Академический Документы

Профессиональный Документы

Культура Документы

Guide Haccp Systems Vol2

Загружено:

Bianca IonescuАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Guide Haccp Systems Vol2

Загружено:

Bianca IonescuАвторское право:

Доступные форматы

Guidance Document

A guide to HACCP systems

in the Meat Industry

Volume 2

23 March 2017

This version contains no change in technical content from the version issued in August 2004,

but is issued with MPI branding, and formatting.

A guidance document issued by the Ministry for Primary Industries

Guidance Document: A guide to HACCP systems in the Meat Industry

23 March 2017

Title

Guidance Document: A guide to HACCP systems in the Meat Industry

About this document

This guidance document provides information to assist meat processors in the development of their Hazard

Analysis Critical Control Point (HACCP) systems.

Related Requirements

Animal Products Notice: Specification for Products Intended for Human Consumption

Animal Products Notice: Specification for Products Intended for Animal Consumption

Document history

No. Current Section Changed Change(s) Description

Version Date

1 August 2004

2 23 March 2017 All New format and branding only.

Content not reviewed

Contact Details

Contact for further information:

Ministry for Primary Industries (MPI)

Regulation & Assurance Branch

Animal Products

PO Box 2526

Wellington 6140

Email: animal.products@mpi.govt.nz

Disclaimer

This guidance does not constitute, and should not be regarded as, legal advice. While every effort has been

made to ensure the information in this guidance is accurate, the Ministry for Primary Industries does not accept

any responsibility or liability whatsoever for any error of fact, omission, interpretation or opinion that may be

present, however it may have occurred.

Copyright

Crown copyright ©. This copyright work is licensed under the Creative Commons Attribution 3.0 New Zealand

licence. In essence, you are free to copy, distribute and adapt the work, as long as you attribute the work to the Ministry for Primary

Industries and abide by the other licence terms. To view a copy of this licence, visit http://creativecommons.org/licenses/by/3.0/nz/.

Please note that no governmental emblem, logo or Coat of Arms may be used in any way which infringes any provision of the Flags,

Emblems, and Names Protection Act 1981 or would infringe such provision if the relevant use occurred within New Zealand.

Attribution to the Ministry for Primary Industries should be in written form and not by reproduction of any such emblem, logo or Coat of

Arms.

