Академический Документы

Профессиональный Документы

Культура Документы

Big Wood Case Study

Загружено:

damindaАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Big Wood Case Study

Загружено:

damindaАвторское право:

Доступные форматы

Structural Stainless Steel Case Study 06

Masonry support system at

Big Wood School

Big Wood Secondary School in Nottingham is situated on the edge of Bestwood Country Park,

with approximately 750 pupils aged between 11 and 16 currently on the roll. As part of the UK

Government’s Building Schools for the Future initiative, the school is being completely rebuilt

and the first phase of the £18 million development, the construction of three two-storey

rectangular teaching blocks (about 40 m x 20 m in plan), was opened in the autumn of 2009.

The buildings are brick-clad, structural steelwork frames, with composite floors. The brickwork

is supported by a stainless steel masonry support system over the windows (some are in

excess of 9 m wide). The support system provides a horizontal ledge for the masonry and is

fixed to rectangular hollow edge beams.

Material Selection

The masonry support system is made from grade 1.4301 (S30400) austenitic

stainless steel, which is the grade used for most support systems. It complies

with material reference 3 in EN 845-1 [1], the European specification for

ancillary components for masonry. The material was specified with a 1D

standard mill finish (hot rolled, heat treated and pickled) in accordance with

EN 10088-2 [2]. (This is equivalent to a No. 1 finish to ASTM A480.)

A stainless steel support system was preferred to a carbon steel system

because the latter is likely to corrode in the damp environment encountered in

a cavity wall, which might lead to cracking of masonry along mortar joints as

well as bulging brickwork. Once a building has been erected, the masonry

support system is inaccessible; no cleaning, inspection or maintenance is

possible to ensure its structural integrity. Stainless steel has a proven track

Figure 1: General view of Big Wood School

record of adequate durability in cavity wall environments for the design life of

the structure.

Table 1: Typical values for thermal conductivity of

Another reason that stainless steel was chosen is that if the surface is building materials

damaged on site, the transparent ‘passive layer’, which seals the stainless Metal Thermal conductivity

steel from the environment, will instantaneously reform and the lifespan of the [W/(mK)]

component will be unaffected. Aluminium 160

Carbon steel 50

Stainless steel has a significantly lower thermal conductivity than carbon steel Austenitic stainless steel 17

(see Table 1). As masonry support systems are attached to the main structure Brick 0.7

and pass through the insulated cavity to the outer leaf, the lower thermal Plastic 0.2

conductivity minimises the effect of cold bridging, leading to a more thermally

efficient building.

Page 1 Structural Stainless Steel Case Study 06

Masonry support system at Big Wood School

Design

The masonry support system consists of a continuous angle, with brackets

welded to the vertical leg of the angle at regular intervals. The brackets are

fixed to the structural steel frame. This system is more economical for wider

cavities than a conventional continuous angle system (where the angle has to

span the full width of the cavity) and hence the thickness of the angle can be

reduced, leading to a lighter solution. The precise dimensions of the bracket

and angle are determined by the cavity and loading for each specific project.

In Big Wood School, the bracket angle support system was designed to

support 4.5 kN/m2 load with a 170 mm cavity and the bracket projects below

the supporting structural member. Figures 2 and 3 show two of the

arrangements adopted on the first floor of the Maths and Design block. The

majority of the angles and brackets were manufactured from 4 mm thick plate.

Several special corner pieces were fabricated from 6 mm thick plate.

The design of the system involves modelling the angle as a cantilever while

taking into account the behaviour of the angle between the brackets. It is

carried out in accordance with steel design standards, backed up by extensive

physical testing and industry experience. The vertical deflection at the toe of

the angle relative to the structural steelwork is limited to 1.5 mm. Figure 2: Bracket directly connected to rectangular

hollow edge beam

The supporting steelwork was designed to BS 5950-1 [3] using RAM structural

system software. To avoid excessive movement of the support system, the

structural edge member was designed to minimise deflections and

accommodate torsional forces created by the eccentric load from the

brickwork in accordance with Reference [4].

