Академический Документы

Профессиональный Документы

Культура Документы

Poultry Farm Waste Management Odor Control Checklist: Source Cause Bmps To Minimize Odor Site Specific Practices

Загружено:

gabinuang0 оценок0% нашли этот документ полезным (0 голосов)

59 просмотров3 страницыThis checklist identifies potential odor sources at poultry farms and best management practices (BMPs) to minimize odors. Sources include poultry production areas, manure collection alleys, conveyors, storage tanks, lagoons, and irrigation systems. BMPs involve proper manure removal, adding biological additives, minimizing agitation, using covers, and following siting and design guidelines. Additional resources are provided on manure management, lagoon design, and nuisance control.

Исходное описание:

Poultry Odor

Оригинальное название

Appen x Poultry Odor 111196

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThis checklist identifies potential odor sources at poultry farms and best management practices (BMPs) to minimize odors. Sources include poultry production areas, manure collection alleys, conveyors, storage tanks, lagoons, and irrigation systems. BMPs involve proper manure removal, adding biological additives, minimizing agitation, using covers, and following siting and design guidelines. Additional resources are provided on manure management, lagoon design, and nuisance control.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

59 просмотров3 страницыPoultry Farm Waste Management Odor Control Checklist: Source Cause Bmps To Minimize Odor Site Specific Practices

Загружено:

gabinuangThis checklist identifies potential odor sources at poultry farms and best management practices (BMPs) to minimize odors. Sources include poultry production areas, manure collection alleys, conveyors, storage tanks, lagoons, and irrigation systems. BMPs involve proper manure removal, adding biological additives, minimizing agitation, using covers, and following siting and design guidelines. Additional resources are provided on manure management, lagoon design, and nuisance control.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 3

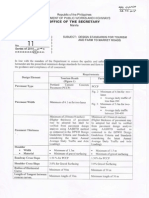

Poultry Farm Waste Management Odor Control Checklist

Source Cause BMPs to Minimize Odor Site Specific Practices

Farmstead • Poultry production r Vegetative or wooded buffers

r Recommended best management practices

r Good judgment and common sense

Floor surfaces • Wet dirty surfaces r Scrape manure, dust, feathers into collection

(walk aisles) alleys

r Splash boards along upper ends of collection

alleys

r Proper ventilation

Cage manure • Manure-covered surfaces r Scrape manure into collection alleys

dropping boards

Manure collection • Partial microbial r Frequent manure removal by flush or scrape

alleys decomposition r Frequent checks and maintenance on waterers

and water pipes

Ventilation exhaust • Volatile gases r Fan maintenance

fans • Dust r Efficient air movement

Indoor surfaces • Dust r Vacuum or washdown between flocks

Manure conveyors • Partial microbial r Keep mechanical equipment in good repair

decomposition r Remove manure accumulations promptly

Storage tank or • Partial microbial r Bottom or midlevel loading

basin surface decomposition r Tank covers

• Mixing while filling r Basin surface mats of solids

r Proven biological additives or oxidants

• Agitation when emptying

Manure slurry or • Agitation when spreading r Soil injection of slurry/sludges

sludge spreader • Volatile gas emissions r Wash residual manure from spreader after use

outlets

r Proven biological additives or oxidants

AMOC - November 11, 1996, page 1

Poultry Farm Waste Management Odor Control Checklist

Source Cause BMPs to Minimize Odor Site Specific Practices

Uncovered manure • Volatile gas emissions while r Soil injection of slurry/sludges

slurry or sludge on drying r Soil incorporation within 48 hours

field surfaces

Outside drain • Agitation during wastewater r Box covers

collection or junction conveyance

boxes

Lift stations • Agitation during sump tank r Sump tank covers

filling and drawdown

End of drainpipes at • Agitation during wastewater r Extend discharge point of pipes underneath

lagoon conveyance lagoon liquid level

Lagoon surfaces • Volatile gas emissions r Proper lagoon liquid capacity

• Biological mixing r Correct lagoon startup procedures

• Agitation r Minimum surface area-to-volume ratio

r Minimum agitation while pumping

r Mechanical aeration

r Proven biological additives

Irrigation sprinkler • High pressure agitation r Irrigate on dry days with little or no wind

nozzles • Wind drift r Minimum recommended operating procedure

r Pump intake near lagoon liquid surface

r Pump from second-stage lagoon

AMOC - November 11, 1996, page 2

Poultry Farm Waste Management Odor Control Checklist

Source Cause BMPs to Minimize Odor Site Specific Practices

Dead birds • Carcass decomposition r Proper disposition of carcasses

Dead bird disposal • Carcass decomposition r Complete covering of carcasses in burial pits

pits r Proper location/construction of disposal pits

r Disposal pit covers tight fitting

Standing water • Improper drainage r Grade and landscape such that water drains away

around facilities • Microbial decomposition of from facilities

organic matter

Mud tracked onto • Poorly maintained access r Farm access road maintenance

public roads from roads

farm access

Additional Information: Available From:

Poultry Manure Management; .0200 Rule/BMP Packet NCSU, County Extension Center

Poultry Layer Production Facility Manure Management: High Rise, Deep Pit; EBAE 131-88 NCSU— BAE

Poultry Layer Production Facility Manure Management: Undercage Flush— Lagoon Treatment; EBAE 130-88 NCSU— BAE

Lagoon Design and Management for Livestock Manure Treatment and Storage; EBAE 103-83 NCSU— BAE

Calibration of Manure and Wastewater Application Equipment; EBAE Fact Sheet NCSU— BAE

Proper Disposal of Dead Poultry; PS&T Guide No. 19 NCSU— Poultry Science

Nuisance Concerns in Animal Manure Management: Odors and Flies; PRO107, 1995 Conference Proceedings Florida Cooperative Extension

AMOC - November 11, 1996, page 3

Вам также может понравиться

- Waste Management Structures: Philippine Agricultural Engineering Standards Agricultural Liquid WasteДокумент72 страницыWaste Management Structures: Philippine Agricultural Engineering Standards Agricultural Liquid WasteEspeeОценок пока нет

- Bio Reactor Land Fills-Impart-Km4Документ24 страницыBio Reactor Land Fills-Impart-Km4manoj kumar GОценок пока нет

- Poultry BiosecurityДокумент1 страницаPoultry BiosecurityAzizrahman AbubakarОценок пока нет

- Ayush Water PollutionДокумент15 страницAyush Water PollutionAman K. SinghОценок пока нет

- Rooftop Rainwater Harvesting: Pre-Implementation Guide For SchoolsДокумент19 страницRooftop Rainwater Harvesting: Pre-Implementation Guide For SchoolsNurul FitrianiОценок пока нет

- Day 1 GWM PPT PrimoveДокумент44 страницыDay 1 GWM PPT PrimoveDebdulal SamantaОценок пока нет

- 6-Chapter 4 Groundwater Pollution Remediation Technique (20210331)Документ102 страницы6-Chapter 4 Groundwater Pollution Remediation Technique (20210331)Thao LyОценок пока нет

- Hybrid Wastewater System For Public Markets: Muntinlupa City, PhilippinesДокумент23 страницыHybrid Wastewater System For Public Markets: Muntinlupa City, PhilippinesArgie AdduruОценок пока нет

- Brackish WaterДокумент20 страницBrackish WaterMarie PeneyraОценок пока нет

- Biological Treatment of Waste Water: Shaswati Saha Csir-Jrf WWT DivisionДокумент21 страницаBiological Treatment of Waste Water: Shaswati Saha Csir-Jrf WWT DivisionShielaMaeRomeroPrestadoОценок пока нет

- Lecture - 6-Wastewater SystemДокумент18 страницLecture - 6-Wastewater SystemZain AshfaqОценок пока нет

- G. Tyler Miller's Living in The Environment 14 EditionДокумент84 страницыG. Tyler Miller's Living in The Environment 14 Editionfawad aliОценок пока нет

- Lecture 40 PDFДокумент78 страницLecture 40 PDFItoo RakshandaОценок пока нет

- Fertilizer Application: BIOL 695Документ30 страницFertilizer Application: BIOL 695wilsnОценок пока нет

- LandfillДокумент163 страницыLandfillShrinish VhanbatteОценок пока нет

- Water ResourcesДокумент20 страницWater ResourcesShubham KumarОценок пока нет

- Review of Previous TopicДокумент29 страницReview of Previous TopicPratik SamalОценок пока нет

- GWM PPT PriMoveДокумент47 страницGWM PPT PriMoveDebdulal SamantaОценок пока нет

- Land Preparation Well-Levelled Field: Key Check 2Документ18 страницLand Preparation Well-Levelled Field: Key Check 2FroyОценок пока нет

- Jamban&Septic TankДокумент55 страницJamban&Septic TankWika Maulany FatimahОценок пока нет

- Modul-8 Dewatering Dan Sistem Pompa AirДокумент67 страницModul-8 Dewatering Dan Sistem Pompa AirJulia AzizahОценок пока нет