Ministry for Primary Industries Page 1 of 233

Guidance Document: A guide to HACCP systems in the Meat Industry

23 March 2017

Contents Page

1 Purpose 6

2 Background 6

3 Definitions 6

4 Template for Establishing a HACCP Plan for Slaughter and Dressing 7

4.1 Prerequisite Requirements 7

4.2 Scope of HACCP Plan 7

4.3 Product Description and Intended Use 7

4.4 Setting Initial Food Safety Objectives for the Process 8

4.5 Constructing a Process Flow Diagram 8

4.6 Job Descriptions 10

4.7 Raw Material Hazard Identification 11

4.8 Process Step Hazard Identification 12

4.9 Hazard Responsibilities 13

4.10 Confirmed Food Safety Objectives (FSOs) 13

4.11 Critical Control Point (CCP) Determination 13

4.12 Establishing Critical Limits 16

4.13 Monitoring CCPs 16

4.14 Setting Corrective Actions 16

4.15 Verification of the HACCP Plan 16

4.16 Documentation and Recordkeeping 17

5 Template for Establishing a HACCP Plan for Further Processing of Meat and Meat

Products 18

5.1 Prerequisite Requirements 18

5.2 Scope of HACCP Plan 18

5.3 Product Description and Intended Use 18

5.4 Setting Initial Food Safety Objectives for the Process 19

5.5 Constructing a Process Flow Diagram 19

5.6 Job Descriptions 21

5.7 Hazard Analysis and CCP Determination 22

5.8 Confirmed Food Safety Objectives (FSOs) 23

5.9 Establishing Critical Limits 23

5.10 Monitoring CCPs 23

5.11 Setting Corrective Actions 25

5.12 Verification of the HACCP Plan 25

5.13 Documentation and Recordkeeping 25

6 Generic HACCP Plan for Slaughter and Dressing of Cattle 27

6.1 Prerequisite Requirements 27

6.2 Scope of HACCP Plan 27

6.3 Product Description and Intended Use 27

6.4 Initial Food Safety Objectives 28

6.5 Process Flow Diagram 28

6.6 Job Descriptions 30

6.7 Raw Material Hazard Identification 30

6.8 Process Step Hazard Identification 31

6.9 Hazard Responsibilities 34

6.10 Confirmed Food Safety Objectives (FSOs) 34

Ministry for Primary Industries Page 2 of 233

Guidance Document: A guide to HACCP systems in the Meat Industry

23 March 2017

6.11 Critical Control Point (CCP) Determination 35

6.12 Completion of the HACCP Plan 37

6.13 Verification of the HACCP Plan 37

6.14 Background Information 42

6.15 References 49

7 Generic HACCP Plan for Cooling and Boning of Beef 52

7.1 Prerequisite Requirements 52

7.2 Scope of HACCP Plan 52

7.3 Product Description and Intended Use 52

7.4 Initial Food Safety Objectives 53

7.5 Process Flow Diagram 53

7.6 Job Descriptions 55

7.7 Hazard Analysis and CCP Determination 55

7.8 Confirmed Food Safety Objectives (FSOs) 62

7.9 Completion of the HACCP Plan 62

7.10 Verification of the HACCP Plan 62

7.11 Background Information 70

7.12 References 76

8 Generic HACCP Plan for the Manufacture of Raw Beef Patties 79

8.1 Prerequisite Requirements 79

8.2 Scope of HACCP Plan 79

8.3 Product Description and Intended Use 79

8.4 Initial Food Safety Objectives 80

8.5 Process Flow Diagram 80

8.6 Job Descriptions 82

8.7 Hazard Analysis and CCP Determination 83

8.8 Confirmed Food Safety Objectives (FSOs) 90

8.9 Completion of the HACCP Plan 90

8.10 Verification of the HACCP Plan 90

8.11 Background Information 93

8.12 References 99

9 Generic HACCP Plan for the Manufacture of Beef Jerky 102

9.1 Prerequisite Requirements 102

9.2 Scope of HACCP Plan 102

9.3 Product Description and Intended Use 103

9.4 Initial Food Safety Objectives 103

9.5 Process Flow Diagram 103

9.6 Job Descriptions 105

9.7 Hazard Analysis and CCP Determination 105

9.8 Confirmed Food Safety Objectives (FSOs) 112

9.9 Completion of the HACCP Plan 112

9.10 Verification of the HACCP Plan 112

9.11 Background Information 117

9.12 References 123

10 Generic HACCP Plan for Canning (Corned Beef) 126

10.1 Prerequisite Requirements 126

10.2 Scope of HACCP Plan 126

10.3 Product Description and Intended Use 126

10.4 Initial Food Safety Objectives 127

10.5 Process Flow Diagram 127

10.6 Job Descriptions 129

Ministry for Primary Industries Page 3 of 233

Guidance Document: A guide to HACCP systems in the Meat Industry

23 March 2017

10.7 Hazard Analysis and CCP Determination 129

10.8 Confirmed Food Safety Objectives (FSOs) 130

10.9 Completion of the HACCP Plan 135

10.10 Verification of the HACCP Plan 135

10.11 References 136

11 Generic HACCP Plan for Slaughter and Dressing of Sheep and Lambs 139

12 Generic HACCP Plan for the Processing of Edible Sheep and Lamb Casings 140

12.1 Prerequisite Requirements 140

12.2 Scope of HACCP Plan 140

12.3 Product Description and Intended Use 140

12.4 Initial Food Safety Objectives 141

12.5 Process Flow Diagram 141

12.6 Job Descriptions 143

12.7 Hazard Analysis and CCP Determination 143

12.8 Confirmed Food Safety Objectives (FSOs) 144

12.9 Completion of the HACCP Plan 144

12.10 Verification of the HACCP Plan 149

12.11 Background Information 150

12.12 References 153

13 Generic HACCP Plan for Slaughter, Dressing, Portioning and Deboning of Chicken

(Broilers) 155

13.1 Supporting Systems 155

13.2 Scope of HACCP Plan 155

13.3 Product Description and Intended Use 156

13.4 Initial Food Safety Objectives 156

13.5 Process Flow Diagram 156

13.6 Job Descriptions 160

13.7 Hazard Analysis and CCP Determination 160

13.8 Confirmed Food Safety Objectives (FSOs) 176

13.9 Completion of the HACCP Plan 176

13.10 Verification of the HACCP Plan 176

13.11 Background Information 181

13.12 References 196

14 Generic HACCP Plan for Slaughter and Traditional Dressing of Farmed Deer 202

14.1 Prerequisite Requirements 202

14.2 Scope of HACCP Plan 202

14.3 Product Description and Intended Use 202

14.4 Initial Food Safety Objectives 203

14.5 Process Flow Diagram 203

14.6 Job Descriptions 205

14.7 Hazard Analysis and CCP Determination 205

14.8 Hazard Responsibilities 215

14.9 Confirmed Food Safety Objectives (FSOs) 215

14.10 Completion of the HACCP Plan 216

14.11 Verification of the HACCP Plan 218

14.12 Background Information 219

14.13 References 225

15 Generic Model for Potable Water 229

15.1 Prerequisite Requirements 229

15.2 Scope of HACCP Plan 229

Ministry for Primary Industries Page 4 of 233

Guidance Document: A guide to HACCP systems in the Meat Industry

23 March 2017

15.3 Product Description and Intended Use 229

15.4 Food Safety Objectives 229

15.5 Process Flow Diagram 229

15.6 Job Descriptions 230

15.7 Raw Material Hazard Identification 230

15.8 Process Step Hazard Identification 230

15.9 Confirmation of food safety objectives 231

15.10 Completion of the HACCP plan 232

15.11 Validation of the HACCP plan 232

Ministry for Primary Industries Page 5 of 233

Guidance Document: A guide to HACCP systems in the Meat Industry

23 March 2017

1 Purpose

The purpose of this document is to assist meat processors in the development of their Hazard Analysis

Critical Control Point (HACCP) systems.

2 Background

The Guide to HACCP Systems in the Meat Industry was produced by the Ministry for Primary Industries (MPI)

in association with the HACCP Steering Group (MPI, a number of food producing industries and the Ministry

of Health) to:

Volume 1 explains the concepts and principles of HACCP and provides guidance on HACCP

development and implementation, auditing HACCP plans, and HACCP training.

Volume 2 (this document) provides templates and generic HACCP plans for a range of meat

processing systems.

HACCP will continuously evolve, and the contents of this document will be updated as new information from

both national and international sources becomes available.

3 Definitions

Refer Guide to HACCP Systems in the Meat Industry Volume 1, Section 3.

Ministry for Primary Industries Page 6 of 233

Guidance Document: A guide to HACCP systems in the Meat Industry

23 March 2017

4 Template for Establishing a HACCP Plan for Slaughter and

Dressing

Previously Appendix VIII.1

4.1 Prerequisite Requirements

List all documented prerequisite programmes/sanitation standard operating procedures (SSOPs) which are

relevant to the HACCP plan.

Prior to starting the HACCP plan, the HACCP team should ensure that all relevant prerequisite programmes

are covered by separate documented systems and that they are substantially in compliance with regulatory

requirements/specifications for good manufacturing practice (GMP). Development of documented systems for

prerequisite programmes may benefit from the application of HACCP principles.

For slaughter and dressing, examples of prerequisite programmes are:

sanitary design;

potable water quality;

sanitation and clean-up procedures for edible areas and food contact surfaces (preoperational and

operational);

hygiene of personnel (protective clothing requirements, personal equipment and use of amenities);

training;

hygienic dressing (dressing techniques and procedures, personnel, equipment, dropped meat);

food contact materials (specifications, handling and storage);

repairs and maintenance of equipment;

control of chemicals;

vermin control;

waste disposal;

condition of stock (cleanliness of animals).

4.2 Scope of HACCP Plan

Establish the scope of the HACCP plan

HACCP application: Food safety

Product: Enter species

Process: Enter process, including segment of food chain

4.3 Product Description and Intended Use

Describe the final product and its intended use. Note any particular food safety requirements for this final

product.

Table 1 provides a template for this purpose. Note any sections that are not applicable. This can be used for

the overall product description, i.e. it is not necessarily restricted to food safety aspects.

Ministry for Primary Industries Page 7 of 233

Guidance Document: A guide to HACCP systems in the Meat Industry

23 March 2017

Table 1: Product description and intended use

Product Intended Use

1 Product name(s)

2 Important product characteristics

3 How is it to be used:

(a) By a further processor or retailer

(b) By the consumer

4 Intended consumer

5 Packaging

6 Shelf life and storage requirements

7 Where it will be sold

(a) Export market

(b) Local market

8 Labelling instructions

9 Special distribution controls required

4.4 Setting Initial Food Safety Objectives for the Process

List the initial food safety objectives (FSOs) for the process.

Food safety objectives describe the expectations of hygiene measures that are applied during a particular

segment of a food production process. These objectives should include measurable outcomes expected for

the final product and may relate specifically to a HACCP plan, to activities outside the scope of a HACCP plan

(i.e. prerequisite programmes), or to both.

The processor should initially formulate food safety objectives when discussing and documenting the

desired/expected levels of control of hazards in the final product, considering its intended use. These

objectives should be confirmed as appropriate in Section 4.10, after the hazard identification and

determination of hazard responsibilities are completed. This ensures that control of all identified hazards

which are the responsibility of the processor are properly addressed, either directly or by association with

other measures (e.g. indicator organisms, on-line physical parameters). The appropriate level of control may

be achieved by the implementation of a HACCP plan and/or by prerequisite (GMP) programmes.

4.5 Constructing a Process Flow Diagram

Construct and confirm the process flow diagram. Show the relevant inputs and edible outputs for each

process step.

Inputs are defined as materials, such as consumable or non-consumable items, added to the product during

the process. These inputs and their hazards must be addressed by a prerequisite programme/SSOP, or

carried through to hazard identification within the HACCP plan.

Tables 2 and 3 provide templates for information on raw materials, other inputs and the process flow diagram.

Ministry for Primary Industries Page 8 of 233

Guidance Document: A guide to HACCP systems in the Meat Industry

23 March 2017

Table 2: Raw materials / other inputs

Product names

Raw material / other inputs Description/specification

Table 3: Process flow diagram

Process

Inputs Process steps Edible outputs

Ministry for Primary Industries Page 9 of 233

Guidance Document: A guide to HACCP systems in the Meat Industry

23 March 2017

4.6 Job Descriptions

Write a job description for each process step.

Table 4 can be used as a template for this information and provides for a summary of food safety

responsibilities.

There is flexibility as to when job descriptions are confirmed. This may be left until after the hazard analysis

and critical control point determination is completed.

Table 4: Example template for job description

Job description

Process step no:

Summary list of food safety responsibilities of operator: (confirm after HACCP plan completed)

Reference:

Ministry for Primary Industries Page 10 of 233

Guidance Document: A guide to HACCP systems in the Meat Industry

23 March 2017

4.7 Raw Material Hazard Identification

Identify biological, chemical and physical hazards relating to raw material and other inputs at each process

step.

Hazards may be specifically defined where appropriate (e.g. Cysticercus bovis) or presented as a class (e.g.

microbiological hazards associated with faeces and ingesta).

4.7.1 Raw material hazards

Raw material consists of the following components:

carcass/head/offals;

gastrointestinal tract (GIT);

fleece/hide/pelt.

Identify the hazards associated with each raw material component. These are summarised in a generic table

in Table 5A.

4.7.2 Other input hazards

Identify any hazards associated with inputs other than the raw material, for each process step. Generally,

these hazards are addressed by appropriate prerequisite programmes/SSOPs. If not, these hazards should

be shown in Table 5B.

Table 5A: Hazard identification for raw materials

Raw material Biological hazard Chemical hazard Physical hazard

The example below shows the range of hazards associated with livestock as a raw material.

Table 5A: Hazard identification for raw material (delete those hazards not applicable to the species

selected)

Raw material Biological hazard Chemical hazard Physical hazard

Carcass/head/offals B1 – Microbiological hazards C1 – Chemical hazards P1 – (As applicable to

associated with grossly- associated with identified species)

detectable abnormalities, i.e. chemical residues, e.g.

fever, abscesses suspect lines, injection site

lesions (ISLs)

B2 – Microbiological hazards

not grossly detectable, e.g. C2 – Chemical hazards

Toxoplasma gondii within the associated with unidentified

musculature; bacteraemia chemical residues, e.g.

anthelmintics, antibiotics,

B3 – Visible parasites environmental contaminants.

