Академический Документы

Профессиональный Документы

Культура Документы

Determining Thickener Unit: Areas

Загружено:

Cristian SaavedraОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Determining Thickener Unit: Areas

Загружено:

Cristian SaavedraАвторское право:

Доступные форматы

'

ENGINEERING, DESIGN, AND PROCESS DEVELOPMENT

Determining Thickener Unit Areas

W. P. T A L M A G E AND E. B. FITCH

The Dorr Co., Westporf, Conn,

0 PERATION of Dorr-type thickeners was analyzed by C,oe

and Clevenger (2) in 1916. They showed how to predict

t'hickener capacity from batch settling tests. The method out-

Kynch started from the postulate t,hat t,he settling velocity, ,T'

of a particle is a function only of the local solids concentration, C,

around the particle, or mathematically, V = f (C). The funct,ion

lined in t,heir classic paper has been used without significant im- is not defined and may change in any manner as the concentration

provement to this time (1). changes. This will be recognized as the same assumption Coe and

A recent paper (3) by Kynch presents a mathematical analysis Clevenger made for the free settling regime.

of batch settling tests t'hat supplements the original picture sup- In a ba,tch test starting a t uniform concentration, all t,he solids

plied by Coe and Clevenger. Application of thc Kynch mathe- start eettling a t uniform velocity since V = f(C). As the settling

matics to thickening problems makes it possible to simplify t,he solids begin to collapse against, the bottom of the vessel, they

experimental procedures and interpretation of results. must pass through all concentrations between Rtarting concentra-

tion and that of the deposited solids. If, a t any of thePe inter-

Simple Geometrical Constructions Aid Direct mediate concentrations, the solids-handling capacity is less than

Determination of Unit Area Requirements that a t the lower concentration occurring immediately above it in

Kynch does not analyze the relationship between batch set- the vessel, a zone of such intermediate concentration must start

tling tests and continuous thickeners. In order to apply the building up, since the solids cannot pass t,hrough it as fast as they

Kynch analysis, it will be useful to review that part of the mech- are eettling down into it.

anism of continuous t'hickening pertinent to the problem. A c - Kynch shovied that' the rat,e of upward propagation of each

cording to Coe and Clevenger ( 8 ) there may be several regimes or such constant concentration zone is constant. Consider the in-

zones in a thickener but the thickener area required is determined finitely thin layer a t the upper boundary of such a zone, having a

by conditions in what they designate as free settling zones. These concent'ration, C, originating a t the bottom at, zero time and mov-

are defined as zones in which the floes are falling through the ing upward a t a velocity of I-7 feet per second. The solids set-

liquid without pressing on layers of floc below. I n a free settling tling into this layer come from a layer having a concentration of

regime, the quantity of solids which can settle through a unit (C - dC)pounds per cubic foot and a settling velocity with re-

cross section in unit time i s equal to the product of bhe settling spect to the ~ e ~ sofe l( V + dT') feet per second but with respect

rate and the solids concentration. Coe and Clevenger tacitly as- +

t o the layer of (Ti d V j-U )feet per second. The concentrat'ion

sumed that, under the operating condit'ions, the settling rate of solids settling out, of this layer will he C with a settling velocity

would be a function solely of the solids concentration. Therefore, of V with respect, to the vessel and (V +

C ) Kith respect to the

the solids-handling capacit,y of any layer is a function only of its layer. Since the concentration of the layer is constant, the

concentration. In a continuous thickener, the solids must, be quantity of solids settling into the layer must equal the quantity

able to subside through any concentration layers b e t w e n the of solids settling out of thc layer and a material balance can there-

concentrations of feed and underflow a t least as rapidly as they fore be made.

are fed to the unit,. Othern-ise, a layer or zone of whatever con-

centrat,ionlimits the solids-handling capacit'y will form and a,ct'as (C - dC) At (V + d V + L!) = C At ( V + U) (1)

a barrier. If insufficient area is present to handle the solids, such By simplifying and solving €or U,dropping out infinitesimals

a barrier layer would build up and all solids in excess of the of the second order,

amount which could subside through this zone would eventually

have to overflow the thickener. Therefore, a, thickener must' have

a t least enough area t o allow the solids to subside through which-

ever concentration layer would have the least solids-handling

capacity. Since, according to the Kynch postulate V = f(C), it follows

The method Coe and Clevenger used for determining the that

thickener area needed was to make a series of batch settling tests

on the pulp at various concentrations and to deterniirie the area

required to handle unit flow of solids for each concentration. The

maximum unit area thus determined was used as a basis of thicli- u = Cf'(C) - f ( C ) (3)

ener design.