The brickwork cladding is tied to the inner leaf wall at a maximum horizontal

spacing of 450 mm and within 300 mm above the support angle. The tie

details were checked to BS 5628: Part 1 [5] using wind loadings to BS 6399-2

[6].

Pre-cast panels comprising blockwork with slip bricks were tied back to the

secondary steelwork and cold rolled steel framing to achieve the desired

vertically stack-bonded brickwork effect.

Figure 3: Bracket connected to angle beneath

rectangular hollow edge beam

Structural Stainless Steel Case Study 06 Page 2

Masonry support system at Big Wood School

Where the stainless steel support system is bolted to the structural carbon

steel frame, there is a slight risk of bimetallic corrosion if the environment

were to become damp. This would not affect the stainless steel but might

lead to increased corrosion of the carbon steel. To prevent this, the two

metals are isolated from each other by inserting short strips of hi-load DPC

(damp proof course), cut down from rolls, between the back face of the

bracket and the supporting carbon steel rectangular hollow section.

In order to support Nottingham City’s aim to become a zero carbon local

authority within 10 years, Big Wood School incorporates a number of

innovative schemes to reduce carbon emissions and water use. The school

has a renewably fuelled combined heat and power (CHP) plant which

substantially offsets the demand for grid energy, leading to 60 % reduction in

carbon emissions against current UK Building Regulations. (It is the first

education building in the UK to have a pure plant oil CHP plant.) It can sell

electricity to the grid and create revenue through green certificates; energy

consumption and production is displayed in the entrance of the school. The

demand for water from the mains supply is reduced by features such as low-

volume, dual-flush cisterns, automated spray taps and low-flow shower taps

and a rainwater harvesting system collects rainwater from building roofs to be

used to flush toilets.

Fabrication and Installation

Figure 4: Construction of support system shown in

Figure 2 The masonry support system was fabricated from plate and cold formed into

shape.

The loading on the support system is vertical and static and the angle is

permanently subjected to its full design loading. Tight tolerances have to be

observed because slight deviations in bracket dimensions and installed

position of the brickwork cause relatively large effects on the position of the

loading, on the associated deflections and stresses.

The as-built position of the structural frame was checked for its line and level

before the support system design was finalised and manufacture

commenced. Facility was provided for small adjustments in the vertical and

horizontal directions during installation (Figure 6).

To permit horizontal adjustment along the length of the angle, the system was

designed with 10 mm nominal gaps between individual angles and pre-drilled

horizontal slots in the steelwork to facilitate adjustment of the angle position.

Figure 5: Construction of vertically stack bonded

brickwork held up by masonry support

system

Page 3 Structural Stainless Steel Case Study 06

Masonry support system at Big Wood School

To cater for minor deviations in the cavity width, the bearing width of the

masonry wall on the support angle was adjustable. Where the cavity width

was smaller than expected, this necessitated cutting the brick to clear the

angle radius. Ideally the design bearing width of the masonry wall on the angle

is at least two thirds of the width of the wall. To cater for a wider cavity than

expected, full height stainless steel shims were provided, to be inserted

between the face of the structural steelwork and the back of the bracket. The

maximum thickness of the shims is the smaller of the outside diameter of the

fixing bolt or 16 mm, so in Big Wood School the maximum shim thickness is

12 mm. The shims had to be of sufficient length to extend to the bottom of the

bracket; individual shims were as thick as possible.

To permit vertical adjustment, the bracket has a vertical slot which allowed

Figure 6: Accommodation of vertical and horizontal

30 mm vertical adjustment in either direction. To ensure no slip occurs in the

tolerances

fixings, the slotted holes in the brackets have a serrated surface and are

secured into the steel frame with stainless steel serrated washers (at the

correct orientation) and stainless steel set fasteners.

Where access was possible on both sides of the structural steelwork, M12 set

screws were used to fix the bracket to the supporting steelwork, installed in a

14 mm wide horizontal slot (see Figure 3).

