Академический Документы

Профессиональный Документы

Культура Документы

Strux Clinch Studs and Nuts: Optimal Performance in Thin Sheet and Aluminum Sheet Applications

Загружено:

neilОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Strux Clinch Studs and Nuts: Optimal Performance in Thin Sheet and Aluminum Sheet Applications

Загружено:

neilАвторское право:

Доступные форматы

STRUX® Clinch Studs and Nuts

Optimal Performance in Thin Sheet and Aluminum Sheet Applications

Acument® Global Technologies has developed a line of products to meet the increasing demand for

fastener attachment in a wide range of steel and aluminum sheet applications. Our STRUX® line of

clinch fasteners provides an external or internal thread in sheet metal stack-ups where welding is

impossible or undesirable.

®

STRUX Clinch Studs – External Threads

Cost-effective, high performance alternative to other staked or welded products.

STRUX® Clinch Nuts – Internal Threads

A unique configuration offers unmatched performance and reliability when compared to competitive

clinch products.

One Of A Kind Performance

Features Benefits

º Heat treated to SAE grades, ISO classes or to your own º Greater strength

specifications º May replace larger diameter, conventional weld or other

Studs: ISO 898-1 (metric), SAE J1199 (metric); non-heat treated studs

SAE J429 (inch)

Nuts: ISO 898-2 (metric); SAE J995 (inch)

º Displacement lobes and Retaining Groove º Resist push-out and rotation during service

º Can be used where welding is impossible or º Eliminates hazardous welding operations

undesirable, such as joining dissimilar materials, º Reduced potential for corrosion

pre-coated sheets and high strength sheet materials º Provides a cleaner appearance than welded fasteners

º Improved centerline-to-centerline tolerances compared to

weld studs and nuts

º Unlike spot welding, joints can be created in-die with º Lowers in-place costs

clinch fasteners and automated installation equipment º Maximizes assembly flexibility

º Can be installed after the painting or coating process º Changes and damage to the application materials are

without aesthetic damage minimized

º Unlike welding, clinch fasteners do not create a heat º No distortion due to excessive heat

zone in the materials during installation

º Easy installation º Increased production rates when used in a progressive die

º Improved product and joint integrity

º Allows simple visual inspection º Joints do not require destructive testing to determine

installed strength

Efficient Installation Options

Installation of STRUX® fasteners can be achieved by using mechanical or hydraulic presses, whether your application

calls for manual installation or fully automated in-line/in-die systems. Most equipment capable of feeding rivets, weld

®

fasteners or conventional clinch fasteners will install STRUX fasteners.

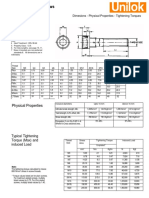

STRUX® Studs Dimensional & Performance Data† – Metric Sizes (all dimensions shown in millimeters)

Approx*

Approx* Unsupported

Mat Recommended Staking Approx* Torsional

Thread S C D K Thick Hole Size Force Pushout Resistance

Size 0.07 0.13 0.25 Max Min Min Max kN kN Nm

1.5 1.0 13.3 1.04 4.80

M4 x 0.7 4.61 1.40 7.75 4.68 4.78

2.3 1.5 16.9 2.27 5.01

1.5 1.0 13.3 1.09 4.00

M5 x 0.8 5.61 1.75 8.75 5.68 5.78

2.3 1.5 16.5 2.22 10.73

1.5 1.0 20.2 1.42 7.69

M6 x 1.0 6.61 2.10 11.00 2.3 1.5 6.68 6.78 25.8 2.56 15.22

3.4 2.3 26.7 4.78 15.22

2.3 1.5 35.6 2.40 26.78

M8 x 1.25 8.61 2.80 15.25 3.4 2.3 8.68 8.78 42.3 6.09 40.06

4.6 3.0 45.4 9.06 40.06

3.4 2.3 66.7 5.92 60.49

M10 x 1.5 10.61 3.50 19.75 10.68 10.78

4.6 3.0 73.4 8.82 84.80

3.4 2.3 73.4 7.26 81.14

M12 x 1.75 12.61 3.80 20.00 12.68 12.78

4.6 3.0 77.8 13.91 124.25

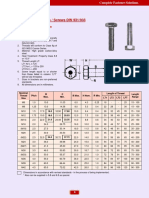

STRUX® Nuts Dimensional & Performance Data† – Metric Sizes (all dimensions shown in millimeters)