Coe and Clevenger realized that in a settling test', concentration Since Cis constant for the layer in question,f( C) andf'(C) have

Iayers of lower solids handling capacity than layers of initial con- fixcd values and therefore C must also be constant.

centration, if they potentially exist, must propagate up from the The constancy of U may now be used to determine the solide

bottom of the vessel and appear eventually a t the upper honnd- concentration of the layer a t the upper boundary of the settling

arg of the settling pulp. They applied this concept to continuous pulp. Let COand Ho be the initial concentration and height, re-

settling t,ests but did not develop it to explain the ever-decreasing spectively, of a column of pulp in a batch settling test. The total

settling rate t,hey observed in the transition between free settling weight of solids in this pulp column is then CoHoA. When any

and compression conditions in a batch test. capacity-limiting concentration layer reaches the pulp .water in-

Kgnch showed how the settling rate and concentration of any terface, all solids in the column must have passed through it since

capacity-limiting concentration layer which may exist can be de- it was propagated up from the bottom of the column. If the con-

termined from the variat,ion in setmilingrate observed in a single centration of this layer is C, and it reaches the interface a t time,

batch settling test. t., then the quantity of solids having passed through this layer,

38 INDUSTRIAL A N D E N G I N E E R I N G CHEMISTRY Vol. 47, No. 1

ENGINEERING, DESIGN, AND PROCESS DEVELOPMENT

C2Atz(Vs + U Z ) ,must equal the total weight of solids in the The total quantity of solids in the batch test is CJIo.4 and it

column. would take time tu for this quantity of solids to subside past a

Equating these expressions layer of concentration CZin a continuous thickener. Therefore,

the quantity of solids that could be brought through layer con-

COHd = CzAtz(V2 + Uz) (4) centration per unit time is CoHoA/t,. “Unit area” of a layer is, by

definition, the area required to allow 1 ton of solids to subside

If HZ represents the height of the interface a t time, k, and since through the layer concentration in 1 day.

it has been proved that the upward velocity of any specific layer

is constant, Unit area = A, square feet/ton solids/day

COHO (10)

Hz

uz = t, (5) I n order to obtain

HO unit area in the

Substituting in Equation 4 and simplifying specified unit8 of

square feet per ton

per day, it is neces-

t- sary in Equation

V2 is equal t o dH/dt a t the point on a plot of H versus t (Figure H: 1 10 to express tu, H ,

LL

I ) a t which the layer having a concentration of C2 comes to the I

and C in units of

surface of the pulp. VZ is then the slope of the tangent to the days, feet, and tons

t per cubic foot, re-

curve a t (Hz, t 2 ) . It follows mathematically that the intercept of I

this tangent on the H axis is Hz +

V~tz(shown as HI). By sub- 9 spectively. How-

stituting H I for Hz+ Vdz in Equation 6, it is shown that CzHl = FH2

ever, it will usually

Colla. From this it follows that H1 is the height the pulp would be convenient t o

a construct the set-

occupy if all the solids present were a t the same concentration as _I

3 tling curve and

the layer a t the pulp-water interface. For any arbitrarily chosen

value of Cz the corresponding value of HI may be calculated. Vz &H” carry out the

can then be determined as the slope of the line drawn through graphical construc-

point H I and tangent to the settling curve, and a complete set of t2 tu tions in terms of

data showing V as f ( C) can therefore be developed from one set- TIME - DAYS more conventional

tling test. Figure 1 . Typical Pulp Height vs. units, using an ap-

I n order to specify the area requirement of a thickener, the Time Relationship for Batch Settling propriate Conver-

concentration layer requiring the maximum area to pass a unit Test sion factor to con-

weight of solids must be determined. This may be done by cal- vert unit area into

culating the unit area required for a series of concentrations, the specified units.

using the data showing B a s j ( C ) developed in the previous para- The method for determining the unit area Corresponding t o any

graph and substituting in the Coe and Clevenger formula pulp concentration C2 in the free settling range is therefore as

follows:

1. Determine H I and H , from the following material balances:

Unit area = point H I corresponding to an arbitrarily selected concentra-

V tion, C2

COHO= CzHi = CuHu

Whichever conrentration lager gives the largest value of unit area

2. Draw an “underflow” line parallel to the time axis a t

is then wed aF a design basis. With Figure 1, a simple geomet- H = H , on a plot of pulp height versus time, as shown in Figure 1.

rical construction may be used to obtain the unit areas directly. 3. Draw a tangent t o the settling curve through point H I on

At time t2 the solids in the layer existing a t the surface of the the H axis.

pulp are settling a t a linear rate of H I - Hz/tz. If the solids of 4. Read t, a t the intersection of the tangent and the underflow

line.

this layer are assumed as a datum, water is passing the solids a t a 5 . Calculate unit area from Equation 10.

bulk rate of A ( H , - Hz)/tz. In a continuous thickener, the

solids in any zone do not have to settle past all of the water in the ’\TJhenthe underflow line, H,, intersects the settling curve above

zone, since part of this water will accompany the solids to the the point wl ere the layer a t the surface of the pulp goes into com-

underflow. The amount of .ivater they must settle past is equal pression, the time, tu, corresponding to maximum unit area will be

rather t o the amount which would be released in bringing solids the coordinate of the intersection since any other tangent will in-

from layer concentration to underflow concentration. The cor- tersect the underflow line a t a lesser value of I, When the under-

responding quantity of water for the solids present in the batch flow line intersects the settling curve below the point where the

test would be A ( H , - H,)) since Hl is the height the pulp would layer a t the surface of the pulp goes into compression, the tangent

occupy if all solids present in the batch test were a t layer concen- giving maximum unit area will be drawn through this compres-

tration and Hu is the height the pulp would occupy if all solids sion point, since this tangent gives the highest value of t, in the

present in the batch test were a t the thickener underflow concen- free settling range and only free settling zones govern the unit

tration. The time that wodd be required to release A ( H l - H,) area.

water through a layer of concmtration C2‘ would then be

Batch Settling Tests Demonstrate

t , -- amount of water to eliminate - A(H1 - H,) (7)

Validity of Kynch Analysis

rate of eliminating water - A(H1 - H z ) It is implicitly assumed in Coe and Clevenger’s treatment that

t2

solids in free settling pulps will obey Kynch’s basic assumption-

Le., that the settling velocity of a particle is a function only of the

local concentration. Since the Kynch conclusions are mathe-

matically certain if the basic assumption is met, the Kynch method

By the law of triangles for determining behavior of free settling layers must be a t least as

t‘ =i tu (9) valid a s that of Coe and Clevenger. The Coe and Clevenger test

January 1955 INDUSTRIAL AND ENGINEERING CHEMISTRY 39

ENGINEERING. DESIGN, AND PROCESS DEVELOPMENT

250 350 450

CONCLNTSATIOU - G./L

COUCE\TRATION - S,/L.

Metallurgical Pulp Calcium Carbonate Cement Rock A Cement Rock B

Figure 2. Comparison of Coe and Clevenger and Kynch Methods for Analysis of Batch Settling Tests

procedure, however, entaile an additional assumption vdiich is not same final concentration should he reached in a11 such tests on a

necessarily valid and which is not contained in applicat,ion of the given material. The results given in Table I show this is not the

Kynch analysis. The Coe and Clevenger test procedure of ob- case. The floc structure was apparently affected by this initial

serving the initial settling rate in a series of batch tests of various concentration, and hence it must he assumed that the settling

initial concentrations assumes that the settling chara,cteristics of rate also would be affected. Therefor?, Coe and Clevenger's ad-

the floc will be independent of the initial solids concent>rationin ditional assumption is not necessarily valid.

the pulp in which they are formed. Roberts (4)iridicated that It ram be concluded that results of the Kynch method will al-

this i s not always true, as is also demonstrated in this paper. il-ays be as good as those of the Coe and Clevenger method and

I n order to compare t.he results of the Coe and Clevengcr in many cases the results of the Kynch procedure should be more

method and t'he Kynch method, batch settling teste were made o n valid. However, since settling characteristics niny vary with

the following materials: rhanging initial pulp concentration, batch tests fo!lowing the

Kx-nch procedure should be made on pulp of the expected thick-

Metallurgical pulp, specific gravity 4.44-settled fairly rapidly caer feed concentration.

to a high final concentration

Calcium carbonate (CaCOa), specific gravity 2.63--aettled

fairly rapidly to an intermediate final concentration Good Correlation le Obicained

