Академический Документы

Профессиональный Документы

Культура Документы

Harc TLC Kd-1revisi

Загружено:

tanjungkasri rayaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Harc TLC Kd-1revisi

Загружено:

tanjungkasri rayaАвторское право:

Доступные форматы

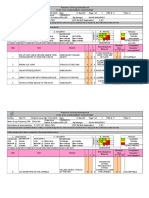

Hazard Analysis and Risk Control Record

Task/Process

Revision: Feb 8, 2010 TLC Logging

Assessed:

Date: 23-Oct-2011 Location: IDJV

Operation: TLC Logging Operation Assessment Team: A.Tarmizi / Awi / Eric Vianney /Imam M./Abu S./Bastomi/Arief B./Herman

HAZARD INITIAL RISK CONTROL MEASURES RESIDUAL RISK

Hazard Description List all Current and Planned Control Measures, taking into Account all

Likelihood

Likelihood

and Worst Case

Risk Level

Risk Level

Loss Contributing and Escalating Factors

Severity

Severity

Consequences with Category/

no Prevention or

Activity Mitigation Measures Population Current and Planned Prevention Current and Planned Mitigation

Steps in Place Affected Measures to reduce Likelihood Measures to reduce Severity

Unlikely (2)

Serious (-2)

Acceptable (-4)

Moving the Gravitational Potential Personnel Certified slings and lifting point. Use mechanical lifting when available.

TLC Energy (Stepping, Assets Full compliance with deck crew lifting Use trolleys to move tools around work

equipment to Handling, Lifting) Reputation assessment. area.

the drill floor. Toolbox talk prior to lifting. Personnel trained in handling techniques.

Catastrophic (-4)

Intolerable (-12)

Dropped objects. Adequate cleared space to spot load. Correct PPE available.

Schlumberger Private

Possible (3)

Damage to equipment. Dedicated flagman to guide crane. Weight of load clearly marked.

Non-essential personnel kept clear of area. All mechanical lifting operations to be

Fatal injury to personnel. Tag lines used on all lifts. conducted by competent rig crew with

Good housekeeping. technical assistance were required from

Restriction on lifting in adverse weather. SLB crew.

Escape routes for available flagman and

crew.

Restricting access to essential personnel

only.

Unlikely (2)

Serious (-2)

Acceptable (-4)

Inexperienced Personnel Detailed pre job meeting with client. Toolbox talk to review JSA.

rig crew. Serious injury. Information Safety meeting with every one involved in Permit to work.

Client operation.

Intolerable (-12)

Damage to equipment. Assets

unaware of Invalid data. Reputation Follow procedures (TLC_SOP_IJDV)

Major (-3)

Likely (4)

TLC operating TLC training given to rig crew by engineer .

procedures. TLC video shown to inexperienced rig crew

Good communication channels between driller

and winchman

Hold toolbox talk prior to job start.

SLB Competent / Trained personnel.

Unlikely (2)

Serious (-2)

Acceptable (-4)

Rig up/down Gravitational Potential Personnel Use certified lifting equipment. Vertical rig up of tools.

tools (bottom Energy (Stepping, Assets Attach sheave to rated structure. PPE to be worn at all times.

Catastrophic (-4)

Intolerable (-12)

hole Handling, Lifting) Reputation SLB competent/trained personnel. Restricting access to essential personnel

Possible (3)

assembly) Dropped objects. SIPP training techniques to be followed. only.

Damage to equipment. Good housekeeping. Open holes cowerd.

Fatal injury to personnel.

HARC Record Template OFS-QHSE-S020 Page 1 of 2 Template Revised: 23 -10- 11

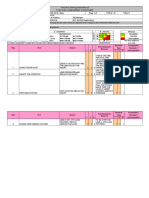

Acceptable (-4)

Unlikely (2)

Serious (-2)

Running tools Gravitational Potential Assets Establish clear communication channels RIH drill pipe at 3 min/stand. Smooth stops

in hole. Energy. Information between rig crew, third party and Schlumberger and starts. Drill pipe not to be rotated.

