Академический Документы

Профессиональный Документы

Культура Документы

Tes

Загружено:

reddy p0 оценок0% нашли этот документ полезным (0 голосов)

12 просмотров1 страницаqaz

Авторское право

© © All Rights Reserved

Доступные форматы

DOCX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документqaz

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

12 просмотров1 страницаTes

Загружено:

reddy pqaz

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 1

IMG Activities

IMG-->Production-->KANBAN-->Define Number Range for Control Cycle ,

Define Replenishment Strategies-->Define Inhouse,Externale,Stock Transfer Strategies

Define Number range for JIT calls

Maintain Short text for Container status

Define number rangee for JIT calls

What is Milk Run ?

Kanban Process

It is physical process in which ROH matl required for prodn will be replenished to that supply

area.

A milk runner will collect a KANBAN cards from a particular supply area and hand over it to

Supermarket people and they will scan KANBAN card and replenish materials to milk run vehicle.

The required qty is mentioned in KANBAN card only but not in Control cycle in UBK/RBAC

1. Introduction

Kanban Process

G.V.SHIVAKKUMAR venkatesansivakumar@yahoo.co.in

The KANBAN method for controlling production and material flow is based on the

actual stock quantity in production. Material that is required on a regular basis is

continually provided in small quantities in production. Replenishment or the production

of a material is only triggered when a higher production level actually requires the

material. This replenishment is triggered directly in

production using previously maintained master data.

In KANBAN, the signal for material replenishment can be triggered, for

example, by the work center that requires the material (demand source) by sending a

card

to the work center that is

responsible for manufacturing the material (supply source). This card describes which

material is

required, the quantity of the material required and where the material is to be delivered.

The name KANBAN originally stems from these cards, which are called “kanban” in

Japanese.

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Highjump One Ui Basics 1.0Документ35 страницHighjump One Ui Basics 1.0reddy pОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Quick Guide - EDIIDoc Interfacing To SAP ECC From External SystemДокумент16 страницQuick Guide - EDIIDoc Interfacing To SAP ECC From External SystemRicky DasОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Training Manual SAP SNC v1.1Документ47 страницTraining Manual SAP SNC v1.1reddy pОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- Improve Supply Chain Visibility with SAP SNCДокумент40 страницImprove Supply Chain Visibility with SAP SNCreddy pОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

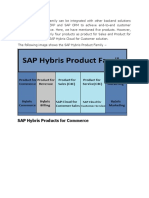

- SAP Hybris Products For CommerceДокумент1 страницаSAP Hybris Products For Commercereddy pОценок пока нет

- Select Field That Would Be Display by This Query. Started by Choosing The Field GroupДокумент8 страницSelect Field That Would Be Display by This Query. Started by Choosing The Field Groupreddy pОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Ale Idoc GuideДокумент11 страницAle Idoc GuideVenkateswara Reddy KolagotlaОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- HybrissДокумент1 страницаHybrissreddy pОценок пока нет

- SAP acquires hybris ecommerce platform in 2013Документ1 страницаSAP acquires hybris ecommerce platform in 2013reddy pОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- SAP PO ConfirmationsДокумент18 страницSAP PO Confirmationsarrowxen8396100% (1)

- SAP Integration Consulting PDFДокумент2 страницыSAP Integration Consulting PDFreddy pОценок пока нет

- Return Po PDFДокумент7 страницReturn Po PDFreddy pОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Add coding in sectionДокумент2 страницыAdd coding in sectionreddy pОценок пока нет

- TyuДокумент3 страницыTyureddy pОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- A Case ScenarioДокумент1 страницаA Case Scenarioreddy pОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Creating ABAP QueryДокумент2 страницыCreating ABAP Queryreddy pОценок пока нет

- What Is ABAP QueryДокумент1 страницаWhat Is ABAP Queryreddy pОценок пока нет

- TyuДокумент7 страницTyureddy pОценок пока нет

- Out of Scope: The Following Areas Are Out of Scope For This Project: Point 1 Point 2 Point 3 Point 4 Point 5Документ2 страницыOut of Scope: The Following Areas Are Out of Scope For This Project: Point 1 Point 2 Point 3 Point 4 Point 5reddy pОценок пока нет

- 1 Project Description: 2.1 in ScopeДокумент1 страница1 Project Description: 2.1 in Scopereddy pОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- YuiДокумент1 страницаYuireddy pОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- Creation of A Batch Search Strategy: Automatic Batch Determination Based On Shelf LifeДокумент1 страницаCreation of A Batch Search Strategy: Automatic Batch Determination Based On Shelf Lifereddy pОценок пока нет

- Example TextДокумент1 страницаExample Textreddy pОценок пока нет

- Goods Receipt & Batch Creation in SAPДокумент1 страницаGoods Receipt & Batch Creation in SAPreddy pОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- YuiДокумент1 страницаYuireddy pОценок пока нет

- TesДокумент1 страницаTesreddy pОценок пока нет

- Configuration in SAP: 1. Import Standard SAP CharacteristicsДокумент1 страницаConfiguration in SAP: 1. Import Standard SAP Characteristicsreddy pОценок пока нет

- Kanban Process: G.V.SHIVAKKUMAR Venkatesansivakumar@yahoo - Co.inДокумент1 страницаKanban Process: G.V.SHIVAKKUMAR Venkatesansivakumar@yahoo - Co.inreddy pОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- TesДокумент1 страницаTesreddy pОценок пока нет