Ministry for Primary Industries Page 11 of 233

Guidance Document: A guide to HACCP systems in the Meat Industry

23 March 2017

Raw material Biological hazard Chemical hazard Physical hazard

Gastrointestinal tract B4 – Microbiological Not applicable Not applicable

hazards1 associated with

faeces and ingesta, e.g.

Salmonella spp., E. coli

O157:H7

Fleece/hide/pelt B5 – Microbiological Not applicable Not applicable

hazards associated with

1

contamination of fleece/ hide

/pelt, with faeces, dirt, e.g.

Salmonella spp., E. coli

O157:H7

1

Hazard may be transferred from one raw material component to another as either unseen or grossly detectable

contamination.

Hazard may be redistributed on a raw material component as either unseen or grossly-detectable contamination.

4.8 Process Step Hazard Identification

Identify hazards that can be reasonably expected to occur for each process step shown in the process flow

diagram, considering raw material and other input hazards. Note any transfer or redistribution of raw material

hazards at a particular step. Record the findings in Table 5B.

Table 5B: Hazard identification information for slaughter and dressing

Process Raw material Transfer2 of Redistribution2 Other inputs

step hazards to of hazards on

product product

Components Hazards1 Components Hazards

1

The following codes have been used in the generic HACCP plans:

B - Biological B1 to B5 apply to raw material

B1 – Microbiological hazards associated with grossly-detectable abnormalities

B2 – Microbiological hazards not grossly detectable

B3 – Visible parasites

B4 – Microbiological hazards associated with faeces and ingesta from GIT

B5 – Microbiological hazards associated with fleece/hide/pelt

B6 – Microbiological hazards associated with other inputs

C - Chemical C1 to C2 apply to raw material

C1 – Chemical hazards associated with identified chemical residues

Ministry for Primary Industries Page 12 of 233

Guidance Document: A guide to HACCP systems in the Meat Industry

23 March 2017

C2 – Chemical hazards associated with unidentified chemical residues

C3 – Chemical hazards associated with other inputs

P - Physical P1 – Physical hazards associated with raw material

P2 – Physical hazards associated with other inputs

2

This is an additive effect through the process.

4.9 Hazard Responsibilities

Identify the processor’s and regulator’s responsibilities relating to control of identified hazards associated with

the carcass in Table 5C. Indicate the process step/s at which the identified hazard is expected to be

controlled.

Some hazards will remain unaddressed at the end of the process and they should be highlighted for

consideration elsewhere in the food chain, e.g. at the farm (pre-harvest segment).

Table 5C: Processor and regulator responsibilities for control of hazards associated with the carcass

Identified Hazard Processor responsibility Regulator responsibility Unaddressed hazard

4.10 Confirmed Food Safety Objectives (FSOs)

List the confirmed food safety objectives.

Food safety objectives that reflect the processor’s responsibilities should be confirmed as appropriate for the

product. These objectives should cover all the identified hazards to be controlled by the processor.

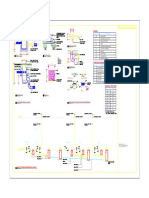

4.11 Critical Control Point (CCP) Determination

Determine the CCPs using the decision tree (see Figure 1 and Table 6), considering only those identified

hazards that the processor is primarily responsible for controlling. Apply the decision tree to each identified

hazard at each step.

The rationale for the answers given to the questions in the decision tree should be documented as

part of the HACCP plan. For Question 1 (i.e. whether the hazard could be present in or on the product

at unacceptable levels), reference to the scientific literature, surveys, company experience and/or

historical data would be helpful as supporting information.

Ministry for Primary Industries Page 13 of 233

Guidance Document: A guide to HACCP systems in the Meat Industry

23 March 2017

Figure 1. CCP Decision tree

Answer each question in sequence at each process step for each identified hazard

Q1. Could the hazard be present in or on the product1 at unacceptable2 levels at this step?

Yes – give reasons and go to Q2 No – not a CCP. Proceed to next identified hazard

Q2. Is there a control measure available at this step that would prevent unacceptable 2 levels of the

hazard?

Yes – this step is a CCP. Answer Q3 No – not a CCP. Answer Q3

Q3. Is there a control measure available at a previous step which would significantly contribute to

preventing unacceptable2 levels of the hazard at this step?

Yes – retrospectively assign the previous step as a No – If the answer to Q2 was also "no", consider the

CCP previous step as a CCP whether any subsequent

steps can control the hazard or whether redesign of

the process/product is necessary to ensure a control

measure is available

Proceed to next identified hazard

1

Product is defined as the edible component of final product.

2

Unacceptable — as demonstrated by data (scientific literature, applied research or on-site experience, National

Microbiological Database) associated with achieving the food safety objectives established for the process. In the

determination of unacceptability, hazards should be considered in terms of:

– level;

– frequency;

– transfer and redistribution;

– severity of effect on consumer.

Ministry for Primary Industries Page 14 of 233

Guidance Document: A guide to HACCP systems in the Meat Industry

23 March 2017

Table 6: CCP determination for a slaughter and dressing process

Process Identified Q1. Could the hazard Q2. Is there a control Q3. Is there a control CCP

step hazard be present in or on measure available at measure available at a no:

the product1 at this step that would previous step which

unacceptable2 levels prevent unacceptable2 would significantly

at this step? levels of the hazard? contribute to preventing

If Yes – give reasons and If Yes – this step is a CCP. unacceptable levels of

2

go to Q2 Go to Q3 the hazard at this step?

If No – not a CCP. If No – not a CCP. Go to If Yes – retrospectively

Proceed to next identified Q3. assign that step as a CCP

hazard If No and if the answer to Q2

was No, consider whether

any subsequent steps can

control the hazard or whether

redesign of the process /

product is necessary to

ensure a control measure is

available

Proceed to next identified

hazard

1

Product is defined as the edible component of final product.

2

Unacceptable — as demonstrated by data (scientific literature, applied research or on-site experience, National

Microbiological Database) associated with achieving the FSOs established for the process. In the determination of

unacceptability, hazards should be considered in terms of:

– level;

– frequency;

– transfer and redistribution;

– severity of effect on consumer.

Ministry for Primary Industries Page 15 of 233

Guidance Document: A guide to HACCP systems in the Meat Industry

23 March 2017

4.12 Establishing Critical Limits

Determine clearly defined and measurable critical limits for each hazard at each CCP. Visual observations will

provide the most useful critical limits for slaughter and dressing.

The rationale for the critical limits should be fully documented as part of the HACCP plan.

Summarise the critical limits in Table 7.

4.13 Monitoring CCPs

Establish monitoring parameters for each CCP.

Monitoring will rarely be continuous for slaughter and dressing systems. Statistically based sampling plans are

useful for providing a meaningful basis for a monitoring programme.

Monitoring procedures should be fully documented as part of the HACCP plan. Monitoring parameters

should include information on what method is to be used, who is responsible for monitoring, where

monitoring is done and how frequently it should be performed.

Summarise the monitoring parameters in Table 7.

4.14 Setting Corrective Actions

Establish specific corrective actions for each CCP to be used when the critical limits are exceeded.

These corrective actions must be designed to rapidly regain control at the CCP and should also have the

objective of preventing re-occurrence. In addition, corrective action may mean retaining product on the

slaughter line and, if necessary, altering its disposition.

Corrective action responsibilities and procedures should be fully documented as part of the HACCP

plan.

Summarise the corrective action responsibilities and procedures in Table 7.

4.15 Verification of the HACCP Plan

Establish verification activities that will confirm whether the HACCP plan is operating effectively and according

to documented procedures. Verification procedures should include the following:

Validation of the HACCP plan. This involves the initial confirmation that the HACCP plan is complete

and will achieve each of the food safety objectives. Validation should demonstrate that the HACCP

plan is at least equivalent to GMP-based controls at the premises, for all food safety objectives.

Identified CCPs should be evaluated to ensure that the control measure applied at that particular

process step will achieve or contribute to the achievement of the relevant food safety objective (FSO).