Catastrophic (-4)

Intolerable (-12)

Damage to equipment crew. Rotary table to be locked

Possible (3)

due to crushing. No hydraulic jars in drill string

Unable to latch due to Minimum dope on drill pipe. Condition mud

contaminated mud. before RIH. Circulate every 10 stands for 5

min.

Acceptable (-4)

Unlikely (2)

Serious (-2)

Latching and Gravitational Potential Personnel Establish clear communication channels Do not exceed clamp rating.

Unlatching of Energy. Information between rig crew, third party and Schlumberger PPE to be worn at all times.

Catastrophic (-4)

Intolerable (-12)

cable and Moving parts. Assets crew.

Possible (3)

cable clamp Injury to personnel. Reputation Clear rig floor while cable is under tension.

test.

Schlumberger Private

Damage to equipment. Stop movement of cable when working on side

entry sub.

Acceptable (-4)

Unlikely (2)

Serious (-2)

POOH Damage to equipment. Damage Establish clear communication channels Do not exceed tool compression/tensile

to between rig crew, third party and ratings.

Catastrophic (-4)

Intolerable (-12)

Data

equipment Schlumberger crew. Move drill pipe at 3 min/stand.

Possible (3)

acquisitio

n. Invalid data. Do not RIH with calipers open. Use TLC kit.

Avoid tagging TD.

HARC Record Template OFS-QHSE-S020 Page 2 of 2 Template Revised: 23 -10- 11

Вам также может понравиться

- Villa LeadsДокумент26 страницVilla LeadsSapan Babbar0% (1)

- Rig Specific Emergency Response Plan Rev1Документ33 страницыRig Specific Emergency Response Plan Rev1bilou100% (1)

- Completion FluildДокумент154 страницыCompletion FluildCHUKWUEMEKE OSONDUОценок пока нет

- Rig Up Rig DownДокумент4 страницыRig Up Rig DownIng IngОценок пока нет

- SPE 81130 A Look at Batch Drilling in Trinidad and TobagoДокумент4 страницыSPE 81130 A Look at Batch Drilling in Trinidad and TobagoDiego LopezОценок пока нет

- Users Manual Tejt C Series 09 2005Документ122 страницыUsers Manual Tejt C Series 09 2005Jorge EvanszОценок пока нет

- Precision Drilling International Task Risk Assessment WorksheetДокумент1 страницаPrecision Drilling International Task Risk Assessment WorksheetAbdul Hameed OmarОценок пока нет

- 3.402-Sop For Vacuum TruckДокумент2 страницы3.402-Sop For Vacuum Truckkirandevi1981Оценок пока нет

- ASCE 7-22 CH 06com - For PC - SouДокумент143 страницыASCE 7-22 CH 06com - For PC - SousharethefilesОценок пока нет

- JHA of Painting PDFДокумент3 страницыJHA of Painting PDFTanver Ali100% (1)

- BFP Best PracticesДокумент18 страницBFP Best PracticesJethro Villasanta100% (1)

- Nipple Up Nipple Down BOP Using BOP Hoist - RA-R9-01-025-01Документ1 страницаNipple Up Nipple Down BOP Using BOP Hoist - RA-R9-01-025-01cmrig74Оценок пока нет

- Moving Convoy Wide Load - RA-R9-01-014-01Документ2 страницыMoving Convoy Wide Load - RA-R9-01-014-01cmrig74Оценок пока нет

- Viking H Se ManualДокумент168 страницViking H Se ManualAF Dowell MirinОценок пока нет

- Newpark 2022 PresentationДокумент32 страницыNewpark 2022 Presentationsarah96.alshawamikh100% (1)

- Hazard Analysis and Risk Control Record: Schlumberger-PrivateДокумент6 страницHazard Analysis and Risk Control Record: Schlumberger-Privatehans vatriolisОценок пока нет

