Академический Документы

Профессиональный Документы

Культура Документы

YL Ductile Iron Pipe Catalogue

Загружено:

Iswadi Bin Zulkarnain100%(1)100% нашли этот документ полезным (1 голос)

415 просмотров13 страницDuctile iron pipe product selection guide

Авторское право

© © All Rights Reserved

Доступные форматы

PDF или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документDuctile iron pipe product selection guide

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

100%(1)100% нашли этот документ полезным (1 голос)

415 просмотров13 страницYL Ductile Iron Pipe Catalogue

Загружено:

Iswadi Bin ZulkarnainDuctile iron pipe product selection guide

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

Вы находитесь на странице: 1из 13

What fs Ductile Iron?

Carbon is always present in the form of graphite flakes, which favour crack initiation and brittleness. In Ductile

Iron, spheroidal graphite iron, the carbon is present in the form of small spheres, thus eliminating the risk of

‘crack propagation and resulting in higher strength.

This is done by adding magnesium into molten iron. Therefore, the continuity of the iron macrix is maintained,

providing excellent ductility, flexibility and impact resistance.

In "Ductile Iron", the graphite is

in spheroidal form and hence, the

risk of cracking is eliminated

In "Cast Iron”, the carbon is

present in flaky form making the

‘material brittle and susceptible to

cracks.

— A Polyethylene Sleeving

B Bitumen Coating

© © Zine Costing

— D Ductile roa

Cement Mortar Lining

Protection

i Internal Lining

i YL offers standard advanced centrfugally applied cement

i mortar lining that gives high mortar compaction, good

i adhesion and silk-smooth surface flow.

Other standard linings such as Mascrete, High Alumina and

Sulphate Resistant cement are also available. YL is also capable

cof supplying superb quality epoxy coated pipes.

f

|

i

i

|

|

|

I

j

;

|

'

|

External Coating

AIIYL pipes come with che basic requirement of Metallic Zinc

coating followed by Bitumen paint as the finishing coat

Mexalic Zinc coating protect the pipe by forming a stable

protective layer of insoluble zine sales. I also has self-healing

characteristics of any damage and therefore, increases the life

span of the pipe.

Other external coatings such as epoxy-based coating are also

available upon request.

Features Of Ductile Iron Pipes:

© Excellent corrosion resistance

© High load bearing capabilities

© Low cost pipe installation

© Complete pipeline in shortest time

© No restriction from adverse weather and traffic

© Easy machining, tapping and cutting

‘© Suitable for piping in tunnels

© Widest range of factory fittings and accessories

© Pipe flanging made to specific length required

Pipe Joints

The push-in-joint, also known as socket-spigot joint,

provides leakctightness even at pipe busting pressures and

allows deflection in any direction up to § degrees.

The push-in method also allows easy and speedy jointing

even in restricted space, or during adverse weather

conditions as it does not require special tools or

‘equipment. This reduces the pipe laying cost and time while

increasing efficiency.

YL flanged joint offers an excellent mechanical system. All

flanges are screwed-on or welded-on with precision

workmanship that offers leak-tightness.

A flanged joint allows pipe sections to be installed or

dismantled in line

Flanged Joint

ORY cx ini

7 et | erie

Mea atm sate RO UE |lin7

Hardness Tester

Tensile Testing

YL Ductile tron pipes and fittings are certified by

the Standard Industrial Research Institute of

= Malaysia (SIRIM) in compliance with BS EN

545:2002 and MS ISO 9001:2000 Quality Systems

for Quality Assurance in Production, Installation and

Servicing. Also in compliance with BS EN $98 : 1995

and ISO 2531

‘Chemical Composition Analy

Comparison Between Ductile Iron Pipes And Mild Steel Pipes re

D1 oni Mild Steet Pip 2

Brinell Hardness (HB) Max 230 Max 40 a

Bending Strength (kg/m Min.61.1 Min. 41 \ =

Elongation (%) 10% < DNI,000 18% \

Modulus of Elasticity (E) 170 GPa 4

De Lovaud Centrifugal Costing

Melting

Recommended transportation and handling

checklist:

Proper procedures for unloading of YL Ductile Iron

pipes should be as recommended below:

© Use sufficient powerful lifting gear, ie. crane, forklift and

ete.

© Manoeuvre gently, controlied by the use of guide ropes.