Validation should use standard techniques that allow in-house comparisons and also comparison with

national performance, e.g. the National Microbiological Database and national “targets” that are

obtained according to standard techniques.

Ongoing independent review of all components of the HACCP system, its documentation and records,

including corrective actions taken. This includes extrinsic review by customers and regulators. All

reviews (both internal and extrinsic) should be done under a formal audit procedure with appropriate

follow up for non-conformances to the HACCP plan.

Ministry for Primary Industries Page 16 of 233

Guidance Document: A guide to HACCP systems in the Meat Industry

23 March 2017

Product tests where appropriate, e.g. microbiological, visual.

Revalidation of the HACCP plan whenever changes are made (e.g. changes to premises product,

process, intended use of the product).

Verification responsibilities and procedures should be fully documented as part of the HACCP plan.

Summarise verification activities in Table 7.

4.16 Documentation and Recordkeeping

The need for appropriate documentation for the HACCP plan has been emphasised throughout this template.

Records also need to be kept for monitoring, corrective actions and verification results.

Summarise the types of records required to support the HACCP plan in Table 7.

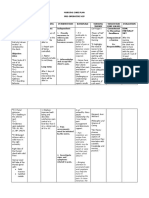

Table 7: HACCP plan summary spreadsheet

Process Hazard CCP Critical limits Monitoring Corrective Verification HACCP

step ID no. procedures/tools actions procedures records

(consider Who, What,

When and How)

Ministry for Primary Industries Page 17 of 233

Guidance Document: A guide to HACCP systems in the Meat Industry

23 March 2017

5 Template for Establishing a HACCP Plan for Further

Processing of Meat and Meat Products

Previously Appendix VIII.2

5.1 Prerequisite Requirements

List all documented prerequisite programmes/sanitation standard operating procedures (SSOPs) which are

relevant to the HACCP plan.

Prior to starting the HACCP plan, the HACCP team should ensure that all relevant prerequisite programmes

are covered by separate documented systems and that they are substantially in compliance with regulatory

requirements/specifications for good manufacturing practice (GMP). Development of documented systems for

prerequisite programmes may benefit from the application of HACCP principles.

For slaughter and dressing, examples of prerequisite programmes are:

sanitary design;

potable water quality;

sanitation and clean-up procedures for edible areas and food contact surfaces (preoperational and

operational);

hygiene of personnel (protective clothing requirements, personal equipment and use of amenities);

training;

hygienic processing (processing techniques and procedures, dropped meat);

food contact materials (specifications, handling and storage);

repairs and maintenance of equipment;

control of chemicals;

vermin control;

waste disposal;

refrigeration management;

handling and disposition of detained and nonconforming products.

5.2 Scope of HACCP Plan

Establish the scope of the HACCP plan

HACCP application: Food safety

Product: Enter species

Process: Enter process, including segment of food chain

5.3 Product Description and Intended Use

Describe the final product and its intended use. Note any particular food safety requirements for this final

product.

Table 1 provides a template for this purpose. Note any sections that are not applicable. This can be used for

the overall product description, i.e. it is not necessarily restricted to food safety aspects.

Ministry for Primary Industries Page 18 of 233

Guidance Document: A guide to HACCP systems in the Meat Industry

23 March 2017

Table 1: Product description and intended use

Product Intended Use

1 Product name(s)

2 Important product characteristics

3 How is it to be used:

(a) By a further processor or retailer

(b) By the consumer

4 Intended consumer

5 Packaging

6 Shelf life and storage requirements

7 Where it will be sold

(a) Export market

(b) Local market

8 Labelling instructions

9 Special distribution controls required

5.4 Setting Initial Food Safety Objectives for the Process

List the initial food safety objectives (FSOs) for the process.

Food safety objectives represent a relatively new concept that is continuing to evolve. An FSO describes the

expected outcomes of hygiene measures that are applied during a particular segment of a food production

process and can be defined by a working definition as: "A statement, in the ideal situation based on a risk

analysis process, which expresses the level of a hazard in a food that is tolerable in relation to an appropriate

level of consumer protection. When justified by either a qualitative or quantitative risk assessment, the FSO

should express the level of the hazard as its maximum tolerable frequency and/or concentration".

Thus an FSO should wherever possible include measurable levels of hazards in the final product that are

tolerable in terms of the validated outcome of a HACCP plan, prerequisite programmes, or both. This provides

an effective "target" for validation of the HACCP plan and/or prerequisite programmes, and ongoing hygiene

performance. In some cases, the "target" may already be specified in an industry-agreed standard, e.g. the

National Microbiological Database, or as a particular market access requirement, e.g. zero Listeria

monocytogenes tolerance in ready-to-eat foods.

The processor should initially formulate FSOs for the product relative to its intended end-use when discussing

the expected outcome of the particular food control programme. These FSOs should be confirmed as

appropriate in Section 5.8, after the hazard analysis has been completed. This allows due consideration to be

given to those hazards found to be unacceptable during the analysis process and additional FSOs to be set

where necessary.

5.5 Constructing a Process Flow Diagram

Construct and confirm the process flow diagram. Show the relevant inputs and edible outputs for each

process step. These inputs and their hazards must be addressed by a prerequisite programme/SSOP, or

specifically considered during hazard identification in the HACCP plan.

Tables 2 and 3 provide templates for information on raw materials, other inputs and the process flow diagram.

Ministry for Primary Industries Page 19 of 233

Guidance Document: A guide to HACCP systems in the Meat Industry

23 March 2017

Table 2: Raw materials / other inputs

Product names

Raw material / other inputs Description/specification

Table 3: Process flow diagram

Process

Inputs Process steps Edible outputs

Ministry for Primary Industries Page 20 of 233

Guidance Document: A guide to HACCP systems in the Meat Industry

23 March 2017

5.6 Job Descriptions

Write a job description for each process step.

Table 4 can be used as a template for this information and provides for a summary of food safety

responsibilities.

There is flexibility as to when job descriptions are confirmed. This may be left until after the hazard analysis

and critical control point determination is completed.

Table 4: Job description

Job description

Process step no:

Summary list of food safety responsibilities of operator: (confirm after HACCP plan completed)

Reference:

Ministry for Primary Industries Page 21 of 233

Guidance Document: A guide to HACCP systems in the Meat Industry

23 March 2017

5.7 Hazard Analysis and CCP Determination

5.7.1 Raw material hazard identification

Identify biological, chemical and physical hazards that are reasonably likely to occur in the raw material. Raw

material may include meat (e.g. chilled beef carcass, trimmings) and non-meat ingredients (e.g. spices,

vegetables, food additives).

Hazards need to be specifically defined (e.g. Taenia saginata, Clostridium botulinum, shotgun pellets) or may

be identified as a class, based on their characteristics, when this is appropriate (e.g. enteric pathogens, spore

forming organisms, metal objects).

To avoid repetition and simplify hazard identification and analysis, codes may be assigned to the different

hazard categories. For example, hazards may be categorised by source (e.g. microbiological hazards from

non-meat ingredients) as well as by type (i.e. biological, chemical, physical). Codes may be carried forward

from a previous plan, particularly when this helps demonstrate continuity of the process and carry over of the

relevant hazards (e.g. slaughter and dressing to cooling and boning). Codes must be clearly defined in the

plan when used.

Identified raw material hazards are summarised in a generic table in Table 5A.

Table 5A: Hazard identification for raw materials

Raw material Biological hazard Chemical hazard Physical hazard

5.7.2 Hazard analysis and CCP determination (raw material, other inputs and process steps)

Record the identified raw material hazards from Section 5.7.1 in the appropriate column in Table 5B.

Identify any biological, chemical or physical hazards resulting from a process step requirement not being met

(e.g. metal from equipment). Process step hazards are expected to be a sporadic occurrence. Frequent

occurrence could indicate that a prerequisite programme is ineffective and needs to be improved. Process

step hazards may be controlled under effective prerequisite programmes and/or dealt with at CCPs in the

HACCP plan. Note that once these hazards are identified, they may become part of the raw material hazards

at subsequent steps if immediate control is unavailable.