Approx*

Approx* Unsupported

Mat Recommended Staking Approx* Torsional

Thread S C D K Thick Hole Size Force Pushout Resistance

Size 0.07 0.19 0.13 Max Min Min Max kN kN Nm

M4 x 0.7 7.13 3.19 10.16 1.5 1.5 7.20 7.30 13.3 0.91 6.19

1.5 1.5 26.7 1.04 12.00

M5 x 0.8 7.61 4.19 11.30 7.68 7.78

1.9 1.9 30.2 1.68 21.32

1.5 1.5 38.7 1.39 18.85

M6 x 1.0 8.61 4.71 14.10 1.9 1.9 8.68 8.78 40.0 2.57 21.04

2.3 2.3 42.3 3.22 32.52

1.5 1.5 44.5 1.53 21.17

M8 x 1.25 10.61 5.93 16.64 1.9 1.9 10.68 10.78 48.9 2.41 41.94

2.3 2.3 57.8 4.58 54.23

2.3 2.3 53.4 4.16 57.21

M10 x 1.5 13.09 7.20 18.42 13.16 13.26

3.4 3.4 57.8 4.28 65.65

2.3 2.3 108.3 4.75 75.39

M12 x 1.75 15.61 9.61 23.88 15.68 15.78

3.4 3.4 109.0 7.66 124.32

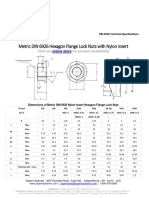

NOTES FOR BOTH STRUX® STUDS AND NUTS:

Other sizes up through M16 available upon request.

Underhead shape and dimensions controlled by manufacturer to meet performance requirements.

*Tests conducted in low carbon steel with a maximum hardness of Rockwell B70.

†Performance data shown are typical results obtained under laboratory conditions. It is recommended that each application be tested individually for precise values.

For performance in materials other than steel, individual testing is a requirement. This data is not to be considered a specification. Contact an Acument® Global

Technologies applications engineer for assistance.

4366 Old US 31 North

Rochester, IN 46975

(574) 223-3131

acument.com

acumentnorthamerica.com

STRUX® and Acument® are trademarks of Acument® Intellectual Properties, LLC.

©2006-11 Acument® Intellectual Properties, LLC. F1051Rev._06/02/11

Вам также может понравиться

- Hex Jam Nut Metric (ISO 4035)Документ1 страницаHex Jam Nut Metric (ISO 4035)Abu IrfanОценок пока нет

- Screw LoadsДокумент2 страницыScrew LoadsserkanОценок пока нет

- RAMSET-DynaBolt PlusДокумент2 страницыRAMSET-DynaBolt PlusPatrick Kelly FontanillaОценок пока нет

- Ramset Specifiers Anchoring Resource Book ANZ - DynaBolt Plus Mechanical AnchoringДокумент2 страницыRamset Specifiers Anchoring Resource Book ANZ - DynaBolt Plus Mechanical AnchoringBrian ChmeisseОценок пока нет

- SS Bolt Properties STD: Din STD ISO 4017 B.S. DIN933 DIN931 DIN931 GB5783 DIN DIN912 Astm DIN603 Ansi DIN6923 JIS EN ASДокумент5 страницSS Bolt Properties STD: Din STD ISO 4017 B.S. DIN933 DIN931 DIN931 GB5783 DIN DIN912 Astm DIN603 Ansi DIN6923 JIS EN ASHithish ReddyОценок пока нет

- Metric DIN 939 Double End Studs (1.25xD) : Visit Our For Product AvailabilityДокумент4 страницыMetric DIN 939 Double End Studs (1.25xD) : Visit Our For Product Availabilitysudarshan pugaliaОценок пока нет