- Elements of Ecological Solid Waste Management SystemДокумент73 страницыElements of Ecological Solid Waste Management SystemNeil RyanОценок пока нет

- Trickling Filter: Shilpa PatilДокумент17 страницTrickling Filter: Shilpa PatildhanushОценок пока нет

- Septic System Basics: Kitt Farrell-Poe Extension Water Quality Specialist Ag & Biosystems Engineering DeptДокумент21 страницаSeptic System Basics: Kitt Farrell-Poe Extension Water Quality Specialist Ag & Biosystems Engineering DeptMasnun RahmanОценок пока нет

- Modul-8 Dewatering Dan Sistem Pompa AirДокумент57 страницModul-8 Dewatering Dan Sistem Pompa AirRani PradotoОценок пока нет

- Sanbe Farma Waste Water Treatment PlantДокумент11 страницSanbe Farma Waste Water Treatment PlantAulia RizkhanОценок пока нет

- Water Treatment ProcessДокумент24 страницыWater Treatment ProcessG TIME OFFICE SYSTEMS pvt.ltdОценок пока нет

- Water PollutionДокумент30 страницWater PollutionAnamolОценок пока нет

- WWT 1Документ33 страницыWWT 1Abhishek AdhikariОценок пока нет

- Sanitary Landfills: Under Solid and Hazardous Waste ManagementДокумент11 страницSanitary Landfills: Under Solid and Hazardous Waste ManagementRiddhiОценок пока нет

- Nutrient Management: Section 5.5 - Phosphorus, Potassium and Heavy MetalsДокумент31 страницаNutrient Management: Section 5.5 - Phosphorus, Potassium and Heavy Metalsbilal sinanОценок пока нет

- Earth Science 2nd QA Reviewer 1Документ2 страницыEarth Science 2nd QA Reviewer 1ponteroniko6Оценок пока нет

- Tricklingfilterppt 190222065634Документ15 страницTricklingfilterppt 190222065634dhanushОценок пока нет

- Eat 4Документ35 страницEat 4Habib UrrehmanОценок пока нет

- Water Pollution Ilhan KlisuraДокумент26 страницWater Pollution Ilhan KlisuraIlhan KlisuraОценок пока нет

- Water Pollution LectureДокумент46 страницWater Pollution LectureSohail AslamОценок пока нет

- Lecture 4 - IrrigationДокумент22 страницыLecture 4 - IrrigationJAYRALD MONTELOYOLAОценок пока нет

- Lecture 3-Ground Water PollutionДокумент86 страницLecture 3-Ground Water PollutionThao LyОценок пока нет

- Water ConservationДокумент19 страницWater ConservationRyan LairdОценок пока нет

- Storm Water: Stormwate RДокумент17 страницStorm Water: Stormwate RAravindan Karthik akОценок пока нет

- Sludge Treatment - Sludge DisposalДокумент44 страницыSludge Treatment - Sludge DisposalAdi PermanaОценок пока нет

- Wastewater TreatmentДокумент66 страницWastewater TreatmentDan NanyumbaОценок пока нет

- 1 IntroductionsДокумент17 страниц1 IntroductionsAakash MandalОценок пока нет

- MTPDF2 - Main Module PDF Open Channels ApplicationsДокумент53 страницыMTPDF2 - Main Module PDF Open Channels ApplicationsEunnice PanaliganОценок пока нет

- Module - 4 Water PollutionДокумент22 страницыModule - 4 Water PollutionAli AbidОценок пока нет

- Floor and Drains Cleaning Procedure SampleДокумент3 страницыFloor and Drains Cleaning Procedure SampleDaniela Arce TraubОценок пока нет

- Refuse Disposal System (1280)Документ12 страницRefuse Disposal System (1280)NamrataОценок пока нет

- Water Resources and Water PollutionДокумент122 страницыWater Resources and Water PollutionEUNAH LimОценок пока нет

- KDHE Advanced Wastewater Treatment August 2019Документ31 страницаKDHE Advanced Wastewater Treatment August 2019Joy Das MahapatraОценок пока нет

- Trickling Filters: Ishwarya R 14B217Документ21 страницаTrickling Filters: Ishwarya R 14B217Ishwarya RaviОценок пока нет

- L1Importance of Irrigation and DrainageДокумент18 страницL1Importance of Irrigation and DrainagemimahmoudОценок пока нет

- Lec3 - Basic ConceptsДокумент4 страницыLec3 - Basic ConceptsRafia AsifОценок пока нет

- Welcome To The PresentationДокумент62 страницыWelcome To The PresentationZannatul ModinaОценок пока нет