Cement rock A, specific gravity 2.56-a highly flocculent, slow-

settling material which had a low final concentration with Field Operating Results

Cement rock B, specific gravity 2.81-a segregating material

which settled E ~ O I V ~toJ ~a high final concentration .1 cor] elation between batch teats interpreted by the K p c h

procedure and actual field operating results was obtained during

Figure 2 slio~rsthe sett,ling rate versus concentration as deter- a survey of the beet sugar industry. The operation of thickcncrs

mined from batch tests on these materials using both the Coe and in the beet sugar industry is subject to manv variables both from

Clevenger procedure and the Kynoh procedure. The results of plant t o plant and from day to day in any one plant. Some of the

the two procedures check in the lovxx concentration ranges, dem- more important variables with respect t o thickening area re-

onstrating that the methods are equlvalent in this range. Ilox- quirements are tons of beets sliced per day, ciihic feet of juice per

ever, the results diverge as the concentration increases and this ton of beets, amount of carbon d i o d e gas used, amount of lime

must be due t o failure to conform to t,he additional assumption added, and quantity and type of flocculating agents added. I n

entailed by the Coe and Clevenger procedure. viem of these variables, the checks on unit areas, as determined

The settling velocity of a floc ma) be presumed to be a function by the Kynch procedure and actual operating data, are eucel-

of the structure of the floc, as well as of the solids concentration. lrnt. These results are presented in Table II. KO tests could be

In order to obtain an indication of the effect of initial pulp con- made according to the Coe and CIevenger procedure as th? floc

centration on floc structure, batch tests mere made on each of the Etructure changed radically when the material was repulped.

four materials a t a series of different initial concrntrations. In Thickener unit areas have sometimes been erroneously based

each case the solids were allon-ed to settle until the pulp line re- solely on the initial settling rate of a cylinder of pulp a t feed con-

mained at comtant height (final concentration). If the structure centration. By using this procedure, the lollowing unit area re-

of the floc were independent of the initial solids concentrat'ion, the quirements in pquare feet per ton solids per day of the four beet

sugar plant3 were calculated:

Plant A 2.4

Table:l. Effect of initial Concentration on Final Concentration Plant B 3.4

Plant C 2.0

________Conerntiation,

~- Grams/Liter

- ~

Plant D 2.5

hlctallulgical Pulp

Initial 182 1%: 242 203 338

Final 1082 iiin 1236 1273 1295

Ca1ciL;in Carbonate Table II. Thickener Unit Areas a t Beet Sugar Plants Deter-

Initial 27.3 70.5 1OR 201 mined from Operating Data and Batch Tests by Kynch

Final 761 795 810 859 Procedure

Unit 4rea. 8 Ft./

Initial 16 1 35.0 63 .n Ton Solids?i)ay

____^__

Final 210 202 307 Plant Location Actual Kync!i

Cement R o c b i i B A Idaho 6.98 6.88

B Colorado 19.4 16 . .5

Initial 151 BFO C Montana 5.23 5 zn

Final IO50 1265 D California 4.64 5.32

40 INDUSTRIAL AND ENGINEERING CHEMISTRY Vol. 47, No. P

ENGINEERING. DESIGN. AND PROCESS DEVELOPMENT

T h e differences between these values and the actual values U = upward layer velocity, ft./day

shown in Table I1 clearly indicate the hazard of this procedure U A = unit area, sq. ft./ton solids/day

V = particle settling velocity, ft./day

and indicate the utility of the Kynch method. V2 = particle settling velocity at concentration GI ft./day

Nomenclature

Acknowledgment

A = cross-sectional area, sq. ft.

C = Concentration, tons/cu. ft. T h e authors wish t o thank R. H. Van Note of the Dorr Co.,

Co = initial concentration, tons/cu. ft. for supplying the thickening data on the sugar beet industry.

C, = concentration of pulp at pulp-water interface, tons/cu. ft.

C , = concentration of underflow, tons/cu. ft.

Ho = initial height, ft. literature Cited

H I = height of intercept of tangent t o point ( H z , ~and

) H axis,

ft. (1) Anable, A., in Chemical Engineers Handbook (J. H. Perry, edi-

H z = pulp height at time h, ft. tor), 3rd ed., p. 397, McGraw-Hill, New York, 1950.