- SP-1010 - Specification For Environmental Noise and VibrationДокумент11 страницSP-1010 - Specification For Environmental Noise and VibrationLeo BartonОценок пока нет

- Safe Cards TCPDC-4002Документ10 страницSafe Cards TCPDC-4002Yaqoob IbrahimОценок пока нет

- Explosives: Schlumberger Field Safety ProceduresДокумент1 страницаExplosives: Schlumberger Field Safety ProceduresfarajОценок пока нет

- Rig Acceptance Check ListДокумент2 страницыRig Acceptance Check ListAhmedОценок пока нет

- Hazard Hunt Status 26-08-2017Документ28 страницHazard Hunt Status 26-08-2017Yaqoob IbrahimОценок пока нет

- Apprisk Assessment HAZOPДокумент1 страницаApprisk Assessment HAZOPHakim YahiaouiОценок пока нет

- SLP STD 28 CHIKSANДокумент20 страницSLP STD 28 CHIKSANmashanghОценок пока нет

- IADC Incident StatisticsДокумент15 страницIADC Incident StatisticsAnisBelhajAissaОценок пока нет

- Work With A Valid Work Permit When Required: ObjectiveДокумент9 страницWork With A Valid Work Permit When Required: ObjectiveRoshin99Оценок пока нет

- Training Requirements - Rig Inspection ChecklistДокумент4 страницыTraining Requirements - Rig Inspection ChecklistNeyaz MD ArFinОценок пока нет

- Drilling Rig Checklist Rev1Документ29 страницDrilling Rig Checklist Rev1Omaira Sánchez OrtizОценок пока нет

- RISK Assement AGE-DSV-HIGH SPEED DOOR-30.05.2023Документ6 страницRISK Assement AGE-DSV-HIGH SPEED DOOR-30.05.2023arabiangulfdoorest2008Оценок пока нет

- JSA-009a Drilling and Mon Well Construction-Sonic - 2Документ4 страницыJSA-009a Drilling and Mon Well Construction-Sonic - 2sudarmanОценок пока нет

- Saudi Aramco Climate Risk VenДокумент22 страницыSaudi Aramco Climate Risk Venxtrooz abiОценок пока нет

- BOP Nipple Down 17-May-2010Документ1 страницаBOP Nipple Down 17-May-2010HAMDI RAFIEK100% (2)

- Halliburton Pre-Spud ChecklistДокумент10 страницHalliburton Pre-Spud ChecklistLijo JohnОценок пока нет

- Step Change Task Risk Assessment Guide PDFДокумент38 страницStep Change Task Risk Assessment Guide PDFnsadnanОценок пока нет

- BSD-GL-HAL-HMS-100 - (Terms & Definitions)Документ42 страницыBSD-GL-HAL-HMS-100 - (Terms & Definitions)Eduard GadzhievОценок пока нет

- JSA CT Cement (Example)Документ2 страницыJSA CT Cement (Example)aneshse100% (1)

- Data Logger Discovery Risk Assessment 1Документ1 страницаData Logger Discovery Risk Assessment 1Coin DozerОценок пока нет

- Rig - LOUISIANA - JSA-IN-HAL-DF-402 CLEANING OF MIXING TANK 2018.10.28Документ7 страницRig - LOUISIANA - JSA-IN-HAL-DF-402 CLEANING OF MIXING TANK 2018.10.28Aziz AndriyantoОценок пока нет

- DrillSafe Forum Mar04 SCHLUMBERGER Paul Young Hazard Management PDFДокумент20 страницDrillSafe Forum Mar04 SCHLUMBERGER Paul Young Hazard Management PDFHamdi RafiekОценок пока нет

- SP1010 HSE Specification - Environmental Noise and VibrationДокумент12 страницSP1010 HSE Specification - Environmental Noise and Vibrationcall_mustafas2361Оценок пока нет