- Ramset SARB ANZ Ed.3 DynaBolt Plus SLEEVE ANCHORSДокумент2 страницыRamset SARB ANZ Ed.3 DynaBolt Plus SLEEVE ANCHORSScott McCallumОценок пока нет

- Ezydek 44 Profile - DimensionsДокумент2 страницыEzydek 44 Profile - DimensionsAnirban BhattacharjeeОценок пока нет

- Datasheet Rigid CouplingДокумент6 страницDatasheet Rigid Couplingaras aliОценок пока нет

- Mechanical Bolt Torque TableДокумент7 страницMechanical Bolt Torque TablesitehabОценок пока нет

- Socket Head Cap ScrewДокумент4 страницыSocket Head Cap ScrewsarbiniОценок пока нет

- PT Bar Systems Brochure 17.05.29Документ8 страницPT Bar Systems Brochure 17.05.29SACHINОценок пока нет

- HayДокумент8 страницHayMinh Tâm TrầnОценок пока нет

- Screws Nuts Washer SizesДокумент5 страницScrews Nuts Washer SizesNanang RisdiantoОценок пока нет

- Wedge Wire Screens - Techincal Info - Screen SystemsДокумент5 страницWedge Wire Screens - Techincal Info - Screen SystemsChris HdezОценок пока нет

- 501-453 Universal Cable GalndsДокумент1 страница501-453 Universal Cable Galndsmeribout adelОценок пока нет

- Is 19781982Документ5 страницIs 19781982Padakandla SumanОценок пока нет

- Pages From Astm-A194-2011pdf - CompressДокумент1 страницаPages From Astm-A194-2011pdf - CompressMuthazhagan SaravananОценок пока нет

- Sizing Steel Sections For BeamsДокумент25 страницSizing Steel Sections For BeamsAnonymous ujfx6mОценок пока нет

- Coupling Forged Steel Astm A105 Class 3000 SWДокумент1 страницаCoupling Forged Steel Astm A105 Class 3000 SWWilliam DelgadoОценок пока нет

- Draka PVCДокумент4 страницыDraka PVCapi-3803155Оценок пока нет

- Style E485-1Документ5 страницStyle E485-1Ummes AhmedОценок пока нет

- HTD HXB cl10.9 Tight TorqДокумент1 страницаHTD HXB cl10.9 Tight Torqaegean227Оценок пока нет

- Iso 965 2 1998Документ8 страницIso 965 2 1998Gerald CelisОценок пока нет

- Metric, Stud, Double End, DIN 939, Class 8.8, Plain: Page 1 of 2 REV-00 Date: September 11, 2018 M.STD - DE.939.8.8.PДокумент2 страницыMetric, Stud, Double End, DIN 939, Class 8.8, Plain: Page 1 of 2 REV-00 Date: September 11, 2018 M.STD - DE.939.8.8.Pdinesh panchalОценок пока нет

- NNDДокумент9 страницNNDdardakОценок пока нет

- Codo 90Документ1 страницаCodo 90RoLopОценок пока нет

- Metric DIN 93 SpecДокумент5 страницMetric DIN 93 SpecJhon Edison Posada MuñozОценок пока нет

- Metric DIN 7980 SpecДокумент4 страницыMetric DIN 7980 SpecGowtham VenkatОценок пока нет

- Dextra: System DescriptionДокумент10 страницDextra: System DescriptionHiba SolimanОценок пока нет

- Victaulic Quick Vic Rigid CouplingsДокумент7 страницVictaulic Quick Vic Rigid Couplingsionut cerneaОценок пока нет

- Hexagon Head Bolts/Screws: Metric Series-DimensionsДокумент7 страницHexagon Head Bolts/Screws: Metric Series-DimensionsVishal MistryОценок пока нет

- Grade 100 Alloy ChainДокумент1 страницаGrade 100 Alloy ChainPanthОценок пока нет

- 27th RA Sump WellДокумент5 страниц27th RA Sump WellKishan Bisalpure RathoreОценок пока нет