H , = height pulp would occupy if solids were at underflow (2) Coe, H. S., and Clevenger, G. H., Trans. Am. Inst. Mining Engrs.,

concentration, It. 55, 356 (1916).

t = time, days (3) Kynch, G. J., Trans. Faraday SOC.,48, 161 (1952).

t’ = time required to eliminate A(Hi -

H,) units of water, (4) Roberts, E. J., Mining Eng., 1, 61 (1949).

days

= time at which pulp height is Hz,days RECEIVED for review May 10, 1954. ACCEPTED October 6, 1054.

tu = time a t intersection of tangent to point (H2,h) and H., Presented before the Division of Industrial and Engineering Chemistry at the

days 126th Meeting of the AMERICAN CBEMICAL SOCIETY, h’ew York, X. Y .

Dynamic Adiabatic Air Drying

with Bead-Type Desiccant

H. G. GRAYSON

Socony-Vacuum Oil Co., Inc., 26 Broadwoy, New York 4, N. Y.

s TRIPPED of individual refinements, dynamic gas drying

units operate on a few basic principles. The air or gas is

forced through t h e bed of desiccant until the bed reaches a certain

Much of the data published on air drying by solid desiccants

have been obtained on laboratory scale equipment operated under

isothermal conditions-Le., the heat of adsorption was removed

degree of saturation At this point the flow is directed to another by proper cooling to maintain a constant temperature (1,4, 6).

bed of desiccant while t h e first bed is being reactivated by the ap- The equipment used for the studies described in this paper was of

plication of heat. T h e most important properties of a desiccant sdmicommercial size containing 6.5 to 24.5 pounds of desiccant.

in dynamic dehumidification are its moisture adsorption capacity depending on bed depth, and runs were made under “adiabatic”

and its ability to lower the dew point of the effluent gas stream. conditions.

When a humid gas stream passes through a bed of desiccant, I n industrial installations truly adiabatic adsorption is never

t h e first gas t h a t comes in contact Fith the desiccant is dried to obtained because insulation is not sufficient to suppress heat losses

the dew point characteristic of the desiccant. The layer of entirely. Consequently, the term “adiabatic” is considered as

desiccant nearest the inlet becomes saturated rapidly during this meaning t h a t no attempt was made to remove the heat of ad-

phase and little or no drying of the gas occurs as it approaches the sorption, and that the equipment was insulated.

outlet side of the bed. As further increments of humid gas pass

through the bed, the zone of saturated desiccant progresses stead-

ily through the bed, but the dew point of the effluent gas remains Semicommercial Size Drying Tower I s

practically constant. As the zone approaches the outlet side, the Operated under Adiabatic Conditions

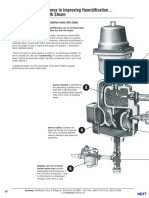

dew point of the effluent gas rises sharply and increases until it The equipment, as shown in Figure 3, comprised the apparatus

equals t h a t of the incoming gas stream. The bed is completely used for the adsorption and desorption runs. The flow was as

mturated at this point, and the amount of moisture adsorbed is follows:

known a8 the equilibrium capacity. The magnitude of the equilib-

Laboratory air from a 100-pound main passed through a 6 X

rium capacity depends on the relative humidity of the incoming 12 inch filter pot filled with a desiccant to remove any entrained

gas and is affected only slightly by temperature, as shown in compressor oil or moisture, then through a fiberglass filter and

Figure 1 for the range 50’ to 150” F Furthermore, air velocity strainer to complete the cleanup. The air flow was controlled

and desiccant bed depth have no effect on this capacity (6). by a hand-control valve and bypass. T h e control of the steam,

which was injected to regulate the inlet humidity, posed somewhat

I n actual operation, a drying unit is seldom run so t h a t the des- of a problem, as the amount was as low as 0.04 pound per hour

iccant reaches its equilibrium capacity If it were, its drying for the low velocity-low humidity runs. The source of steam

efficiency would decrease rapidly near the end of the cycle. A from the 100-pound main was wet as the boilers were located

typical adiabatic drying run dew point curve (Figure 2) indicates several thousand feet away. The steam required not only

throttling and accurate control, b u t also continuous bleeding

a sharp rise in the dew point versus capacity curve. The instant t o remove any condensed water. The eteam system consisted of

of eitluent dew point rise is known as t h e break point, and the a hand-control valve (of the type used in instrument air throb

quantity of moisture adsorbed up t o that point is known as the tling), a separator pot with bleed line and pressure gage, a needle

break point capacity, dry gas capacity, or capacity at maximum valve in the vapor line off the separator, and a restricting orifice

just upstream of the steam-air mixing point. The size of the

efficiency. It is the break point capacity t h a t is of greatest im- restricting orifice was determined by trial and error. Several

portance to the designer and operator of drying units producing orifices were drilled; the smallest size was tried first and found to

very low dew point effluents and not the equilibrium capacity be adequate to handle the total range of flows required.