M12 Steelgrip fasteners in 20 mm diameter fixing holes were specified for

fixing the bracket directly to the hollow steel section where access is only

available from one side (see Figure 2). They feature a serrated washer that

corresponds with the serrations on the bracket. The serrated surfaces Figure 7: Steelgrip (Patent no. 241 0307)

interlock, and as the head is tightened to the correct torque the sleeve Image courtesy of Ancon Building Products

expands. The fastener consists of a zinc plated sleeve and cone, and a

stainless steel screw and serrated washer (Figure 7).

Information for this case study was kindly provided by Capita Symonds and Ancon Building Products.

References and Bibliography Procurement Details

[1] EN 845-1: 2003 Specification for ancillary components for masonry - Part 1: Client: Inspiredspaces

Ties, tension straps, hangers and brackets (Nottingham) Ltd/

[2] EN 10088-2:2005 Stainless steels. Technical delivery conditions for Nottingham City Council

sheet/plate and strip of corrosion resisting steels for general purposes. Architect: Capita Architecture

[3] BS 5950-1:2000 Structural use of steelwork in building. Code of practice for Civil & Structural Capita Symonds

design - Rolled and welded sections Engineer:

[4] Design of members subject to combined bending and torsion, SCI, 1989 Main contractor: Carillion Building

[5] BS 5628: Part 1:2000 Code of practice for use of masonry. Structural use of Design and Ancon Building Products

unreinforced masonry manufacture of

masonry support

[6] BS 6399-2: 1997 Loading for buildings. Code of practice for wind loads system:

Online Information Centre for Stainless Steel in Construction:

www.stainlessconstruction.com

This series of Structural Stainless Steel Case Studies is sponsored by Team Stainless.

© 2010 SCI, Silwood Park, Ascot, Berks, UK, SL5 7QN Tel: + 44(0)1344 636525 Web: www.steel-sci.org

Вам также может понравиться

- AQA GCSE Combined P5 Test 6 Advanced QPДокумент15 страницAQA GCSE Combined P5 Test 6 Advanced QPdamindaОценок пока нет

- Aqaphysics Epb Paper1Документ11 страницAqaphysics Epb Paper1damindaОценок пока нет

- P1 - Test 7 Energy Advanced: Grade MarkДокумент21 страницаP1 - Test 7 Energy Advanced: Grade MarkdamindaОценок пока нет

- AQA GCSE Triple P5 Test 6 Advanced MSДокумент9 страницAQA GCSE Triple P5 Test 6 Advanced MSdamindaОценок пока нет

- AQA Physics Practice Paper AnswersДокумент3 страницыAQA Physics Practice Paper AnswersdamindaОценок пока нет

- Nov 2002Документ9 страницNov 2002api-26543952Оценок пока нет

- P5 - Test 6 Forces Advanced: Grade MarkДокумент20 страницP5 - Test 6 Forces Advanced: Grade MarkdamindaОценок пока нет

- Science A Physics: Higher Tier Unit Physics P1Документ20 страницScience A Physics: Higher Tier Unit Physics P1damindaОценок пока нет

- Answers For Practice Papers: English LanguageДокумент2 страницыAnswers For Practice Papers: English LanguagedamindaОценок пока нет

- AQA Chemistry Paper 2: Temperature Concentration of Hydrochloric Acid Size of Marble Chips Volume of Carbon DioxideДокумент10 страницAQA Chemistry Paper 2: Temperature Concentration of Hydrochloric Acid Size of Marble Chips Volume of Carbon DioxidedamindaОценок пока нет

- Biology Paper2Документ8 страницBiology Paper2damindaОценок пока нет

- AQA Biology Practice Papers Answers: Paper 1Документ2 страницыAQA Biology Practice Papers Answers: Paper 1damindaОценок пока нет

- Paper1 Shakespeareandthe19th-Centurynovel-Sp-1602829Документ13 страницPaper1 Shakespeareandthe19th-Centurynovel-Sp-1602829damindaОценок пока нет