- Forged Machinery Eye Bolts: See Application and Warning InformationДокумент1 страницаForged Machinery Eye Bolts: See Application and Warning InformationHasrul SunОценок пока нет

- Metric DIN 439 Spec PDFДокумент4 страницыMetric DIN 439 Spec PDFHasib SejdinovicОценок пока нет

- Drive Technology: Couplings Torque Limiters Clamping Elements Torque Measuring SystemsДокумент3 страницыDrive Technology: Couplings Torque Limiters Clamping Elements Torque Measuring SystemsELİF ORTAОценок пока нет

- Style 807NДокумент7 страницStyle 807NUmmes AhmedОценок пока нет

- Torque Details-Hex Bolt DIN 933Документ2 страницыTorque Details-Hex Bolt DIN 933coolkaisy100% (2)

- Metric DIN 609 SpecДокумент4 страницыMetric DIN 609 SpecCAT MINING SHOVELОценок пока нет

- Examples of ConductorsДокумент16 страницExamples of ConductorsJubert PerezОценок пока нет

- 6991 1726 01 Elemex Catalogue English LR Tcm795-1785111Документ44 страницы6991 1726 01 Elemex Catalogue English LR Tcm795-1785111Jacky_LEOLEOОценок пока нет

- Service DataДокумент12 страницService DataGianni DaBolognaОценок пока нет

- NonPre Hex 4.6 Bolts Eurocode3 1 - 27 - 2020Документ8 страницNonPre Hex 4.6 Bolts Eurocode3 1 - 27 - 2020Alden CayagaОценок пока нет

- 9greens Wire New Rates 8 OctДокумент14 страниц9greens Wire New Rates 8 OctTejas AgrawalОценок пока нет

- Metallic Gaskets - Installation & Torque - October 2020Документ6 страницMetallic Gaskets - Installation & Torque - October 2020Alberto CaveroОценок пока нет

- Expanded Metals PDFДокумент3 страницыExpanded Metals PDFMichael MirandaОценок пока нет

- Veriflex Intercon 1.8-3kV Cable - 1Документ2 страницыVeriflex Intercon 1.8-3kV Cable - 1anastasia abengoaОценок пока нет

- FR Codo de 90 Ac Ced80 Astm A234 Gr. WPBДокумент1 страницаFR Codo de 90 Ac Ced80 Astm A234 Gr. WPBSERVICIOS INTEGRALES OSDAОценок пока нет

- Technical Data: Eagle Opaque 80Документ12 страницTechnical Data: Eagle Opaque 80Emerson FerreiraОценок пока нет

- Installation and Maintenance Instructions For Three Phase Induction MotorsДокумент9 страницInstallation and Maintenance Instructions For Three Phase Induction MotorsAnibal QuezadaОценок пока нет

- 60HSD Series: Hybrid Stepper Motors (1.8 Degree)Документ1 страница60HSD Series: Hybrid Stepper Motors (1.8 Degree)norbertoОценок пока нет

- Tools TipsExtensionsДокумент4 страницыTools TipsExtensionsSolina AlunorteОценок пока нет

- Dimensions of Metric Hex NutsДокумент2 страницыDimensions of Metric Hex Nutsdidik sОценок пока нет

- Peer Tapered Bearing Catalog0413aДокумент210 страницPeer Tapered Bearing Catalog0413aMarceloОценок пока нет

- Metric DIN 6926 SpecДокумент4 страницыMetric DIN 6926 Spec叶开Оценок пока нет

- STPC520 - Viti A Testa Cilindrica Con Esagono IncassatoДокумент18 страницSTPC520 - Viti A Testa Cilindrica Con Esagono IncassatoLucaОценок пока нет

- The Mechanical Behaviour of Engineering Materials: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionОт EverandThe Mechanical Behaviour of Engineering Materials: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionОценок пока нет

- Propeller ShaftДокумент22 страницыPropeller ShaftDede Si Engghe SurenggheОценок пока нет

- Honda MB5 Owners ManualДокумент74 страницыHonda MB5 Owners ManualVijay DanielОценок пока нет

