Академический Документы

Профессиональный Документы

Культура Документы

FC102 Pid PDF

Загружено:

KwameOpareОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

FC102 Pid PDF

Загружено:

KwameOpareАвторское право:

Доступные форматы

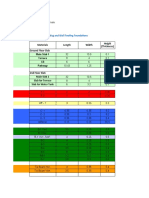

Connection Example

VLT® HVAC Drive Software: 3.4

Closed loop operation from 0 - 300kPa pressure transmitter with 0-10V output. If the transmitter output is 4-20mA,

change the DIP switch settings behind the LCP.

Relevant Parameters

Par. Function Settings

FC 102

202 0-02 Motor Speed Unit [1] Hz

+24 V 12 0-21 Display 1.2 small [1652] Feedback

+24 V 13 1-00 Configuration mode [3] Closed loop

D IN 18 Start / Stop 20-12 Unit [73] kPa

D IN 19 3-41 Ramp up time 20s

COM 20 3-42 Ramp down time 20s

D IN 27 Coast Inverse 3-02 Min reference 0

D IN 29 3-03 Max reference 300

D IN 32 315 Reference Source 1 [0] No function

D IN 33 6-24 Min feedback 0

D IN (S.Stopp)**37 Safety Stop 6-25 Max Feedback 300

20-13 Min reference 0

+10 V 50 Pressure transducer 20-14 Max refeerence 300

A IN (S201 U-I) 53 0-10V (or 4-20mA) 20-21 Setpoint 150

A IN (S202 U-I) 54 20-73 Min feedback 0

COM 55 20-74 Max Feedback 300

A OUT 42 20-81 Normal / Inverse [0] Normal

A OUT 39 20-83 PID start frequency 10

20-93 Proportional gain 2

01 20-94 Integral time 10

Relay 1

02

03

*04

Relay 2

*05

*06

NOTE: Erstellt von: Schulung

All settings are based on factory settings.

It is recommended to set all the motor parameters in Par. 1-20 to 1-26 and then perform Automatic Motor

Adaption (AMA) in Par. 1-29.

Вам также может понравиться

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Standard Cost EstimateДокумент21 страницаStandard Cost EstimateMOORTHYОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Native Data Sheet Asme b73.1Документ4 страницыNative Data Sheet Asme b73.1Akhmad Faruq Alhikami100% (1)

- GCSE AstronomyДокумент30 страницGCSE Astronomyharris123mc100% (1)

- Solutions GoldsteinДокумент10 страницSolutions GoldsteinAnyiОценок пока нет

- 3200AMMe - Part 4Документ207 страниц3200AMMe - Part 4Tanja Kesic100% (1)

- Bomba MixerДокумент2 страницыBomba MixerBinelli79Оценок пока нет

- 2nd Lecture - Legal Aspects of ITДокумент7 страниц2nd Lecture - Legal Aspects of ITKwameOpareОценок пока нет

- ContinueДокумент2 страницыContinueKwameOpareОценок пока нет

- 3A DeclarationДокумент1 страница3A DeclarationKwameOpareОценок пока нет

- H0 ECOM100 Spec EngДокумент2 страницыH0 ECOM100 Spec EngKwameOpareОценок пока нет

- Beamex White Paper - Manual Data Entry Errors ENG UpdatedДокумент6 страницBeamex White Paper - Manual Data Entry Errors ENG UpdatedKwameOpareОценок пока нет

- GE Automation Proficy Machine Edition Software System RequirementsДокумент9 страницGE Automation Proficy Machine Edition Software System RequirementsKwameOpareОценок пока нет

- Welcome To Module 2: Understanding VirtualizationДокумент8 страницWelcome To Module 2: Understanding VirtualizationKwameOpareОценок пока нет

- Forensic Analysis of Virtual Hard Drives: NtroductionДокумент6 страницForensic Analysis of Virtual Hard Drives: NtroductionKwameOpareОценок пока нет

- SCADAvantage Network Topology System Software ProductsДокумент8 страницSCADAvantage Network Topology System Software ProductsKwameOpareОценок пока нет

- Vmaware Foresics - 1Документ12 страницVmaware Foresics - 1KwameOpareОценок пока нет

- Ijmerr v3n1 9Документ8 страницIjmerr v3n1 9KwameOpareОценок пока нет

- Forensic Acquisition and Analysis of VMware Virtual Hard DisksДокумент8 страницForensic Acquisition and Analysis of VMware Virtual Hard DisksKwameOpareОценок пока нет