January 1955 INDUSTRIAL AND ENGINEERING CHEMISTRY 41

Вам также может понравиться

- Talmage Determining Thickener Unit Areas PDFДокумент4 страницыTalmage Determining Thickener Unit Areas PDFpixulinoОценок пока нет

- Current Theory and Thickener Design PDFДокумент11 страницCurrent Theory and Thickener Design PDFMabel Ginestar100% (1)

- Document 2Документ7 страницDocument 2Paen ZulkifliОценок пока нет

- Consolidation Test: Askari - Med Al Eng - Moham Soil LabДокумент7 страницConsolidation Test: Askari - Med Al Eng - Moham Soil LabAmira SyazanaОценок пока нет

- Application of Surface-Renewal-Stretch Model For Interface Mass TransferДокумент13 страницApplication of Surface-Renewal-Stretch Model For Interface Mass Transfer季理Оценок пока нет

- Iv PDFДокумент41 страницаIv PDFEd Gar YundaОценок пока нет

- Thickener Design 1Документ8 страницThickener Design 1Piyush SahuОценок пока нет

- Secondary SedimentationДокумент7 страницSecondary SedimentationSalem GarrabОценок пока нет

- Schlichthaerle & Werther - Axial Pressure Profiles and Solids Concentration Distributions in The CFB Bottom ZoneДокумент9 страницSchlichthaerle & Werther - Axial Pressure Profiles and Solids Concentration Distributions in The CFB Bottom ZoneJoão RibeiroОценок пока нет

- Brittle DuctileДокумент12 страницBrittle DuctileMahmood KhanОценок пока нет

- Lect.12&13 ConsolidationДокумент34 страницыLect.12&13 ConsolidationlkhdasouОценок пока нет

- 11-Rate of ConsolidationДокумент25 страниц11-Rate of ConsolidationHoracioCruiseОценок пока нет

- 03-Control of Primary PatriculatesДокумент239 страниц03-Control of Primary PatriculatesYolanda Hadameon SiregarОценок пока нет

- SedimentationДокумент6 страницSedimentationmunazzil.cscОценок пока нет

- Mass Transfer Theories - AbsorptionДокумент56 страницMass Transfer Theories - Absorptionmamidi padmakar100% (1)

- ChromatographyДокумент43 страницыChromatographyhiuОценок пока нет

- Gravity Sedimentation (Thickeners) -محولДокумент14 страницGravity Sedimentation (Thickeners) -محولمروان الشباليОценок пока нет

- Ktunotes - In: Geotechnical Engineering I (Ce208) Compressibility and ConsolidationДокумент10 страницKtunotes - In: Geotechnical Engineering I (Ce208) Compressibility and Consolidationameena ameeraliОценок пока нет

- Artículo Liquid Phase Mass Transfer Resistancec in Small Scale Packed Distillation CollumnДокумент7 страницArtículo Liquid Phase Mass Transfer Resistancec in Small Scale Packed Distillation CollumnAnaid GarciaОценок пока нет

- C1-1 Paper1Документ16 страницC1-1 Paper1hastomiОценок пока нет

- Kinetics of Flotation PDFДокумент24 страницыKinetics of Flotation PDFishuОценок пока нет

- An Experimental Approach: Luis Alfonso Torres, Imelda Hernandez-Contreras, and Juan Antonio GuardadoДокумент4 страницыAn Experimental Approach: Luis Alfonso Torres, Imelda Hernandez-Contreras, and Juan Antonio GuardadoArmando LermaОценок пока нет

- Mass Transfer During Single Drop Formation A. T. POPOVICH, R. E. JERVIS and 0. TRASS PDFДокумент9 страницMass Transfer During Single Drop Formation A. T. POPOVICH, R. E. JERVIS and 0. TRASS PDFMuhammad Al-DulaimyОценок пока нет

- Classical Nucleation TheoryДокумент11 страницClassical Nucleation Theorypapillon tubaОценок пока нет

- AdsorptionДокумент56 страницAdsorptionSiti Nurshahira100% (1)