Identify any biological, chemical or physical hazards that are reasonably likely to occur in association with

other inputs at each process step (e.g. packaging, processing aids). Generally, these hazards will be

addressed by appropriate prerequisite programmes (e.g. Supplier Quality Assurance (SQA) programme, food

contact materials). For more complex processes, such as those with multiple ingredients, a separate hazard

identification for each input may be essential.

Hazards must be analysed for each process step. Record comments on the potential impact of a process step

on hazards that are reasonably likely to occur (e.g. transfer or redistribution of raw material hazards, pathogen

growth). These comments can be recorded in the same column as process step hazards (see Table 5B

for the presentation). Careful consideration should be given to the effectiveness of the prerequisite

programmes when evaluating the impact of a process step.

Ministry for Primary Industries Page 22 of 233

Guidance Document: A guide to HACCP systems in the Meat Industry

23 March 2017

Hazard analysis may result in changes to the initial food safety objectives set in Section 5.4. See

Section 5.8 for confirmed objectives.

Consider whether each hazard could be present at an unacceptable level in relation to achieving the FSOs for

the process (Question 1, Table 5B) and provide justification. Reference to the scientific literature, surveys,

company experience and/or historical data will be helpful as supporting information. Record the outcomes of

the hazard analysis.

When Question 1 is answered “yes” (i.e. a hazard could be present at an unacceptable level), then answer

both questions 2 and 3 relating to control measures.

Even when there are control measures available at the step at which the hazard(s) is being analysed,

previous process steps should also be considered for control of the hazard. The absence of adequate control

measures at any step in the process means that redesign of the process/product should be undertaken so

that the FSO can be achieved. If redesign is impossible, the hazard must be identified as unaddressed within

the HACCP plan (or under GMP where it is the only identified hazard) for this product and process.

5.8 Confirmed Food Safety Objectives (FSOs)

List the confirmed FSOs.

FSOs relating to hazards identified as reasonably likely to occur may be controlled by both the HACCP plan

and/or prerequisite programmes. The confirmed FSOs may differ from those initially recorded, as a result of

the hazard analysis and CCP determination process.

5.9 Establishing Critical Limits

Determine clearly defined and measurable critical limits for control of unacceptable hazard(s) at each CCP.

The critical limits may be parameters that are indirectly related to these hazards, e.g. job descriptions.

The rationale for the critical limits should be fully documented as part of the HACCP plan

Summarise the critical limits in Table 6.

5.10 Monitoring CCPs

Establish monitoring parameters for each CCP.

Monitoring may be continuous (e.g. CATR monitoring) or intermittent (e.g. teardown procedure) for further

processing. Statistically based sampling plans are useful for providing a meaningful basis for a monitoring

programme.

Monitoring procedures should be fully documented as part of the HACCP plan. Monitoring procedures

shall include information on who is responsible for monitoring, what method is to be used, where

monitoring is to be done and how frequently it is to be performed.

Ministry for Primary Industries Page 23 of 233

Guidance Document: A guide to HACCP systems in the Meat Industry

23 March 2017

Table 5B: Hazard analysis and CCP determination (raw material, other inputs and process steps)

Process Inputs i) Process step Q1. Could the hazard be present in or on Q2. Is there a control Q3. Is there a control CCP

steps raw materials and other inputs hazards the product1 at unacceptable levels2 at this measure at this step that measure available at a No.

ii) Potential step? would prevent previous step that would

impact of If yes, answer Q2 and Q3. unacceptable levels of prevent unacceptable

process step the hazard? levels of the hazard?

on existing If yes, this step is a CCP. If yes, retrospectively assign

Component Hazards hazards Yes/No Justification If no, not a CCP. the previous step as a CCP.

1

Product is defined as the edible component of final product.

2

Unacceptable — as demonstrated by data (scientific literature, applied research or on-site experience) associated with achieving the FSOs established for the process. In the determination of

unacceptability, hazards should be considered in terms of:

– level;

– frequency;

– transfer and redistribution;

– severity of effect on consumer.

Ministry for Primary Industries Page 24 of 233

Guidance Document: A guide to HACCP systems in the Meat Industry

23 March 2017

5.11 Setting Corrective Actions

For each CCP, establish corrective actions to be used when the critical limits are exceeded.

These corrective actions must be designed to rapidly regain control at the CCP and shall also have the

objective of preventing re-occurrence wherever possible. Disposition of affected product is an important

component of corrective action procedures.

Corrective action responsibilities and procedures should be fully documented as part of the HACCP

plan.

Summarise the critical limits in Table 6.

5.12 Verification of the HACCP Plan

Establish verification activities that will confirm whether the HACCP plan is operating effectively and according

to documented procedures. Verification procedures shall include the following:

Validation of the HACCP plan. This involves the initial confirmation that the HACCP plan is complete

and will achieve each of the FSOs. Identified CCPs should be evaluated to ensure that the control

measure applied at that particular process step will achieve or contribute to the achievement of the

relevant FSO.

Validation should use standard techniques (where appropriate) that allow in-house comparisons and

also comparison with national performance, e.g. the National Microbiological Database and national

"targets".

Ongoing independent review of all components of the HACCP system, its documentation and records,

including corrective actions taken. This includes extrinsic review by customers and regulators. All

reviews (both internal and extrinsic) should be done under a formal audit procedure with appropriate

follow up for non-conformances to the HACCP plan.

Product tests where appropriate, e.g. microbiological, visual.

Revalidation of the HACCP plan whenever changes are made (e.g. changes to premises, product,

process, intended use of the product) or when process failure that may compromise product safety,

has been identified.

Verification responsibilities and procedures should be fully documented as part of the HACCP plan.

Summarise verification activities in Table 6.

5.13 Documentation and Recordkeeping

The need for appropriate documentation for the HACCP plan has been emphasised throughout this template.

Records also need to be kept for monitoring, corrective actions and verification results.

Summarise the types of records required to support the HACCP plan in Table 6.

Ministry for Primary Industries Page 25 of 233

Guidance Document: A guide to HACCP systems in the Meat Industry

23 March 2017

Table 6: HACCP plan summary spreadsheet

Process Hazard CCP Critical limits Monitoring Corrective Verification HACCP

step ID no. procedures/tools actions procedures records

(consider Who, What,

When and How)

Ministry for Primary Industries Page 26 of 233

Guidance Document: A guide to HACCP systems in the Meat Industry

23 March 2017

6 Generic HACCP Plan for Slaughter and Dressing of Cattle

Previously Appendix IX.1

6.1 Prerequisite Requirements

The following are documented prerequisite programmes:

sanitary design;

potable water quality;

sanitation and clean-up procedures for edible areas and food contact surfaces (preoperational and

operational);

personnel hygiene (protective clothing requirements, personal equipment and use of amenities);

training;

hygienic dressing (dressing techniques and procedures, personnel, equipment, dropped meat);

food contact materials (specifications, handling and storage);

repairs and maintenance of equipment;

control of chemicals;

vermin control;

waste disposal;

condition of stock (cleanliness of animals).

6.2 Scope of HACCP Plan

HACCP application: Food safety

Product: Bovine (excluding bobby calf)

Process: Slaughter and dressing of cattle, from receipt of livestock through to carcass

leaving slaughter floor.

6.3 Product Description and Intended Use

Table 1: Product description and intended use

Product Intended Use

1 Product name(s) Beef carcass

2 Important product characteristics Passed ante- and post-mortem inspection

Product meeting microbiological targets set by company

3 How is it to be used:

(a) By a further processor or retailer (a) Chilled/hot boned

(b) By the consumer (b) Raw or cooked

4 Intended consumer General public ("high-risk" groups not specified for this plan)

5 Packaging Not applicable

6 Shelf life and storage requirements Not applicable

7 Where it will be sold List countries, if applicable

(a) Export market

Ministry for Primary Industries Page 27 of 233

Guidance Document: A guide to HACCP systems in the Meat Industry

23 March 2017

(b) Local market

8 Labelling instructions Branded

Carcass ticket

9 Special distribution controls required Immediate dispatch to chiller or boning room

6.4 Initial Food Safety Objectives

(To be confirmed after hazard identification and determination of hazard responsibilities. See Section 6.10 for

confirmed objectives).

To minimise transfer and redistribution of microbiological hazards from the gastrointestinal tract and

the hide to the carcass, including control of grossly-detectable contaminants, to within specified

microbiological targets.