- Tennin HAZOPДокумент4 страницыTennin HAZOPMohamed SamirОценок пока нет

- JSA HEMP Well Services Pg25-30Документ5 страницJSA HEMP Well Services Pg25-30Ashok SureshОценок пока нет

- List of Oil Field Acronyms (00000003)Документ31 страницаList of Oil Field Acronyms (00000003)Htoo Htoo KyawОценок пока нет

- RA-0021 Eastern Perumai at Fujairah Port (Drydock Area) BLASTING & PAINTINGДокумент6 страницRA-0021 Eastern Perumai at Fujairah Port (Drydock Area) BLASTING & PAINTINGJustine Christian DimaculanganОценок пока нет

- F0810 - Pre-Post Rig Move Meetings FormsДокумент18 страницF0810 - Pre-Post Rig Move Meetings FormsPaulОценок пока нет

- High H2S Content in Bunker Risk AssessmentДокумент5 страницHigh H2S Content in Bunker Risk AssessmentCharalampos ChatzivasileiouОценок пока нет

- Lay Down Drill PipeДокумент2 страницыLay Down Drill PipeAbdul Hameed OmarОценок пока нет

- Wellcontrol dwc01Документ13 страницWellcontrol dwc01daburto2Оценок пока нет

- Change Out Rig Tong DiesДокумент1 страницаChange Out Rig Tong DiesAbdul Hameed OmarОценок пока нет

- PTW #: Location of work:RIG FLOOR Task Description: INSTALL T Piece Supervisor: TBRA #:D-111Документ2 страницыPTW #: Location of work:RIG FLOOR Task Description: INSTALL T Piece Supervisor: TBRA #:D-111DrillerОценок пока нет

- Equipment Register - Pat Testing Original CertificateДокумент3 страницыEquipment Register - Pat Testing Original CertificateSayed AbbasОценок пока нет

- Emergency Response & Contigency Planning StandardДокумент15 страницEmergency Response & Contigency Planning Standardbilou100% (1)

- Segregation of Paper and Cardboard Waste, Polymeric Materials Waste, Glass and TiresДокумент10 страницSegregation of Paper and Cardboard Waste, Polymeric Materials Waste, Glass and Tiresfaik395Оценок пока нет

- Unity Health Safety ManualДокумент19 страницUnity Health Safety ManualKakaraparti SatishОценок пока нет

- Well Handover DocumentДокумент1 страницаWell Handover DocumentCadiffОценок пока нет

- FEHM Final June 2016Документ96 страницFEHM Final June 2016Fatchur RizalОценок пока нет

- Guidelines For Hse AuditingДокумент15 страницGuidelines For Hse AuditingSteppesonОценок пока нет

- Precision Drilling International Task Risk Assessment WorksheetДокумент2 страницыPrecision Drilling International Task Risk Assessment WorksheetAbdul Hameed OmarОценок пока нет

- WSHC - Landscape and Horticulture Guidelines - 16 Jan 2012Документ69 страницWSHC - Landscape and Horticulture Guidelines - 16 Jan 2012lwin_oo2435Оценок пока нет

- HIRAC CraneДокумент2 страницыHIRAC CranetaufikОценок пока нет

- 5.2.2.8 Pick Up Drill Pipes1Документ2 страницы5.2.2.8 Pick Up Drill Pipes1khrayzie bhoneОценок пока нет

- HARC Mast Rais & LowerДокумент2 страницыHARC Mast Rais & LowerBarkat UllahОценок пока нет

- 5.2.2.9 Laydown Drill Pipes1Документ2 страницы5.2.2.9 Laydown Drill Pipes1khrayzie bhone100% (1)

- Telescopic Boom CranesДокумент76 страницTelescopic Boom Cranestanjungkasri rayaОценок пока нет

- Cranes 1Документ27 страницCranes 1tanjungkasri rayaОценок пока нет

- Guidance (RootCause Analysis)Документ4 страницыGuidance (RootCause Analysis)tanjungkasri raya100% (1)

