznake ISO15787Документ7 страницTO Oznake ISO15787Diego ReggianiniОценок пока нет

- Solutions For AdhesivesДокумент2 страницыSolutions For AdhesivesPranshu JainОценок пока нет

- Rendercon ChemДокумент4 страницыRendercon ChemHarshvardhan PathakОценок пока нет

- Questioned: Document ExaminationДокумент4 страницыQuestioned: Document ExaminationApple AsneОценок пока нет