To remove all grossly-detectable abnormalities from carcasses that are retained at post mortem

inspection.

To identify all chemical "suspect" lines of livestock that are presented for slaughter, for subsequent

regulatory action.

6.5 Process Flow Diagram

Table 2: Raw materials / other inputs

Product names Beef carcass

Inputs Description/specification

Raw Material

Live animals Components

carcass/head/offals

gastrointestinal tract (GIT)

hide

Other Inputs1

Carcass tickets Suitable for use as food contact materials.

Branding ink Suitable for use as food contact materials.

1

Inputs are defined as incoming materials, such as consumable or non-consumable items, added to the product during

the process. These inputs and their hazards must be addressed by a prerequisite programme/SSOP, or carried through

to hazard identification within the HACCP plan.

2

Specifications and hygienic handling of these materials are covered by specific premises prerequisite programmes for

food contact materials.

Ministry for Primary Industries Page 28 of 233

Guidance Document: A guide to HACCP systems in the Meat Industry

23 March 2017

Table 3: Process flow diagram

Process Slaughter and dressing of cattle

Inputs Process steps Edible outputs

Livestock 1. Receive

2. Wash

3. Pen

4. Ante-mortem

Suspects

5. Pre-stun shower

6. Stun

7. Anal wash / shackle

8. a Thoracic stick1

8. b Halal stick1,2

9. Rod

10. Head removal Head

11. Hind leg

12. Ring

13. Hide removal

14. Brisket cut

15. Evisceration Offals

16. Carcass split

17. Post-mortem inspection

18 a Retain

18 b Reinspect

19. Trim

Carcass ticket / ink 20. Grade

21. Final wash Beef carcass

1

Process options.

Ministry for Primary Industries Page 29 of 233

Guidance Document: A guide to HACCP systems in the Meat Industry

23 March 2017

2.

For halal slaughter, regulations to ensure humane slaughter require that sticking of the animal is done before

shackling.

6.6 Job Descriptions

Table 4 should be completed and confirmed for each step in the particular process.

Table 4: Example template for job description

Job description

Process step no:

Summary list of food safety responsibilities of operator: (confirm after HACCP plan completed)

Reference:

6.7 Raw Material Hazard Identification

Table 5A: Hazard identification for cattle

Raw material Biological hazard Chemical hazard Physical hazard

Carcass/head/ B1 - Microbiological hazards C1 - Chemical hazards P1 - Shotgun pellets

offals associated with grossly- associated with identified

detectable abnormalities, i.e. chemical residues, e.g. suspect

fever, abscesses lines, injection site lesions

(ISLs)

B2 - Microbiological hazards

not grossly detectable, e.g. C2 - Chemical hazards

bacteraemia, Toxoplasma associated with unidentified

gondii chemical residues, e.g.

Ministry for Primary Industries Page 30 of 233

Guidance Document: A guide to HACCP systems in the Meat Industry

23 March 2017

Raw material Biological hazard Chemical hazard Physical hazard

B3 - Visible parasites, e.g. anthelmintics, antibiotics,

Taenia saginata (Cysticercus environmental contaminants.

bovis)

Gastrointestinal B4 - Microbiological hazards1 Not applicable Not applicable

tract associated with faeces and

ingesta, e.g. Salmonella spp.,

E. coli O157:H7, Clostridium

spp., Campylobacter jejuni

Hide B5 - Microbiological hazards1 Not applicable Not applicable

associated with contamination

of hide with faeces and dirt,

e.g. Salmonella spp., E. coli

O157:H7, Clostridium spp.,

Campylobacter jejuni

Udder (for cows) B72 - Microbiological hazards Not applicable Not applicable

associated with contamination

from mastitic milk, e.g.

Staphylococcus aureus

1

Hazards may be transferred from one raw material component to another as either unseen or gross contamination.

Hazards may be redistributed on a raw material component as either unseen or gross contamination.

2

B6 has already been allocated in Section 6.8 for slaughter and dressing as: "biological hazards associated with other

inputs"; hence B7 refers to contamination with mastitic milk

6.8 Process Step Hazard Identification

Table 5B: Process step hazard identification for slaughter and dressing of cattle

Process Raw material Transfer of Redistribution Other inputs

Step hazards to of hazards on

Components Hazards1 product 2,3 product2 Components Hazards

1. Receive Carcass/head/ B1, B2, B3, C1, C2,

offals P1

GIT B4

Hide B5

Udder (for cows) B7

2. Wash Carcass/head/ B1, B2, B3, C1, C2,

offals P1

GIT B4

Hide B5

Udder (for cows) B7

3. Pen Carcass/head/ B1, B2, B3, C1, C2,

offals P1

GIT B4

Hide B5

Udder (for cows) B7

4. Ante- Carcass/head/ B1, B2, B3, C1, C2,

mortem offals P1

GIT B4

Ministry for Primary Industries Page 31 of 233

Guidance Document: A guide to HACCP systems in the Meat Industry

23 March 2017

Process Raw material Transfer of Redistribution Other inputs

Step hazards to of hazards on

Components Hazards1 product 2,3 product2 Components Hazards

Hide B5

Udder (for cows) B7

5. Prestun Carcass/head/ B1, B2, B3, C1, C2,

shower offals P1

GIT B4

Hide B5

Udder (for cows) B7

6. Stun Carcass/head/ B1, B2, B3, C1, C2,

offals P1

GIT B4

Hide B5

Udder (for cows) B7

7. Anal Carcass/head/ B1, B2, B3, C1, C2, B5

wash/ offals P1

shackle GIT B4

Hide B5

Udder (for cows) B7

8a. Carcass/head/ B1, B2, B3, B5, C1, B5

Thoracic offals C2, P1

stick GIT B4

Hide B5

Udder (for cows) B7

8b. Halal Carcass/head/ B1, B2, B3, B5, C1, B4, B5

stick offals C2, P1

GIT B4

Hide B5

Udder (for cows) B7

9. Rod Carcass/head/ B1, B2, B3, B4, B5, B4

offals C1, C2, P1

GIT B4

Hide B5

Udder (for cows) B7

10. Head Carcass/head/ B1, B2, B3, B4, B5, B4, B5

removal offals C1, C2, P1

GIT B4

Hide B5

Udder (for cows) B7

11. Hind Carcass/head/ B1, B2, B3, B4, B5, B5, B74

leg offals C1, C2, P1

GIT B4

Hide B5

Udder (for cows) B7

12. Ring Carcass/offals B1, B2, B3, B4, B5, B4, B5

C1, C2, P1

GIT B4

Hide B5

Ministry for Primary Industries Page 32 of 233

Guidance Document: A guide to HACCP systems in the Meat Industry

23 March 2017

Process Raw material Transfer of Redistribution Other inputs

Step hazards to of hazards on

Components Hazards1 product 2,3 product2 Components Hazards

13. Hide Carcass/offals B1, B2, B3, B4, B5, B5

removal C1, C2, P1

GIT B4

Hide B5

14. Brisket Carcass/offals B1, B2, B3, B4, B5,

cut C1, C2, P1

GIT B4

15. Evis-- Carcass/offals B1, B2, B3, B4, B5, B4, B15

ceration C1, C2, P1

GIT B4

16. C/C Carcass B1, B2, B3, B4, B5, B4, B5

split C1, C2, P1

17. Post- Carcass B1, B2, B3, B4, B5, B4, B5

mortem C1, C2, P1

18a. Retain Carcass B1, B2, B4, B5, B4, B5

C16, C2, P1

18b. Carcass B2, B4, B5, C1, C2, B4, B5

Reinspect P1

Carcasses able to contact each other after step 17 on main chain and after step 18b if

retained

19. Trim Carcass B2, B4, B5, C1, C2, B4, B5 B4, B5

P1

20. Grade Carcass B2, B4, B5, C1, C2, B4, B5 Tickets Nil

P1 Ink Nil

21. Final Carcass B2, B4, B5, C1, C2, B4, B5

wash P1

1

The following codes have been used in the generic HACCP plan:

B - Biological B1 – Microbiological hazards associated with grossly-detectable abnormalities

B2 – Microbiological hazards not grossly detectable

B3 – Visible parasites

B4 – Microbiological hazards associated with faeces and ingesta from the GIT

B5 – Microbiological hazards associated with the hide

B6 – Microbiological hazards associated with other inputs

B7 – Microbiological hazards associated with mastitic milk

C - Chemical C1 – Chemical hazards associated with identified chemical residues

C2 – Chemical hazards associated with unidentified chemical residues

P - Physical P1 – Physical hazards associated with shotgun pellets

2

There is an additive effect through the process.