- English Paper2 ModerntextsandpoetryДокумент9 страницEnglish Paper2 ModerntextsandpoetrydamindaОценок пока нет

- AQA Chemistry Paper 2: Temperature Concentration of Hydrochloric Acid Size of Marble Chips Volume of Carbon DioxideДокумент10 страницAQA Chemistry Paper 2: Temperature Concentration of Hydrochloric Acid Size of Marble Chips Volume of Carbon DioxidedamindaОценок пока нет

- Technical Information Schoeck Isokorb For Steel Structures (8404)Документ104 страницыTechnical Information Schoeck Isokorb For Steel Structures (8404)damindaОценок пока нет

- AQA Biology Practice Papers Answers: Paper 1Документ2 страницыAQA Biology Practice Papers Answers: Paper 1damindaОценок пока нет

- GCSEPaper 2 HSet Aedxe QPДокумент16 страницGCSEPaper 2 HSet Aedxe QPdamindaОценок пока нет

- Paper 1H (Non-Calculator) : GCSE (9-1)Документ11 страницPaper 1H (Non-Calculator) : GCSE (9-1)damindaОценок пока нет

- Tissues, Organs and Organ Systems: ReviewДокумент1 страницаTissues, Organs and Organ Systems: ReviewdamindaОценок пока нет

- Jost-208 ManualДокумент198 страницJost-208 ManualdamindaОценок пока нет

- Fire Protection: Reinforced Concrete - Reinforced ConcreteДокумент8 страницFire Protection: Reinforced Concrete - Reinforced ConcretedamindaОценок пока нет

- Raimondi MR 36+3: Flat Top Tower CraneДокумент3 страницыRaimondi MR 36+3: Flat Top Tower CranedamindaОценок пока нет

- Comansa 5 LC 4010: Flat Top Tower CraneДокумент4 страницыComansa 5 LC 4010: Flat Top Tower CranedamindaОценок пока нет

- Supreme KM 640014 Lintel KitemarkДокумент4 страницыSupreme KM 640014 Lintel KitemarkdamindaОценок пока нет

- City Lifter CL25 Brochure DIGITALДокумент4 страницыCity Lifter CL25 Brochure DIGITALdamindaОценок пока нет

- Prestressed and Precast Lintels: For Strength and ValueДокумент7 страницPrestressed and Precast Lintels: For Strength and ValuedamindaОценок пока нет

- Hip, Valley, & Jack Rafters: Chapter ObjectivesДокумент26 страницHip, Valley, & Jack Rafters: Chapter ObjectivesdamindaОценок пока нет

- Brick Dimensions ChartДокумент1 страницаBrick Dimensions ChartdamindaОценок пока нет

- Simson Joist HangerДокумент5 страницSimson Joist HangerdamindaОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Castro Cafe - Jmi, New DelhiДокумент14 страницCastro Cafe - Jmi, New DelhiAr Ayoushika AbrolОценок пока нет

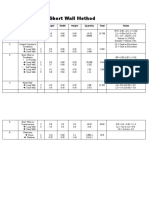

- Long Wall and Short Wall MethodДокумент2 страницыLong Wall and Short Wall MethodRafayMalikОценок пока нет

- Introduction Case Study-Netaji Subhash Place Architectural FeaturesДокумент1 страницаIntroduction Case Study-Netaji Subhash Place Architectural FeaturescharuОценок пока нет

- KPMG Artificial Intelligence Risk and Controls Matrix PDFДокумент111 страницKPMG Artificial Intelligence Risk and Controls Matrix PDFAntar ShaddadОценок пока нет

- Formwork System: CatalogueДокумент83 страницыFormwork System: CatalogueashenafiiОценок пока нет