- Grease Pertamina Epx-Nl 2Документ4 страницыGrease Pertamina Epx-Nl 2Achmad Reynaldo MaldiniОценок пока нет

- FOSC-R Training: US Coast Guard Federal On-Scene Coordinator RepresentativeДокумент12 страницFOSC-R Training: US Coast Guard Federal On-Scene Coordinator Representativediegocely700615Оценок пока нет

- SBM MovsДокумент40 страницSBM Movsmervin dipayОценок пока нет

- Disaster Management in IndiaДокумент3 страницыDisaster Management in IndiaAndrew RayanОценок пока нет

- Awareness EditedДокумент123 страницыAwareness Editedmarimar carlonОценок пока нет

- Api 580Документ6 страницApi 580Fernando ArévaloОценок пока нет

- Alameda Fire Department Salaries 2008Документ4 страницыAlameda Fire Department Salaries 2008Action Alameda NewsОценок пока нет

- First Aid PDFДокумент100 страницFirst Aid PDFBettyblazetech100% (3)

- Barangay BudgetДокумент10 страницBarangay BudgetMelvs Navarra100% (1)

- Eia Vijayawada Project PDFДокумент241 страницаEia Vijayawada Project PDFAr Muhammad RiyasОценок пока нет

- DRRR SpeechДокумент1 страницаDRRR SpeechMarl SumaelОценок пока нет

- EMP For The PPG For TA To Afghanistan - AILA Project (Clean Version)Документ30 страницEMP For The PPG For TA To Afghanistan - AILA Project (Clean Version)Ahmad BelalОценок пока нет

- Notice: Meetings: Delaware and Lehigh National Heritage Corridor CommissionДокумент1 страницаNotice: Meetings: Delaware and Lehigh National Heritage Corridor CommissionJustia.comОценок пока нет

- Pittsfield Police Log 9-15-2014Документ5 страницPittsfield Police Log 9-15-2014iBerkshires.comОценок пока нет

- Acknowlegement ReceiptДокумент3 страницыAcknowlegement ReceiptJoanne CaronaОценок пока нет

- Brgy. Camalig, Meycauayan City, BulacanДокумент3 страницыBrgy. Camalig, Meycauayan City, BulacanCarolina VillenaОценок пока нет

- Humanitarian Logistics ThesisДокумент9 страницHumanitarian Logistics Thesisjanchampagnefargo100% (1)

- Potencio Mary Lorelie BalikbayanДокумент32 страницыPotencio Mary Lorelie BalikbayanLorelie PotencioОценок пока нет

- Final Template A GUIDE For EnSciMaTДокумент6 страницFinal Template A GUIDE For EnSciMaTmarvin siegaОценок пока нет

- Environmental Impact Assessment of Uttarakhand Disaster-264 PDFДокумент8 страницEnvironmental Impact Assessment of Uttarakhand Disaster-264 PDFAr Abhinav SrivastavОценок пока нет

- Progress in Disaster Science: Invited ViewpointДокумент9 страницProgress in Disaster Science: Invited ViewpointHalidaAnNabilaОценок пока нет

- Landslide Disaster Risk Management in Bosnia and Herzegovina - RevДокумент19 страницLandslide Disaster Risk Management in Bosnia and Herzegovina - RevIan Conan JuanicoОценок пока нет

- AcronymДокумент10 страницAcronymtarek221Оценок пока нет

- Fire Drill Action PlanДокумент1 страницаFire Drill Action PlanRuby Kris Perez AngelesОценок пока нет

- ICT PolicyДокумент33 страницыICT PolicyBiplobHasanОценок пока нет

- C11 Arc ProtectionДокумент16 страницC11 Arc ProtectionShailesh ChettyОценок пока нет

- ArticlesДокумент92 страницыArticlesryazahamedrОценок пока нет