3

Product is defined as the edible component of the final product.

4

With certain cows, B7 may be transferred during removal of the udder. If this hazard is relevant to the company’s

process, then its transfer and redistribution at subsequent steps should be considered. However, for the purpose of this

generic model, this hazard will not be considered any further through succeeding sections of the HACCP plan.

Ministry for Primary Industries Page 33 of 233

Guidance Document: A guide to HACCP systems in the Meat Industry

23 March 2017

5

With certain classes of cattle, B1 may be transferred at evisceration. If this hazard is relevant to the company’s

process, then its transfer and redistribution at subsequent steps should be considered. However, for the purpose of this

generic model, this hazard will not be considered any further through succeeding sections of the HACCP plan.

6

Carcasses associated with chemical suspect lines are sampled and retained according to MPI specification. The

carcasses may progress through the remainder of the process as retained product.

6.9 Hazard Responsibilities

Table 5C: Processor and regulator responsibilities for control of hazards associated with the carcass

Identified Hazard Processor’s Regulator’s Unaddressed hazard

responsibility responsibility

B1 – Microbiological hazards Yes (Retain rail trim Yes (Antemortem

associated with grossly- only) inspection / postmortem

detectable abnormalities inspection / re-inspection)

B2 – Microbiological hazards No No Yes

not grossly detectable

B3 – Visible parasites No Yes (Post-mortem

inspection)

B4 – Micro hazards

transferred / redistributed

from gut

Unseen Yes (Key process Yes (Audit, NMD)

steps)

associated with gross Yes (Key process Yes (Inspection / re-

contamination with steps) inspection / audit)

faeces/ingesta

B5 – Micro hazards

transferred / redistributed

from hide

Unseen Yes (Key process Yes (Audit, NMD)

steps)

associated with gross Yes (Key process Yes (Inspection / re-

contamination from hide steps) inspection / audit)

C1 – Chemical hazards – Yes (Receiving only) Yes (Retain / sample /

suspect lines audit)

C2 – Chemical hazards – No Random sampling as per Yes (unaddressed by

unknown national programme processor)

P1 – Shotgun pellets No Yes (Inspection1) Yes (unaddressed by

processor)

1

Carcasses are inspected for shotgun pellets but detection rate is low due to low sensitivity of the inspection method.

6.10 Confirmed Food Safety Objectives (FSOs)

FSO1: To minimise transfer and redistribution of microbiological hazards from the gastrointestinal tract and

the hide to the carcass, including control of grossly-detectable contaminants, to within specified

microbiological targets.

Ministry for Primary Industries Page 34 of 233

Guidance Document: A guide to HACCP systems in the Meat Industry

23 March 2017

FSO2: To remove all grossly-detectable abnormalities from carcasses that are retained at post mortem

inspection.

FSO3: To identify all chemical "suspect" lines of livestock that are presented for slaughter, for subsequent

regulatory action.

6.11 Critical Control Point (CCP) Determination

Table 6: CCP determination for slaughter and dressing of cattle

Process step Identified hazard Q1. Could the Q2. Is there a Q3. Is there a control measure CCP

hazard be present control measure available at a previous step no

in or on the available at this step which would significantly

product1 at that would prevent contribute to preventing

unacceptable2 unacceptable2 levels unacceptable2 levels of the

levels at this step? of the hazard? hazard at this step?

If Yes, give reasons If Yes, this step is a If Yes, retrospectively assign that

and go to Q2 CCP. Go to Q3 step as a CCP

If No, not a CCP If No, not a CCP. Go If No, and if the answer to Q2

Proceed to next to Q3 was No, consider whether any

identified hazard subsequent steps can control the

hazard or whether redesign of

the process / product is

necessary to ensure a control

measure is available.

Proceed to next identified hazard

1. Receive B4. Micro – GIT No

B5. Micro – Hide No

C1. Chem Yes – reported Yes – identification of No 1

suspects incidences of non- suspect lines at this

compliance. Refer step

to Section 6.14.3.

2. Wash B4. Micro – GIT No

B5. Micro – Hide No

3. Pen B4. Micro – GIT No

B5. Micro – Hide No

4. A/M Refer to regulator

5. Prestun B4. Micro – GIT No

shower

B5. Micro – Hide No

6. Stun B4. Micro – GIT No

B5. Micro – Hide No

7. Anal B4. Micro – GIT No

wash/shackle

B5. Micro – Hide No

8a. Thoracic B4. Micro – GIT No

stick

B5. Micro – Hide No

8b. Halal B4. Micro – GIT No

stick

B5. Micro – Hide No

Ministry for Primary Industries Page 35 of 233

Guidance Document: A guide to HACCP systems in the Meat Industry

23 March 2017

Process step Identified hazard Q1. Could the Q2. Is there a Q3. Is there a control measure CCP

hazard be present control measure available at a previous step no

in or on the available at this step which would significantly

product1 at that would prevent contribute to preventing

unacceptable2 unacceptable2 levels unacceptable2 levels of the

levels at this step? of the hazard? hazard at this step?

9. Rod B4. Micro – GIT No

B5. Micro – Hide No

10. Head B4. Micro – GIT No

removal

B5. Micro – Hide No

11. Hind leg B4. Micro – GIT No

B5. Micro – Hide Yes – incorrect Yes – prevent No 2

procedures for unacceptable

opening cuts and contamination from

flaying will exceed the hide to the

acceptable micro carcass by correct

counts over a operator technique

significant surface

area on the hind

quarter. Refer to

Section 6.14.5.

12. Ring B4. Micro – GIT Yes - incorrect Yes – prevent faecal No 3

ringing will exceed contamination from

acceptable micro the bung by correct

counts over a operator technique

significant surface

area on the hind

section. Refer to

Section 6.14.5.

B5. Micro – Hide No

13. Hide B4. Micro – GIT No

removal

B5. Micro – Hide No

14. Brisket B4. Micro – GIT No

cut

B5. Micro – Hide No

15. Evisc B4. Micro – GIT No

B5. Micro – Hide No

16. Carcass B4. Micro – GIT No

split

B5. Micro – Hide No

17. PM Refer to regulator

inspection

18a.Retain B1. Micro – Yes – failure to trim Yes – hygienic No 4

grossly- / unhygienic trimming

detectable removal of grossly-

abnormalities detectable

abnormalities.

Refer to IS 5.

Ministry for Primary Industries Page 36 of 233

Guidance Document: A guide to HACCP systems in the Meat Industry

23 March 2017

Process step Identified hazard Q1. Could the Q2. Is there a Q3. Is there a control measure CCP

hazard be present control measure available at a previous step no

in or on the available at this step which would significantly

product1 at that would prevent contribute to preventing

unacceptable2 unacceptable2 levels unacceptable2 levels of the

levels at this step? of the hazard? hazard at this step?

B4. Micro – GIT Yes – failure to trim Yes – hygienic

/ unhygienic trimming

removal of gross

contamination.

Refer to IS 5.

B5. Micro – Hide Yes – failure to trim Yes – hygienic

/ unhygienic trimming

removal of gross

contamination.

Refer to IS 5.

18b. Re- Refer to regulator

inspect

Note: Carcasses may contact each other after step 17 on main chain and after 18a if retained.

19. Trim B4. Micro – GIT No

B5. Micro – Hide No

20. Grade B4. Micro – GIT No

B5. Micro – Hide No

21. Final B4. Micro – GIT No

wash

B5. Micro – Hide No

1

Product is defined as the edible component of the final product.

2

Unacceptable & as demonstrated by data (scientific literature, applied research or on-site experience, National

Microbiological Database) associated with achieving the FSOs established for the process. In the determination of

unacceptability, hazards should be considered in terms of: level, frequency, transfer and redistribution, and severity of

effect on consumer.

6.12 Completion of the HACCP Plan

Information on the critical limits applied for each of the CCPs, monitoring, corrective action and

verification procedures, and HACCP records should be fully documented as part of the HACCP plan.