- Initial F-1 Checklist: Academic YearДокумент4 страницыInitial F-1 Checklist: Academic YearKwameOpareОценок пока нет

- Precision Calibration Solution For Conductivity CLY 11: EndressДокумент4 страницыPrecision Calibration Solution For Conductivity CLY 11: EndressKwameOpareОценок пока нет

- Plcs and Scada Systems: Practical Troubleshooting and Problem Solving ofДокумент2 страницыPlcs and Scada Systems: Practical Troubleshooting and Problem Solving ofKwameOpareОценок пока нет

- Robert Smith: HR Administrator/HRISДокумент1 страницаRobert Smith: HR Administrator/HRISKwameOpareОценок пока нет

- Switching TypesДокумент4 страницыSwitching TypesKwameOpareОценок пока нет

- Liquisys M CLM223/253: Technical InformationДокумент20 страницLiquisys M CLM223/253: Technical InformationKwameOpareОценок пока нет

- Interruption of Water SupplyДокумент2 страницыInterruption of Water SupplyKwameOpareОценок пока нет

- Owner'S Manual: 2023 Chassis CabДокумент444 страницыOwner'S Manual: 2023 Chassis CabDmitry DimasОценок пока нет

- Board Replacement CasesДокумент41 страницаBoard Replacement CasesNadeeshОценок пока нет

- Poly 103Документ20 страницPoly 103Sharifah Zulaikha BenYahyaОценок пока нет

- Curing Obesity, WorldwideДокумент6 страницCuring Obesity, WorldwideHernán SanabriaОценок пока нет

- Midterm Exam Gor Grade 11Документ2 страницыMidterm Exam Gor Grade 11Algelle AbrantesОценок пока нет

- Course Syllabus: Course Code Course Title ECTS CreditsДокумент3 страницыCourse Syllabus: Course Code Course Title ECTS CreditsHanaa HamadallahОценок пока нет

- Column, Slab, Footing and Wall Footing Foundations: Class A MixingДокумент47 страницColumn, Slab, Footing and Wall Footing Foundations: Class A MixingGioharry Nul PanambulanОценок пока нет

- Cambridge IGCSE Paper 2Документ4 страницыCambridge IGCSE Paper 2irajooo epik zizterОценок пока нет

- Food Taste Panel Evaluation Form 2Документ17 страницFood Taste Panel Evaluation Form 2Akshat JainОценок пока нет

- FemДокумент4 страницыFemAditya SharmaОценок пока нет

- Passenger Lift Alert - Health and Safety AuthorityДокумент4 страницыPassenger Lift Alert - Health and Safety AuthorityReginald MaswanganyiОценок пока нет

- Bulacan Agricultural State College: Lesson Plan in Science 4 Life Cycle of Humans, Animals and PlantsДокумент6 страницBulacan Agricultural State College: Lesson Plan in Science 4 Life Cycle of Humans, Animals and PlantsHarmonica PellazarОценок пока нет

- Bhil Tribal Mobilisation in AlirajpurДокумент14 страницBhil Tribal Mobilisation in Alirajpurrahul banerjeeОценок пока нет

- Mahindra & MahindraДокумент13 страницMahindra & MahindraAbhishek DharmadhikariОценок пока нет

- 02-Building Cooling LoadsДокумент3 страницы02-Building Cooling LoadspratheeshОценок пока нет

- 9 5 - 358 362 PDFДокумент5 страниц9 5 - 358 362 PDFمالك مناصرةОценок пока нет

- Cisco 2500 Series RoutersДокумент16 страницCisco 2500 Series RoutersJull Quintero DazaОценок пока нет

- Tree Growth CharacteristicsДокумент9 страницTree Growth CharacteristicsMunganОценок пока нет

- Industrial Artificial Intelligence For Industry 4.0-Based Manufacturing SystemsДокумент5 страницIndustrial Artificial Intelligence For Industry 4.0-Based Manufacturing SystemsMuhammad HaziqОценок пока нет

- Lecture 12Документ8 страницLecture 12Mechanical ZombieОценок пока нет

- Worlds Apart: A Story of Three Possible Warmer WorldsДокумент1 страницаWorlds Apart: A Story of Three Possible Warmer WorldsJuan Jose SossaОценок пока нет

- AssessmentДокумент9 страницAssessmentJuan Miguel Sapad AlpañoОценок пока нет

- Clevo W940tu Service ManualДокумент93 страницыClevo W940tu Service ManualBruno PaezОценок пока нет

- Catalogo GatesДокумент255 страницCatalogo GatesBenjamin HedoneweОценок пока нет