- Grundfosliterature 3153478 PDFДокумент5 страницGrundfosliterature 3153478 PDFRobin GomezОценок пока нет

- Quarry and Borrow Area Operations and Material HualingДокумент4 страницыQuarry and Borrow Area Operations and Material HualingahmedОценок пока нет

- EPA Lagoon Design Manual - Paul Krauft Utah State PDFДокумент79 страницEPA Lagoon Design Manual - Paul Krauft Utah State PDFNataliaKОценок пока нет

- Water QualityДокумент41 страницаWater QualityFayazullahShinwariОценок пока нет

- Ecosystem DiversityДокумент3 страницыEcosystem DiversityChamsОценок пока нет

- Wastewater LagoonsДокумент49 страницWastewater LagoonsMatthew BennettОценок пока нет

- How Water Is Being Processed - Metropolitan Waterworks and Sewerage SystemДокумент9 страницHow Water Is Being Processed - Metropolitan Waterworks and Sewerage SystemgabinuangОценок пока нет

- Open Channel Flow Hydraulics BesavillaДокумент4 страницыOpen Channel Flow Hydraulics BesavillagabinuangОценок пока нет

- Sewer Maintenance - Steel and McGheeДокумент8 страницSewer Maintenance - Steel and McGheegabinuangОценок пока нет

- Rubric - Lab ActivityДокумент3 страницыRubric - Lab ActivitygabinuangОценок пока нет

- Rubric - DesignДокумент2 страницыRubric - DesigngabinuangОценок пока нет

- Rubric - Lab Activity PDFДокумент3 страницыRubric - Lab Activity PDFgabinuangОценок пока нет

- Rubric - DesignДокумент2 страницыRubric - DesigngabinuangОценок пока нет

- Fugitive Dust Control PlanДокумент3 страницыFugitive Dust Control Plangabinuang100% (1)

- Climate PhilppinesДокумент2 страницыClimate PhilppinesgabinuangОценок пока нет

- Rubric - DesignДокумент2 страницыRubric - DesigngabinuangОценок пока нет

- Problem Solving Box Plots Answer Key PDFДокумент1 страницаProblem Solving Box Plots Answer Key PDFgabinuang100% (1)

- Problem Solving Box Plots Answer Key PDFДокумент1 страницаProblem Solving Box Plots Answer Key PDFgabinuang100% (1)

- SkewStatSignif PDFДокумент16 страницSkewStatSignif PDF3rlangОценок пока нет

- Rubric - DesignДокумент2 страницыRubric - DesigngabinuangОценок пока нет

- CHB WeightДокумент3 страницыCHB WeightgabinuangОценок пока нет

- Zampen Quickstat May 2019Документ2 страницыZampen Quickstat May 2019gabinuangОценок пока нет

- SEE-I-003 (IBD - CO2 Sequestration)Документ6 страницSEE-I-003 (IBD - CO2 Sequestration)gabinuangОценок пока нет

- Rules and Land Use ConversionДокумент61 страницаRules and Land Use ConversionAlthea AcasОценок пока нет

- Estimasi Fuel ConsumptionДокумент7 страницEstimasi Fuel ConsumptionDanu PutraОценок пока нет

- Toyota Innova Maintenance ScheduleДокумент10 страницToyota Innova Maintenance ScheduleSunil Nair100% (1)

- Name of River Station Location Region Class List of Classified Water Bodies As of 2013Документ1 страницаName of River Station Location Region Class List of Classified Water Bodies As of 2013gabinuangОценок пока нет

- Eastern Samar Workashop OutputДокумент9 страницEastern Samar Workashop OutputLive LikeОценок пока нет

- Accreditation SystemДокумент8 страницAccreditation Systemgabinuang100% (1)

- Do - 026 - S2011 (Ibd-Dpwh Diggind On Natl Roads) PDFДокумент20 страницDo - 026 - S2011 (Ibd-Dpwh Diggind On Natl Roads) PDFgabinuang100% (4)

- Farm To Market RoadsДокумент5 страницFarm To Market RoadsWira PutrantoОценок пока нет

- Handbook Safety PDFДокумент219 страницHandbook Safety PDFJia IdrisОценок пока нет

- .. Iquas Gpgs Painting PCommondefects PDFДокумент9 страниц.. Iquas Gpgs Painting PCommondefects PDFrohalestatОценок пока нет

- DPWH Road Signs and Pavement Markings May 2011 Complete PDFДокумент360 страницDPWH Road Signs and Pavement Markings May 2011 Complete PDFManuel Lawrence Kenniker100% (3)