Refer to Sections 4.12 to 4.16 of the Template for Establishing a HACCP Plan for Slaughter and Dressing for

detailed requirements.

Table 7 provides a summary of the plan. References to documented procedures should be shown in this table

6.13 Verification of the HACCP Plan

6.13.1 Validation of the HACCP plan

Validation of the HACCP plan involves the initial confirmation that the HACCP plan is complete and will

achieve each of the food safety objectives. Validation should also demonstrate that the HACCP plan is at

least equivalent to GMP-based controls at the premises, for all food safety objectives. Identified CCPs should

Ministry for Primary Industries Page 37 of 233

Guidance Document: A guide to HACCP systems in the Meat Industry

23 March 2017

be evaluated to ensure that the control measure applied at that particular process step, will achieve or

contribute to the achievement of the relevant food safety objective (FSO).

An example of how this generic HACCP plan may be validated is given below:

FSO1: To minimise transfer and redistribution of microbiological hazards from the gastrointestinal

tract and hide to the carcass.

The first FSO is expected to be achieved by providing adequate control measures at CCP2 (hind legging) and

at CCP3 (ringing). Therefore CCP2 and CCP3 should be evaluated as they relate to the achievement of

FSO1.

CCP2 (Hind legging)

For this CCP, the use of microbiological observations is appropriate for validation. Historical data

based on a standardised microbiological sampling programme (e.g. NMD) may be used for evaluating

this CCP. Companies that do not have a database should implement an appropriate standardised

microbiological sampling programme. Data obtained before the HACCP plan implementation (i.e.

historical data) should be compared to data obtained after HACCP implementation to ensure that the

HACCP plan is at least equivalent to GMP-based controls at the premises.

It should be noted that NMD data provides an on-going verification of the microbiological performance

of the whole process plan. However, NMD data may be used for evaluating CCP2 because the

microbiological consequence of this process step is reflected in data obtained from the NMD

programme.

When historical data is not available or is inadequate, microbiological validation will involve the

collection of new data from when the HACCP plan is implemented.

The following is an example of an appropriate design for microbiological validation in the absence of

benchmark or historical data:

Sample size: 25 carcasses or alternative number as determined by statistical techniques.

(Under most New Zealand situations, a sample size of 25 carcasses will provide

a basis for statistical comparison.)

Sample time frame: Two week period. Random selection of five sampling days, random selection of

five carcasses per day.

Methodology: MIRINZ 873 standard or as described in NMD, Manual 15. Enumerate mean

APCs and E. coli counts. Duplicate spread plates. Carcasses to be sampled

while temporarily railed on to the detain rail, or another suitable position that does

not mask the microbiological consequences of slaughter and dressing.

CCP3 (Ringing)

The use of NMD data for evaluating this CCP is of limited value because the NMD does not include a

sampling site that could be routinely affected by the ringing operation. However, sporadic occurrence of gross

contamination and redistribution due to failure at this step may be reflected in NMD data. Microbiological

validation using relevant sampling sites may need to be done for this CCP. However, it is suggested that the

use of visual observation of sporadic faecal leakage and/or observation of operator technique may be a more

practical means for evaluating the adequacy of procedures at this process step. In this context, it would be

expected that any premises that does not use bagging should validate operator performance as meeting

appropriate food safety objectives according to visual parameters defining process control.

An appropriate design for microbiological validation is given above. Guidance on establishing sampling

regimes for validation using visual observation may be obtained from publications on statistical process

control.

Ministry for Primary Industries Page 38 of 233

Guidance Document: A guide to HACCP systems in the Meat Industry

23 March 2017

FSO2: To remove all grossly-detectable abnormalities from carcasses that are retained at post-

mortem inspection.

The second objective is addressed at CCP4 (retain rail trim). Regulations require that all carcasses which go

to the retain rail are re-inspected by the regulator. Historical data on visual observations of removal of gross

abnormalities and contaminants at this process step may be used to confirm that the procedures in place will

achieve FSO2. Data obtained before the HACCP plan implementation (i.e. historical data) should be

compared to data obtained after HACCP implementation to ensure that the HACCP plan is at least equivalent

to GMP-based controls at the premises.

FSO3: To identify all chemical "suspect" lines of livestock that are presented for slaughter, for

subsequent regulatory action.

The third objective is addressed at CCP1 (receiving). The control measure at CCP1 is a regulatory

requirement. It is therefore expected that premises will have historical data or documentation which may be

used to show that procedures in-place are adequate and will achieve the FSO.

6.13.2 Ongoing verification

Ongoing verification activities confirm whether the HACCP plan is operating effectively and according to

documented procedures. Examples of these activities are internal and extrinsic audits, HACCP review, and a

product testing programme. The NMD is an example of a microbiological sampling programme which provides

an ongoing verification of the microbiological performance of the whole process plan.

6.13.3 Revalidation

A revalidation of the HACCP plan is required whenever changes are made (e.g. changes to premises,

product, process, intended use of the product).

Ministry for Primary Industries Page 39 of 233

Guidance Document: A guide to HACCP systems in the Meat Industry

23 March 2017

Table 6: HACCP plan summary spreadsheet

Process Hazard ID CCP Critical limits Monitoring Corrective actions Verification procedures HACCP records

step no. procedures/tools (consider

Who, What, When and How)

1. Receive C1. Chemical 1 Identify all suspect lines 100% check of incoming ID after receiving but FSO validation Validation record

known for regulator lines against current before slaughter. Notify Internal audit Daily CCP monitoring

suspect lines chemical suspect list. Production Manager and Extrinsic audit (e.g. worksheet

Note on pen card for Regulator. regulator, client) Corrective action report

regulator. If already slaughtered, HACCP review Internal audit report

notify Production Manager Extrinsic audit report

and Regulator. HACCP review record

11. Hind leg B5. Micro – 2 Operator technique – Random observation of Talk to operator FSO validation Validation record

hide 100% compliance with operator technique being Increase supervision Internal audit Daily CCP monitoring

food safety components of applied to a pre- and/or monitoring level Extrinsic audit (e.g. worksheet

job description determined number of Retrain or remove regulator, client) Corrective action report

carcasses per 2 hour run3 operator HACCP review Internal audit report

Microbiological sampling Extrinsic audit report

programme (e.g. NMD) HACCP review record

12. Ring B4. Micro – 3 Operator technique – Random observation of Talk to operator FSO validation Validation record

GIT 100% compliance with operator technique being Increase supervision Internal audit Daily CCP monitoring

food safety components of applied to a pre- and/or monitoring level Extrinsic audit (e.g. worksheet

job description determined number of Retrain or remove regulator, client) Corrective action report

carcasses per 2 hour run3 operator HACCP review Internal audit report

Microbiological sampling Extrinsic audit report

programme (e.g. NMD) HACCP review record

Ministry for Primary Industries Page 40 of 233

Guidance Document: A guide to HACCP systems in the Meat Industry

23 March 2017

Process Hazard ID CCP Critical limits Monitoring Corrective actions Verification procedures HACCP records

step no. procedures/tools (consider

Who, What, When and How)

18a. Retain B1. Micro – 4 Removal of all grossly- 100% re-inspection by Retain product until FSO validation Validation record

grossly detectable abnormalities. regulator will identify non- correctly trimmed Internal audit Daily CCP monitoring

detectable Removal of all visible removal of gross Talk to operator Extrinsic audit (e.g. worksheet

abnormalities faeces and ingesta. abnormalities and Increase supervision regulator, client) Corrective action report

B4. Micro – Removal of all skin contaminants. Note: This and/or monitoring level HACCP review Internal audit report

GIT pieces. is not a processor activity. Retrain or remove Extrinsic audit report

B5. Micro – Operator technique – Random observation of operator HACCP review record

Hide 100% compliance with operator technique being

food safety components of applied to a pre-

job description determined number of

carcasses per 2 hour run3

1

Corrective actions should reflect an escalating response when ongoing non-compliance occurs.

2

Validation of the FSO relating to microbiological outcomes relates to the performance of the whole HACCP plan, e.g. NMD.

3

Sampling regime should be established by the company.

Ministry for Primary Industries Page 41 of 233

Guidance Document: A guide to HACCP systems in the Meat Industry

23 March 2017

6.14 Background Information

6.14.1 Foodborne Illness Associated With Beef