- PRICELISTДокумент112 страницPRICELISTCatherine AbarabarОценок пока нет

- Ten LakhsДокумент5 страницTen Lakhsvikram BargurОценок пока нет

- S.Kanjibhai Jewellers Indian Architecture Group Indian Retail Spaces in Jewellery Section Feb 2018 PDFДокумент8 страницS.Kanjibhai Jewellers Indian Architecture Group Indian Retail Spaces in Jewellery Section Feb 2018 PDFarun kumarОценок пока нет

- Inspections and Reports On Dwellings Assessing Age (Philip Santo (Author) ) (Z-Library)Документ287 страницInspections and Reports On Dwellings Assessing Age (Philip Santo (Author) ) (Z-Library)Manuel FigueroaОценок пока нет

- Astm C90 PDFДокумент5 страницAstm C90 PDFАртем ТитовОценок пока нет

- RI Rehabilitation Building and Fire CodeДокумент59 страницRI Rehabilitation Building and Fire Codehayeska3527Оценок пока нет

- Sloping Roof Top of A Residential BuildingДокумент34 страницыSloping Roof Top of A Residential BuildingAnjaliОценок пока нет

- Box Culvert Estimate 3/53/0Документ69 страницBox Culvert Estimate 3/53/0veevimalОценок пока нет

- ARX - Museu de IlhavoДокумент3 страницыARX - Museu de IlhavoJosé Eduardo CostaОценок пока нет

- Payment Recommend - Keruing - Beyond - IPC No.9 For M - E WorksДокумент8 страницPayment Recommend - Keruing - Beyond - IPC No.9 For M - E WorksHazim ZakariaОценок пока нет

- Case Study NLДокумент22 страницыCase Study NLEllita RianaОценок пока нет

- Hassan Fathy: "Build Your Architecture From What Is Beneath Your Feet."Документ15 страницHassan Fathy: "Build Your Architecture From What Is Beneath Your Feet."Pranav ChandranОценок пока нет

- Summarecon Makassar: Type XLДокумент51 страницаSummarecon Makassar: Type XLzaidОценок пока нет

- HHPC in BridgeДокумент12 страницHHPC in BridgeAbrahamHidalgoBermúdezОценок пока нет

- Five Stars Hotel HamidaДокумент129 страницFive Stars Hotel Hamidashachika100% (1)

- Material Portfolio: Name:Priyanka V Naik USN:1MS19AT042 Subject:Bmct-Iv Soa, BangaloreДокумент10 страницMaterial Portfolio: Name:Priyanka V Naik USN:1MS19AT042 Subject:Bmct-Iv Soa, Bangalore1MS19AT036 Hemanth kumarОценок пока нет

- Big R Steel BridgesДокумент4 страницыBig R Steel Bridgesstratus02Оценок пока нет

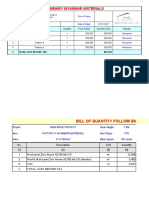

- Summary Myanmar Materials: Project Time of Issue Nien Made Project Factory 3-6Документ9 страницSummary Myanmar Materials: Project Time of Issue Nien Made Project Factory 3-6thang TranОценок пока нет

- Josephgangooresumeupdated 2017Документ2 страницыJosephgangooresumeupdated 2017api-395907496Оценок пока нет

- Inbar Technical Report No19Документ113 страницInbar Technical Report No19alejandra acevedoОценок пока нет

- 6 - Metropol Parasol 2Документ16 страниц6 - Metropol Parasol 2AnshikaSrivastavaОценок пока нет

- Boq Comparative ChartДокумент4 страницыBoq Comparative ChartDeepak Sonkar100% (1)

- Toa Assignment-3 (Theorist)Документ16 страницToa Assignment-3 (Theorist)HimayGajjarОценок пока нет

- Schedule of Rate SarawakДокумент55 страницSchedule of Rate SarawakShiko Shin0% (1)

- Project: Exedy New Factory & Office SUBJECT: Compressor, Air Dryer & Pump PoundationДокумент7 страницProject: Exedy New Factory & Office SUBJECT: Compressor, Air Dryer & Pump PoundationsarkimankimanОценок пока нет