- Do - 015 - s2000 (Ibd-Dpwh Tree Planting)Документ2 страницыDo - 015 - s2000 (Ibd-Dpwh Tree Planting)gabinuangОценок пока нет

- OILS MEASUREMEN-WPS OfficeДокумент2 страницыOILS MEASUREMEN-WPS OfficeMr NaijatimОценок пока нет

- 1.0 District Agriculture Profile: State: GUJARAT Agriculture Contingency Plan For District: BANASKANTHAДокумент34 страницы1.0 District Agriculture Profile: State: GUJARAT Agriculture Contingency Plan For District: BANASKANTHAastuteОценок пока нет

- Rainbird PC506 ManualДокумент40 страницRainbird PC506 Manualtewa999Оценок пока нет

- Prof. Shu-Qing YangДокумент83 страницыProf. Shu-Qing YangYasruddin MtОценок пока нет

- Water Efficiency ReportДокумент41 страницаWater Efficiency ReportImran YasinОценок пока нет

- Ancient Egyptian Gardens (The Ostrakon, Bigelow, 2000)Документ6 страницAncient Egyptian Gardens (The Ostrakon, Bigelow, 2000)MithotОценок пока нет

- Engenharia Hidraulica - InglesДокумент8 страницEngenharia Hidraulica - InglesPekirОценок пока нет

- B83 Soil Moisture Sensor Installation Guide WebДокумент42 страницыB83 Soil Moisture Sensor Installation Guide WebulseceОценок пока нет

- Methods and Techniques of IrrigationДокумент9 страницMethods and Techniques of IrrigationEmmanuel Sto TomasОценок пока нет

- DUUBEДокумент11 страницDUUBELemi TuroОценок пока нет

- Prospects of Rainwater Harvesting in IndiaДокумент11 страницProspects of Rainwater Harvesting in IndiaSameer sayedОценок пока нет

- Water Resource Management Notes For MNNITДокумент6 страницWater Resource Management Notes For MNNITParth NakhaleОценок пока нет

- Ministry of Agriculture's Performance Report 2015-2020Документ149 страницMinistry of Agriculture's Performance Report 2015-2020NikoBОценок пока нет

- WB Practice QP 3Документ10 страницWB Practice QP 3tushitvijay00Оценок пока нет

- Cambridge IGCSE ™: GeographyДокумент9 страницCambridge IGCSE ™: GeographyEmmanuel GobaОценок пока нет

- Drip IRRIGATION SYSTEMДокумент20 страницDrip IRRIGATION SYSTEMvirajain100% (1)

- Geography Worksheet¬esДокумент44 страницыGeography Worksheet¬esCanttell SpookehОценок пока нет

- Multi StageДокумент4 страницыMulti StageYhia EbrahimОценок пока нет

- Agriculture Exercise Questions 2059/02Документ6 страницAgriculture Exercise Questions 2059/02mishi mosh50% (2)

- Minor Project: Smart Irrigation Using ArduinoДокумент13 страницMinor Project: Smart Irrigation Using ArduinoSwarup UritiОценок пока нет

- Simplified Keys To Soil Series Negros OrientalДокумент64 страницыSimplified Keys To Soil Series Negros OrientalNoy JuanОценок пока нет

- 4.2 Development of Rice Farming and Environmental Conservation Strategy in West Africa 4.2.1 Roles and Limitations of NERICA Rice/WARDAДокумент21 страница4.2 Development of Rice Farming and Environmental Conservation Strategy in West Africa 4.2.1 Roles and Limitations of NERICA Rice/WARDAakhgieОценок пока нет

- Horticulture Study in Tribal South Gujarat RegionДокумент138 страницHorticulture Study in Tribal South Gujarat RegionshivabiradarОценок пока нет

- WaterДокумент295 страницWatersalilОценок пока нет

- Iesc115 PDFДокумент13 страницIesc115 PDFSanjeev ShahОценок пока нет

- Existing SystemДокумент5 страницExisting Systemprabhujaya97893Оценок пока нет

- 1 - Irrigation Techniques and Quality of Irrigation Water PDFДокумент21 страница1 - Irrigation Techniques and Quality of Irrigation Water PDFdil afroza karim LinaОценок пока нет

- Concluding 1Документ7 страницConcluding 1Fashola AbdulhamidОценок пока нет

- 3CA-59 Canal WorkДокумент44 страницы3CA-59 Canal WorkLakhan MathaneОценок пока нет

- Capsule Proposal 3Документ2 страницыCapsule Proposal 3Jerry CincoОценок пока нет