- Toor Marchello膜渗透理论 PDFДокумент5 страницToor Marchello膜渗透理论 PDFGoKwo WongОценок пока нет

- Settling and Floatation - Part 2Документ67 страницSettling and Floatation - Part 2donsombreroОценок пока нет

- Kinetics of Flotation.Документ24 страницыKinetics of Flotation.Muayad100% (1)

- Chromat Draft1Документ5 страницChromat Draft1deebieroyОценок пока нет

- NKN Fåíêççìåíáçå: H.-J. G. DierschДокумент9 страницNKN Fåíêççìåíáçå: H.-J. G. Dierschcristian.quilicheОценок пока нет

- Sedimentation 4Документ1 страницаSedimentation 4ace dela cruzОценок пока нет

- Sunneset & Al (1989) - Evaluation of Soil Parameters FromДокумент14 страницSunneset & Al (1989) - Evaluation of Soil Parameters FromJennifer MillerОценок пока нет

- Mass Transfer TheoriesДокумент4 страницыMass Transfer TheoriespandianvijaybharathiОценок пока нет

- Thickener Design and Theory ProblemsДокумент9 страницThickener Design and Theory ProblemsRodrigo GarcíaОценок пока нет

- Nuclear Reactor Theory by Bell and GlasstoneДокумент637 страницNuclear Reactor Theory by Bell and Glasstonemarort91Оценок пока нет

- Sedimentation: μ dz dθ k z−zДокумент2 страницыSedimentation: μ dz dθ k z−zace dela cruzОценок пока нет

- Lect 3 Mass Transfer - PTДокумент17 страницLect 3 Mass Transfer - PTOmed. HОценок пока нет

- Assignment 1Документ11 страницAssignment 1Robert JacksonОценок пока нет

- Lec.3 Part 1 Mass Transfer PDFДокумент15 страницLec.3 Part 1 Mass Transfer PDFاحمد حمید کارسول عزیزОценок пока нет

- Unit 4Документ13 страницUnit 4Ajay ThonteshОценок пока нет

- Mencinger 2011Документ20 страницMencinger 2011Mahfoud AMMOURОценок пока нет

- Two Film TheoryДокумент25 страницTwo Film TheoryamirulОценок пока нет

- Di8Nsion A-Iron : Coefbcient of C inДокумент5 страницDi8Nsion A-Iron : Coefbcient of C inMahsaОценок пока нет

- The Diffusion Equation A Multi - Dimensional TutorialДокумент12 страницThe Diffusion Equation A Multi - Dimensional Tutorialmanjumv27Оценок пока нет

- Impo1 9Документ20 страницImpo1 9mouhcine maouhoubОценок пока нет

- Black Holes and Gravitational Waves in SДокумент6 страницBlack Holes and Gravitational Waves in SDiogo MesquitaОценок пока нет

- Bell Glasstone Nuclear Reactor TheoryДокумент637 страницBell Glasstone Nuclear Reactor Theorysavelyk135167% (6)

- Black Hole Quasibound Sates From A Draing Bathtub Vortex FlowДокумент6 страницBlack Hole Quasibound Sates From A Draing Bathtub Vortex FlowDelcio AlmeidaОценок пока нет

- Difusion Pryde PDFДокумент5 страницDifusion Pryde PDFadrianaОценок пока нет

- Hindered Settling of Mud Ocs: Theory and Validation: P.J.T. Dankers, J.C. WinterwerpДокумент15 страницHindered Settling of Mud Ocs: Theory and Validation: P.J.T. Dankers, J.C. Winterwerpsdevoe14Оценок пока нет

- Settling Velocities of Particulate Systems, 6 Kynch Sedimentation ProcessesДокумент20 страницSettling Velocities of Particulate Systems, 6 Kynch Sedimentation ProcessesChristy Alexandra Solano GavelánОценок пока нет

- C8 CusslerДокумент33 страницыC8 Cusslerraj_zzz80Оценок пока нет

- SedimentationДокумент1 страницаSedimentationmarianmicianoОценок пока нет

- Onda Et Al-1959-AIChE JournalДокумент5 страницOnda Et Al-1959-AIChE Journalsunilsaini262hbtiОценок пока нет

- Design of Fixed Bed Adsorption ColumnsДокумент9 страницDesign of Fixed Bed Adsorption ColumnsDipaloy DattaОценок пока нет