‘Avoid swinging, sudden jerking motions, impacts or pipes

rubbing against other pipes. the ground or any other

objects.

© Chain securing the pipe to the truck should not be

released before ensuring the truck is positioned on level

ground

© Timber battens should be placed on the ground about

Im each end to the pipes to absorb shock and to

prevent damage to the coatings (Picture 1).

(© Aways secure pipe with chocks with the same shape and

size (Picture 2)

© Arrangement of the pipe should be parallel and equally

spaced on top of the timber (Picture 3)

Methods of lifting should be as shown below:

Barrel Lifting

© Use wide, long and flat slings to maineain sufficienely wide

apart support to prevent accidental sippage (Picture 4).

Use of wire ropes as chain slings may potentially slip and

damage the coating of pipes (strictly prohibited).

A single sling may be used on site, In this case, lft the

pipe at its centre of gravity, with the sling gripping the

pipe to prevent slippage (Picture 5)

© Bundle Lifting

DN 100 to DN300 bundles is unloaded with tong flat

textile slings or a spreader bar (Picture 6).

© Forklifts

Use of forklift equipment for lifting is allowed,

Pied

Pied

so)

St ker

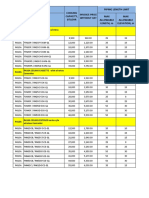

Storage & Stacking Nomina! Size py __ReCommended Maximum

© Theisenaris io Number Of Layers in Sack

Avoid: Marshy ground, Siting, Corrsive sols

© Sek tayo lees ple (oe eee too 8

accordance with rational storage plan = 2

(© Use suficienty strong, good quality hard woods (cimbers, 350 io

wedges) 300 @

(© Commonly used methods of stacking should be of 350 7

pre-bundle stacking, square stacking or pyramid stack as 400 6

shown in pictures 7,8 and 9. ase 5

500 5

609 4

| Recommended Stacking Height oo ‘

| © The height of stacks are determined by consideration of:

| The stress on the lowest layer of pipes in the stack

The total life given by the availabe crane.

-The facilities available to ensure stable stacking PicT:Pre-Bundle

Must Avoid

© Dragging the pipes on the ground, s this risks damaging

the external coating

‘© Dropping pipes to the ground, even with tyres or sand

interposed

© Scringing out pipes in areas of risk: e.g frequently moving Pic 8: Square Stacking

machines, use of explosives (risk of airborne stones)

‘© Depositing pipes on precariously balanced surfaces

Pic. Pyramid Stacking ,

BSc rol ation 8 (ola aa

Piei0 Assembly of Rubber Ring

‘© Ensure socket seat and gasket are free from all sol, sand

and debris particles. :

© Ensure spigot is chamfer and in good condition. even after |

Pipe is cu. re-chamfer is needed, i

x ae ‘© Ensure lubrication paste is apply to exposed surface of the

‘gasket. the spigot end and chamfer. :

y Joint Preparation i

eens

© Apply a thin fim of lubricant to the internal surface of the

rubber ring and to outside surface of spigot.

Pic.13: Crowbar:DN 100-DN 150

nt Assembly

© Align and center the spigot with the socket.

‘© Assembie by using either Crowbar Method (for smaller

diameter only) or Excavator Bucket (Pic.13 & 14)

‘© Push slowly and steadily unul the joint s made to

the correct insertion depth, where one of the painted

stripes on the spigot end disappears and the other stripe

is visible outside,

Pic. 4: Assembly using excavator bucket

‘Check the insertion condition. Confirm the proper

position of the rubber ring by inserting a feeler gauge

into the gap between the socket and spigot. and the

socket end is positioned between the two dotted lines

provided by the manufacturer on the spigot end

(Consult YLI technical personnel if necessary),

The pipe socket face must be protected with a piece of

hard wood

Push slowly and steadily, observing the rules for pipe

Night faving Fipe laying jointing (consult YLI if necessary)

ln Penang, Malaysia fn East Malaysia

aa :

Over 200 various sizes of fittings are available at your convenience. Tees, Bends, Flanged Sockets, Flanged

Spigots, Concentric Tapers, Flanged Belimouths, Blank Flanges, Reducing Flanges, and others (see technical

specifications catalogue),

YL also offers a full range of tapping saddles and Joints (Gate valves) for Ductile Iron,

gate valves and other accessories.

Bitumen coated externally,

‘Cement Mortar lined internally

Hot Fusion epoxy coated

(both internally and externally)

3

Oo?