- Series: Masoneilan Spring Diaphragm Actuators Instruction ManualДокумент155 страницSeries: Masoneilan Spring Diaphragm Actuators Instruction ManualWade WaderОценок пока нет

- Accessories Catalogue 17000187 UEL 1Документ12 страницAccessories Catalogue 17000187 UEL 1quiquenuОценок пока нет

- Rotary Base Fluting Jig PDFДокумент4 страницыRotary Base Fluting Jig PDFJaime MontielОценок пока нет

- KcdataДокумент1 страницаKcdatacrash2804Оценок пока нет

- HydraMax and GT-Series Topside Bolt Tensioners en-USДокумент8 страницHydraMax and GT-Series Topside Bolt Tensioners en-USAhmed AlmaghrbyОценок пока нет

- Instrucciones y Manual de Servicio PZ 8, 9 y LДокумент22 страницыInstrucciones y Manual de Servicio PZ 8, 9 y LFernando Mina Reyes100% (1)

- PB 180 Parts Manual 2013 1001Документ14 страницPB 180 Parts Manual 2013 1001VladimirОценок пока нет

- Komatsu Pw160 7h Shop ManualДокумент20 страницKomatsu Pw160 7h Shop Manualdavid100% (53)

- Meritor UpdateTimkenBearings PDFДокумент44 страницыMeritor UpdateTimkenBearings PDFAgus YulfizarОценок пока нет

- Design For Manufacturing and AssemblyДокумент168 страницDesign For Manufacturing and Assemblygnanasekar100% (2)

- Bearing Housing and Shaft DesignДокумент3 страницыBearing Housing and Shaft DesignsjnicholsonОценок пока нет

- Bob Tail Small Diameter PDFДокумент8 страницBob Tail Small Diameter PDFEduardo Granados SánchezОценок пока нет

- VW 20l CBDB Common Rail Engines Timing Belt Guide 1Документ2 страницыVW 20l CBDB Common Rail Engines Timing Belt Guide 1Alberto DiazОценок пока нет

- Bolt, Nut, WasherДокумент9 страницBolt, Nut, WasherAndri EkoОценок пока нет

- FT MedPress AutoclaveДокумент12 страницFT MedPress AutoclaveAymeeenОценок пока нет

- Stainless - 304 Vs F593 PDFДокумент2 страницыStainless - 304 Vs F593 PDFsingaravelan narayanasamyОценок пока нет

- Through Bolt Design EC2Документ3 страницыThrough Bolt Design EC2Mungkorn Satt100% (1)

- Ga90-160 Wux404068 PDFДокумент68 страницGa90-160 Wux404068 PDFGelap Hitam Mencari PutihОценок пока нет

- Befcog34-G42-G50 - (231 530) 5-2010 PDFДокумент60 страницBefcog34-G42-G50 - (231 530) 5-2010 PDFcoyote556Оценок пока нет

- 4865 - 4870B 1999-2007 Parts & Ops 91163Документ99 страниц4865 - 4870B 1999-2007 Parts & Ops 91163Fernando Manuel MichligОценок пока нет

- SKF Manual de ApertosДокумент44 страницыSKF Manual de ApertosA RОценок пока нет

- U35000 PDFДокумент16 страницU35000 PDFsujit5584Оценок пока нет

- Mercury Outboard Motor Installation GuideДокумент20 страницMercury Outboard Motor Installation GuideMick Bissett100% (3)

- Invacare PDFДокумент164 страницыInvacare PDFVisegan CosminОценок пока нет

- DGT BrochureДокумент2 страницыDGT BrochureAungОценок пока нет

- Euclid Wheel Attatching Tech TipsДокумент12 страницEuclid Wheel Attatching Tech Tipstim winkelmanОценок пока нет

- Chapt 02Документ144 страницыChapt 02Tony LoweОценок пока нет

- Southwest Oilfield Products, Inc.: Mud Pump Expendable Parts ListДокумент8 страницSouthwest Oilfield Products, Inc.: Mud Pump Expendable Parts Listjuan penaОценок пока нет