- Adsorption in Packed Bed: Experiment No-3Документ7 страницAdsorption in Packed Bed: Experiment No-3Harsh DuttaОценок пока нет

- On Liquid Diffusion: Adolph FickДокумент6 страницOn Liquid Diffusion: Adolph FickJulio SantosОценок пока нет

- Chapter 14Документ22 страницыChapter 14carlos neiraОценок пока нет

- Spreadsheet To Design SeparatorsДокумент21 страницаSpreadsheet To Design Separatorssemarasik_651536604Оценок пока нет

- 2004-Zhiliang Et Al. - Thermodynamics of The Single-Step Synthesis of-DME From Syngas PDFДокумент9 страниц2004-Zhiliang Et Al. - Thermodynamics of The Single-Step Synthesis of-DME From Syngas PDFMarija SaricОценок пока нет

- Directive 077Документ58 страницDirective 077Les VadnaiОценок пока нет

- Twin FilterДокумент5 страницTwin Filterjinyuan74Оценок пока нет

- Kobelco KNW L-Series Water Cooled Compressor DatasheetДокумент2 страницыKobelco KNW L-Series Water Cooled Compressor DatasheetelrajilОценок пока нет

- ChE 206.01 Introduction To Hydrate Inhibition and DehydrationДокумент79 страницChE 206.01 Introduction To Hydrate Inhibition and DehydrationMo'tasem Serdaneh100% (1)

- Epc Spam - FeedДокумент58 страницEpc Spam - FeedMeylisa SinagaОценок пока нет

- Mercer Valves PDFДокумент16 страницMercer Valves PDFJamesTorresPalmaОценок пока нет

- RMS 30 To 55Документ2 страницыRMS 30 To 55nuno paivaОценок пока нет

- Service Training ElectricДокумент64 страницыService Training ElectricКеня КеняОценок пока нет

- Atlas Copco XAS 185 JD7Документ2 страницыAtlas Copco XAS 185 JD7Oscar Eduardo Veloza QuinteroОценок пока нет

- GX 2 5 Aib 20158004Документ70 страницGX 2 5 Aib 20158004AR COMPRESSORESОценок пока нет

- UmidificadorДокумент2 страницыUmidificadorRenan Zanella LorenzoniОценок пока нет

- RACOR 500FG Turbine SeriesДокумент8 страницRACOR 500FG Turbine Serieswarrimaint2Оценок пока нет

- 518 STD USA Centrifuge Manual Part 90-90-061-RevAДокумент109 страниц518 STD USA Centrifuge Manual Part 90-90-061-RevAkanwarОценок пока нет

- EcoTop o M Ecotechnic EnglishДокумент8 страницEcoTop o M Ecotechnic EnglishmartinОценок пока нет

- Working InstructionsДокумент666 страницWorking Instructionsjamukanak padОценок пока нет

- KESSEL 010 382 Grease SeparatorsДокумент31 страницаKESSEL 010 382 Grease SeparatorsDenise Koh Chin HuiОценок пока нет

- SPM 2000Документ696 страницSPM 2000ENMANUELОценок пока нет

- Compressor Ingersool PDFДокумент52 страницыCompressor Ingersool PDFFabripreta Santos100% (1)

- 15 PPM Bilge AlarmДокумент9 страниц15 PPM Bilge AlarmIgnacio SantanaОценок пока нет

- GR 110Документ40 страницGR 110Johnny Martinez100% (1)

- Delbag Filter System MultiAir Eco 2000-MWFДокумент12 страницDelbag Filter System MultiAir Eco 2000-MWFnileshОценок пока нет

- Kitchen Design GuideДокумент48 страницKitchen Design GuideSongAn Bui100% (1)

- Drainage Philosophy: Page 1 of 9Документ9 страницDrainage Philosophy: Page 1 of 9Javad MonfaredОценок пока нет

- Specifying SeparatorsДокумент33 страницыSpecifying Separatorsdinesh_hsenid100% (1)

- TR Diss 1672 PDFДокумент302 страницыTR Diss 1672 PDFsalamrefighОценок пока нет

- Overview of Artificial Lift SystemsДокумент19 страницOverview of Artificial Lift SystemsyesicaОценок пока нет

- A Review of Rapid Gas-Solid Separation Techniques, Int J Chem Reactor Eng 2010Документ75 страницA Review of Rapid Gas-Solid Separation Techniques, Int J Chem Reactor Eng 2010ejhnoram0% (1)