Hydrostatic Pressure Test

Ck

PVC and AC pipelines,

Ductile fron Fittings

Sizes Available:

DN 100 - 700 mm

Bend

= Double-socket 90° bend

= Double-socket 45° bend

= Double-socker 22 1/2° bend

= Double-socket 11 1/4° bend

= Double-flanged 90° bend

- Double-flanged 45° bend

- Double-flanged 22 1/2° bend

= Double-flanged 11 1/4° bend

= Double-flanged 90° long bend

Duckfoot Bend

- Double-flanged 90° bend

Tee

= All-socket tee

~All flanged tee

= Double-socket tee with flanged branch

Concentric Taper

= Double-socket taper

Double-flanged taper

Gate Valve BS 5163 Type B

DN 80 - DN 300

A

Technical Specifications

PUSHLIN JOINT DUCTILE IRON PIPES

YEW LEAN FOUNDRY & COMPANY SDN. BHD. ane

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Traffic Analysis - Express ElevatorДокумент30 страницTraffic Analysis - Express ElevatorIswadi Bin ZulkarnainОценок пока нет

- Lakasa Sediment InterceptorДокумент1 страницаLakasa Sediment InterceptorIswadi Bin ZulkarnainОценок пока нет

- Aura Lite General Brochures Malaysia Rainwater Harvesting 2015Документ7 страницAura Lite General Brochures Malaysia Rainwater Harvesting 2015Iswadi Bin Zulkarnain100% (1)

- NIKKON HID Lighting Catalogue PDFДокумент95 страницNIKKON HID Lighting Catalogue PDFIswadi Bin ZulkarnainОценок пока нет

- Lighting PDFДокумент99 страницLighting PDFIswadi Bin ZulkarnainОценок пока нет

- Lakasa Sand InterceptorДокумент1 страницаLakasa Sand InterceptorIswadi Bin ZulkarnainОценок пока нет

- Fidic Codeofethics 201510Документ2 страницыFidic Codeofethics 201510Iswadi Bin ZulkarnainОценок пока нет

- 11.ACMV (Electrical) PDFДокумент22 страницы11.ACMV (Electrical) PDFIswadi Bin Zulkarnain100% (1)

- Building Services 2 BLD 60503 Case Study PDFДокумент88 страницBuilding Services 2 BLD 60503 Case Study PDFIswadi Bin Zulkarnain100% (3)

- 3.ACMV (Air Cooled Split Unit) - PDFДокумент3 страницы3.ACMV (Air Cooled Split Unit) - PDFIswadi Bin ZulkarnainОценок пока нет

- 12.ACMV (Painting & Labelling) - PDFДокумент3 страницы12.ACMV (Painting & Labelling) - PDFIswadi Bin ZulkarnainОценок пока нет

- Epp 20Документ2 страницыEpp 20Iswadi Bin ZulkarnainОценок пока нет

- List of Suppliers M&EДокумент6 страницList of Suppliers M&EIswadi Bin ZulkarnainОценок пока нет

- DAIKIN PRICING & PIPING LENGTH - Inverter Series (19 - 5 - 16) PDFДокумент1 страницаDAIKIN PRICING & PIPING LENGTH - Inverter Series (19 - 5 - 16) PDFIswadi Bin ZulkarnainОценок пока нет

- DAIKIN PRICING & PIPING LENGTH - Non Inverter Series (19 - 5 - 16) PDFДокумент3 страницыDAIKIN PRICING & PIPING LENGTH - Non Inverter Series (19 - 5 - 16) PDFIswadi Bin ZulkarnainОценок пока нет

- PBA Jadual 5 Anggaran Permintaan Air 2015Документ2 страницыPBA Jadual 5 Anggaran Permintaan Air 2015Iswadi Bin ZulkarnainОценок пока нет

- DAIKIN PRICING & PIPING LENGTH - Non Inverter Series (19 - 5 - 16) PDFДокумент3 страницыDAIKIN PRICING & PIPING LENGTH - Non Inverter Series (19 - 5 - 16) PDFIswadi Bin ZulkarnainОценок пока нет

- Battery RoomДокумент7 страницBattery RoomIswadi Bin ZulkarnainОценок пока нет

- List of Suppliers M&EДокумент2 страницыList of Suppliers M&EIswadi Bin ZulkarnainОценок пока нет